Choosing the wrong tile adhesive1 can lead to costly failures, with tiles cracking or falling off walls. Many contractors face this problem daily, wasting time and money on repairs that could have been avoided.

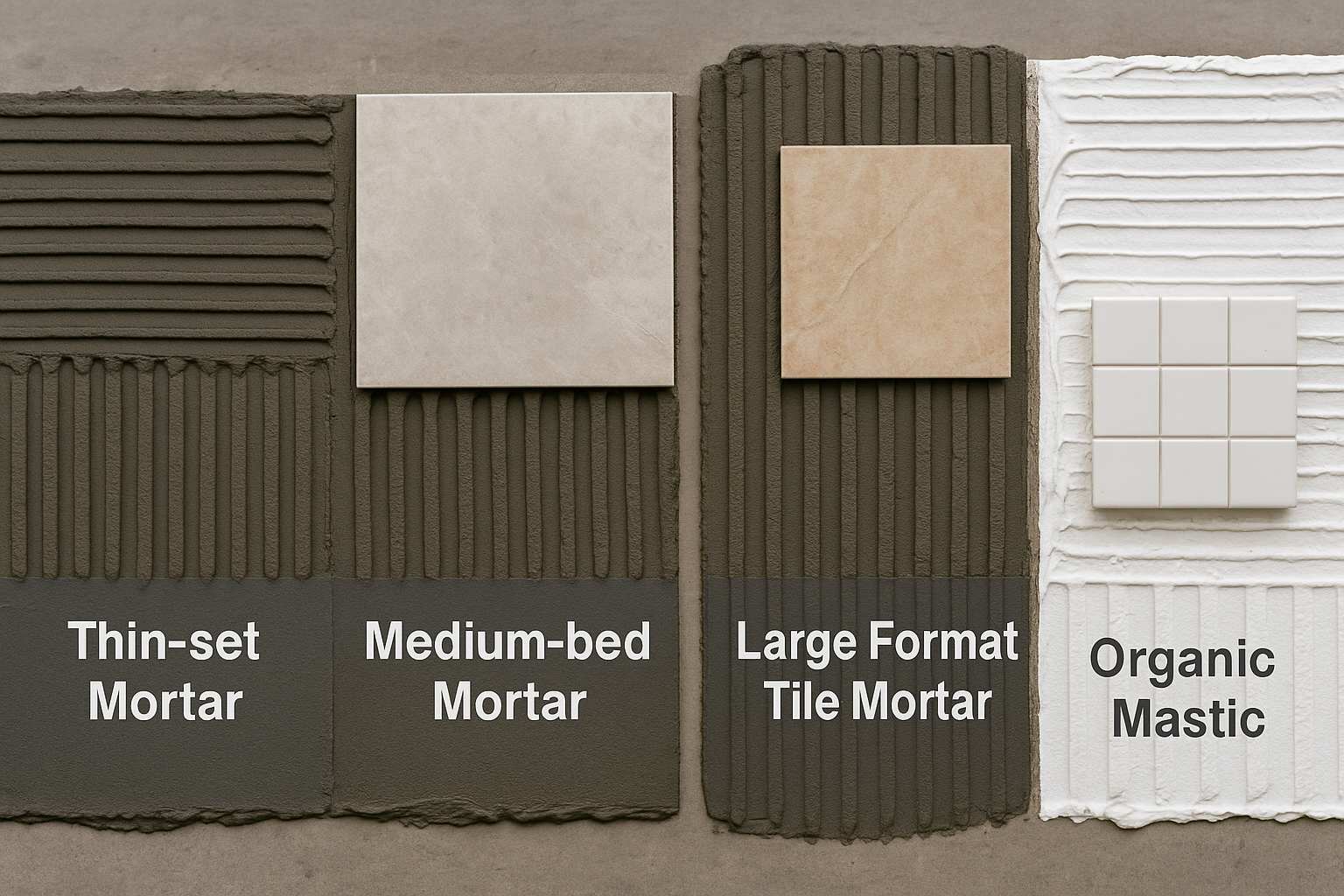

Tile adhesives are specialized bonding agents designed to securely attach tiles to surfaces. The main types include organic mastics, thin-set mortars, dry-set mortars, latex-modified mortars, and medium-bed mortars, each suited for specific applications based on tile size, location, and moisture exposure.

I've been in the construction materials2 industry for over 15 years, and I've seen countless projects fail because contractors didn't understand which adhesive to use. Let me walk you through the different types of tile adhesives and help you make the right choice for your next project.

What Are the Main Types of Tile Adhesives Available Today?

Poor adhesive selection often results in tiles detaching from walls or floors. This not only damages reputation but creates significant safety hazards for building occupants.

The five main types of tile adhesives are organic mastics, thin-set mortars, dry-set mortars, latex-modified mortars, and medium-bed mortars. Each type has specific applications based on moisture exposure, tile size, and installation location.

Selecting the appropriate tile adhesive1 involves understanding the specific requirements of your project. In my experience working with clients across Saudi Arabia, UAE, and other markets, I've found that different environments demand different solutions. Let's examine each type in detail.

What Makes Organic Mastics Suitable for Certain Applications?

Many DIYers choose organic mastics because they're convenient and easy to use. However, using them in wet areas can lead to mold growth and tile failure within months.

Organic mastics are premixed adhesives made from organic resins suitable for dry indoor wall applications with smaller tiles. They should never be used in showers, bathrooms, or other wet areas as they remain water-soluble after drying.

Organic mastics offer several advantages for certain applications, but they have important limitations. These adhesives come ready to use straight from the container, making them popular for quick installations and repairs. However, their water sensitivity makes them unsuitable for moisture-prone areas.

When working with organic mastics, I always advise my clients to consider both the immediate and long-term environment where tiles will be installed. For example, kitchen backsplashes in dry areas work well with mastics, but a backsplash behind a sink might fail prematurely due to occasional water exposure.

Application Areas for Organic Mastics

| Suitable For | Not Suitable For |

|---|---|

| Kitchen backsplashes (dry areas) | Bathroom walls |

| Interior dry wall areas | Shower enclosures |

| Small format tiles (under 8×8 inches) | Floors with heavy traffic |

| Light-colored tiles | Exterior applications |

During my visit to a client's factory in Iran last year, I noticed they were planning to use organic mastics for their bathroom tile installation. I immediately advised them to switch to a cement-based adhesive, potentially saving them from a costly reinstallation just months later.

Why Is Thin-Set Mortar Considered the Most Versatile Tile Adhesive?

Many contractors apply thin-set mortar incorrectly, creating voids under tiles that lead to cracks and failure. This common mistake costs thousands in repairs and replacement.

Thin-set mortar, a cement-based adhesive mixed with water, is the most widely used tile adhesive due to its versatility, strength, and suitability for most indoor and outdoor applications, including wet areas and floor installations.

Thin-set mortar stands as the industry standard for good reason. Its cement base provides excellent adhesion and durability across various conditions. I've recommended this option to countless clients facing challenging installation environments, from outdoor patios in Saudi Arabia's extreme heat to commercial kitchen floors in busy UAE restaurants.

The key to successful thin-set installation lies in proper mixing and application. The mortar should have a peanut butter-like consistency - not too runny or too stiff. When applied correctly with a notched trowel, it creates ridges that collapse under tile pressure, forming a strong, void-free bond.

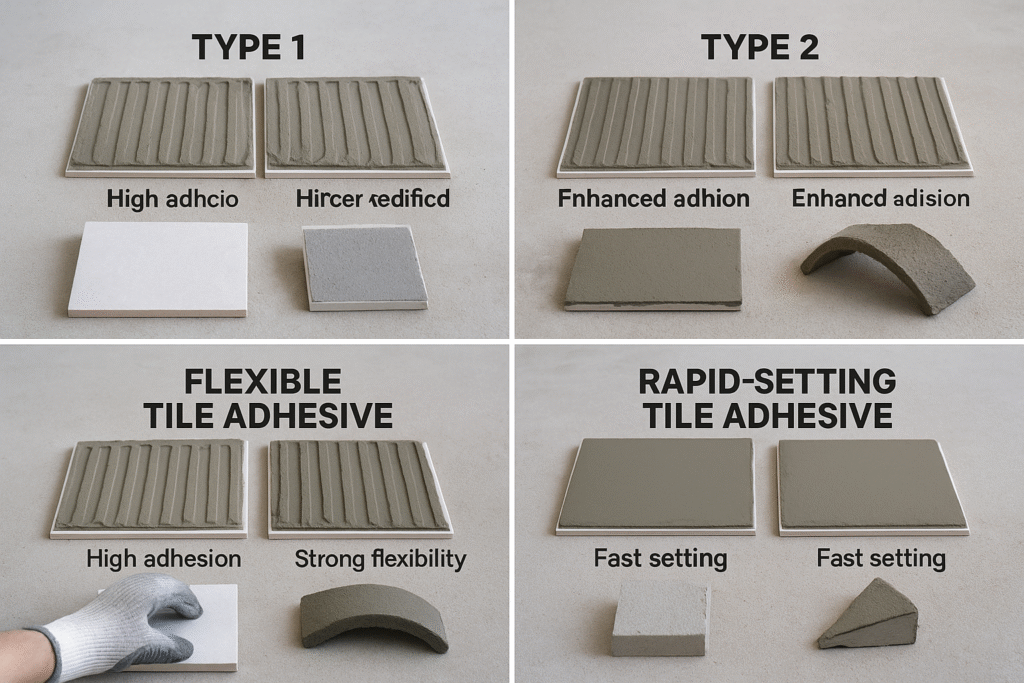

Types of Thin-Set Mortars

| Type | Best For | Special Considerations |

|---|---|---|

| Standard Thin-Set | General purpose installations | Requires 24+ hours curing time |

| Rapid-Setting | Projects needing quick completion | Higher cost, less working time |

| High-Flexibility | Areas with movement or vibration | Enhanced with polymers for flexibility |

| Large Format Tile | Tiles larger than 12×12 inches | May need medium-bed formulation |

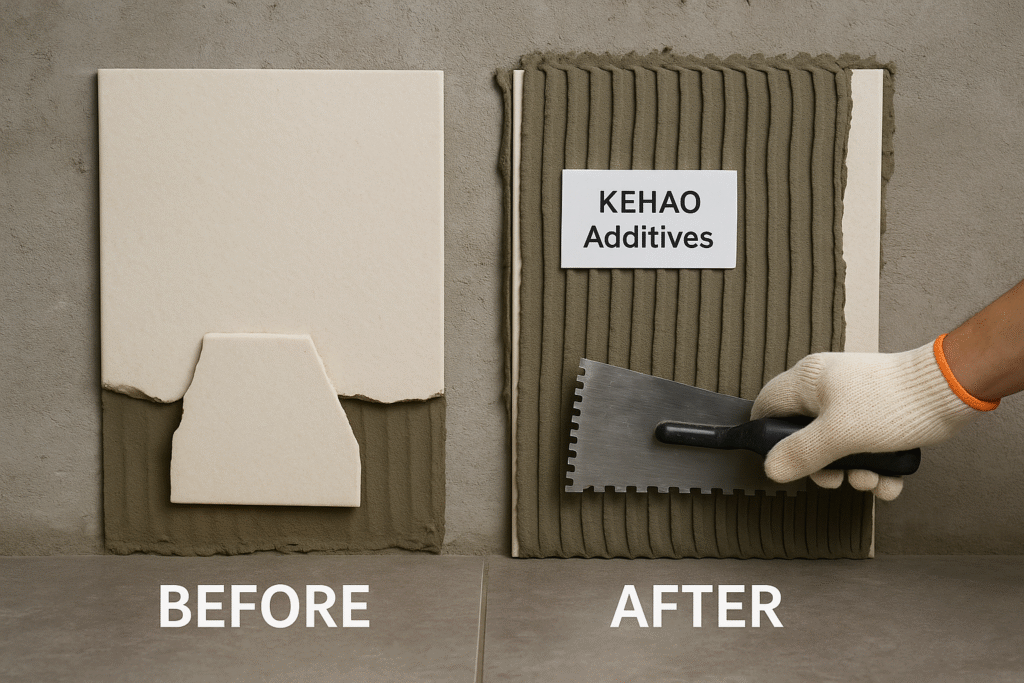

I recently consulted on a large hotel project in Pakistan where thin-set mortar with KEHAO additives3 was used throughout all bathroom installations. The enhanced workability and bond strength resulted in zero tile failures during the critical inspection phase, saving both time and reputation.

How Does Water-Mixed or Dry-Set Mortar Differ from Other Adhesives?

Using standard dry-set mortar for exterior installations can lead to freeze-thaw damage. I've seen entire building façades fail because contractors didn't use the right mortar for outdoor conditions.

Water-mixed or dry-set mortar is a basic cement-based adhesive that forms a rigid bond when mixed with water. It's suitable for standard tile installations in areas without extreme conditions but lacks the flexibility and bonding strength of modified mortars.

Dry-set mortar represents the traditional foundation of tile installation materials. This straightforward combination of Portland cement, sand, and water-retentive additives creates a workable adhesive suitable for many basic applications. However, its limitations become apparent in challenging environments.

When working with dry-set mortars, proper substrate preparation becomes even more critical. Unlike modified mortars that offer some forgiveness on slightly imperfect surfaces, dry-set demands nearly perfect substrates. Additionally, these mortars require careful water addition - too much water weakens the bond, while too little creates poor adhesion.

Comparing Dry-Set Performance

| Factor | Performance | Notes |

|---|---|---|

| Cost | Lower | Most economical option |

| Flexibility | Low | Prone to cracking with substrate movement |

| Water Resistance | Moderate | Not ideal for constant moisture exposure |

| Bond Strength | Moderate | May require mechanical anchoring for certain applications |

| Working Time | Moderate | Typically 15-20 minutes open time |

During my visit to a construction site in Georgia last month, I noticed workers using basic dry-set mortar for an exterior wall installation. Given the region's temperature fluctuations, I recommended upgrading to a latex-modified mortar to prevent future tile failures due to thermal expansion and contraction.

What Advantages Do Latex and Acrylic Mortars Provide?

Standard mortars often fail in freeze-thaw conditions or areas with vibration. Modified mortars solve this problem but require proper mixing to achieve their full performance potential.

Latex and acrylic mortars are cement-based adhesives enhanced with polymers to improve flexibility, adhesion strength, and water resistance. These modifications make them ideal for challenging installations including exterior applications, wet areas, and high-traffic floors.

Latex and acrylic-modified mortars represent a significant advancement in tile installation4 technology. These products combine the reliable strength of cement with the enhanced properties of polymers to create superior adhesives. In my work with major construction projects across developing markets, I've consistently recommended these modified mortars for installations where failure simply isn't an option.

The polymer modification provides several critical advantages: increased flexibility to accommodate substrate movement, improved adhesion to difficult surfaces, and enhanced water resistance. These properties make latex and acrylic mortars the preferred choice for exterior installations, wet areas, and areas subject to thermal cycling.

Modified mortars come in two forms: pre-mixed dry powders with polymer additives already incorporated, or traditional mortars that are mixed with a liquid latex additive instead of water. The liquid latex option often provides superior performance but requires more precise mixing on the jobsite.

Modified Mortar Performance Factors

| Feature | Benefit | Application Example |

|---|---|---|

| Enhanced flexibility | Resists cracking during substrate movement | Installations over wood subfloors |

| Improved adhesion | Bonds to difficult substrates | Glass tile or porcelain installations |

| Water resistance | Prevents moisture damage | Swimming pools, fountains |

| Freeze-thaw durability | Withstands temperature cycling | Exterior installations in variable climates |

| Extended open time | Allows for larger working areas | Large format tile installation4s |

When consulting with a major hotel development in Dubai, I recommended KEHAO HPMC additives in their latex-modified mortars5 for all wet areas. The improved workability allowed installers to achieve nearly perfect coverage, while the enhanced water resistance provided long-term protection against moisture penetration.

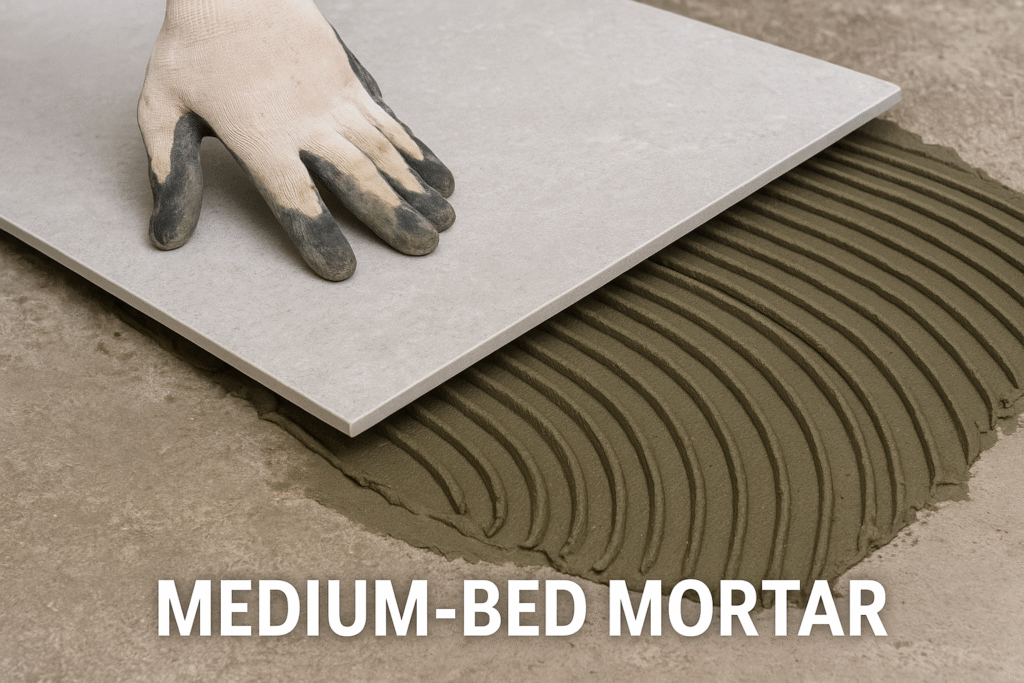

When Should You Use Medium-Bed Mortar Instead of Thin-Set?

Large format tiles often fail when installed with standard thin-set due to inadequate support. Medium-bed mortars prevent lippage and hollow sounds that plague many large tile installations.

Medium-bed mortar is specially formulated for installing large or heavy tiles, natural stone, and irregular-thickness materials. It can be applied in thicker layers (up to 3/4 inch) compared to thin-set, providing better support and preventing lippage.

Medium-bed mortars address a specific challenge in modern tile installation: the growing popularity of large format tiles. These specialized mortars can be built up to accommodate variations in tile thickness or substrate irregularities while maintaining proper bond strength. In my work consulting for luxury developments in the UAE and Saudi Arabia, I've seen medium-bed mortars solve numerous installation challenges.

Unlike traditional thin-set applied at 3/16-inch thickness, medium-bed mortars can be built up to 3/4 inch, providing crucial support for heavy materials like natural stone or large porcelain slabs. This prevents two common problems: lippage (uneven tile edges) and hollow sounds that indicate voids beneath the tile.

Another advantage of medium-bed mortars is their resistance to shrinkage during curing. When installing large format tiles (anything larger than 12×12 inches), this property becomes essential for maintaining a level surface across the installation.

Medium-Bed Applications

| Material Type | Benefits of Medium-Bed | Installation Notes |

|---|---|---|

| Large format porcelain | Prevents lippage between tiles | Requires proper trowel selection |

| Natural stone | Accommodates thickness variations | May need back-buttering technique |

| Irregular tiles | Provides uniform support | Consider double-troweling method |

| Heavy tiles | Supports weight without sagging | Check weight limits per specifications |

| Floors with slight unevenness | Helps level minor substrate issues | Not a substitute for proper floor preparation |

Last year, I advised a major commercial project in Pakistan having issues with their large format floor tile installation. Switching to a medium-bed mortar modified with KEHAO cellulose additives solved their lippage problems and dramatically improved installation efficiency.

What Key Factors Should Guide Your Choice of Tile Adhesive?

Selecting adhesive based solely on price often leads to costly failures. Many contractors learn this expensive lesson after tiles begin falling off walls or cracking under foot traffic.

The key factors in choosing tile adhesives include installation location (indoor/outdoor), moisture exposure, tile size and type, substrate material, and project timeline. These variables determine whether to use organic mastic, standard thin-set, or modified mortars.

Selecting the right tile adhesive requires a comprehensive assessment of your specific installation conditions. Through my years working with contractors across developing markets, I've developed a systematic approach to adhesive selection that considers all critical variables.

First, evaluate the installation environment. Will the tiles be exposed to constant moisture? Temperature fluctuations? Heavy foot traffic? Each condition narrows your adhesive options. For example, exterior installations in regions with freeze-thaw cycles absolutely require latex-modified thin-sets with high flexibility.

Next, consider the tile material and size. Large format tiles need medium-bed or specially formulated large-tile thin-sets. Glass tiles typically require white, polymer-modified adhesives6. Natural stone may need special consideration for staining potential.

The substrate material also significantly impacts adhesive selection. Cement board, plywood, existing tile, and concrete each have different requirements for proper bonding. Some difficult substrates like vinyl or metal may require special bonding agents before any mortar can be applied.

Adhesive Selection Matrix

| Factor | Recommendation | Considerations |

|---|---|---|

| Wet areas | Latex-modified thin-set | Never use organic mastics |

| Exterior locations | High-quality latex-modified thin-set | Consider climate conditions |

| Large format tiles | Medium-bed or specialized large-tile mortar | Check for sagging resistance |

| Glass or translucent tile | White |

During a recent consultation with a major hotel chain developing properties across the Middle East, I created a comprehensive adhesive specification guide that matched each installation area with the appropriate adhesive type. This systematic approach prevented failures and reduced warranty claims by nearly 80% compared to their previous projects.

How Can KEHAO Additives Optimize Your Tile Adhesive Performance?

Many contractors struggle with tile adhesives that dry too quickly in hot climates, making installation difficult and reducing bond strength. This challenge leads to wasted material and failed installations.

KEHAO additives like hydroxypropyl methylcellulose (HPMC)7 and redispersible polymer powders8 enhance tile adhesives by improving water retention, extending working time, increasing flexibility, and strengthening the bond. These modifications result in better performance across various installation environments.

In my experience working with major mortar manufacturers across developing markets, KEHAO additives have consistently delivered superior performance in tile adhesive formulations. These specialized chemicals address common challenges faced by installers, particularly in challenging environments like the extreme heat of Saudi Arabia or the high humidity of Southeast Asian countries.

Hydroxypropyl methylcellulose (HPMC) serves as a critical component in quality tile adhesives by enhancing water retention. This property extends open time, allowing installers to work more efficiently without the adhesive skinning over prematurely. In hot or dry climates, this benefit becomes particularly valuable, preventing the rapid moisture loss that leads to poor bonding.

Redispersible polymer powders (RDP) add flexibility and adhesion strength to cement-based mortars. When incorporated into thin-set formulations, these polymers create molecular bridges that enhance bonding to difficult substrates like existing tile or concrete with minor cracks. This flexibility also helps the adhesive accommodate substrate movement from thermal expansion or structural settling.

KEHAO Additive Benefits in Tile Adhesives

| Additive | Primary Benefit | Secondary Benefits |

|---|---|---|

| HPMC | Water retention | Extended working time, improved sag resistance |

| Redispersible polymer powder | Enhanced flexibility | Better adhesion to difficult substrates, improved water resistance |

| Cellulose ethers | Improved workability | Enhanced thixotropy, easier troweling |

| Specialized blends | Customized performance | Tailored to specific climate conditions or application requirements |

| Anti-sagging agents | Prevents tile slippage | Particularly valuable for wall installations and heavy tiles |

I recently worked with a major mortar manufacturer in India who was struggling with product performance in their regional market. By incorporating KEHAO HPMC with precisely controlled viscosity and modified particle size, they achieved a 40% improvement in open time while maintaining excellent sag resistance. This formulation adjustment dramatically reduced installation failures and strengthened their market position.

Conclusion

Choosing the right tile adhesive is essential for successful installations. Consider your specific project conditions, tile type, and location to select between organic mastics, thin-sets, or modified mortars for the best results.

-

Explore this link to understand the various types of tile adhesives and their specific uses. ↩ ↩

-

Stay updated on the latest innovations in construction materials that can improve tile installations. ↩

-

Discover how KEHAO additives enhance the performance of tile adhesives for better results. ↩

-

Get insights into critical factors that influence tile adhesive selection for successful installations. ↩ ↩

-

Find out how latex-modified mortars enhance tile adhesion and flexibility. ↩

-

Learn about the advantages of using polymer-modified adhesives for enhanced performance. ↩

-

Explore how HPMC enhances tile adhesive performance, improving water retention and extending working time for better installations. ↩

-

Learn about the role of RDP in enhancing flexibility and adhesion strength in tile adhesives, crucial for challenging environments. ↩