Are you experiencing rapid mortar drying, poor workability, and cracking issues? These problems can seriously impact your construction project's quality and durability, costing you time and money on repairs.

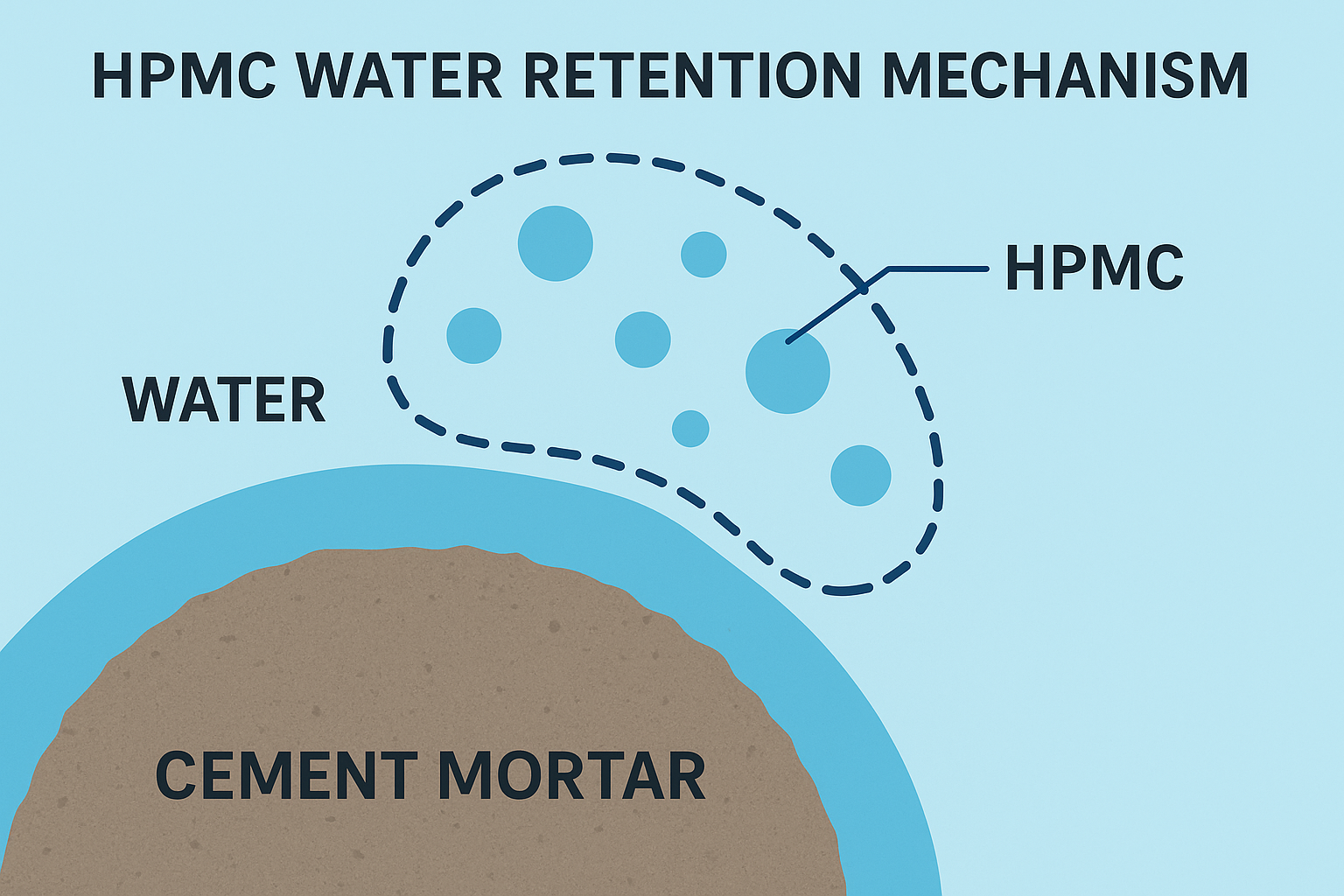

Hydroxypropyl methylcellulose (HPMC)1 solves these issues by forming a protective colloidal network in cement mortar that traps water molecules. This network slows water evaporation and migration, ensuring proper cement hydration while improving workability, adhesion, and overall mortar performance.

I've been supplying HPMC to construction material manufacturers for over 15 years, and water retention remains the benefit customers seek. Understanding how HPMC actually works will help you select the right grade for your specific applications and climate conditions.

What is Hydroxypropyl Methylcellulose (HPMC)?

Does your mortar dry too quickly, leaving you with poor adhesion and cracking? Traditional mortars without modern additives often present these frustrating challenges that compromise project quality.

HPMC is a semi-synthetic polymer derived from cellulose through chemical modification with hydroxypropyl and methyl groups. It's a white powder that dissolves in cold water to form a viscous solution with remarkable water retention, thickening, and binding properties essential for modern construction materials.

HPMC comes in various viscosity grades and substitution levels to suit different applications. As a manufacturer, I produce HPMC with viscosities ranging from 5 to 200,000 mPa·s and methoxyl content between 19-30%.

The viscosity directly impacts water retention capability - higher viscosity typically means better water retention.

However, extremely high viscosity can reduce workability, so finding the optimal balance is crucial. Our customers in hot, arid regions like Saudi Arabia and UAE typically prefer HPMC with higher viscosity (75,000-150,000 mPa·s) for enhanced water retention, while those in more temperate climates might use lower viscosity grades (15,000-60,000 mPa·s).

The molecular weight distribution also matters significantly. A wider distribution provides better water retention across different temperature ranges, which is why our premium HPMC grades undergo specialized processing to achieve this characteristic.

What is the Role of HPMC in Cement Mortar?

Are you struggling with mortar that shrinks, cracks, or fails to adhere properly to surfaces? These issues often stem from improper water management during the critical cement hydration process.

In cement mortar, HPMC serves multiple functions including water retention2, improved workability, enhanced adhesion, sag resistance, and extended open time. The primary role remains water retention, which ensures proper cement hydration by preventing premature water loss through evaporation or substrate absorption.

HPMC3 transforms ordinary cement mortar into a high-performance building material through several mechanisms. At typical dosage levels of 0.2-0.5% by weight of dry mortar, HPMC creates a remarkable difference in mortar behavior.

When added to mortar, HPMC molecules disperse throughout the mixture and interact with water through hydrogen bonding.

This interaction changes the rheological properties of the fresh mortar, making it more cohesive and easier to apply. I've observed firsthand how this improves trowelability - masons can work more efficiently and achieve better finishes.

Beyond water retention, HPMC provides critical benefits to cement-based materials:

| Function | Mechanism | Benefit |

|---|---|---|

| Workability enhancement | Lubrication effect between cement particles | Smoother application, less effort |

| Adhesion improvement | Formation of polymer bridges between mortar and substrate | Better bonding to various surfaces |

| Sag resistance | Increased yield stress | Ability to apply thicker layers without slumping |

| Air entrainment | Stabilization of microscopic air bubbles | Improved freeze-thaw resistance |

From our factory testing, HPMC with 27-29% methoxyl content typically provides optimal balance between water retention and workability for general-purpose mortars.

For tile adhesives, where stronger water retention is needed, we recommend formulations with higher hydroxypropyl substitution.

How Do the Mechanisms of Water Retention by HPMC Work?

Have you noticed how quickly regular cement mortar dries out in hot weather or when applied to absorbent substrates? This rapid water loss prevents proper cement hydration, leading to weak, brittle mortar that fails prematurely.

HPMC3 retains water through three primary mechanisms: formation of a reversible hydrogel network that physically traps water molecules, increased solution viscosity that slows water movement, and creation of a temporary barrier film that reduces evaporation and absorption rates at mortar interfaces.

The water retention capability of HPMC operates through sophisticated molecular interactions. When HPMC dissolves in the aqueous phase of mortar, its polymer chains unfold and create a three-dimensional network through hydrogen bonding and hydrophobic associations.

This network functions like a microscopic sponge, holding water molecules against gravitational forces and suction from porous substrates.

I've conducted numerous lab tests comparing water retention rates, and the results consistently show HPMC-modified mortars retain 95-98% of mixing water after 30 minutes under standardized test conditions, compared to just 60-70% for unmodified mortars.

The molecular structure of HPMC plays a critical role in its effectiveness:

- Hydroxypropyl groups - These hydrophilic components attract and bind water molecules through hydrogen bonding. Higher hydroxypropyl substitution generally improves water retention capability.

- Methyl groups - These hydrophobic elements help control dissolution rate and contribute to the formation of the hydrogel network. The methoxyl content affects thermal gelation properties.

- Polymer chain length - Longer polymer chains (higher molecular weight) create more extensive networks, improving water retention but potentially reducing workability.

Temperature significantly influences HPMC's water retention mechanism. As temperature rises, HPMC undergoes thermal gelation, forming a stronger network that can actually improve water retention at moderate temperature increases (up to about 40°C).

However, at extremely high temperatures, the network can collapse, reducing effectiveness - a consideration for projects in extremely hot climates.

What is the Impact of HPMC on Mortar Properties?

Are you experiencing inconsistent mortar performance across different weather conditions and substrate types? Without proper additives, achieving reliable results becomes nearly impossible, especially when working with highly absorbent surfaces or in challenging environmental conditions.

HPMC significantly improves both fresh and hardened mortar properties. In fresh mortar, it extends working time, enhances consistency, and improves adhesion. In hardened mortar, it increases flexural strength, reduces shrinkage cracking, and improves bond strength due to more complete cement hydration.

The water retention mechanism of HPMC creates a cascade of beneficial effects throughout the mortar's lifecycle. From mixing through application and curing, HPMC transforms ordinary mortar into a high-performance building material.

In fresh mortar, the immediate benefits include:

- Extended open time - Our tests show HPMC can extend working time by 15-45 minutes depending on dosage and environmental conditions. This gives applicators more flexibility and reduces waste from premature setting.

- Improved sag resistance - By increasing the yield stress of fresh mortar, HPMC allows for thicker application on vertical surfaces without slumping. In testing tile adhesives, we've achieved sag resistance up to 15mm thickness with optimized HPMC formulations.

- Enhanced water demand - HPMC typically increases water demand by 10-15%, which might seem counterintuitive, but this additional water becomes bound in the hydrogel network, contributing to workability without compromising strength.

In the hardened state, the long-term benefits become apparent:

| Property | Improvement with HPMC | Underlying Mechanism |

|---|---|---|

| Compressive strength | 5-15% increase | More complete cement hydration |

| Flexural strength | 10-25% increase | Better particle distribution and reduced microcracking |

| Bond strength | 20-40% increase | Improved interface transition zone formation |

| Shrinkage reduction | 15-30% decrease | Controlled water release during curing |

The dosage of HPMC must be carefully optimized for each application. From our experience supplying to hundreds of mortar producers, we've found that tile adhesives typically require 0.3-0.5% HPMC content, while renders and plasters perform best with 0.2-0.3%. Exceeding these levels can lead to excessive air entrainment and potential strength reduction.

Climate adaptation is another critical consideration. For our customers in hot regions like Saudi Arabia and UAE, we recommend HPMC grades with higher thermal stability and delayed dissolution properties to maintain water retention under extreme conditions.

Conclusion

HPMC creates a protective water-trapping network in cement mortar that ensures proper hydration while improving workability, adhesion, and durability. Selecting the right HPMC grade for your specific application and environmental conditions is crucial for optimal mortar performance.

-

Explore how HPMC enhances construction materials by improving water retention and workability, crucial for project success. ↩

-

Understanding water retention's role can help you optimize mortar performance and prevent issues like cracking and poor adhesion. ↩

-

Explore this link to understand the role of HPMC in improving cement mortar performance and its benefits in construction. ↩ ↩