Are you struggling with mortar drying too fast, causing cracks and poor adhesion? This common problem costs construction companies thousands in repairs and damages their reputation with clients.

Water retention in HPMC (Hydroxypropyl Methylcellulose) is critical because it controls how long mortar stays workable by preventing premature water evaporation. This property ensures proper cement hydration, improved adhesion, and prevents cracking in tile adhesives, renders, and self-leveling compounds.

In my 15 years of manufacturing HPMC at Kehao, I've seen how water retention can make or break a construction project. Let me share what I've learned about this crucial property and why it matters for your business.

Why is water retention important?

Have you ever applied mortar that dried before you could even finish the job? It's frustrating and wastes both time and materials.

Water retention in construction mortars prevents premature drying by holding water within the mixture long enough for proper cement hydration to occur. This provides extended working time, prevents cracking, and ensures strong adhesion to surfaces, especially in hot or windy conditions.

I remember visiting a client's site in Saudi Arabia during summer when temperatures reached 45°C. Their standard mortar dried almost immediately after application, causing severe bonding issues. After switching to our high water retention HPMC, they could work comfortably even in extreme heat.

Water retention is particularly crucial in hot, dry climates like those found in our main markets - Saudi Arabia, UAE, and India. The technical performance of water retention can be measured using standard tests like DIN 18555, which evaluates the percentage of water retained after specific time intervals.

Impact of Water Retention on Different Applications

| Application | Low Water Retention | High Water Retention |

|---|---|---|

| Tile Adhesive | Quick drying, poor bonding, tile slippage | Extended open time, better adhesion, easier adjustability |

| Wall Putty | Cracking, poor surface finish | Smooth application, excellent finish, reduced callbacks |

| Self-leveling Compounds | Uneven curing, surface defects | Uniform flow, proper hardening, perfect level surface |

The molecular structure of HPMC directly affects its water retention capacity. Our premium grade HPMC products feature optimized molecular weight and substitution degree, specifically engineered to maintain workability longer in challenging environments.

Why is water retention important in plants?

Do you know that the principles of water retention in construction materials mirror those in natural systems? The similarities are both fascinating and instructive.

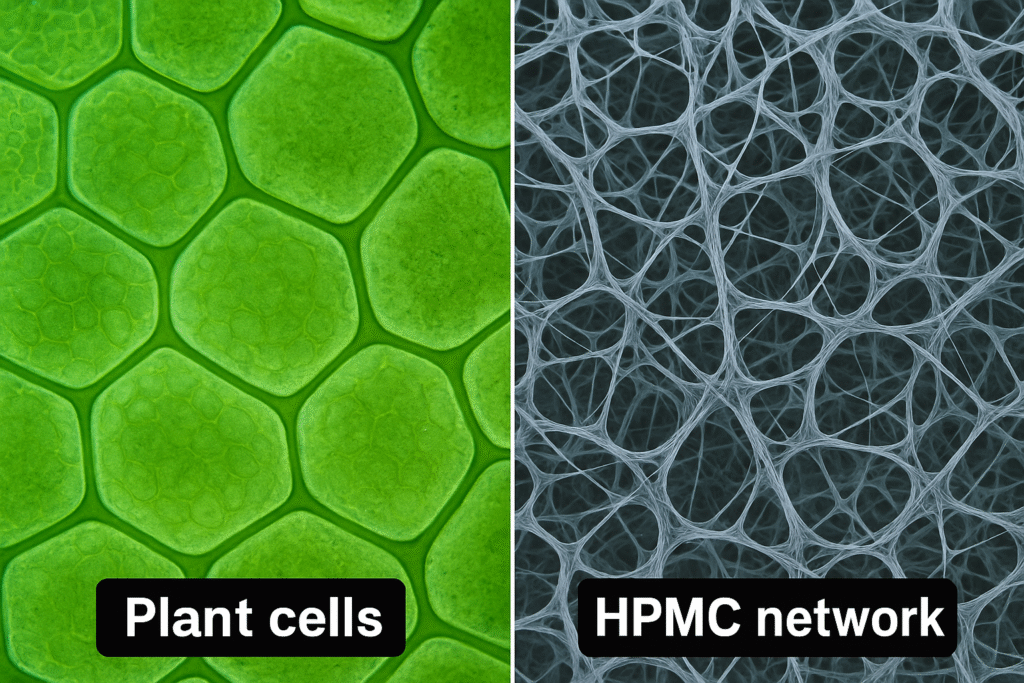

Water retention in plants is essential because it maintains cellular structure, enables nutrient transport, and prevents wilting during drought conditions. Plants use specialized cells and biochemical compounds to hold water, similar to how HPMC creates a gel network to retain moisture in construction materials.

Our R&D team at Kehao draws inspiration from nature's water retention mechanisms. I've always been fascinated by how plants survive in extreme conditions, from deserts to high mountains. This natural resilience sparked our development of specialized HPMC formulations1.

The science behind water retention in both plants and HPMC involves hydrogen bonding and molecular networks. In plants, cellulose and other polysaccharides form complex structures that trap water molecules.

Similarly, our HPMC creates three-dimensional networks in mortar systems that effectively hold water against evaporation and substrate absorption.

Comparative Water Retention Mechanisms

| System | Retention Method | Benefits | Application Insights |

|---|---|---|---|

| Plants | Cell wall polysaccharides, Specialized cell structures | Drought resistance, Structural integrity | Inspired gradual release technology |

| HPMC in Mortar | Hydrogen bonding, Gel network formation | Extended working time, Improved adhesion | Customizable retention periods |

| Enhanced HPMC | Modified hydroxypropyl groups, Optimized viscosity | Extreme condition performance, Consistent workability | Specialized for hot/dry climates |

We've developed testing protocols that measure water retention under various temperature and humidity conditions, simulating real-world application environments from the humid tropics to the dry Middle East.

This allows us to provide customers with precisely calibrated HPMC products for their specific regional needs.

What are the benefits of HPMC?

Are you wondering if investing in quality HPMC is worth the cost? The performance differences between standard and premium grades can significantly impact your bottom line.

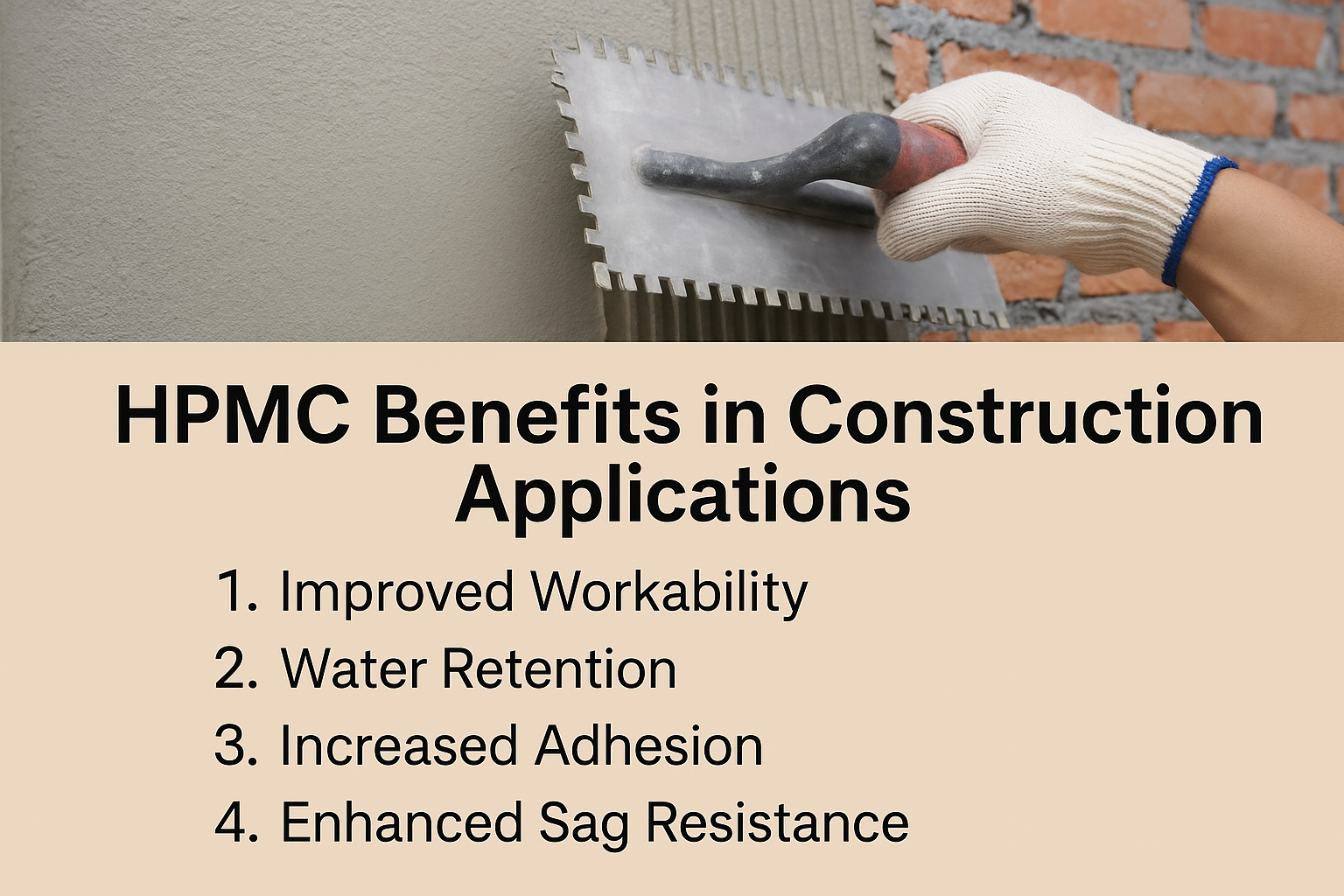

HPMC offers multiple benefits including excellent water retention, improved workability, enhanced adhesion, thickening capabilities, and air entrainment. These properties result in easier application, reduced material waste, better finishing quality, and increased durability of the final construction product.

Last year, I visited a major mortar manufacturer in Dubai who was struggling with inconsistent product performance. After analyzing their process, we recommended our HPMC2-100000 grade with optimized water retention. The switch resolved their quality issues and reduced customer complaints by 78%.

The versatility of HPMC makes it invaluable across numerous construction applications. Beyond its primary water retention function, HPMC contributes significantly to the overall performance and durability of finished products.

Our technical team has documented how proper HPMC selection can reduce project callbacks and warranty claims.

HPMC Performance Comparison by Application

| Application | Without HPMC | With Standard HPMC | With Premium Kehao HPMC |

|---|---|---|---|

| Cement-based Tile Adhesive | Rapid water loss, poor bonding | Basic water retention, acceptable adhesion | Extended open time, superior bonding strength |

| Exterior Insulation Systems | Inconsistent curing, poor durability | Standard performance, some seasonal issues | All-weather consistency, enhanced durability |

| Gypsum-based Products | Cracking, poor workability | Improved application, some limitations | Excellent finish, reduced material consumption |

Our laboratory testing has quantified these performance differences. For example, our premium HPMC-150000 grade demonstrates 95% water retention after 30 minutes at 35°C, compared to industry standard products showing only 75-80% retention under identical conditions. This translates directly to extended working time in hot weather applications.

How do you hydrate HPMC?

Have you struggled with lumps and poor dispersion when adding HPMC to your mixtures? There's a simple technique that can dramatically improve your results.

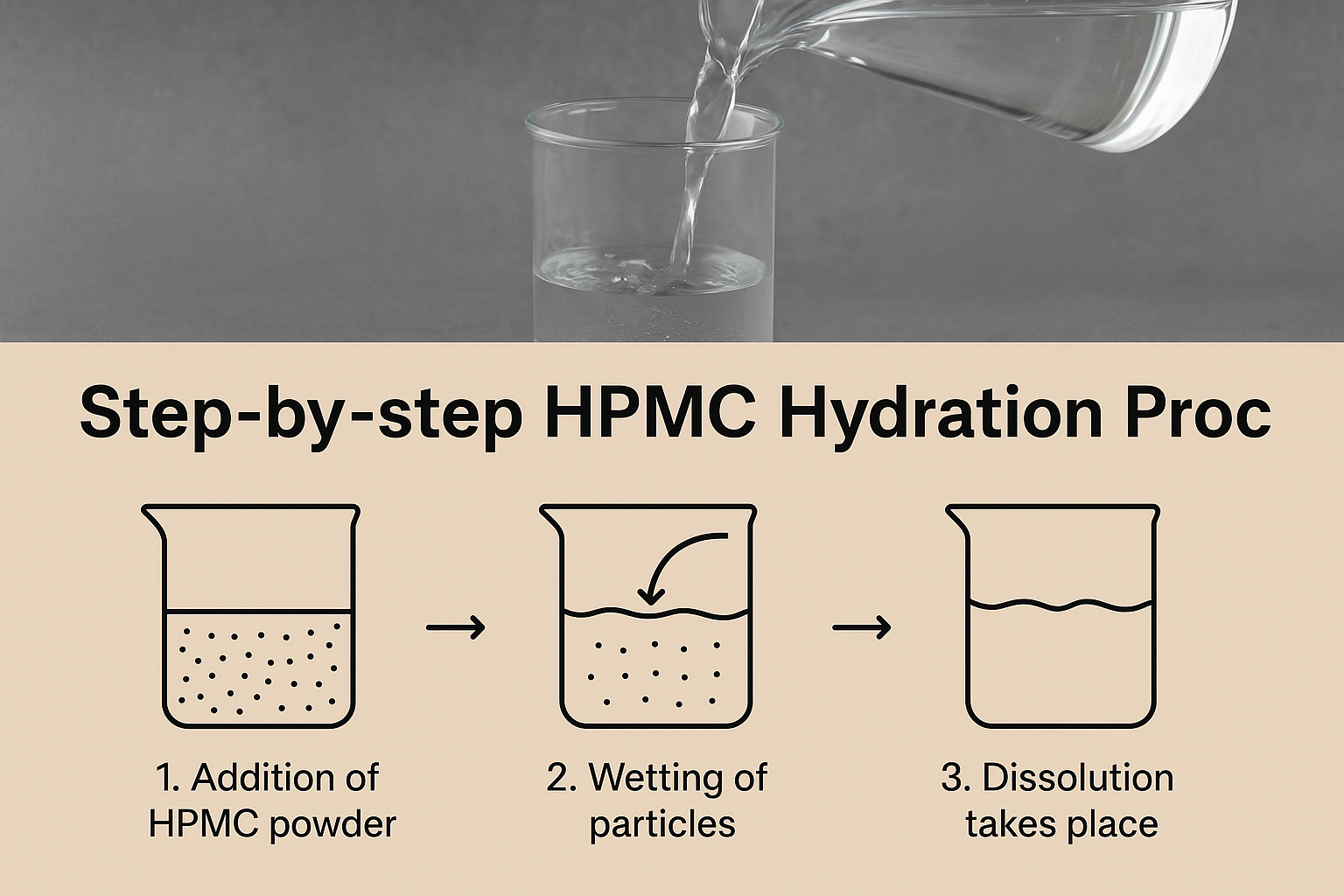

HPMC2 is properly hydrated through the "hot-cold" method, where it's first dispersed in hot water (above 85°C) to prevent immediate gel formation, then allowed to fully hydrate as the mixture cools. Alternatively, it can be pre-blended with other dry ingredients before adding room temperature water.

I often demonstrate proper hydration techniques during customer visits. At a factory in Pakistan, operators were adding HPMC directly to cold water, creating lumps that affected quality.

After implementing our recommended process, their production efficiency improved by 35%.

The science behind HPMC hydration3 involves understanding its unique temperature-dependent solubility. At Kehao, we've optimized our manufacturing process to produce HPMC with specific gel points tailored to different application requirements. This allows for predictable, consistent performance across varying climate conditions.

HPMC Hydration Methods Comparison

| Method | Process Steps | Advantages | Limitations | Best For |

|---|---|---|---|---|

| Hot-Cold Method | 1. Heat water >85°C 2. Disperse HPMC 3. Cool while stirring |

Complete hydration, No lumps, Consistent results | Requires heating capability, More time-consuming | Laboratory preparation, Small batches |

| Dry-Blending Method | 1. Mix HPMC with cement/sand 2. Add room temperature water 3. Mix thoroughly |

Simple process, No heating required, Industrial scale compatible | Requires efficient mixing equipment | Factory production, Large volumes |

| Surface-Treated HPMC | 1. Add directly to mix water 2. Mix at recommended speed 3. Allow brief standing time |

Quickest method, Minimal equipment requirements | Premium product cost, Specific grades required | Fast production cycles, Ready-mix applications |

We've developed specialized HPMC grades with surface treatments that significantly improve dispersion characteristics. These grades reduce hydration time by up to 65% compared to conventional HPMC while maintaining excellent water retention properties.

This technology has proven especially valuable for customers with high-volume production requirements.

Conclusion

Proper water retention through quality HPMC is crucial for successful construction projects, especially in challenging climates. By understanding and optimizing this property, you'll achieve better workability, stronger adhesion, and superior finished results.

-

Exploring the benefits of HPMC formulations can help you make informed decisions for construction projects, improving efficiency and quality. ↩

-

Explore the advantages of HPMC in construction to understand its impact on product performance and durability. ↩ ↩

-

Explore this resource to understand the best practices for HPMC hydration, ensuring optimal performance and quality in your applications. ↩