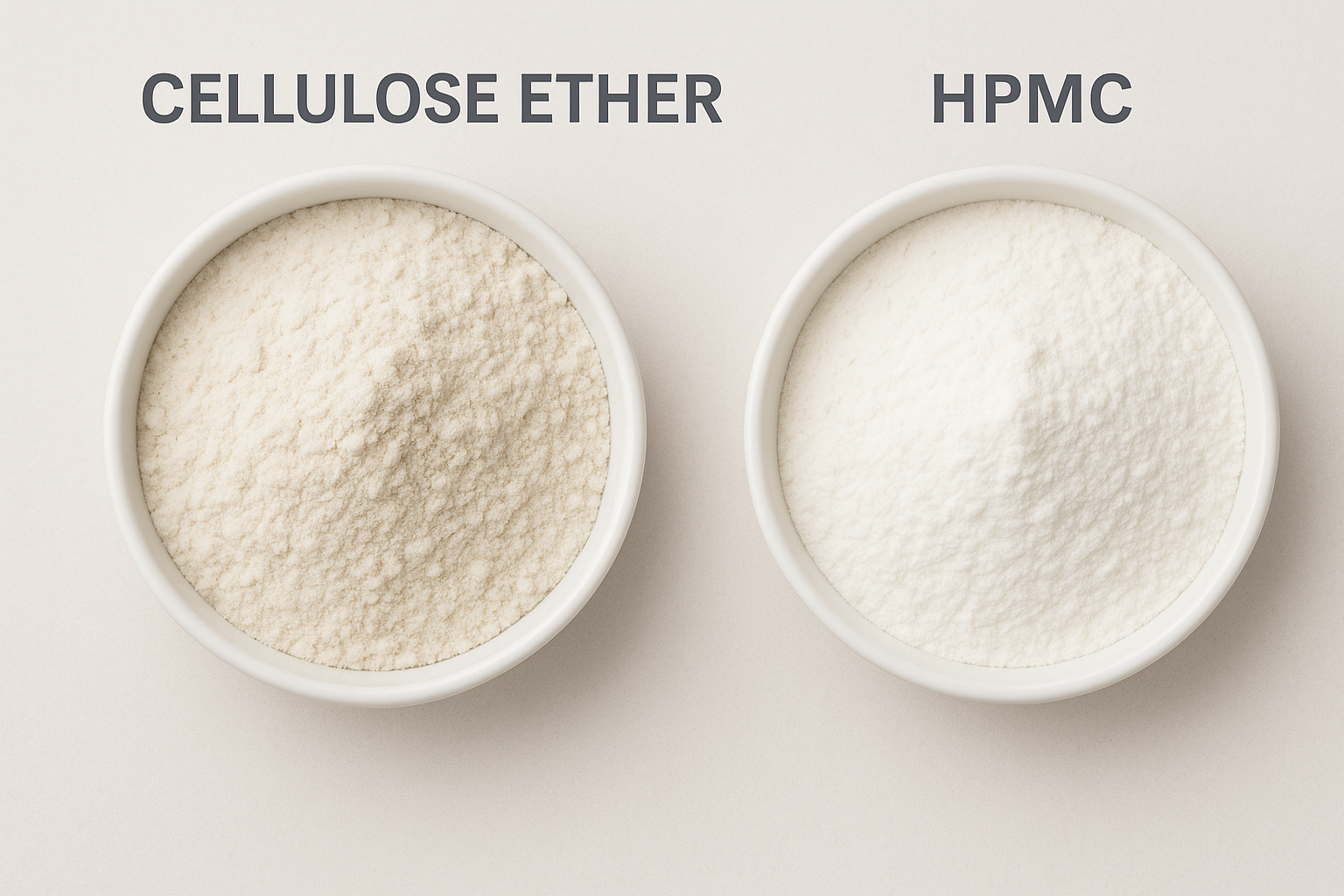

Many construction projects fail due to using the wrong cellulose derivatives. Choosing between basic cellulose and modified versions like HPMC can determine if your mortar will crack or your paint will adhere properly.

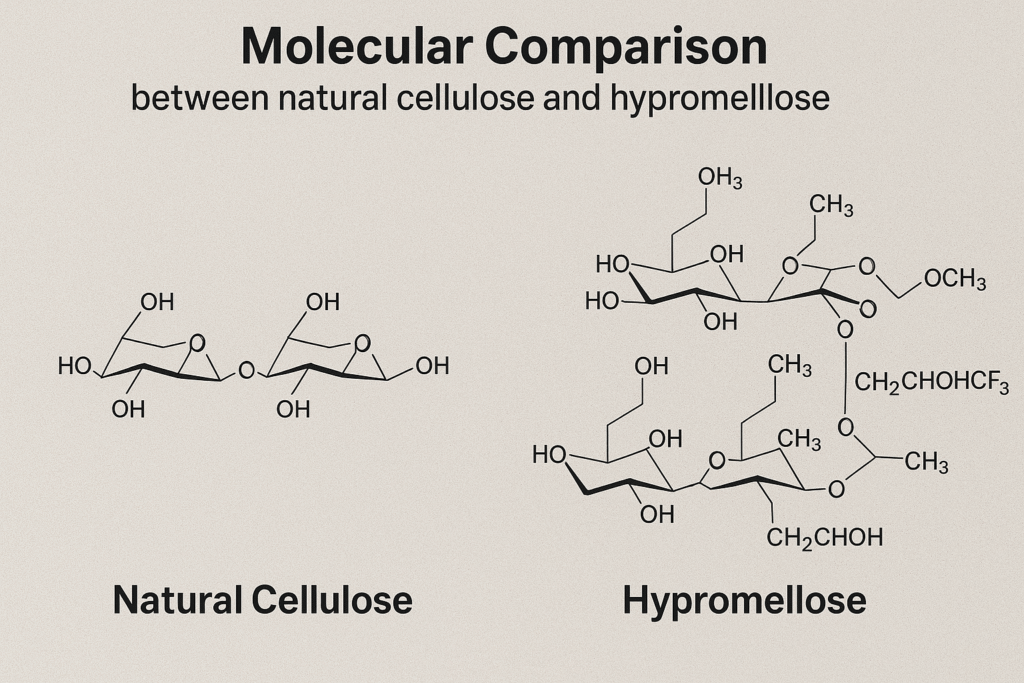

HPMC (Hydroxypropyl Methylcellulose) is a chemically modified form of cellulose with added methyl and hydroxypropyl groups, while cellulose is the natural plant fiber. This modification gives HPMC water solubility, thermal gelation properties, and enhanced performance in construction materials.

I've been manufacturing cellulose derivatives for over 15 years, and one question I hear repeatedly from customers visiting our factory is about the fundamental differences between natural cellulose and HPMC. Let me break down these materials in a way that helps you understand which one might be right for your specific application.

What is the difference between methyl cellulose and HPMC?

Clients often experience product failures when using methyl cellulose where HPMC1 would be more suitable. Understanding the key differences can prevent costly mistakes in your construction projects.

Methyl cellulose contains only methyl groups attached to the cellulose backbone, while HPMC has both methyl and hydroxypropyl groups. This additional hydroxypropyl modification gives HPMC better water retention, improved workability at various temperatures, and enhanced adhesion properties.

Methyl cellulose (MC) and HPMC are often confused because they share similar applications, but their chemical differences create significant performance variations. Having worked with both materials extensively in our production facilities, I've observed firsthand how these differences affect real-world applications.

Key Performance Differences

The additional hydroxypropyl groups in HPMC create important physical property differences you should consider:

| Property | Methyl Cellulose (MC) | HPMC |

|---|---|---|

| Thermal gelation | Lower gelation temperature (50-55°C) | Higher gelation temperature (65-90°C) |

| Surface activity | Good but limited | Superior surface activity |

| Water retention | Good | Excellent |

| Salt tolerance | Moderate | High |

| pH stability | 3-11 | 2-12 |

| Cold water solubility | Limited | Excellent |

I remember visiting a customer in Saudi Arabia who had been using methyl cellulose in their exterior render formulation. During the hot summer months, they experienced severe application problems as the MC was gelling too quickly in the heat.

After switching to our HPMC product with its higher gelation temperature, their application window increased by 30 minutes, solving their problems immediately.

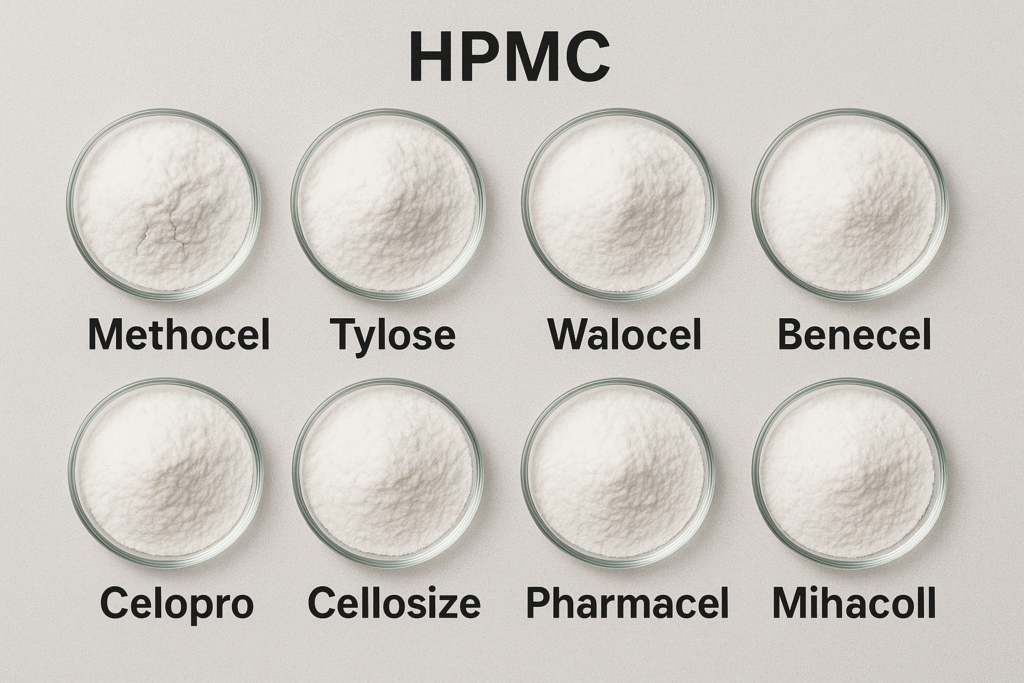

What is another name for HPMC?

Manufacturers sometimes receive material with different labeling, causing confusion when comparing products. Knowing all names for HPMC ensures you're getting the right material.

HPMC1 is also commonly known as hypromellose, especially in pharmaceutical applications. Other names include hydroxypropyl methylcellulose ether, E464 (as a food additive designation), Methocel, Benecel, Walocel, and Metolose, which are various trade names for the same chemical compound.

The proliferation of names for HPMC2 can be confusing but understanding the terminology helps when sourcing materials from different suppliers. In our factory, we primarily use the term HPMC for construction applications and hypromellose when discussing pharmaceutical grades with clients.

Regional Naming Conventions

Different regions and industries have developed their own naming conventions for HPMC:

| Industry | Common Name | Regulatory Code |

|---|---|---|

| Construction | HPMC | - |

| Pharmaceutical | Hypromellose | USP/EP/JP |

| Food | Hydroxypropyl methylcellulose | E464 |

| Research | HPMC ether | CAS: 9004-65-3 |

When clients visit our production facilities, I often demonstrate how the same base HPMC powder can be modified for different applications through viscosity control and substitution level adjustments.

Despite the different names, the fundamental chemistry remains the same, though specific grades are optimized for particular end uses.

Is hypromellose the same as cellulose?

Many project specifications list "cellulose" as an ingredient, leading to uncertainty about whether hypromellose meets this requirement. This confusion has serious implications for quality control.

No, hypromellose (HPMC2) is not the same as cellulose. Cellulose is the natural polymer found in plant cell walls, while hypromellose is a semi-synthetic, chemically modified derivative of cellulose that has been processed to include methyl and hydroxypropyl functional groups, giving it different properties.

The transformation from natural cellulose to hypromellose involves significant chemical processing. I've had numerous clients tour our production facility in China to understand this conversion process, which fundamentally changes how the material behaves in applications.

From Natural to Modified: The Processing Journey

The conversion of natural cellulose to HPMC/hypromellose involves several critical steps that dramatically alter its properties:

- Purification: Natural cellulose from cotton or wood pulp undergoes extensive cleaning

- Alkalization: Treatment with sodium hydroxide creates reactive sites on the cellulose chain

- Etherification: Addition of methyl chloride and propylene oxide to attach the methyl and hydroxypropyl groups

- Neutralization: Removal of excess chemicals and stabilization of the final product

- Purification and Drying: Final processing to achieve specific quality parameters

During one factory tour, I showed a customer from Mexico the dramatic difference by demonstrating how natural cellulose remains completely insoluble in water, while our hypromellose dissolves readily to form a clear, viscous solution.

This visual demonstration helped them understand why hypromellose works so effectively as a water-retention agent in their tile adhesive formulations.

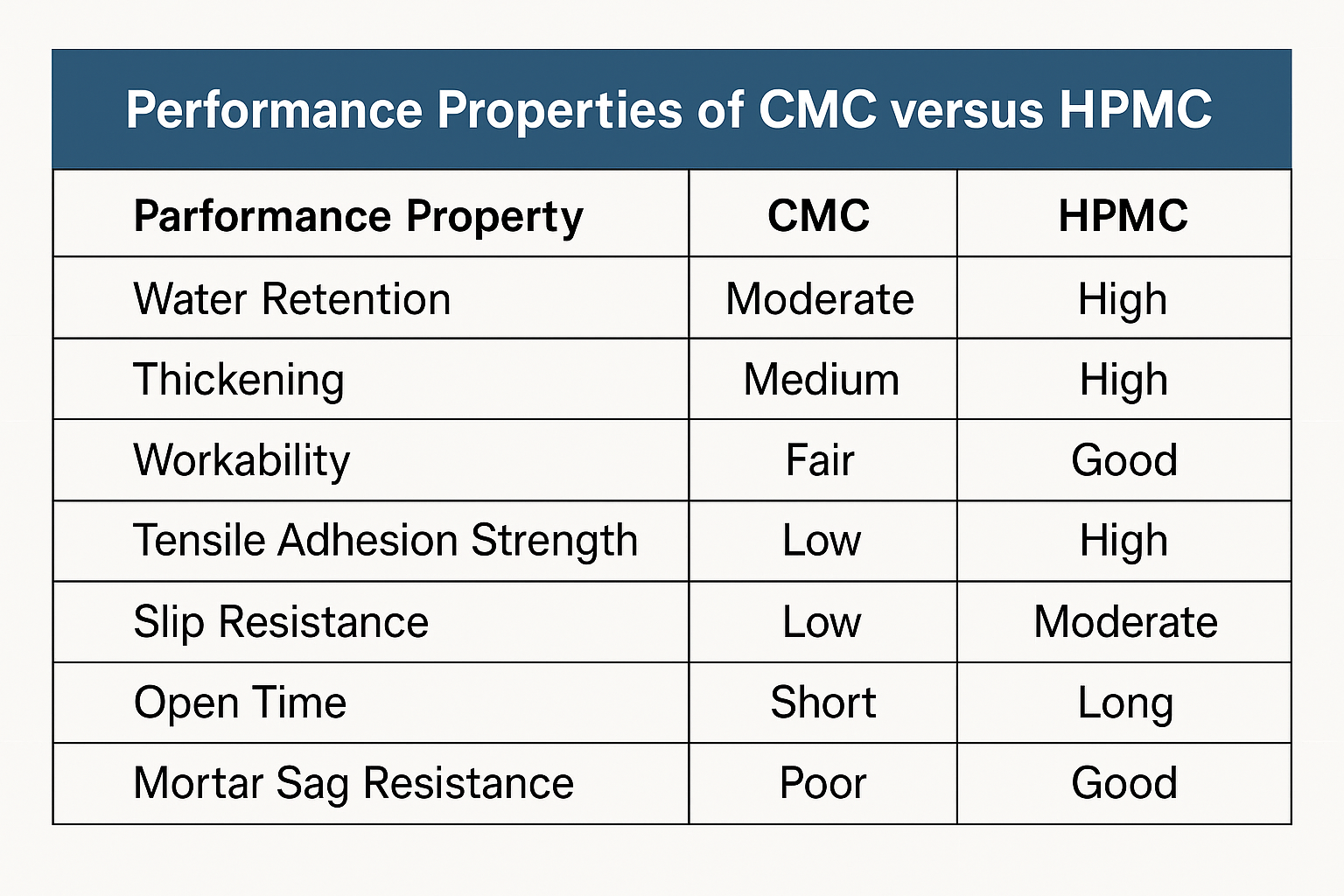

What is the difference between carboxymethyl cellulose3 and hydroxypropyl methylcellulose4?

Using the wrong cellulose derivative can lead to product failure. I've seen customers mix up CMC and HPMC with disastrous results because they didn't understand the fundamental differences.

Carboxymethyl cellulose (CMC) contains carboxymethyl groups (−CH₂COOH) attached to the cellulose backbone, making it highly ionic and pH-sensitive. HPMC contains neutral methyl and hydroxypropyl groups, providing better temperature stability, surface activity, and compatibility with other ingredients in construction formulations.

Having manufactured both CMC and HPMC5 in our facilities, I've developed a deep understanding of their different applications and performance characteristics. The chemical differences between these materials create significant practical implications for formulations.

Critical Application Differences

The functional differences between CMC and HPMC make each suitable for specific applications:

| Property | CMC | HPMC |

|---|---|---|

| Ionic nature | Anionic (charged) | Non-ionic (neutral) |

| Calcium ion sensitivity | High (precipitates) | Low (stable) |

| pH stability range | Narrow (4-10) | Wide (2-12) |

| Thermal gelation | No | Yes |

| Salt tolerance | Poor | Excellent |

| Cost | Generally lower | Generally higher |

| Biodegradability | Faster | Slower |

I recall a customer from the UAE who was experiencing mysterious clumping in their cement-based tile adhesive. They were using CMC, which was reacting with the calcium ions in the cement. After switching to our HPMC product, the problem disappeared completely because HPMC remains stable in the presence of calcium ions.

This chemistry lesson might seem technical, but it has direct implications for your product performance. The non-ionic nature of HPMC makes it far more versatile in construction applications, particularly those containing cement or high mineral content.

Conclusion

While cellulose forms the natural base material, its derivatives like HPMC, MC and CMC have distinct chemical properties that make them suitable for specific applications. Understanding these differences ensures you select the right cellulose derivative for your construction project needs.

-

Explore this link to understand HPMC's unique properties and advantages over methyl cellulose, crucial for your projects. ↩ ↩

-

Explore this link to understand the various applications of HPMC in construction, enhancing your knowledge of its uses and benefits. ↩ ↩

-

Learn about carboxymethyl cellulose's characteristics and applications to avoid mixing it up with other cellulose derivatives. ↩

-

Discover the advantages of hydroxypropyl methylcellulose in formulations, ensuring you choose the right cellulose derivative for your needs. ↩

-

Exploring HPMC's applications can enhance your understanding of its versatility in construction, especially in cement-based products. ↩