Floor preparation can be a nightmare when you're dealing with uneven surfaces. Cracks, dips, and bumps not only look unsightly but can lead to installation failures and safety hazards.

A cementitious self-leveling compound1 is a specialized cement-based material designed to create smooth, flat surfaces on uneven floors. It flows and spreads easily when poured, finding its own level with minimal manual intervention, providing an ideal substrate for tile, carpet, vinyl, or other finished flooring.

I've seen many contractors struggle with uneven floors before discovering the benefits of using quality self-leveling compounds. My experience in the construction materials industry has shown me that using the right product can save significant time and effort while delivering superior results.

What Is the Definition of Self-leveling Compound?

Many flooring projects are delayed and compromised by inconsistent floor heights. Without proper leveling, even the highest quality flooring materials can fail prematurely.

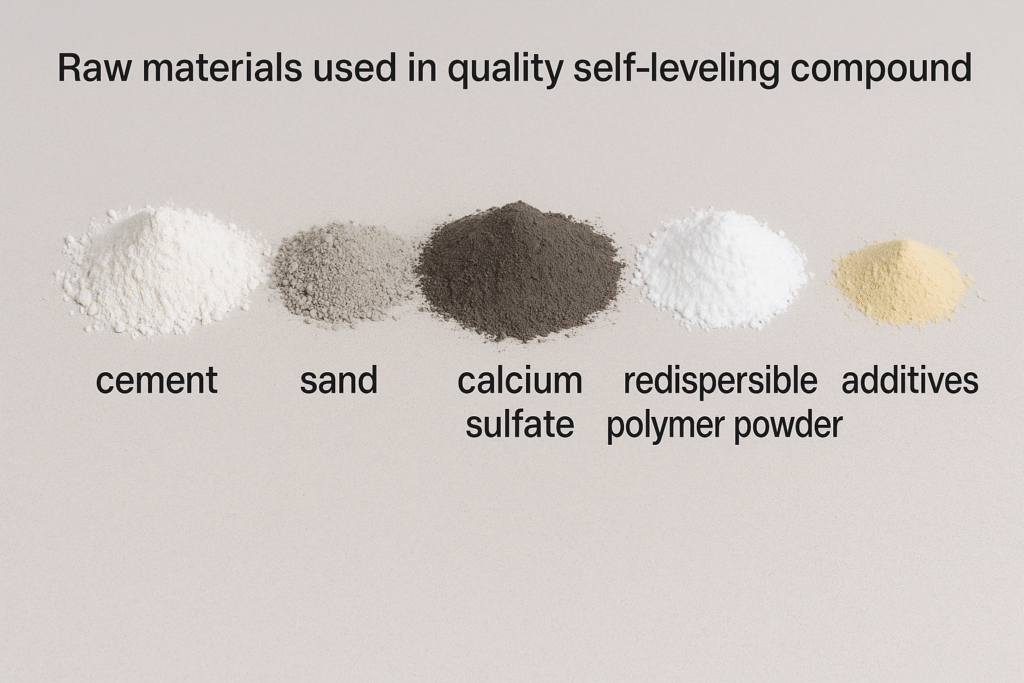

Self-leveling compound is a polymer-modified cement2-based product that flows when poured, automatically seeking its own level and creating a flat, smooth surface. It typically consists of Portland cement, fine aggregates, polymers, and additives that provide flow properties and rapid curing characteristics.

https://placehold.co/600x400)

Self-leveling compounds have revolutionized floor preparation in both residential and commercial construction. The technology behind these products has advanced significantly over the past decade. Traditional floor leveling methods required skilled masons and extensive labor to create level surfaces manually. Modern self-leveling compound1s, by contrast, can be mixed and poured by workers with minimal training.

The key to their effectiveness lies in their carefully balanced formulation. The base Portland cement provides strength and durability, while polymers enhance flexibility and adhesion. Various additives control setting time, flow characteristics, and prevent shrinkage during curing. High-quality hydroxypropyl methylcellulose (HPMC3) is particularly important as a water-retention agent, ensuring proper hydration of the cement and preventing premature drying.

At our factory, we've developed specialized HPMC for self-leveling compounds that maintains optimal viscosity throughout the working time, allowing for smooth application while preventing separation of components.

What Are the Advantages of Using Self-leveling Compounds?

Uneven floors frustrate contractors and compromise final installations. Traditional floor correction methods are labor-intensive, time-consuming, and often yield inconsistent results.

Self-leveling compounds offer significant advantages including rapid installation, exceptional flatness (±1mm tolerance over 2m), early traffic capability (usually within 24 hours), high compressive strength (typically 25-40 MPa), and compatibility with various flooring materials including tiles, carpet, and vinyl.

The advantages of self-leveling compounds extend far beyond just creating flat surfaces. From my experience supplying materials to major construction projects across Saudi Arabia and the UAE, I've witnessed firsthand how these products transform challenging projects.

One notable advantage is the significant labor savings. A small team can level hundreds of square meters in a single day, versus the multiple days required using traditional methods. This translates to substantial cost savings, especially in projects with tight deadlines.

Self-leveling compounds also offer exceptional durability. When properly formulated with quality raw materials, these products develop compressive strengths exceeding 40 MPa, making them suitable even for industrial flooring applications subjected to heavy traffic and equipment loads.

Comparison of Self-leveling Compounds vs. Traditional Methods

| Feature | Self-leveling Compounds | Traditional Methods |

|---|---|---|

| Installation Speed | 1,000+ m²/day | 100-300 m²/day |

| Labor Requirements | Minimal (2-3 workers) | High (5-8 workers) |

| Flatness Tolerance | ±1mm over 2m | ±3-5mm over 2m |

| Skill Level Needed | Moderate | High |

| Cost Efficiency | High initial material cost, low labor | Low material cost, high labor |

What Standards Govern Self-leveling Compounds?

Low-quality self-leveling compounds can crack, shrink, or delaminate after installation. Without proper standards, it's difficult to determine product quality and suitability.

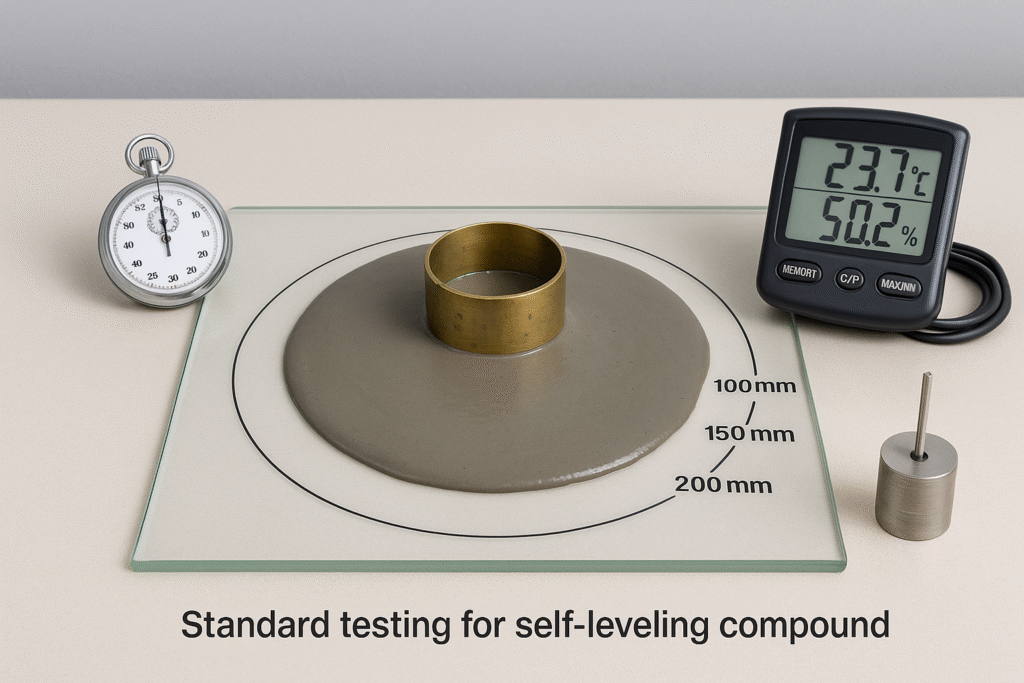

The JC/T 985-2017 standard establishes critical parameters for cementitious self-leveling compounds including compressive strength (≥25 MPa), flexural strength (≥5 MPa), bond strength (≥1.0 MPa), and dimensional stability (shrinkage ≤0.05%).

Understanding industry standards is essential for selecting appropriate self-leveling compounds for specific applications. The JC/T 985-2017 standard provides comprehensive guidelines that ensure performance reliability in real-world conditions.

The standard classifies self-leveling compounds into different grades based on their compressive strength, with C25 being the minimum acceptable grade for most commercial applications. For industrial floors subject to heavy loads, C30 or higher is typically recommended.

Testing procedures under this standard are rigorous and scientifically validated. Compressive strength is measured after 28 days of curing under controlled conditions. Bond strength tests involve applying tensile force to the interface between the compound and substrate until failure occurs. Shrinkage is measured using precision calipers at specified intervals during the curing process.

As a manufacturer of key raw materials for self-leveling compounds, we ensure our HPMC and redispersible latex powder meet or exceed the requirements needed for formulators to achieve JC/T 985-2017 compliance. Our technical team regularly conducts compatibility testing with various cement types to optimize performance across different formulations.

What's the Recommended Formula for Self-leveling Compounds?

Many contractors struggle with inconsistent self-leveling compounds that either flow too much or too little. The wrong formula leads to installation problems, extended setting times, and potential failure.

A balanced self-leveling compound formula typically contains 30-35% Portland cement, 50-60% graded silica sand, 0.2-0.5% HPMC3, 3-5% redispersible polymer powder, 0.5-1% setting modifiers, and 0.1-0.3% defoaming agents. This combination provides optimal flow, strength, and workability.

Creating an effective self-leveling compound requires careful balancing of multiple components. Each ingredient plays a specific role in the final performance of the product. From my experience working with major mortar manufacturers, I've found that the quality of key components significantly impacts the reliability of the final product.

Portland cement provides the basic binding strength, but its properties can vary significantly between sources. We typically recommend using Type I Portland cement with controlled setting characteristics for predictable performance. The silica sand component must have precisely controlled particle size distribution to achieve proper flow while minimizing segregation during application.

The cellulose ether component (typically HPMC) is critically important despite its small percentage in the formula. Our HPMC for self-leveling applications has a viscosity range of 15,000-30,000 mPa·s, which provides the optimal balance of water retention and flow properties. We've found that using lower quality cellulose ethers often results in rapid water loss and poor leveling performance.

Recommended Proportions for Self-leveling Compound

| Component | Percentage | Function |

|---|---|---|

| Portland Cement | 30-35% | Primary binder |

| Graded Silica Sand | 50-60% | Provides bulk and dimensional stability |

| HPMC | 0.2-0.5% | Water retention and flow control |

| Redispersible Polymer Powder | 3-5% | Flexibility and adhesion enhancement |

| Setting Modifiers | 0.5-1% | Control setting time |

| Defoaming Agents | 0.1-0.3% | Minimize air entrainment |

How Can I Solve Common Problems With Self-leveling Compounds?

Contractors frequently encounter cracking, bubbling, or insufficient flow when applying self-leveling compounds. These issues lead to project delays, additional material costs, and unhappy clients.

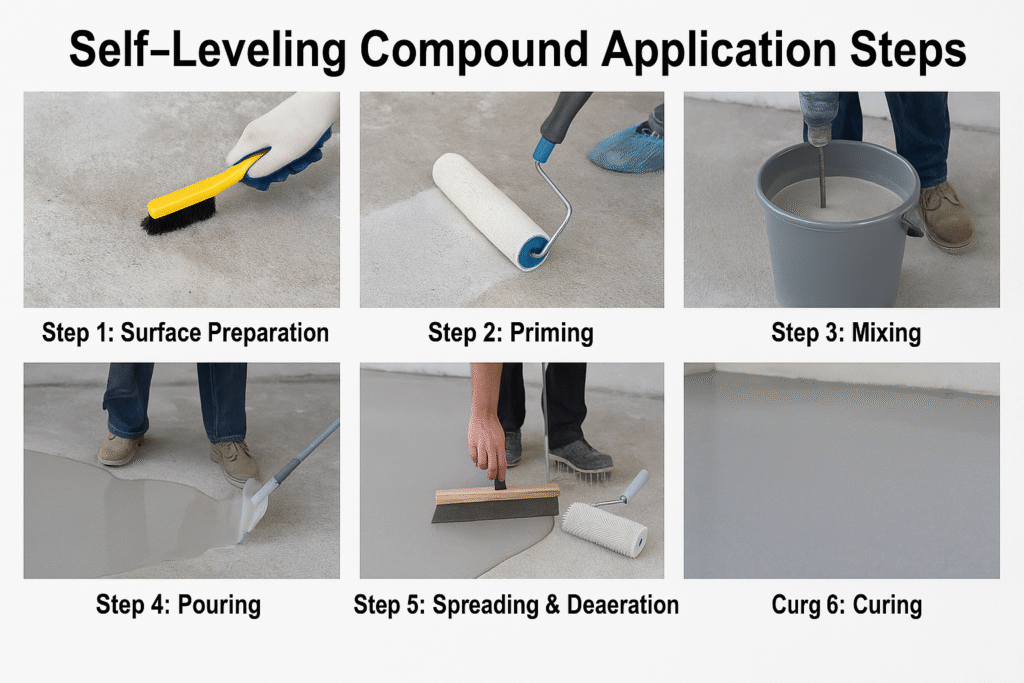

Common problems with self-leveling compounds can be solved through proper preparation: ensuring substrate cleanliness, applying appropriate primers, maintaining correct mixing ratios (typically 4-5L water per 20kg powder), controlling ambient temperature (ideal range 15-25°C), and preventing drafts during curing.

Through years of providing technical support to our customers, I've encountered virtually every possible problem with self-leveling compound installations. The most frequent issues have clear solutions once you understand the underlying causes.

Surface cracking is often the result of excessive water in the mix or rapid moisture loss during curing. When mixing, it's essential to follow manufacturer specifications precisely – adding extra water to improve flow will compromise strength and increase shrinkage. For large installations, we recommend using moisture meters to monitor ambient humidity and applying curing compounds when necessary.

Delamination (separation from the substrate) typically results from inadequate surface preparation or primer application. The substrate must be thoroughly cleaned of oils, dust, and loose particles. Concrete should be mechanically abraded to create a profile that enhances bonding. Different substrates require specific primers – our technical team provides compatibility charts based on extensive testing.

Bubble formation is another common issue, usually caused by air trapped in porous substrates that rises through the compound as it cures. The solution is two-fold: proper priming to seal the substrate and using appropriate defoaming agents in the formulation. Our redispersible powders are formulated with compatible defoamers that minimize this issue when used correctly.

Troubleshooting Guide for Common Issues

| Problem | Possible Causes | Solutions |

|---|---|---|

| Cracking | Excessive water, rapid drying, improper thickness | Follow mix ratio exactly, prevent drafts, ensure proper depth |

| Poor Flow | Insufficient water, expired product, improper mixing | Use recommended water ratio, check product date, mix thoroughly (3-5 minutes) |

| Bubbling | Air entrapment, porous substrate, incompatible primer | Apply appropriate primer, use quality defoamers, maintain proper environment |

| Slow Setting | Low temperature, high humidity, contamination | Ensure ambient temperature above 15°C, protect from excess humidity |

Conclusion

Self-leveling compounds transform challenging floor preparation into a manageable process. By selecting quality materials, following proper mixing procedures, and addressing substrate conditions, you can achieve professional results that will stand the test of time.

-

Explore this resource to understand the mechanics and benefits of self-leveling compounds in flooring. ↩ ↩

-

Discover the benefits of polymer-modified cement in enhancing the performance of construction materials. ↩

-

Discover how HPMC enhances the performance of self-leveling compounds in flooring applications. ↩ ↩