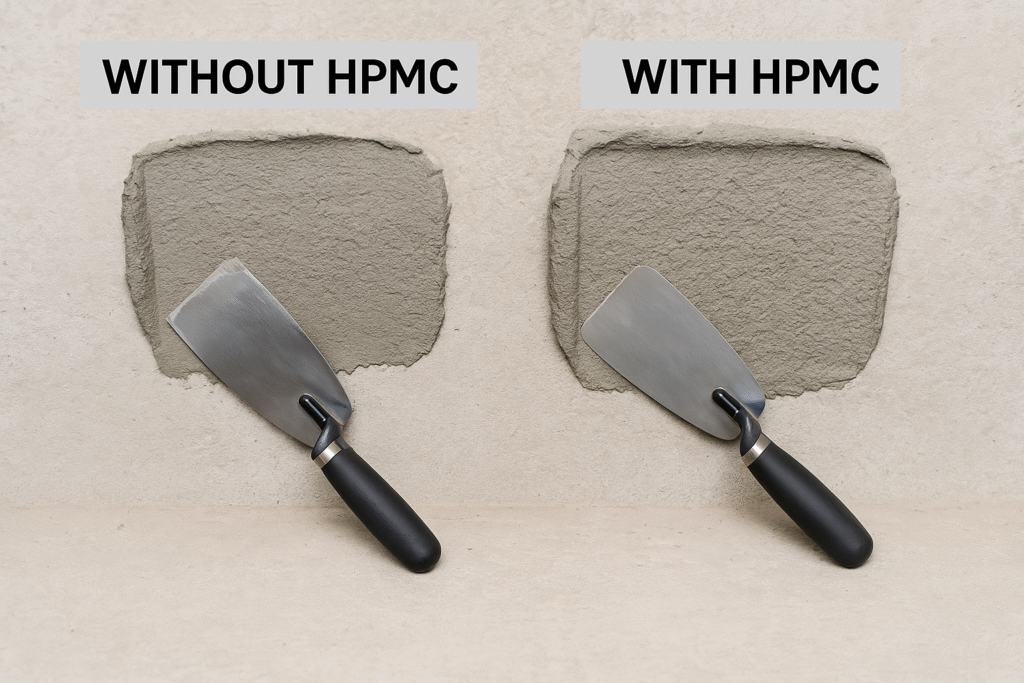

Every builder knows the frustration of mortar that cracks, dries too quickly, or lacks workability. These problems cause project delays, increased costs, and unsatisfied clients. HPMC offers a simple solution.

HPMC (Hydroxypropyl Methylcellulose) serves five main functions in dry mix mortar: water retention, improved workability, increased adhesion, enhanced sag resistance, and controlled setting time. These properties ensure mortar remains workable longer and creates stronger bonds with substrates.

I've been supplying HPMC to construction companies for over 15 years, and I've seen firsthand how this additive transforms ordinary mortar into a high-performance building material. Let me share what makes HPMC so essential and why selecting the right grade makes all the difference in your construction projects.

What Is Hydroxypropyl Methylcellulose (HPMC)1?

Builders often struggle with inconsistent mortar performance across different weather conditions and application methods. Poor quality cellulose ethers can make these problems worse, leading to project failures and costly rework.

Hydroxypropyl Methylcellulose (HPMC)1 is a modified cellulose ether derived from natural cellulose. It's a white, odorless powder that dissolves in cold water to form a clear solution, creating a viscous gel that dramatically improves mortar properties without affecting the final strength.

HPMC works through a fascinating mechanism when added to mortar. When mixed with water, HPMC molecules unfold and create a three-dimensional network that traps water.

This network acts like tiny water reservoirs distributed throughout the mortar mix. As the cement hydrates, these reservoirs slowly release water, ensuring proper curing even in challenging conditions.

The manufacturing process of HPMC involves several critical steps. First, natural cellulose (usually from cotton or wood pulp) undergoes alkaline treatment. Then, it reacts with propylene oxide and methyl chloride under controlled conditions. The resulting product is washed, dried, and ground to specific particle sizes.

Different viscosities of HPMC serve different construction applications:

| Viscosity (mPa·s) | Typical Applications |

|---|---|

| 380-400 | Self-leveling compounds |

| 15,000-30,000 | Tile adhesives, plasters |

| 30,000-100,000 | Renders, thick-bed mortars |

| >100,000 | Special high-retention mortars |

The molecular weight of HPMC directly correlates with its performance - higher molecular weight products generally provide better water retention but may require more mixing time.

In my factory, we carefully control these parameters to ensure consistent quality across all production batches.

Real Construction Problems—and How HPMC Solves Them

Many contractors face mortar that dries too quickly in hot weather, leading to poor bonding, cracks, and failed installations. Without proper additives, these issues can destroy reputations and cause significant financial losses.

HPMC solves construction problems by creating a water-retaining gel network within the mortar. This prevents premature drying, reduces moisture loss to porous substrates, extends working time, prevents cracking, and ensures optimal cement hydration for maximum strength development.

I once visited a major construction site in Dubai where temperatures regularly exceeded 40°C (104°F). The contractor was experiencing severe issues with their tile adhesive drying before proper bonding could occur.

After analyzing their mixture, I recommended a high-viscosity HPMC2 with enhanced water retention properties. The results were immediate - installation failures dropped from 15% to less than 1%.

HPMC addresses several specific construction challenges through its unique properties. For exterior applications, it prevents rapid water evaporation that can lead to shrinkage cracks. The polymer forms a protective film that regulates moisture movement while still allowing the cement to hydrate properly.

For vertical applications like wall renders, HPMC increases the sag resistance through thixotropic behavior - the mortar remains stiff when undisturbed but becomes workable when troweled. This dual property allows for thicker application without sliding down the wall.

Temperature sensitivity is another challenge HPMC helps overcome:

| Temperature Condition | HPMC Benefit |

|---|---|

| Hot Climate (>30°C) | Prevents premature drying, extends open time |

| Cold Climate (<10°C) | Controls water separation, ensures proper hydration |

| Fluctuating Conditions | Stabilizes mortar properties throughout curing |

| High Humidity | Reduces excessive water absorption, prevents softening |

Our testing laboratory regularly conducts real-world simulations under various climate conditions to optimize HPMC formulations for specific regional requirements. This ensures our customers receive products tailored to their actual working environments.

Benefits of Adding HPMC to Mortar

Construction companies constantly struggle with inconsistent mortar quality, unpredictable working times, and poor adhesion to difficult substrates. These problems lead to project delays, increased labor costs, and reputation damage from failed installations.

Adding HPMC3 to mortar provides numerous benefits: extended working time (up to 4 hours), improved adhesion to various substrates, reduced water requirements, enhanced freeze-thaw resistance, prevention of segregation, and consistency across batches. These improvements significantly reduce application failures and callbacks.

I've worked with countless construction material manufacturers who have transformed their products by incorporating our HPMC. One tile adhesive producer in Saudi Arabia increased their market share by 30% after reformulating with our premium-grade HPMC, which provided exceptional open time even in extreme desert conditions.

The economic benefits of HPMC extend beyond just improved technical performance. Though HPMC represents an additional raw material cost, the overall formulation often becomes more economical. This occurs because HPMC allows for reduction in other expensive components like cement while maintaining or improving final properties.

Our analysis typically shows a return on investment of 3:1 when considering the reduced callbacks, improved productivity, and enhanced product reputation.

Long-term durability also improves dramatically with proper HPMC incorporation. The controlled hydration process results in more complete cement curing, creating a denser microstructure with fewer micro-cracks.

We've conducted accelerated aging tests showing that properly formulated HPMC mortars retain up to 95% of their adhesive strength after equivalent 10-year aging simulations, compared to only 70% retention in non-modified mortars.

The dosage optimization is critical for maximizing benefits:

| Application Type | Recommended HPMC Dosage (% of dry mix) | Key Benefit |

|---|---|---|

| Tile Adhesives | 0.2-0.5% | Extended open time, slip resistance |

| Renders/Plasters | 0.1-0.3% | Workability, reduced sagging |

| Self-Leveling | 0.05-0.2% | Flow properties, reduced bleeding |

| Repair Mortars | 0.2-0.4% | Adhesion, reduced shrinkage |

Our technical team works closely with customers to determine the precise dosage and HPMC3 specification that delivers optimal performance for their specific applications and regional conditions. This customized approach ensures they receive maximum value from their HPMC investment.

Conclusion

HPMC transforms ordinary dry mix mortar into a high-performance building material by improving water retention, workability, adhesion, and consistency. Choosing the right grade and dosage ensures optimal results for your specific construction applications.

-

Explore the benefits of HPMC in construction to understand how it enhances mortar performance and solves common issues. ↩ ↩

-

Learn about the advantages of high-viscosity HPMC in tile adhesives and its impact on installation success. ↩

-

Explore how HPMC enhances construction materials, improving adhesion and performance in various climates. ↩ ↩