Are you struggling with lumpy HPMC1 mixtures and wasting valuable production time? Proper dissolution techniques can save you hours of frustration and significant material costs in your construction projects.

To dissolve HPMC1 properly, you need to match the dissolution method to the specific type: for instant (surface-treated) HPMC, add directly to cold water with agitation; for hot-soluble (non-surface-treated) HPMC, disperse in hot water (80-90°C) first, then add cold water for hydration.

I've been helping clients optimize their HPMC dissolution processes for years now. The difference between proper and improper dissolution isn't just about efficiency—it directly impacts your final product quality and project timelines. Let me walk you through everything you need to know about getting this crucial step right.

How to Dissolve Instant Type (Surface Treated) HPMC?

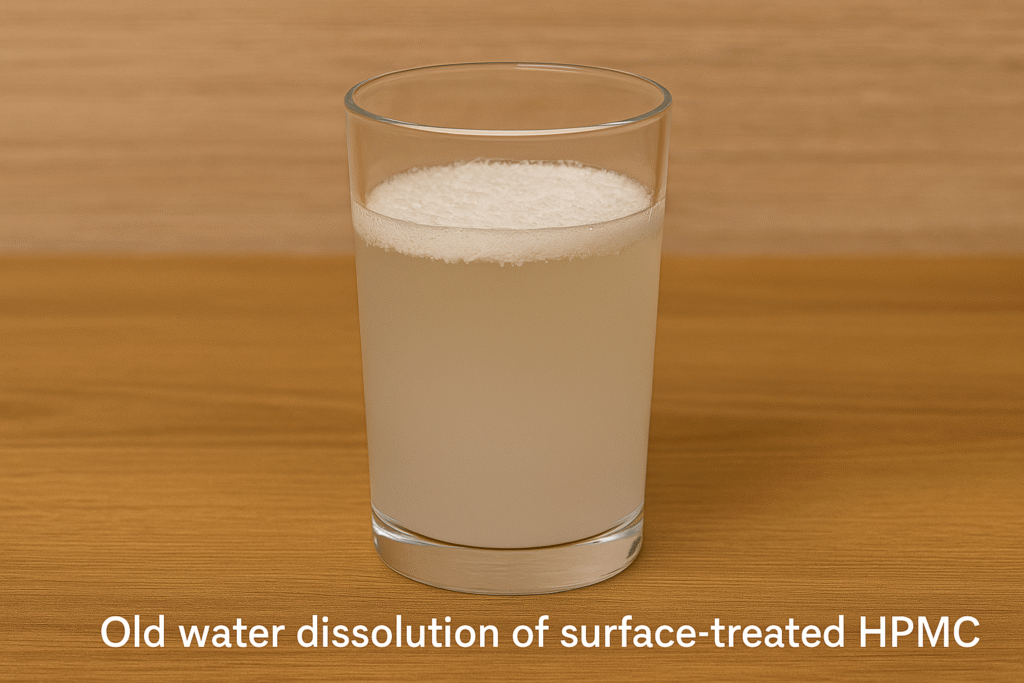

Have you ever added HPMC powder to water only to watch it clump immediately? This common problem wastes both material and time, but there's a simple solution when working with surface-treated varieties.

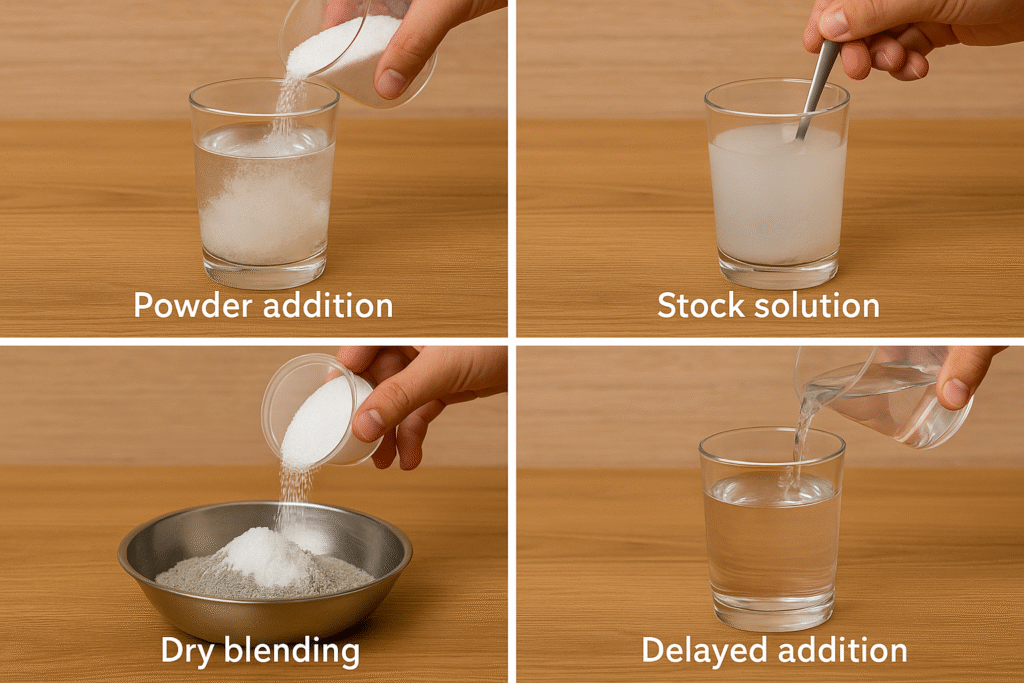

Instant-type HPMC2 dissolves easily in cold water because its surface has been chemically treated to prevent immediate gel formation. Simply add the powder gradually to cold water (below 30°C) while stirring continuously for 15-30 minutes until completely dissolved.

Dissolution of instant-type HPMC is much more straightforward than its non-surface treated counterpart, which is why many of our customers prefer it for time-sensitive projects. The surface treatment creates a temporary barrier that allows the powder to disperse before hydration begins, preventing the dreaded "fish-eye" lumps that plague improper dissolution.

When dissolving instant-type HPMC, water temperature is critical. Always use water below 30°C (86°F) - I typically recommend 20-25°C (68-77°F) for optimal results. The dissolution process typically follows these steps:

- Fill your mixing tank with the required amount of cold water

- Start mechanical agitation at moderate speed

- Add the HPMC powder gradually, not all at once

- Continue mixing for 15-30 minutes until the solution is completely clear

For larger industrial applications, we recommend using high-shear mixers to speed up the process. The table below summarizes the key parameters for instant HPMC dissolution:

| Parameter | Recommended Value | Notes |

|---|---|---|

| Water Temperature | Below 30°C (20-25°C ideal) | Higher temperatures reduce dissolution efficiency |

| Addition Method | Gradual, steady addition | Avoid dumping all powder at once |

| Mixing Time | 15-30 minutes | Depends on agitation intensity and batch size |

| Agitation | Moderate to high | Higher for larger batches |

What Are the Main Applications for Different HPMC Types?

Do you know which type of HPMC will perform best in your specific application? Choosing incorrectly can lead to inconsistent results and wasted resources.

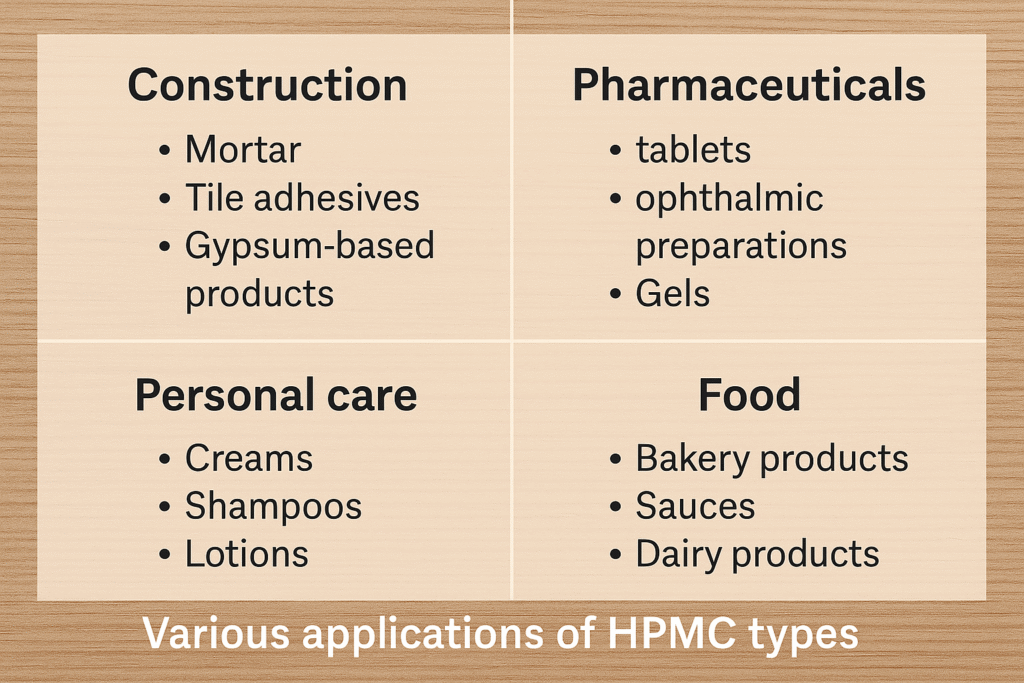

Surface-treated HPMC is ideal for dry-mix mortars, ready-mix compounds, and applications requiring quick dissolution. Non-surface-treated HPMC works better for products manufactured in slurry form, paint production, and applications where controlled dissolution is needed.

The application scope for HPMC extends far beyond just construction materials. Based on my experience working with manufacturers across various industries, I've seen how critical matching the right HPMC type to the application can be.

Instant-type HPMC dominates in dry-mix formulations because of its ease of integration. When manufacturers produce pre-mixed construction compounds, the ability of surface-treated HPMC to disperse evenly without pre-mixing is invaluable. This type is particularly popular in:

- Tile adhesives and grouts

- Self-leveling compounds

- Renders and plasters

- Joint compounds

- Ready-mix cement formulations

Meanwhile, hot-soluble HPMC finds its niche in manufacturing processes where controlled dissolution is beneficial. For example, in paint production, the gradual thickening provided by non-surface-treated HPMC allows formulators to better control viscosity development. Common applications include:

- Water-based paints and coatings

- Pharmaceutical tablet binding

- Personal care products

- Food products requiring controlled thickening

- Industrial slurry production

The choice between these types often depends not just on the final application but also on the manufacturing equipment available and production throughput requirements.

How to Dissolve Hot Soluble Type (Non-Surface Treated) HPMC?

Are your non-surface treated HPMC solutions turning into a lumpy mess? This type requires a special dissolution technique that many first-time users miss.

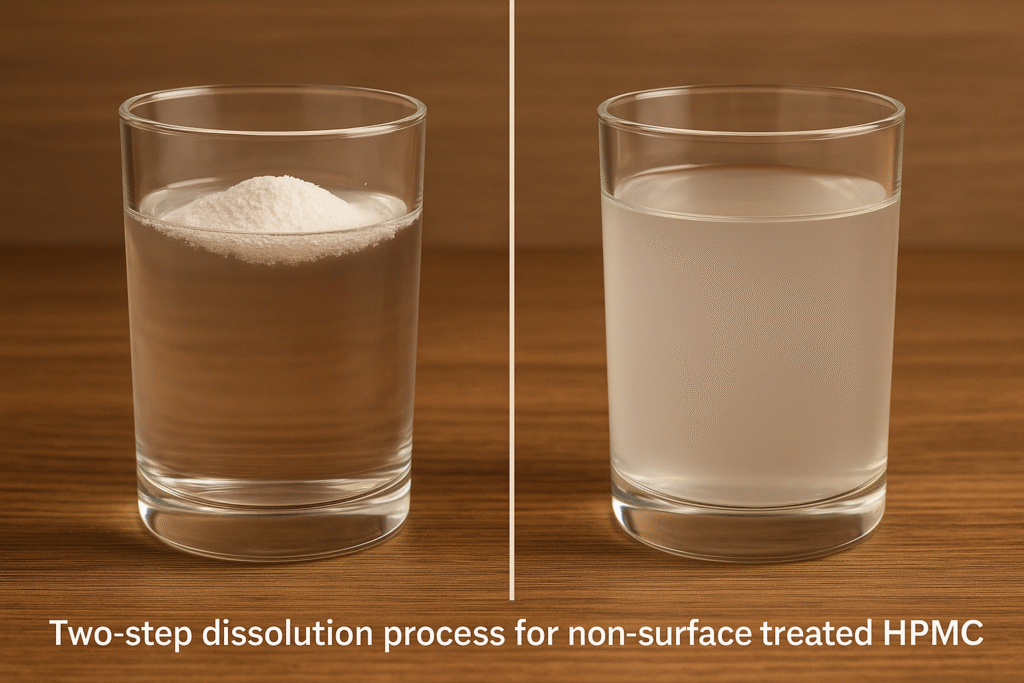

Hot soluble HPMC requires a two-step dissolution process: first disperse the powder in hot water (80-90°C) where it won't hydrate, then add cold water or let it cool to below 30°C to activate hydration. Complete dissolution typically takes 30-60 minutes with proper agitation.

The dissolution of non-surface treated HPMC is more complex and requires careful attention to temperature. I've helped many clients troubleshoot their processes when they encounter difficulties with this type. The key insight is understanding the temperature-dependent behavior of HPMC.

Non-surface treated HPMC exhibits what we call "inverse solubility" - it doesn't dissolve in hot water but dissolves as the water cools. This property allows us to use a two-phase dissolution approach:

- Dispersion Phase: When added to hot water (80-90°C), HPMC particles disperse without hydrating or forming gels

- Hydration Phase: As the water cools below 30°C or when cold water is added, the HPMC begins to hydrate and dissolve

This process can be implemented in several ways depending on your equipment:

| Method | Process Steps | Equipment Needed |

|---|---|---|

| Cooling Method | 1. Add HPMC to hot water with agitation 2. Continue mixing while cooling |

Jacketed tank with cooling capability |

| Cold Water Addition | 1. Add HPMC to 1/3 of required water heated to 80-90°C 2. Add remaining 2/3 as cold water |

Standard mixing tank |

| Ice Addition | 1. Add HPMC to hot water 2. Add ice to rapidly cool mixture |

Standard mixing tank |

The cooling method generally produces the most consistent results but requires specialized equipment. For smaller operations, the cold water addition method offers a good balance of effectiveness and equipment simplicity.

What Practical Considerations Should Be Taken Into Account?

Have you experienced inconsistent results even when following dissolution guidelines? Several practical factors can significantly impact the success of your HPMC dissolution process.

Practical considerations for HPMC dissolution include water quality (hardness and pH), agitation type and intensity, dissolution time, batch size scaling, and pre-mixing with other dry ingredients. These factors can significantly affect dissolution efficiency and final solution properties.

Through my years of helping clients optimize their HPMC processes, I've identified several practical considerations that often get overlooked but can make or break a successful dissolution operation.

Water quality is perhaps the most underappreciated factor. Hard water with high mineral content can interfere with HPMC hydration and reduce its effectiveness. I've seen cases where simply switching to deionized or softened water resolved persistent dissolution problems. Similarly, extreme pH values can affect dissolution kinetics - a neutral pH (6.5-7.5) generally works best for most HPMC grades.

The mixing equipment selection is equally critical. Different agitator designs create different flow patterns:

- Propeller mixers work well for low to medium viscosity solutions

- Anchor agitators are better for higher viscosity mixtures

- High-shear mixers significantly reduce dissolution time but may increase equipment costs

Scaling production from laboratory to industrial levels introduces additional challenges. What works in a 5-liter beaker may not translate directly to a 5,000-liter tank. The table below outlines scaling considerations:

| Scale Factor | Adjustment Needed |

|---|---|

| Agitation | Increased power per unit volume required at larger scales |

| Addition Time | More gradual addition for larger batches |

| Temperature Control | More difficult in larger vessels - may need enhanced cooling/heating systems |

| Dissolution Time | Often longer for larger batches |

Pre-mixing HPMC with other dry ingredients before adding to water can sometimes help prevent agglomeration, especially when specialized dissolution equipment isn't available. This technique works particularly well with surface-treated HPMC in dry-mix formulations.

What Are the Recommended Uses for Each Dissolution Method?

Are you unsure which HPMC type and dissolution method best fits your manufacturing setup? The wrong choice could lead to inefficient processes and inconsistent product quality.

Use instant-type HPMC with cold water dissolution for batch productions with limited mixing equipment, tight production schedules, and dry-mix formulations. Choose hot-soluble HPMC with the hot/cold method for slurry production lines, applications requiring controlled thickening, and when working with other heat-sensitive ingredients.

Selecting the appropriate HPMC type and dissolution method depends heavily on your production environment, equipment limitations, and end product requirements. I've guided clients through this decision process countless times, weighing the trade-offs between convenience, cost, and performance.

For batch production environments where mixing equipment may be limited, instant-type HPMC3 offers significant advantages. The single-step cold water dissolution means:

- Simpler equipment requirements (no heating/cooling needed)

- Faster batch turnover

- Lower energy consumption

- Reduced risk of operator error

This makes instant-type particularly suitable for:

- Smaller manufacturers with basic equipment

- Job-site mixing scenarios

- Products where rapid dissolution is critical to workflow

- Formulations where other ingredients might be heat-sensitive

Conversely, hot-soluble HPMC4 finds its sweet spot in continuous production environments and specialized applications. Its two-stage dissolution provides:

- More controlled hydration dynamics

- Often better dispersion in complex formulations

- Compatibility with production lines already equipped with heating capabilities

- Sometimes lower cost (as surface treatment adds to production cost)

I've found that companies transitioning from small-batch to larger continuous production often need to reevaluate their HPMC type selection. What worked efficiently at smaller scales may become a bottleneck in larger operations.

How Do Instant and Hot-Soluble HPMC Types Compare?

Are you trying to decide between instant and hot-soluble HPMC for your formulation? The differences extend well beyond just dissolution methods and can impact your entire production process.

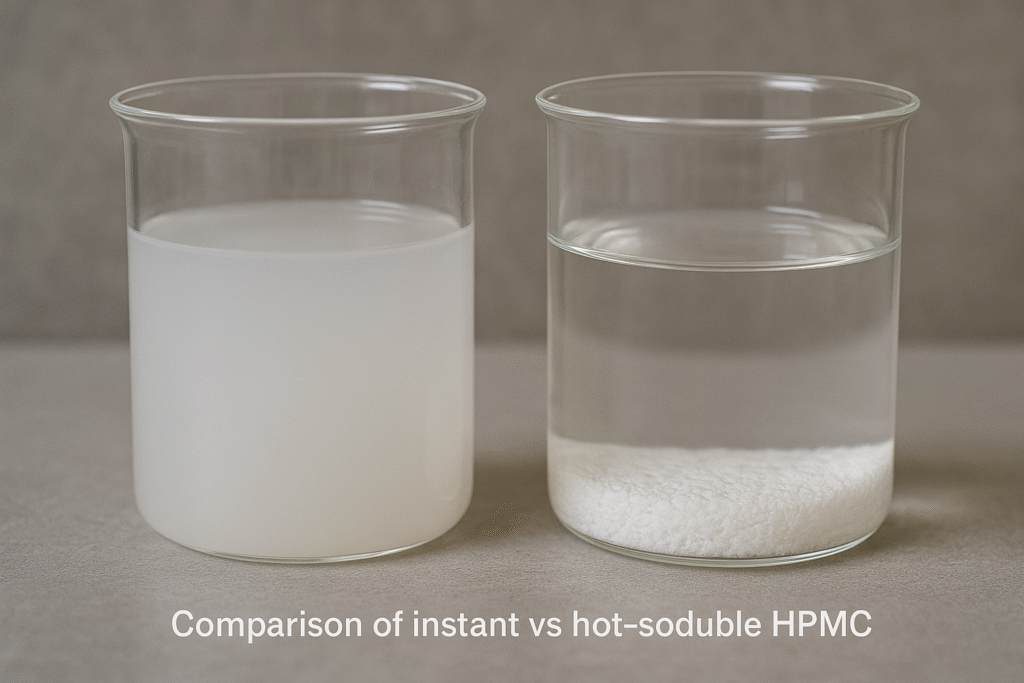

Instant-type HPMC offers faster dissolution, simpler processing, and better dry-mix compatibility but at a higher cost and with limitations in some applications. Hot-soluble HPMC provides more controlled hydration, often lower cost, and better compatibility with continuous processes, though requires more complex equipment.

After supplying both types of HPMC to various industries for years, I've developed a comprehensive understanding of their comparative strengths and limitations. The choice between them often represents a significant strategic decision for manufacturers.

The table below summarizes the key differences between these two HPMC varieties:

| Factor | Instant (Surface-Treated) HPMC | Hot Soluble (Non-Surface-Treated) HPMC |

|---|---|---|

| Dissolution Speed | Fast (15-30 minutes) | Slower (30-60 minutes) |

| Equipment Requirements | Simple mixing equipment | Heating and cooling capabilities |

| Production Complexity | Lower | Higher |

| Cost | 5-15% more expensive | Standard pricing |

| Dry-Mix Compatibility | Excellent | Limited |

| Controlled Hydration | Less controlled | More controlled |

| Energy Consumption | Lower | Higher |

| Viscosity Development | Immediate | Gradual |

| Batch Size Flexibility | More flexible | Less flexible |

| Continuous Processing | Less suitable | More suitable |

Beyond these technical differences, market availability and supplier specialization may influence your decision. Some manufacturers specialize in one type over the other, affecting quality and consistency. Our Kehao factory produces both varieties to pharmaceutical-grade standards, with customizable surface treatment levels for specific application requirements.

It's worth noting that while surface treatment adds to the production cost of instant-type HPMC, this may be offset by savings in production time, energy costs, and simplified equipment needs. Many of our customers find that the total cost of ownership actually favors instant-type HPMC when all factors are considered.

What Are the Best Methods for Dissolving Instant Type HPMC?

Are you getting the most efficient dissolution from your instant-type HPMC? Even surface-treated varieties require proper techniques to achieve optimal results.

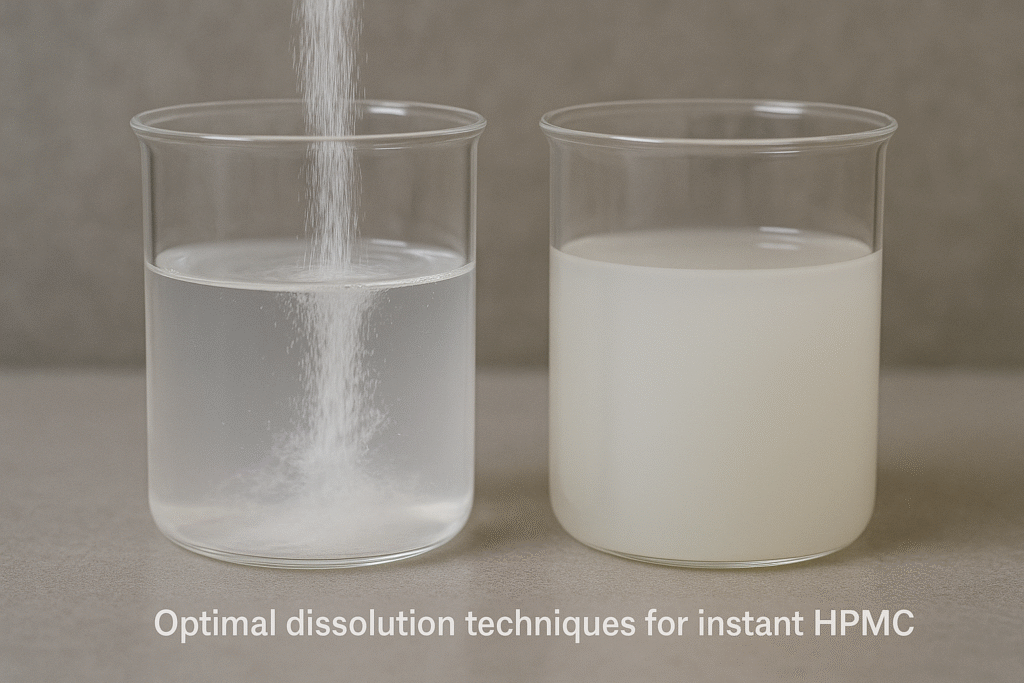

For best results with instant-type HPMC, use the "sprinkle" method (gradually adding powder to the vortex of stirred cold water), maintain water temperature below 30°C, consider using high-shear mixers for larger batches, and allow sufficient hydration time (15-30 minutes) before adding other ingredients.

Through extensive work with our clients' manufacturing processes, I've identified several advanced techniques that significantly improve dissolution efficiency for instant-type HPMC.

The "sprinkle" method remains the gold standard for achieving lump-free dissolution. This involves creating a vortex in the water through agitation, then slowly adding the HPMC powder to the edge of the vortex where shear forces are highest. This prevents the formation of agglomerates by immediately separating individual particles.

For industrial-scale operations, specialized equipment can dramatically improve dissolution:

- Pre-dispersion systems: These use venturi effects to pre-wet powder before it enters the main tank

- In-line powder induction: Systems like the Silverson Flashmix pull powder directly into high-shear zones

- Recirculation loops: Pumping the solution through external high-shear devices while adding powder to the main tank

The dissolution rate of instant-type HPMC is also affected by several physical and chemical factors:

- Particle size: Finer grades dissolve faster but are more prone to dusting and agglomeration

- Viscosity grade: Higher viscosity grades generally take longer to fully hydrate

- Substitution type: The ratio of methoxyl to hydroxypropoxyl groups affects dissolution dynamics

- Degree of surface treatment: More heavily treated grades disperse faster in cold water

I've found that many clients benefit from establishing a standardized dissolution protocol with clear parameters for each grade they use. Such protocols typically specify:

- Precise water temperature range

- Powder addition rate (kg/minute)

- Agitation speed (RPM)

- Minimum hydration time

- Visual/physical checks for complete dissolution

This systematic approach eliminates variability between batches and operators, ensuring consistent results every time.

Conclusion

Proper HPMC dissolution techniques—matching method to type, controlling temperature, ensuring appropriate agitation, and allowing sufficient hydration time—are essential for quality results in your construction and manufacturing projects. Choose wisely between instant and hot-soluble varieties based on your specific needs.

-

Understanding HPMC's role in construction can enhance your project efficiency and material usage. ↩ ↩

-

Learn more about the unique properties of Instant-type HPMC and how to effectively use it in your formulations. ↩

-

Explore the benefits of instant-type HPMC for faster dissolution and simpler processing in various production environments. ↩

-

Learn how hot-soluble HPMC can enhance hydration control and compatibility in continuous production settings. ↩