I've seen many construction companies struggle with inconsistent quality and high labor costs. Traditional on-site mixing is becoming increasingly problematic as projects grow in complexity and scale.

Dry-mix mortar1 offers significant advantages including consistent quality, reduced labor costs, faster application, minimal waste, and extended shelf life. Factory-produced under controlled conditions, these pre-mixed formulations ensure reliable performance while cutting overall project expenses and construction time.

"Bags of dry-mix mortar on construction site")

"Bags of dry-mix mortar on construction site")

As someone who has supplied materials to construction projects for years, I've witnessed firsthand how switching to dry-mix mortar transforms building efficiency. Let me walk you through the main benefits that make this modern solution increasingly popular among professionals worldwide.

How Does Dry-Mix Mortar Improve Construction Quality?

I often hear from contractors about inconsistent mortar quality causing serious problems. Improper material proportioning on construction sites leads to structural weaknesses and costly repairs.

Dry-mix mortar1 delivers consistent quality through precise factory mixing under controlled conditions. Each batch contains exact proportions of cement, aggregates, and additives like HPMC, ensuring uniform strength, workability, and appearance across the entire project.

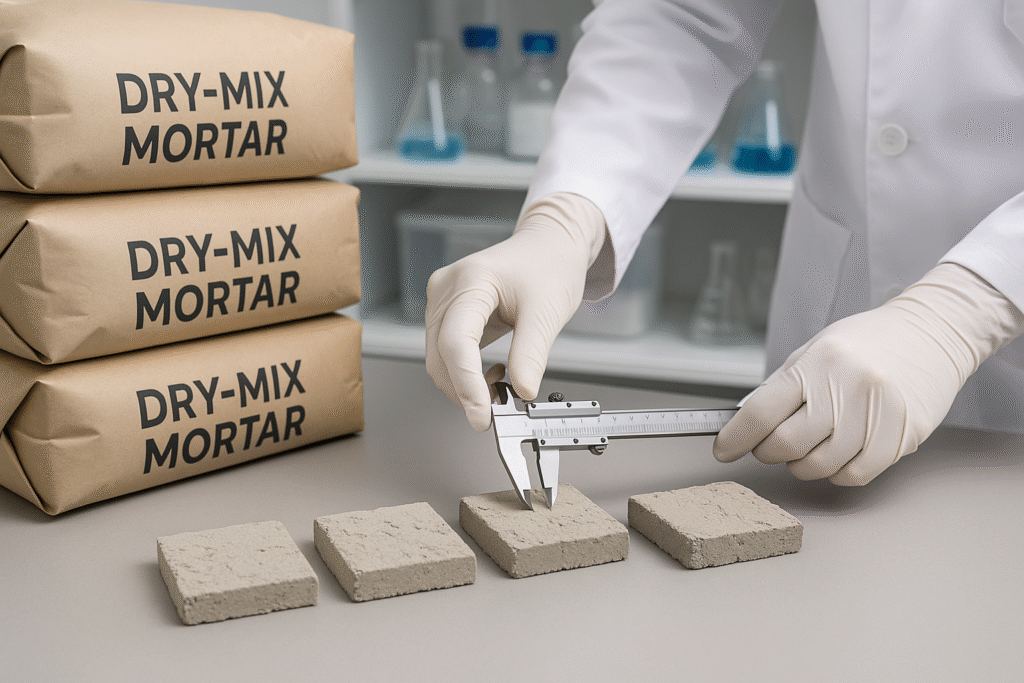

Having visited numerous production facilities, I'm always impressed by the rigorous quality control measures employed in dry-mix mortar manufacturing. The process begins with careful selection of raw materials, which undergo thorough testing before entering the production line.

Quality Control Factors in Dry-Mix Production

Unlike traditional on-site mixing where proportions may vary based on individual workers' judgment, factory production uses computerized systems to ensure perfect consistency. Every batch is mixed under ideal temperature and humidity conditions, with specialized equipment that achieves a level of homogeneity impossible on construction sites.

The addition of chemical admixtures like hydroxypropyl methylcellulose (HPMC)2 and redispersible polymer powder further enhances performance. These additives are precisely dosed to improve workability, water retention, and adhesion – properties that significantly impact the final strength and durability of masonry structures.

Regular quality checks throughout production verify that each bag meets exact specifications. This means contractors can count on consistent performance from the first bag to the last, eliminating the variability that often plagues traditional mortar mixing methods.

How Can Dry-Mix Mortar Reduce Construction Costs?

I've calculated project expenses for years and found traditional mortar mixing consumes excessive labor hours. Workers spend valuable time measuring, mixing, and correcting inconsistent batches.

Dry-mix mortar reduces labor costs by eliminating on-site measuring and mixing. Workers simply add water to the pre-mixed formula and apply it immediately, increasing productivity by up to 40%. This efficiency translates directly into lower labor expenses and faster project completion.

The economic impact of switching to dry-mix mortar extends far beyond the immediate labor savings seen during application. Having analyzed numerous construction projects across different markets, I've identified several key cost-reduction mechanisms.

Cost Savings Breakdown

First, the reduced labor requirement means teams can complete more work in less time. A typical project might require 4-5 workers for traditional mortar preparation, while dry-mix systems often need only 2-3 workers to achieve the same or better output. This staffing efficiency becomes increasingly valuable in markets experiencing labor shortages or rising wages.

Transportation and logistics costs also decrease significantly. Instead of coordinating deliveries of separate components (sand, cement, lime) that require different handling and storage, companies receive a single, ready-to-use product. This simplification reduces administrative overhead and minimizes the risk of material shortages interrupting work schedules.

Material waste – a major hidden cost in construction – drops dramatically with dry-mix products. Traditional on-site mixing typically generates 15-20% waste through spillage, incorrect proportioning, and unused mixed material that hardens before application. Dry-mix systems reduce this waste to approximately 5-8%, representing substantial savings on high-volume projects.

The table below illustrates typical cost comparisons:

| Cost Factor | Traditional Mortar | Dry-Mix Mortar | Savings |

|---|---|---|---|

| Labor hours | 100 hrs/1000 sq.ft | 60 hrs/1000 sq.ft | 40% |

| Material waste | 15-20% | 5-8% | 7-15% |

| Equipment needs | Mixers, measuring tools | Simple mixing container | Reduced |

| Project timeline | Standard | 30% faster completion | Improved cash flow |

What Environmental Benefits Does Dry-Mix Mortar Offer?

I've seen construction sites littered with excess materials and packaging waste. Traditional mortar mixing creates environmental problems through inefficient resource use and improper disposal.

Dry-mix mortar reduces environmental impact through precise material usage, minimal waste generation, and optimized transportation. Modern formulations also incorporate recycled materials and require less energy during application, supporting sustainable building practices.

Sustainability has become increasingly important in construction, and I've had many discussions with environmentally-conscious clients about reducing their ecological footprint. Dry-mix mortar offers several significant advantages in this area that are worth examining in detail.

Environmental Impact Reduction

The manufacturing process for dry-mix products allows for precise resource management that isn't possible with traditional on-site mixing. Factory production enables efficient energy use through economy of scale, with modern facilities utilizing energy recovery systems and optimized equipment that minimizes carbon emissions per ton of product.

Water conservation is another critical benefit. Traditional mortar mixing often uses excessive water due to imprecise measurement methods, contributing to water waste on construction sites. Dry-mix products are designed with specific water requirements, typically reducing overall water consumption by 15-25% compared to traditional methods.

Many manufacturers now incorporate sustainable practices throughout their production chain. This includes using recycled aggregates, incorporating industrial by-products like fly ash or slag, and developing low-carbon cement alternatives. These innovations reduce the embodied carbon in the final product while maintaining or even improving performance.

Transportation efficiency also contributes to environmental benefits. Shipping optimized dry-mix products in bulk or on palletized systems reduces the total number of deliveries required for a project. Some manufacturers have developed concentrated formulations that further reduce packaging materials and transportation emissions.

For contractors seeking green building certifications like LEED or BREEAM, properly sourced dry-mix products can contribute valuable points toward certification goals, potentially increasing the project's marketability and value.

How Does Dry-Mix Mortar Improve Worksite Safety?

I've witnessed numerous accidents related to traditional mortar preparation. Workers regularly suffer injuries from handling cement, improper mixing, and exposure to caustic materials.

Dry-mix mortar improves worksite safety by reducing dust exposure, eliminating hazardous material handling, and decreasing physical strain. The pre-mixed formula minimizes respiratory risks, skin contact with raw cement, and back injuries from heavy material lifting.

Safety considerations are paramount on modern construction sites, and I've observed numerous incidents that could have been prevented by using dry-mix products. The safety benefits extend throughout the entire application process and address several critical risk factors.

Workplace Safety Improvements

Traditional mortar preparation involves handling raw cement, which contains alkaline compounds that can cause severe skin burns and eye damage with prolonged contact. Workers mixing conventional mortar often develop dermatitis or suffer from respiratory issues due to cement dust inhalation. Dry-mix products, while still requiring basic safety precautions, significantly reduce these risks through their controlled preparation process.

Ergonomic advantages are equally important. The repetitive lifting and mixing required for traditional mortar preparation contributes to musculoskeletal injuries and chronic back problems among construction workers. Modern dry-mix systems often incorporate mechanical mixing with minimal physical exertion, reducing strain-related injuries.

Site organization also improves with dry-mix systems. Traditional mixing creates cluttered work areas with separate piles of sand, cement, and additives, increasing trip hazards and impeding movement. The simplified logistics of dry-mix products allows for cleaner, more organized worksites with clear pathways and reduced accident potential.

Many dry-mix manufacturers now offer specialized training programs3 for proper product use, further enhancing safety awareness. These programs typically cover mixing techniques, application methods, and specific safety precautions, creating a more knowledgeable and safety-conscious workforce.

For project managers, the improved safety profile translates directly to reduced insurance costs, fewer work stoppages due to accidents, and higher overall productivity – creating a compelling business case beyond the immediate safety benefits.

Conclusion

Dry-mix mortar delivers consistent quality, reduced costs, environmental benefits, and improved safety that traditional mixing can't match. As construction demands increase, this modern solution offers efficiency and reliability that smart builders simply can't ignore.