In our factory tours, I often see confusion when customers try to understand the different types of cellulose polymers. This confusion costs them money when they order the wrong grade for their specific application.

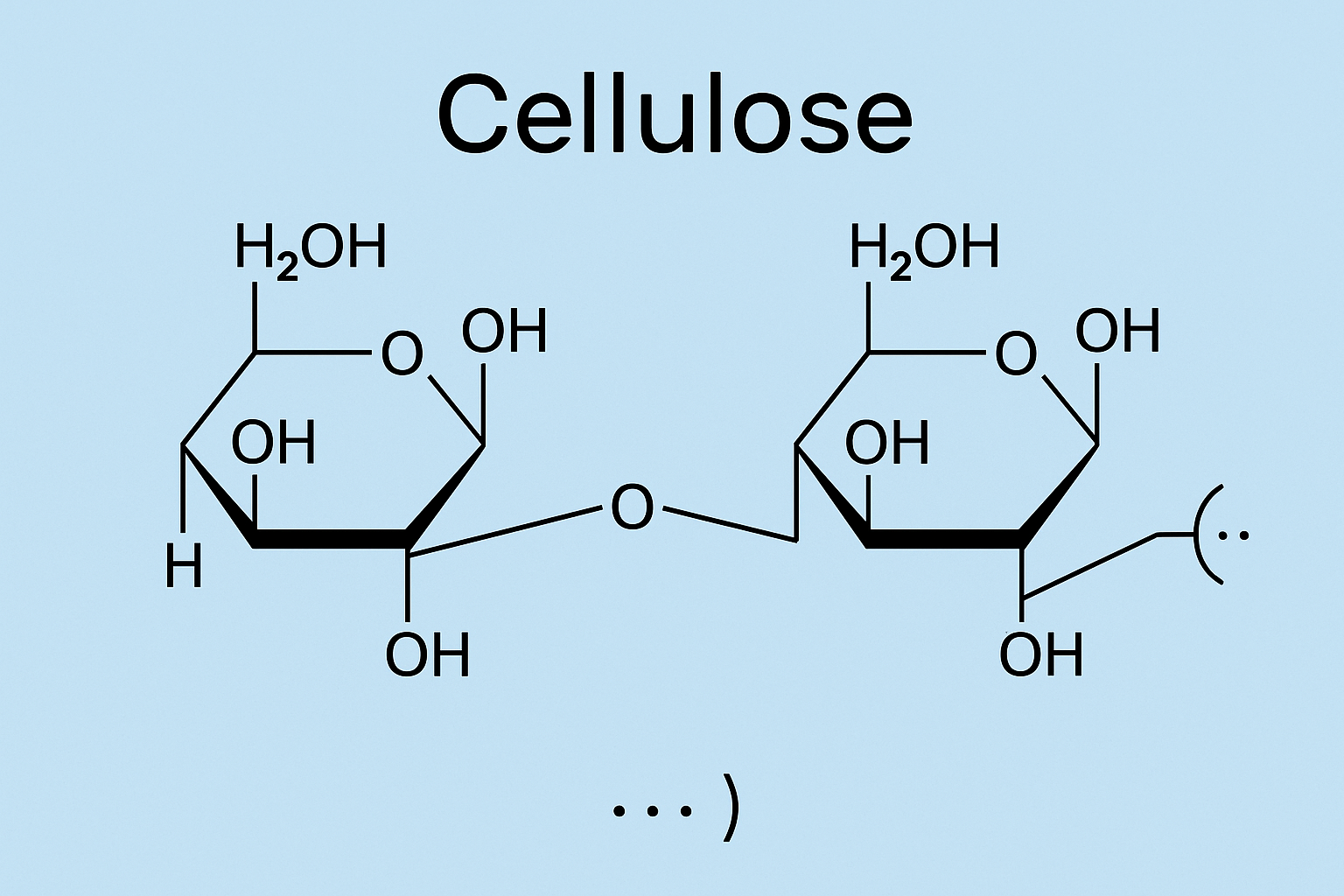

Cellulose-based polymers are naturally derived materials organized into four main categories: pure cellulose, regenerated cellulose, cellulose ethers1 (like HPMC and CMC), and cellulose esters. Each type has unique properties that make them suitable for specific pharmaceutical, packaging, and industrial applications.

I remember when Mark, a long-time customer from Saudi Arabia, visited our production facility last year. He was amazed at how the same basic material—cellulose—could be transformed into so many different products. Let me walk you through the main types of cellulose polymers2 and their applications that every industry professional should understand.

Pure Cellulose and Its Pharmaceutical Grades?

When talking with our pharmaceutical clients, they often mention struggling with excipient selection. Choosing the wrong grade of pure cellulose can lead to formulation failures and wasted production runs.

Pure cellulose in pharmaceutical applications primarily includes microcrystalline cellulose3 (MCC) and powdered cellulose. MCC is widely used as a tablet binder, disintegrant, and filler due to its excellent compressibility, while powdered cellulose serves mainly as a bulking agent and disintegrant in capsules and tablets.

Pure cellulose represents the most basic form of this remarkable polymer. In our industry, we categorize pharmaceutical grades of pure cellulose based on particle size, moisture content, and bulk density—factors that significantly impact their performance in drug formulations.

Key Pharmaceutical Grades of Pure Cellulose

| Grade Type | Average Particle Size | Key Applications | Special Properties |

|---|---|---|---|

| MCC PH101 | 50 μm | Direct compression tablets | Good flowability |

| MCC PH102 | 100 μm | Wet granulation | Enhanced compressibility |

| MCC PH105 | 20 μm | Controlled release formulations | High surface area |

| Powdered Cellulose | 120-250 μm | Capsule fillers | Low cost alternative |

I've seen pharmaceutical manufacturers achieve up to 30% improvement in tablet hardness by selecting the right MCC grade. The crystallinity of MCC provides mechanical strength while maintaining excellent disintegration properties. This unique combination makes pure cellulose invaluable in modern pharmaceutical manufacturing, where it helps formulators balance competing requirements for tablet integrity and drug release profiles.

Regenerated Cellulose and Its Packaging Role?

Many of our customers in the packaging industry struggle with finding sustainable alternatives to plastic films. They face increasing pressure from consumers and regulations to reduce their environmental footprint.

Regenerated cellulose includes materials like cellophane and rayon, produced by dissolving and regenerating cellulose fibers. In packaging, cellophane provides excellent transparency, barrier properties against air and moisture, biodegradability, and heat-sealability, making it ideal for food packaging and industrial applications.

Regenerated cellulose represents one of the earliest man-made polymers, yet it remains relevant in today's sustainability-focused market. The process involves dissolving natural cellulose in chemical solvents, then regenerating it into new forms with enhanced properties.

Applications of Regenerated Cellulose

| Material Type | Production Method | Primary Uses | Advantages |

|---|---|---|---|

| Cellophane | Viscose process | Food wrapping, tapes | Biodegradable, transparent |

| Rayon | Cuprammonium process | Textile fibers, medical applications | Soft texture, absorbent |

| Lyocell | NMMO solvent process | Sustainable textiles | Environmentally friendly production |

| Viscose sponge | Specialized viscose | Medical sponges, cleaning products | Highly absorbent, soft |

In our manufacturing experience, regenerated cellulose films provide oxygen barrier properties comparable to some petroleum-based plastics while being fully biodegradable. This combination makes them particularly valuable for food packaging applications where product freshness must be maintained while addressing environmental concerns. The reduced carbon footprint of these materials has helped our customers in Saudi Arabia and UAE meet their sustainability goals4 while maintaining packaging performance standards.

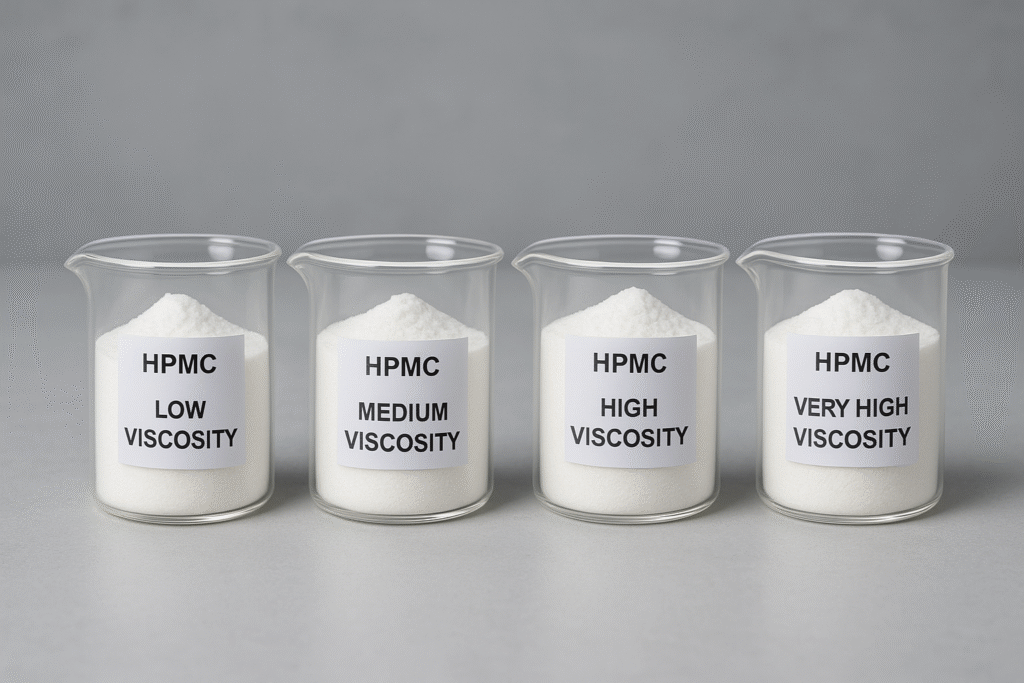

Cellulose Ether Derivatives and Their Pharmaceutical Applications?

Last month, a pharmaceutical manufacturer called me panicking because their tablet coating was failing quality control tests. They didn't realize that the grade of cellulose ether they selected wasn't designed for their specific application.

Cellulose ethers like hydroxypropyl methylcellulose5 (HPMC), carboxymethyl cellulose (CMC), and hydroxyethyl cellulose (HEC) are crucial pharmaceutical excipients. HPMC is widely used in controlled-release matrix systems and film coatings, CMC as a tablet binder and stabilizer, and HEC as a thickening agent and binder in various formulations.

Cellulose ethers represent the most versatile group of cellulose derivatives in our product portfolio. They're created through chemical modification of cellulose using alkali treatment followed by etherification with different reagents. The substitution pattern and degree significantly impact their properties and applications.

Pharmaceutical Applications of Common Cellulose Ethers

| Cellulose Ether | Viscosity Range | Key Pharmaceutical Uses | Special Properties |

|---|---|---|---|

| HPMC E5 | 4-6 mPa·s | Immediate release film coating | Fast dissolution |

| HPMC K100M | 80,000-120,000 mPa·s | Extended release matrices | Strong gel layer formation |

| HPMC AS | Various | Enteric coating | pH-dependent dissolution |

| Sodium CMC | 50-2,000 mPa·s | Tablet binder, suspending agent | Negatively charged, bioadhesive |

| HEC | 300-5,000 mPa·s | Thickener in topical formulations | Compatible with ionic drugs |

In our technical support work, we've observed that the molecular weight and substitution pattern of cellulose ethers directly correlate with drug release profiles. For example, higher viscosity grades of HPMC create thicker gel layers that slow drug diffusion. This knowledge allows pharmaceutical formulators to fine-tune release profiles simply by selecting the appropriate cellulose ether grade. Our customers in India and Pakistan particularly value this flexibility when developing generic medications with specific dissolution profiles.

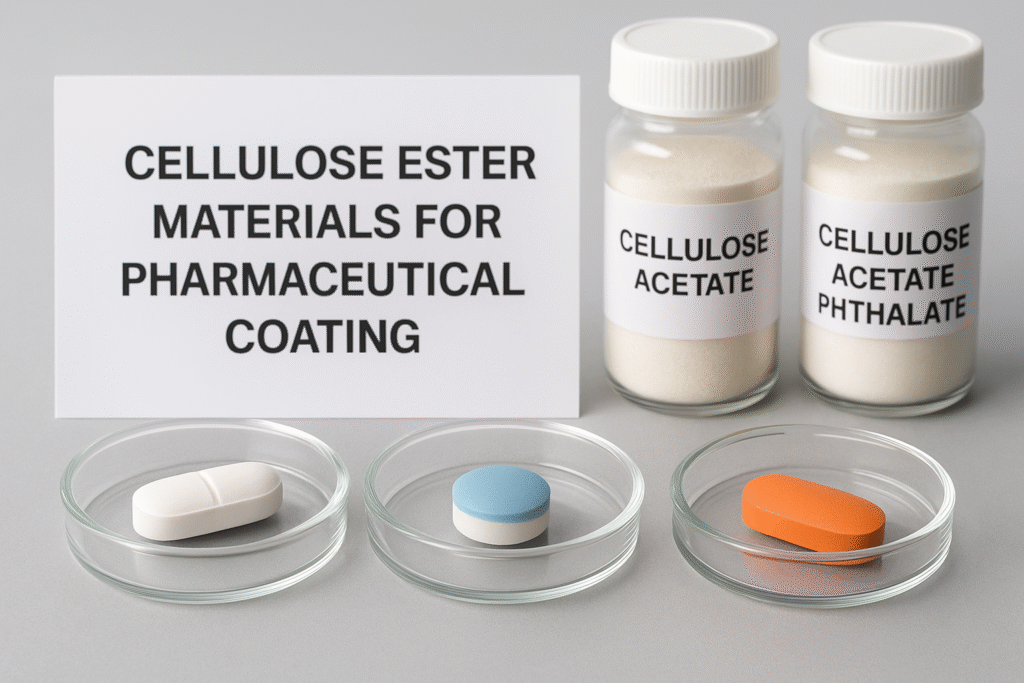

Cellulose Ester Derivatives in Coating and Delivery Systems?

During a recent product development project, our team encountered challenges with coating stability in tropical climates. The conventional cellulose materials were failing under high humidity conditions, causing significant product losses.

Cellulose esters, including cellulose acetate (CA), cellulose acetate phthalate (CAP), and cellulose acetate butyrate (CAB), are produced by reacting cellulose with organic acids. CAP provides excellent enteric coating for gastric protection, CA forms semipermeable membranes for osmotic pumps, and CAB delivers excellent film-forming properties for sustained release systems.

Cellulose esters differ from ethers in their preparation and properties. While ethers are water-soluble or water-swellable, esters typically exhibit higher hydrophobicity and solubility in organic solvents. This fundamental difference expands the application range of cellulose-based materials.

Pharmaceutical Applications of Cellulose Esters

| Cellulose Ester | Substitution Degree | Primary Applications | Performance Characteristics |

|---|---|---|---|

| Cellulose Acetate | 2.0-2.5 DS | Semipermeable membranes, sustained release | Controlled porosity |

| Cellulose Acetate Phthalate | 1.7-2.0 DS acetyl | Enteric coating | Dissolves above pH 6 |

| Cellulose Acetate Butyrate | 1.5-2.0 DS acetyl, 0.5-1.0 DS butyryl | Taste masking, sustained release | Enhanced moisture resistance |

| Cellulose Acetate Trimellitate | 1.8-2.1 DS | Advanced enteric coating | Improved thermal stability |

From our product development experience, cellulose esters6 provide superior options for challenging drug delivery applications. For instance, cellulose acetate membranes in osmotic pump systems deliver near zero-order release kinetics independent of pH changes throughout the GI tract. This property has proven invaluable for customers in Brazil and Mexico developing treatments for conditions requiring consistent blood plasma levels of medication throughout the day.

Specialty Applications: Cellulose Nitrate and Filters?

A customer from Georgia once asked me why we don't promote cellulose nitrate more widely. I had to explain the specialized nature of this derivative and its specific safety requirements that limit its applications.

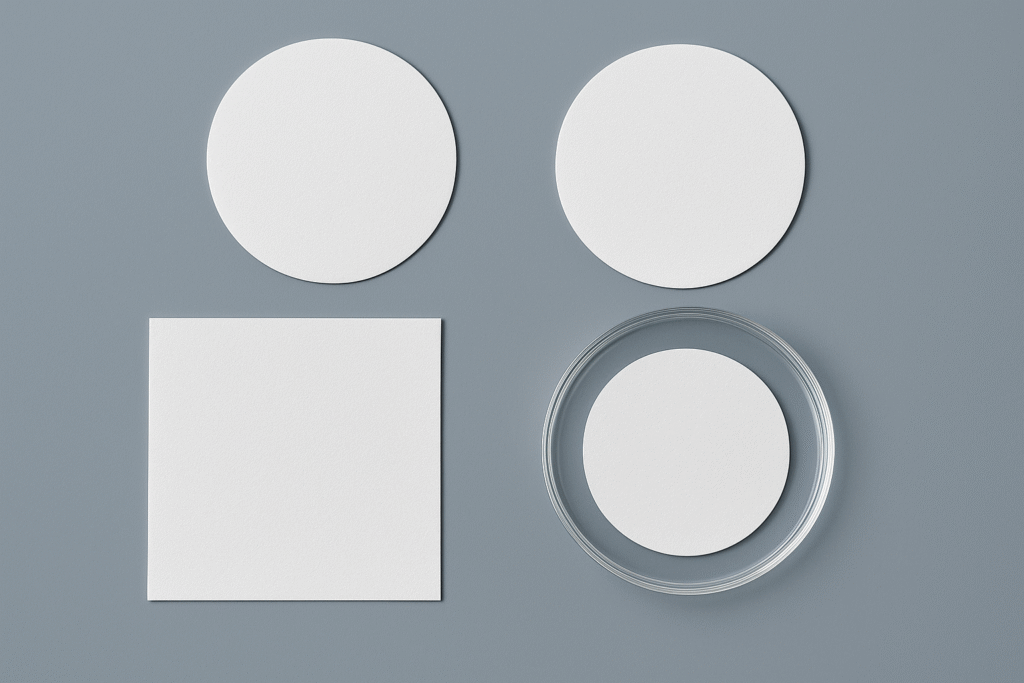

Cellulose nitrate (nitrocellulose) is a highly specialized cellulose derivative produced by nitration, while cellulose filters utilize either pure or modified cellulose fibers. Nitrocellulose serves as a membrane for diagnostic tests and historical photographic films, while cellulose filters are essential for pharmaceutical processing, laboratory filtration, and cigarette manufacturing.

https://placehold.co/600x400 "Specialized cellulose membrane filters")

https://placehold.co/600x400 "Specialized cellulose membrane filters")

Specialty cellulose derivatives showcase how this versatile polymer can be adapted for highly specific technical applications. These products typically serve niche markets but play critical roles in important industries and processes.

Key Specialty Applications of Cellulose Materials

| Specialty Type | Production Method | Critical Applications | Technical Features |

|---|---|---|---|

| Nitrocellulose | Nitration of cellulose | Lateral flow assays, membranes | Protein binding, controlled porosity |

| Cellulose Depth Filters | Specialized paper-making | Pharmaceutical clarification | High dirt-holding capacity |

| Regenerated Cellulose Membranes | Phase inversion process | Laboratory ultrafiltration | Precise molecular weight cutoffs |

| Oxidized Cellulose | Nitrogen dioxide treatment | Hemostatic medical materials | Biodegradable, bactericidal |

In our work with pharmaceutical manufacturers, we've found that specialty cellulose filters can reduce production costs while improving product purity. For example, depth filters made from cellulose fibers can remove particulates and colloids in a single step that might otherwise require multiple filtration stages. These efficiency improvements have been particularly valuable for our customers in Vietnam and the Philippines, where manufacturing infrastructure is still developing. The natural origin of cellulose makes these materials compatible with sustainability initiatives while maintaining high performance standards.

Conclusion

Cellulose-based polymers offer incredible versatility across pharmaceutical, packaging, and specialty applications. Understanding their classification helps select the right material for specific needs, ensuring optimal performance and sustainability in your products.

-

Understand the importance of cellulose ethers in drug formulations and their unique properties. ↩

-

Explore the diverse applications of cellulose polymers in various industries and their unique properties. ↩

-

Discover how microcrystalline cellulose enhances tablet formulations and its benefits in drug manufacturing. ↩

-

Discover strategies for companies to meet sustainability goals through innovative packaging solutions. ↩

-

Find out how hydroxypropyl methylcellulose is used in controlled-release systems and film coatings. ↩

-

Explore the role of cellulose esters in drug delivery systems and their performance characteristics. ↩