Many construction professionals face challenges with traditional plastering methods - time-consuming application, inconsistent results, and labor shortages. Machine spray gypsum plaster1 offers a promising solution to these common industry pain points.

Machine spray gypsum plaster1 is a specialized plaster formulation designed for mechanical application that provides faster installation, superior finish quality, and reduced labor requirements compared to traditional methods. It contains gypsum binder, lightweight aggregates, and chemical additives2 for workability and adhesion.

I've been in the construction materials industry for over 15 years, and I've witnessed firsthand how machine spray gypsum plaster has revolutionized interior finishing. The technology has advanced significantly in recent years, making it increasingly popular among contractors seeking efficiency and quality. Let's explore why this solution might be right for your projects.

Gypsum Plaster vs Cement Mortar: Performance Comparison?

Contractors often struggle with choosing the right plastering material, balancing cost against performance. Making the wrong choice can lead to project delays, additional expenses, and dissatisfied clients.

Gypsum plaster outperforms cement mortar in several key aspects including faster setting time (2-3 hours vs 24+ hours), better thermal insulation (λ=0.18 W/mK vs λ=0.93 W/mK), and significantly lighter weight (800-1200 kg/m³ vs 1800-2000 kg/m³), making it ideal for interior applications.

I recently consulted on a large hotel renovation project where the timeline was critical. By switching from traditional cement mortar to machine spray gypsum plaster, the contractor reduced the plastering schedule by nearly 40%. This wasn't just about the faster application - the quicker drying time meant subsequent trades could start their work earlier.

Material Properties

| Property | Gypsum Plaster | Cement Mortar |

|---|---|---|

| Density | 800-1200 kg/m³ | 1800-2000 kg/m³ |

| Setting Time | 2-3 hours | 24+ hours |

| Thermal Conductivity | 0.18 W/mK | 0.93 W/mK |

| Shrinkage | Minimal (0.1-0.2%) | Moderate (0.2-0.5%) |

| pH Value | Neutral (7-8) | Alkaline (12-13) |

Application Efficiency

The efficiency gains with machine spray application are substantial. A skilled operator with proper equipment can apply gypsum plaster at rates of 80-100 m² per hour, compared to 15-25 m² for manual application of cement mortar. This efficiency translates directly to labor cost savings, which can be significant on large projects. Additionally, the reduced material waste (typically 5-8% for spray application versus 10-15% for manual methods) further enhances the economic benefits.

Technical Characteristics Comparison?

Project managers often wrestle with technical specifications without understanding their real-world implications. Choosing materials without proper technical evaluation can result in performance issues down the line.

Machine spray gypsum plaster1 offers superior technical characteristics including better fire resistance (Class A, non-combustible), higher sound insulation (up to 3-5 dB improvement), and excellent crack resistance due to its flexibility (elastic modulus of 2000-2500 N/mm² versus 8000-12000 N/mm² for cement).

During my time overseeing production at our factory, we've continuously refined our gypsum formulations based on customer feedback and field performance. The technical improvements we've made have directly addressed the challenges faced by applicators in various climatic conditions.

Performance Metrics

| Characteristic | Machine Spray Gypsum | Traditional Cement Plaster |

|---|---|---|

| Compressive Strength | 2.5-5.5 N/mm² | 6-10 N/mm² |

| Flexural Strength | 1.0-2.5 N/mm² | 1.5-3.0 N/mm² |

| Bond Strength | 0.3-0.5 N/mm² | 0.2-0.4 N/mm² |

| Surface Hardness | Shore C 60-80 | Shore C 80-90 |

| Water Absorption | Moderate (20-30%) | Low (10-15%) |

Environmental Impact

The environmental footprint of construction materials is becoming increasingly important for green building certification. Gypsum plaster has approximately 80% lower carbon emissions during production compared to Portland cement. The manufacturing process requires temperatures of around 150-180°C for gypsum versus 1400-1450°C for cement, resulting in significant energy savings. Many of our clients in Saudi Arabia and UAE have shifted to gypsum-based products specifically to meet green building requirements.

Key Features of Machine Spray Gypsum Plaster?

Builders face mounting pressure to deliver projects faster while maintaining quality standards. Traditional plastering methods often create a bottleneck in construction schedules and require skilled labor that's increasingly hard to find.

Machine spray gypsum plaster1 features specialized additives for extended workability (1-2 hours), self-leveling properties3, excellent pumpability through hoses up to 30m, and consistent mix quality. These properties enable single-coat application at thicknesses of 10-25mm with minimal supervision.

I visited a construction site in Dubai last month where the contractor was applying our machine spray gypsum on a 40-story residential tower. The efficiency was remarkable - each floor was completed in about two days, compared to the 5-7 days they previously needed with traditional methods.

Key Performance Indicators

The success of machine spray gypsum plaster depends largely on its formulation. High-quality products contain precisely balanced components:

| Component | Function | Typical Percentage |

|---|---|---|

| Calcium Sulfate Hemihydrate | Main binding agent | 50-70% |

| Lightweight Fillers | Weight reduction, workability | 15-25% |

| Polymer Additives | Adhesion, flexibility | 0.5-2% |

| Retarders | Setting time control | 0.1-0.3% |

| Air-entraining Agents | Workability enhancement | 0.01-0.05% |

| Water Retention Agents | Prevent premature drying | 0.1-0.3% |

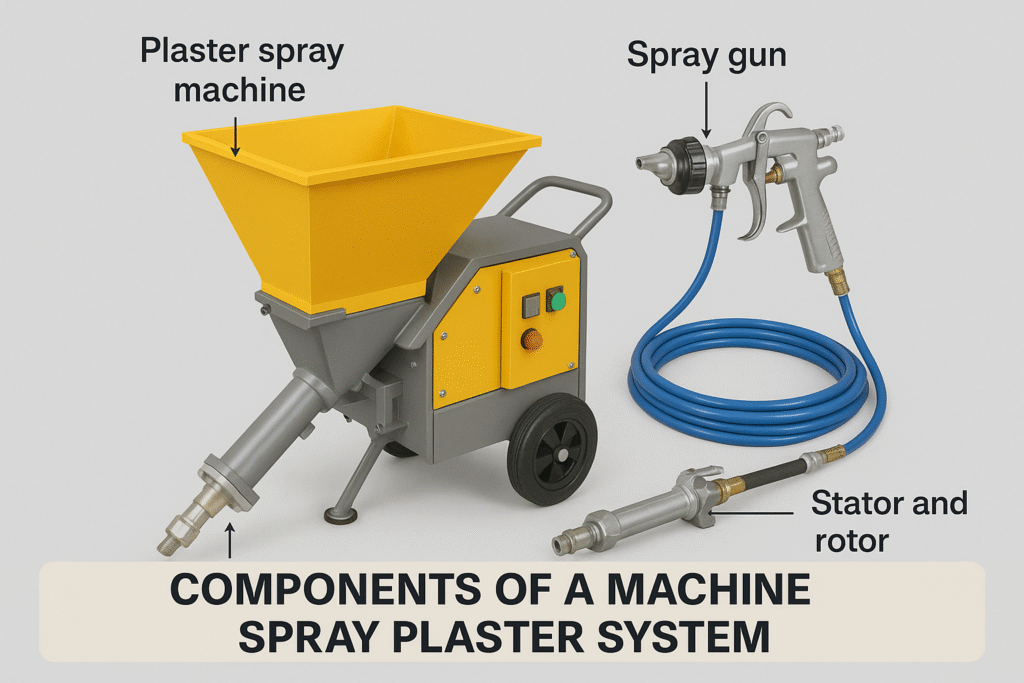

Equipment Considerations

The machine spray system is a crucial component of successful application. Modern plastering machines can mix and pump material at rates of 15-40 liters per minute, allowing rapid coverage of large wall areas. The investment in quality equipment pays dividends through increased productivity - I've seen contractors recoup their equipment costs in as little as 3-4 large projects due to labor savings. Regular maintenance of spray nozzles, pumps, and mixing chambers is essential for consistent performance and longevity of the equipment.

Application Considerations?

Many first-time users of machine spray plaster face unexpected challenges that delay projects and increase costs. Improper substrate preparation or application techniques can lead to adhesion failures and costly rework.

Successful machine spray gypsum plaster application requires proper substrate treatment (primer application for high-absorption surfaces), consistent water-to-plaster ratio (typically 0.5-0.6), appropriate ambient conditions (5-35°C), and specific curing protocols to prevent premature drying.

Last year, I worked with a contractor in Pakistan who was having adhesion issues with machine spray plaster. After visiting the site, I discovered they weren't properly treating the concrete substrate, which was highly absorbent. A simple primer application solved the problem completely.

Substrate Requirements

The quality of the substrate significantly impacts the performance of any plaster system. For machine spray gypsum plaster, the following considerations are critical:

| Substrate Type | Preparation Requirement | Recommended Primer |

|---|---|---|

| Concrete (smooth) | Roughening, removal of form-release agents | Bonding agent with quartz sand |

| Concrete (rough) | Cleaning, dust removal | Standard primer diluted 1:1 |

| AAC/Lightweight blocks | Dust removal, pre-wetting in hot conditions | Deep-penetrating primer |

| Brick/Ceramic | Surface cleaning, joint treatment | Special adhesion primer |

| Painted surfaces | Complete removal of paint | Heavy-duty bonding agent |

Climate Considerations

Application environment significantly affects gypsum plaster performance. In Gulf countries like Saudi Arabia and UAE, high temperatures accelerate setting time, requiring special formulations with extended workability. Conversely, in humid regions like Vietnam or Philippines, drying time may be prolonged, necessitating adequate ventilation. I've developed custom formulations for these varying conditions, including specialized retarders for hot climates that maintain workability for up to 3 hours without affecting final strength development.

Recommended Additives for Enhanced Performance?

Construction professionals often struggle with special conditions like high humidity, rapid temperature changes, or challenging substrates. Standard plaster formulations may fail under these conditions, causing project delays and reputation damage.

Key performance-enhancing additives include hydroxypropyl methylcellulose (HPMC) for water retention and workability, redispersible polymer powder for adhesion (0.5-2%), cellulose ethers for sag resistance (0.1-0.3%), and setting retarders for extended working time (0.05-0.2%).

In our production facility, we've conducted extensive testing on additive combinations. One breakthrough came when we developed a specialized HPMC formulation that increased water retention by 40% while maintaining excellent workability, solving a chronic problem for customers in hot, dry regions.

Critical Additives and Their Functions

The science behind high-performance plaster formulations lies in the precise selection and dosage of key additives:

| Additive Type | Function | Dosage Range | Effect on Performance |

|---|---|---|---|

| HPMC (Hydroxypropyl Methylcellulose) | Water retention, workability | 0.1-0.3% | Extends working time by 30-100% |

| Redispersible Polymer Powder | Adhesion, flexibility | 0.5-2.0% | Increases bond strength by 40-80% |

| Air Entrainers | Workability, pumpability | 0.01-0.05% | Reduces density by 10-15% |

| Accelerators (if needed) | Setting time control | 0.05-0.2% | Reduces setting time by 30-60% |

| Retarders (if needed) | Setting time control | 0.05-0.2% | Extends setting time by 30-100% |

Customizing for Project Requirements

Different projects demand different performance characteristics from spray gypsum plaster. For high-rise buildings with significant structural movement, increased flexibility is crucial - achieved by increasing redispersible polymer powder content to 1.5-2.0%. For hospital or school projects requiring enhanced durability, surface hardeners and water-resistant additives can be incorporated. Our technical team regularly consults with large mortar factories in developing countries to create custom formulations4 addressing specific regional requirements and local raw material characteristics.

Conclusion

Machine spray gypsum plaster offers significant advantages over traditional methods, including faster application, better technical performance, and reduced labor requirements. With proper substrate preparation, appropriate additives, and correct application techniques, it delivers superior results for modern construction projects.

-

Discover how machine spray gypsum plaster can enhance efficiency and quality in your construction projects. ↩ ↩ ↩ ↩

-

Explore the role of chemical additives in achieving optimal plaster characteristics. ↩

-

Discover how self-leveling properties can simplify the plastering process. ↩

-

Learn about the process of creating tailored gypsum plaster formulations for specific projects. ↩