Building materials need effective additives to improve workability and performance. Many manufacturers struggle with consistency issues that lead to product failures and unhappy customers.

HPMC (Hydroxypropyl Methylcellulose)1 is a versatile cellulose ether used in construction materials to improve water retention, workability, and adhesion. It functions as a thickener, binder, and water-retaining agent in mortars, cement-based products, and paints, extending working time and enhancing application properties.

I've been supplying HPMC to construction material manufacturers for over 15 years, and I've seen firsthand how the right cellulose ether can transform product performance. Let me share what makes this additive essential for modern building materials and how it can benefit your products.

What Are the Main Applications of HPMC in Construction?

Many manufacturers struggle with inconsistent mortar setting times and poor workability that lead to application problems and customer complaints. These issues often stem from using improper additives.

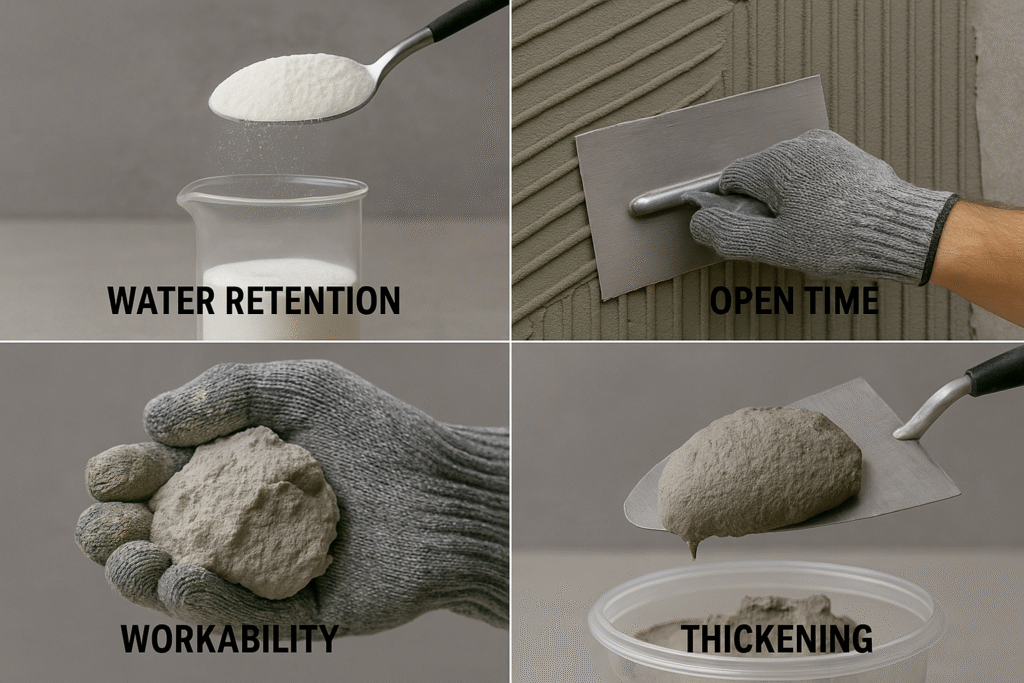

HPMC is primarily used in dry-mix mortars2, tile adhesives, plasters, self-leveling compounds, and exterior insulation finishing systems (EIFS). It improves water retention3, enhances workability, prevents sagging, and extends open time, allowing for better application and stronger bonding to substrates.

When I visit construction sites in Saudi Arabia and UAE, I often notice the significant difference between materials formulated with quality HPMC and those without. The versatility of HPMC makes it indispensable across numerous construction applications.

Dry-mix Mortars and Tile Adhesives

HPMC plays a crucial role in these products by controlling water retention and improving adhesion. In hot climates like Saudi Arabia, where water evaporates quickly, HPMC ensures that cement has enough time to properly hydrate. This prevents premature drying and cracking, a common issue that leads to adhesive failure.

Gypsum-based Products

For gypsum plasters and joint compounds, HPMC provides the perfect balance of workability and setting time. It increases the air content slightly, making the material lighter and easier to apply. Our customers in Pakistan and India particularly value this property for their gypsum-based product lines.

Wall Putties and Paints

HPMC serves as an excellent thickener and stabilizer in wall putties4 and paints. It prevents sagging during application and ensures a smooth finish. The anti-settling properties keep the mixture homogeneous during storage, extending shelf life significantly.

What Are the Key Properties of HPMC That Benefit Construction Materials?

Formulators often face challenges balancing water demand, open time, and final strength in their products. Poor quality additives can lead to inconsistent performance and project failures.

HPMC's key properties include excellent water retention (90-98%), thermal gelation at specific temperatures, controlled viscosity (from 5-200,000 mPa·s), pH stability (2-13), and compatibility with cement minerals. These properties help control workability, setting time, and final strength in construction materials.

In my 15 years working with construction material manufacturers, I've found that understanding HPMC's properties is essential for proper formulation. Let me break down the most important characteristics and how they impact your products.

Viscosity and Its Impact on Application Properties

HPMC viscosity directly affects the consistency and workability of mortars and paints. We measure viscosity in mPa·s (millipascal-seconds), and different applications require specific viscosity ranges:

| Application | Recommended Viscosity Range | Benefits |

|---|---|---|

| Tile Adhesives | 15,000-30,000 mPa·s | Prevents slipping, maintains open time |

| Self-leveling Compounds | 5,000-15,000 mPa·s | Promotes flow without segregation |

| Wall Putties | 30,000-80,000 mPa·s | Provides sag resistance, smooth application |

| Exterior Renders | 20,000-50,000 mPa·s | Balanced workability and water retention |

I remember visiting a customer in Brazil who switched from a 20,000 mPa·s to a 40,000 mPa·s HPMC in their tile adhesive. The higher viscosity significantly reduced tile slippage during installation, resolving their main customer complaint and increasing sales by 20%.

Water Retention and Setting Control

Water retention is perhaps HPMC's most valuable property for construction applications. It ensures that water remains available for cement hydration rather than being lost to evaporation or absorption into porous substrates. Our laboratory tests confirm that high-quality HPMC can achieve water retention rates of 95-98%, even in adverse conditions.

Why Choose KEHAO as Your HPMC Manufacturer?

Finding reliable suppliers who understand construction applications and deliver consistent quality can be challenging. Many manufacturers have experienced production delays due to inconsistent raw materials.

KEHAO offers high-quality HPMC5 with consistent batch-to-batch performance, customizable specifications, and technical support. With six production lines and extensive export experience to developing countries, we provide reliable supply, professional quality control, and comprehensive certifications to meet your specific requirements.

I've been helping customers optimize their formulations for over a decade, and I understand the unique challenges faced by manufacturers in hot climates and developing markets. Our approach at KEHAO focuses on your specific needs rather than just selling a standard product.

Production Capacity and Quality Control

With six dedicated production lines, KEHAO can ensure stable supply even during peak demand seasons. This has proven invaluable to our customers in Saudi Arabia, UAE, and India, where construction schedules are tight and delays can be costly.

Our quality control process includes:

- Raw material inspection and testing

- In-process monitoring of critical parameters

- Final product testing for viscosity, moisture content, and ash content

- Performance testing in actual application scenarios

Last year, when a customer in Mexico experienced inconsistent setting times in their tile adhesive, our technical team identified that their previous supplier was providing HPMC with variable methoxyl content. After switching to our consistent product, their quality complaints decreased by 85%.

Customization and Technical Support

We understand that different markets have different requirements. Our technical team works closely with customers to determine the optimal HPMC specifications for their specific applications, considering local raw materials, climate conditions, and application methods.

For example, we developed a specialized HPMC grade for a customer in the Philippines that provided excellent water retention while still allowing their exterior render to dry quickly enough to resist the frequent rain showers in their region.

Conclusion

HPMC is a vital component in modern construction materials, providing crucial properties like water retention and workability. By choosing KEHAO as your supplier, you gain a reliable partner with the expertise and capacity to support your specific needs.

-

Explore how HPMC enhances water retention and workability in construction materials, making it essential for quality performance. ↩

-

Gain insights into dry-mix mortars and how they benefit from additives like HPMC for improved performance. ↩

-

Understanding water retention is crucial for ensuring proper hydration and preventing issues like cracking in construction. ↩

-

Learn about wall putties, their applications, and how HPMC improves their performance and finish. ↩

-

Explore this link to understand how high-quality HPMC can enhance construction materials and improve performance. ↩