Struggling with construction material quality? HPMC (Hydroxypropyl Methylcellulose1) could be your solution. This versatile cellulose ether improves workability and performance across various building applications.

HPMC is a modified cellulose derivative that functions as a water-retaining agent, thickener, binder, film former, and protective colloid in construction materials. It significantly improves workability, water retention, adhesion, and overall stability in mortars, renders, tile adhesives2, and paints.

Let me take you through everything you need to know about this essential construction additive. After working with HPMC for over 15 years at our factory, I've seen firsthand how it transforms ordinary mixtures into high-performance building materials.

What is Hydroxypropyl Methylcellulose1 (HPMC)?

Are you confused about what exactly HPMC is and why it matters for your construction projects? Many builders struggle with this knowledge gap, leading to suboptimal material choices.

HPMC is a non-ionic cellulose ether produced by chemically modifying cellulose with methyl and hydroxypropyl groups. It comes as a white to off-white powder that dissolves in cold water to form a clear, viscous solution with excellent film-forming properties.

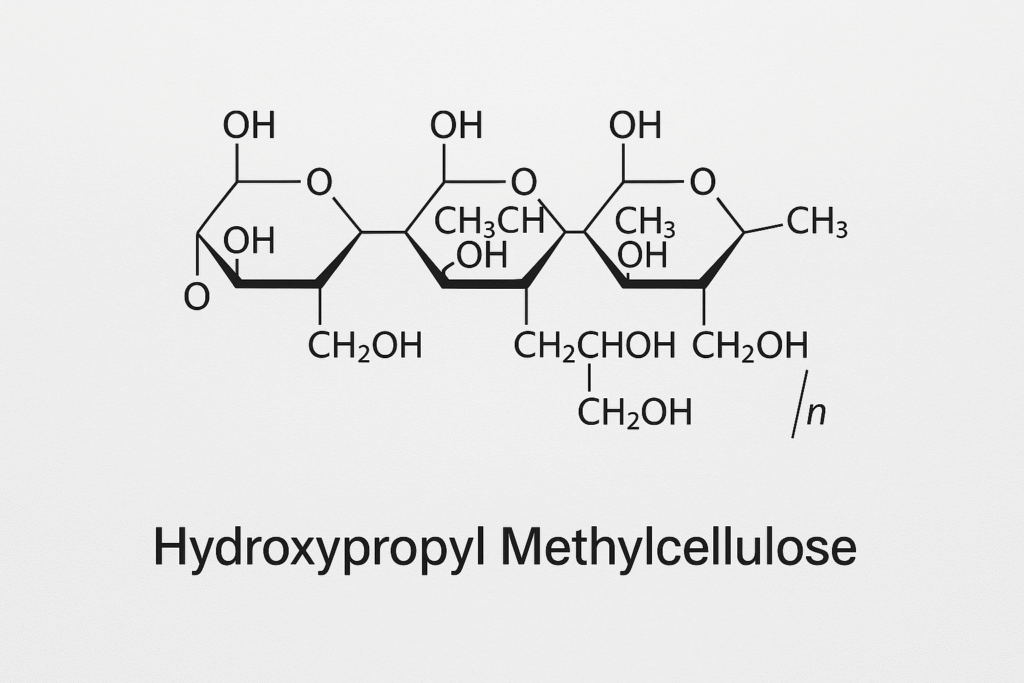

HPMC starts its life as natural cellulose, typically sourced from cotton or wood pulp. Through a series of chemical reactions, the cellulose undergoes alkalization with sodium hydroxide, followed by etherification with methyl chloride and propylene oxide. This transforms it into the versatile HPMC powder we use in construction applications.

The manufacturing process is quite complex and requires strict quality control. At our Kehao factory, we run six dedicated production lines to ensure consistent quality. The raw cellulose first undergoes an alkalization process where it reacts with sodium hydroxide in specialized reactors. This activates the cellulose structure, making it receptive to the etherification agents.

Next comes the critical etherification phase, where methyl chloride and propylene oxide are introduced under controlled temperature and pressure conditions. The degree of substitution - how many hydroxyl groups get replaced with methyl or hydroxypropyl groups - determines the final properties of the HPMC product. After reaction completion, the material undergoes washing, drying, and milling to create the fine powder that's ready for use.

The resulting HPMC has a unique molecular structure that gives it its valuable properties. The methyl groups provide water solubility, while the hydroxypropyl groups add thermal gelation capabilities and better water retention.

What Are the Key Applications of HPMC in Construction?

Do you know where HPMC can have the biggest impact in your building projects? Many manufacturers miss opportunities to improve their products by not understanding the full application range.

HPMC is widely used in dry-mix mortars3, tile adhesives2, self-leveling compounds4, exterior insulation systems, gypsum plasters5, and water-based paints. It improves workability, water retention, open time, slip resistance, and adhesion strength in these applications, resulting in better product performance and ease of application.

HPMC has transformed the construction industry through its versatility across multiple applications. In dry-mix mortars3, HPMC acts as a critical water-retention agent, preventing premature water loss that would otherwise compromise strength development. This is especially important in hot and dry climates like Saudi Arabia or the UAE, where one of our biggest customers, Mark, operates his building materials business.

For tile adhesives2, HPMC provides extended open time – the period when the adhesive remains workable after application. This gives installers more flexibility during tile placement, reducing waste and improving efficiency. The anti-sag properties are particularly valuable for vertical applications, preventing tiles from slipping during installation.

In exterior insulation finishing systems (EIFS), HPMC contributes significantly to the adhesiveness of the base coat, ensuring proper bonding between insulation boards and substrates. It also enhances the workability of the finish coat, allowing for smoother application and better aesthetic results.

Water-based paints benefit from HPMC's thickening and stabilizing effects. It provides proper rheology control, preventing dripping during application while maintaining good flow and leveling properties for a smooth finish. Additionally, it acts as a protective colloid, stabilizing the emulsion and preventing particle separation during storage.

In joint compounds and gypsum plasters5, HPMC improves adhesion to various substrates while enhancing water retention for proper curing. It also contributes to better sandability and reduced shrinkage, resulting in smoother finished surfaces.

What Are the Key Properties of HPMC That Make It Essential?

Why does HPMC perform so much better than alternatives? Many builders have tried cheaper substitutes only to find their materials failing prematurely or being difficult to work with.

The key properties of HPMC include excellent water retention, thermal gelation, thickening effects, binding capability, pH stability (7-9), and compatibility with cement systems. These properties directly improve workability, prevent material sagging, extend open time, enhance adhesion, and provide consistent performance across various temperature conditions.

HPMC's water retention capability stands out as perhaps its most valuable property in construction applications. When I visit our testing laboratory, I'm always impressed by the difference between mortars with and without our HPMC. The standard water retention test shows that quality HPMC can retain over 95% of mixing water, compared to just 40-50% in untreated mixtures.

This water retention translates directly to field performance. When mortar is applied to porous substrates like concrete blocks or bricks in hot weather, untreated mixtures dry out rapidly. The cement doesn't have enough time to hydrate properly, resulting in weak bonds and eventual failure. HPMC creates a protective film around water molecules, slowing evaporation and allowing proper cement hydration.

The viscosity of HPMC solutions follows a unique profile that benefits construction materials. At lower temperatures, HPMC dissolves to form a viscous solution that provides workability. As temperatures rise (typically above 60-80°C depending on the grade), HPMC undergoes thermal gelation, forming a stronger structure that prevents material sagging - crucial for overhead applications.

The molecular weight of HPMC directly correlates with its viscosity and performance characteristics. Our factory produces multiple grades ranging from low viscosity (15,000-30,000 mPa·s) to high viscosity (100,000+ mPa·s) to match specific application requirements. Lower viscosity grades work well in self-leveling compounds, while higher viscosity types excel in thick-bed mortars and renders.

HPMC's chemical stability in alkaline environments is another critical property. Construction materials frequently contain cement, lime, and other alkaline components with pH values of 12 or higher. Unlike some additives that degrade in these conditions, HPMC maintains its functionality, ensuring consistent performance throughout the product's working life.

Why Choose Kehao as Your HPMC Manufacturer?

Are you frustrated with inconsistent product quality from your current supplier? Many builders face production delays and customer complaints due to variable raw material performance.

Kehao offers premium HPMC manufactured on six dedicated production lines with strict quality control protocols. Our products feature customizable viscosity (15,000-200,000 mPa·s), particle sizes (80-150 mesh), and specialized constructions grades. We provide technical support, consistent supply chain reliability, and certification compliance for international markets.

At Kehao, we've invested heavily in quality control and consistency. Our manufacturing facility in China features state-of-the-art production equipment with real-time monitoring systems that track critical parameters throughout the production process. This attention to detail ensures that every batch meets our stringent specifications.

Our quality control begins with careful raw material selection. We source premium cellulose from sustainable suppliers and rigorously test all incoming materials. During production, our automated systems monitor reaction conditions, including temperature, pressure, and reaction time, to ensure optimal etherification. After production, each batch undergoes comprehensive testing for viscosity, substitution degree, moisture content, particle size, and application performance before release.

We understand that different applications require specific HPMC properties. That's why we offer customizable solutions based on your exact requirements. Our technical team can adjust viscosity ranges, substitution patterns, particle size distributions, and moisture content to optimize performance for your specific formulations. Whether you need HPMC for tile adhesives, renders, EIFS, or paints, we can provide a tailored solution.

Our commitment to sustainability also sets us apart. We've implemented water recycling systems that reduce our environmental footprint, and our energy-efficient manufacturing processes minimize carbon emissions. These initiatives help our customers meet their own sustainability goals and appeal to environmentally conscious end-users.

With six dedicated production lines and large warehousing capabilities, we ensure reliable supply even during peak demand seasons. Many of our customers, like Mark from Saudi Arabia, appreciate our ability to maintain consistent delivery schedules regardless of market fluctuations. Our strategic location and established logistics networks allow us to serve markets across Saudi Arabia, UAE, Iran, India, Pakistan, Brazil, Mexico, and beyond with competitive shipping times.

FAQ: Hydroxypropyl Methylcellulose1 (HPMC)

Do you have specific questions about using HPMC in your formulations? Many first-time users are unsure about proper dosage, mixing procedures, or compatibility issues.

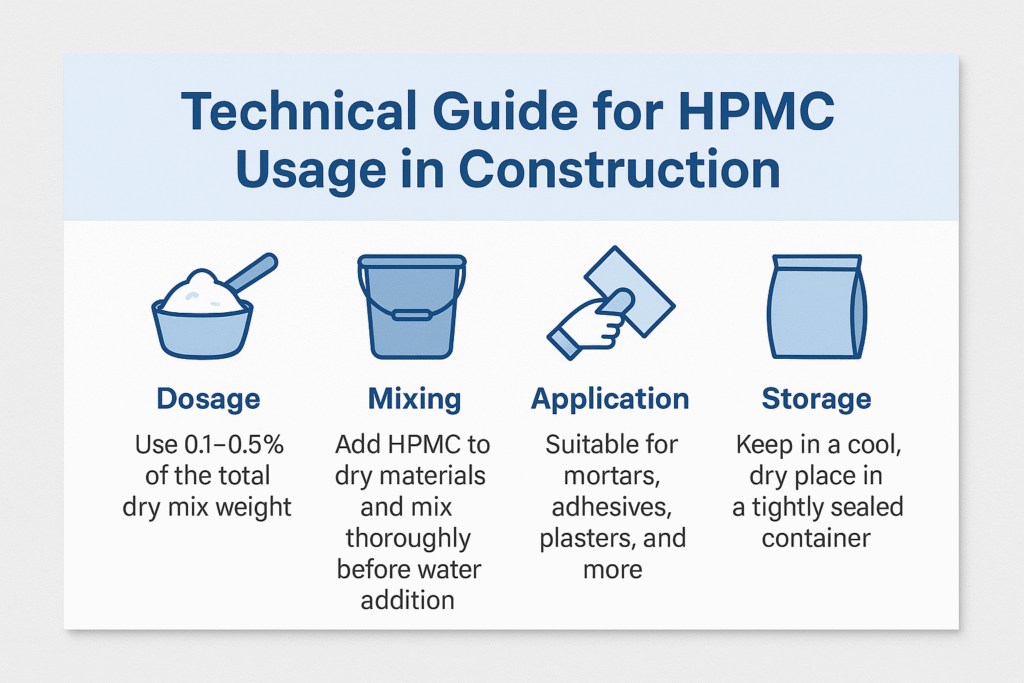

The optimal HPMC dosage typically ranges from 0.2-0.5% for most construction applications. It should be pre-mixed with dry components before adding water, requires cold water for dissolution, and remains stable for approximately 2 years when stored properly. HPMC is compatible with most construction materials but may require adjustments when used with highly charged polymers.

Proper HPMC incorporation is essential for optimal performance. I always advise our customers to follow specific mixing procedures based on their equipment and formulation type. For dry-mix mortars, the "dry blend" method works best - HPMC should be thoroughly mixed with cement and aggregates before water addition. This prevents the formation of lumps that can occur when HPMC contacts water directly.

Storage stability often raises questions among our customers. HPMC powder itself has excellent shelf life when stored properly - typically 24 months in cool, dry conditions. Once mixed into a formulation, stability depends on the specific application. Dry-mix products containing HPMC maintain properties for at least 12 months when properly packaged, while ready-mixed products generally have shorter shelf lives of 3-6 months due to the presence of water.

Temperature sensitivity is another common concern. HPMC performs optimally within specific temperature ranges that vary by grade. Standard construction grades work best between 5-35°C (41-95°F). At temperatures approaching 0°C, dissolution slows significantly, while extremely high temperatures accelerate the thermal gelation process. For projects in extreme climates, we offer specialized grades with adjusted gelation temperatures.

Dosage optimization requires consideration of multiple factors. While the general range is 0.2-0.5% of the dry mix weight, specific applications may require adjustments. Tile adhesives typically need higher dosages (0.3-0.5%) to achieve extended open time, while renders may use slightly lower amounts (0.2-0.3%). Water conditions, particularly hardness and pH, can also influence optimal dosage. Our technical team provides dosage recommendations based on formulation analysis and application requirements.

Compatibility with other additives is crucial for formulation success. HPMC works synergistically with most construction additives, including redispersible polymer powders, which enhance flexibility and adhesion. However, interactions with highly charged polymers or certain superplasticizers may require dosage adjustments. We recommend laboratory testing when combining HPMC with new additives to ensure optimal performance.

Conclusion

HPMC transforms ordinary construction materials into high-performance products by improving water retention, workability, adhesion, and stability. With Kehao's premium HPMC and technical support, you can overcome common construction challenges and deliver superior results to your customers.

-

Explore this link to understand the significance of HPMC in enhancing construction material performance. ↩ ↩ ↩

-

Learn about tile adhesives and their critical role in ensuring strong and durable tile installations. ↩ ↩ ↩

-

Explore the benefits of using dry-mix mortars in construction for improved efficiency and performance. ↩ ↩

-

Discover how self-leveling compounds simplify flooring projects and enhance surface quality. ↩

-

Explore the versatility of gypsum plasters in creating smooth and durable surfaces. ↩ ↩