Are you struggling with inconsistent mortar quality1 and excessive waste at your construction sites? Traditional wet-mixed mortars often lead to unpredictable results, wasted materials, and project delays that eat into your profits.

Dry mix mortar2 is a pre-mixed combination of sand, cement, and additives that requires only water addition before application. It provides consistent quality, reduced waste, extended shelf life, and improved workability compared to traditional site-mixed mortars while significantly cutting labor costs and construction time.

https://placehold.co/600x400 "Bags of dry mix mortar at a construction project")

https://placehold.co/600x400 "Bags of dry mix mortar at a construction project")

I remember visiting a large housing development in Dubai where the contractor switched from traditional mortar mixing to our dry mix products mid-project. The difference was clear immediately - more uniform application, faster completion times, and noticeably better finish quality. This transformation isn't unique - it's happening across the global construction industry.

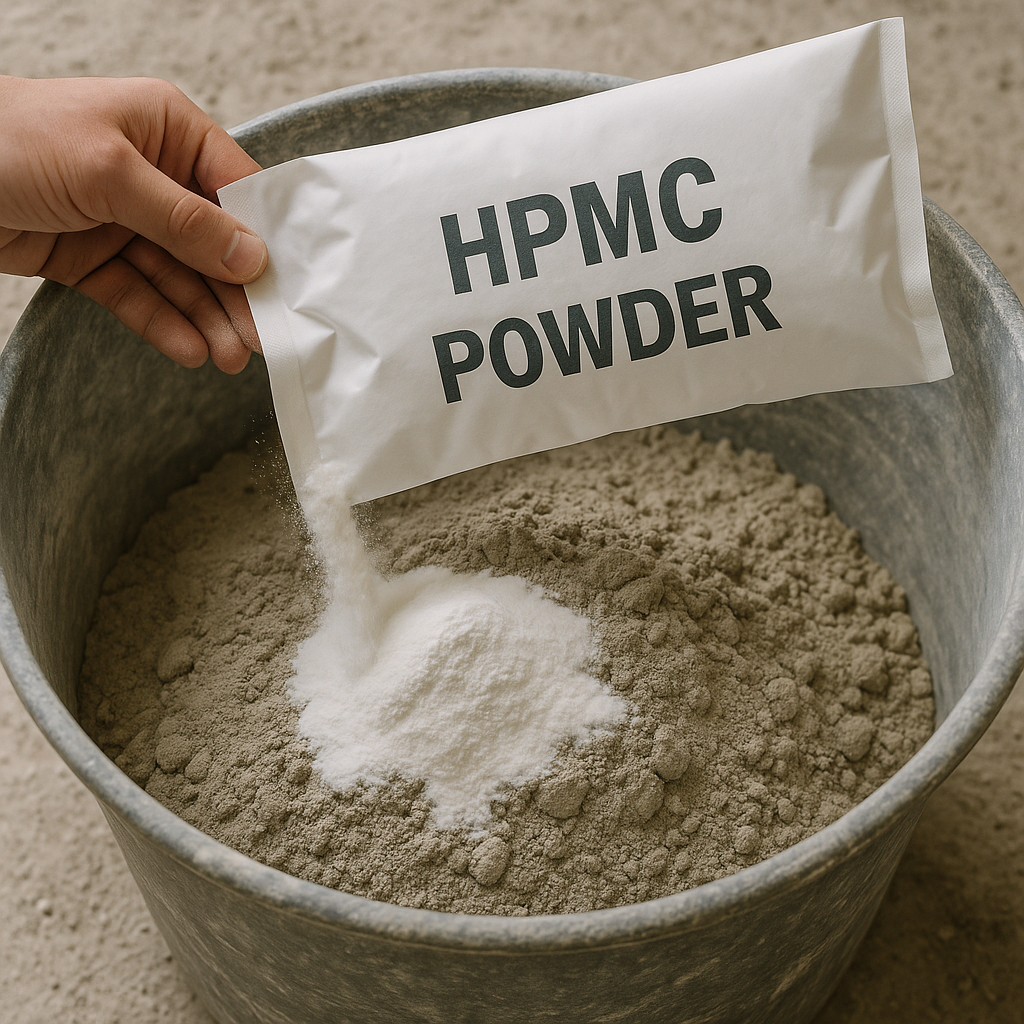

How Does HPMC3 Transform Dry Mix Mortar Performance?

Construction projects often face mortar that dries too quickly, sags during application, or lacks proper adhesion to surfaces. These issues cause rework, material waste, and unhappy clients who notice the poor finish quality.

Hydroxypropyl methylcellulose (HPMC) is a cellulose-based additive that enhances mortar workability, water retention, and adhesion. When added to dry mix mortar, HPMC improves open time, prevents premature drying, increases bond strength, and ensures consistent application even in challenging conditions.

The science behind HPMC's effectiveness lies in its molecular structure and interaction with other mortar components. HPMC creates a gel-like network within the mortar that traps water molecules, releasing them slowly during the cement hydration process. This controlled water release is crucial for proper cement curing and strength development.

Key Benefits of HPMC3 in Dry Mix Mortar

HPMC comes in various viscosities and substitution levels, each offering specific performance characteristics for different applications. The table below highlights common HPMC grades and their primary uses in construction:

| HPMC Grade | Viscosity | Primary Applications | Key Benefits |

|---|---|---|---|

| HPMC K4M | Low (4,000 mPa·s) | Self-leveling compounds | Improves flow without segregation |

| HPMC K15M | Medium (15,000 mPa·s) | Tile adhesives, renders | Enhanced adhesion, good workability |

| HPMC K100M | High (100,000 mPa·s) | Thick-bed mortars, EIFS | Excellent water retention, sag resistance |

When I visited a tile adhesive factory in Pakistan last year, they were struggling with product consistency in their hot climate. By recommending the correct HPMC grade and dosage, we helped them extend their mortar open time by nearly 45 minutes - a game-changer for their installers working in high temperatures.

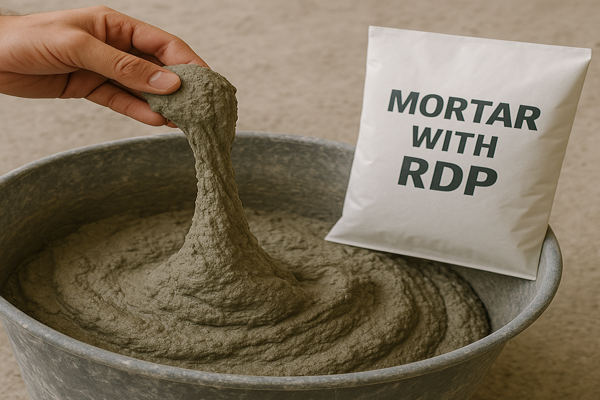

Why Is Redispersible Polymer Powder Essential for Modern Dry Mix Mortars?

Traditional cement-based mortars often crack, have poor flexibility, and fail to bond properly to smooth surfaces like concrete or drywall. These limitations restrict their use in modern construction systems and lead to premature failures.

Redispersible polymer powder4 (RDP) is a spray-dried polymer that reactivates when water is added to dry mix mortar. It significantly enhances mortar flexibility, adhesion to difficult substrates, and impact resistance while reducing cracking. RDP is essential for specialty mortars like tile adhesives, EIFS, and repair compounds.

RDP works through a fascinating process called polymer film formation. When water activates the mortar, the polymer particles disperse throughout the mixture. As the mortar dries, these particles form continuous polymer films that interlock with the cement matrix, creating a composite material with properties superior to traditional mortars.

Different RDP Types for Various Applications

The choice of redispersible polymer powder significantly impacts the final mortar performance. There are several polymer bases used in RDP production, each with specific performance characteristics:

| RDP Base | Primary Properties | Best Applications | Performance Considerations |

|---|---|---|---|

| VAE (Vinyl Acetate-Ethylene) | Good adhesion, moderate flexibility, cost-effective | General-purpose tile adhesives5, renders | Balanced cost/performance ratio |

| VA/VeoVa | Excellent water resistance, UV stability | Exterior renders, waterproofing mortars | Higher cost but superior durability |

| Acrylic | Outstanding flexibility, adhesion to difficult substrates | High-performance tile adhesives, repair mortars | Premium pricing, specific applications |

I once conducted testing with a major mortar manufacturer in Brazil comparing different RDP types in their exterior render formulation. The VA/VeoVa-based product showed 65% better water resistance after accelerated weathering tests, completely justifying its higher cost for their coastal applications.

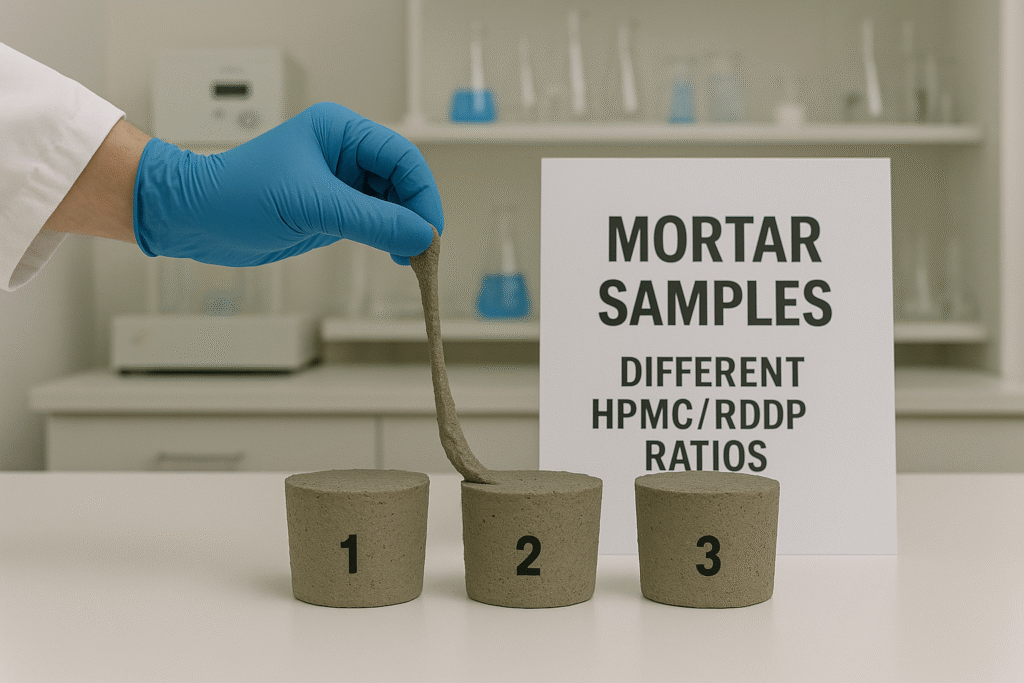

How Do HPMC3 and RDP Work Together in Dry Mix Mortars?

When used separately, HPMC and RDP each improve specific mortar properties. But many formulators miss the critical synergistic effects when these additives are not properly balanced, resulting in poor workability, reduced bond strength, or excessive cost.

HPMC and RDP work synergistically in dry mix mortars - HPMC provides the necessary water retention and workability during application, while RDP enhances the final cured properties. The optimal balance between these additives depends on the specific application, climate conditions, and performance requirements.

Finding the perfect balance between HPMC and RDP requires understanding both the chemical interactions and the practical application requirements. For instance, certain HPMC grades can delay the polymer film formation of some RDP types, affecting final strength development. Additionally, the cement chemistry and aggregate quality play important roles in determining the optimal additive levels.

Optimizing HPMC and RDP Levels for Different Applications

Based on our extensive laboratory testing and field experience, we've developed recommendations for HPMC and RDP dosage levels in different mortar applications:

| Application | Typical HPMC Dosage | Typical RDP Dosage | Critical Properties |

|---|---|---|---|

| Tile Adhesive (Standard) | 0.25-0.30% | 1.5-2.5% | Open time, slip resistance |

| Tile Adhesive (Flexible) | 0.20-0.25% | 3.0-5.0% | Deformability, bond strength |

| EIFS Base Coat | 0.25-0.35% | 2.5-4.0% | Impact resistance, crack resistance |

| Self-Leveling Compound | 0.05-0.15% | 1.0-2.0% | Flow properties, surface finish |

| Repair Mortar | 0.30-0.40% | 3.0-6.0% | Shrinkage control, adhesion |

When I worked with a large mortar producer in the UAE, they were using excessive HPMC levels trying to achieve better water retention. By reducing the HPMC slightly and adjusting their RDP type and dosage, we not only improved performance but also reduced their formula cost by nearly 8% - proving that optimal formulation isn't just about adding more additives.

Conclusion

By incorporating the right balance of HPMC and RDP in dry mix mortar formulations6, manufacturers can create superior products with excellent workability, adhesion, and durability while controlling costs and ensuring reliable performance across varying environmental conditions.

-

Find strategies to maintain high mortar quality, reducing waste and project delays. ↩

-

Explore the advantages of dry mix mortar, including consistency and reduced waste, to enhance your construction projects. ↩

-

Learn how HPMC enhances workability and adhesion in dry mix mortars, crucial for achieving high-quality results. ↩ ↩ ↩

-

Discover the role of RDP in improving mortar flexibility and adhesion, essential for modern construction applications. ↩

-

Learn best practices for tile adhesives to ensure strong and lasting installations. ↩

-

Learn how to optimize mortar formulations for enhanced performance and cost-effectiveness. ↩