Are you struggling with wall imperfections before painting? Traditional putties can be heavy and difficult to work with, causing unnecessary strain on your building's structure and extending project timelines.

Gypsum putty1 is a lightweight, premixed compound made primarily from gypsum and additives used to create smooth wall surfaces before painting or decorating. It fills cracks, holes, and imperfections while being easier to apply, quicker to dry, and placing less load on building structures compared to cement-based alternatives.

I've been in the construction materials industry for years, and I've seen many contractors switch to gypsum putty after experiencing its benefits firsthand. The transformation in their workflow efficiency and end results is remarkable. Let me show you why gypsum putty is becoming the preferred choice for modern construction projects.

What are the advantages of gypsum paste?

Do you know why more construction professionals are choosing gypsum putty over traditional options? The weight and time savings alone might surprise you, but there's much more to consider.

Gypsum putty1 offers excellent adhesion to most surfaces, dries faster than cement-based alternatives, creates minimal shrinkage, and significantly reduces the overall weight load on building structures. It also provides better workability and can be sanded to achieve perfectly smooth finishes.

Key Benefits of Gypsum Putty

When I first introduced gypsum putty to our product line, I was amazed by the positive feedback from our customers. Here's a deeper look at why this material is gaining popularity:

-

Lightweight Properties: Gypsum putty can reduce wall finishing weight by up to 65% compared to cement-based putties. This creates less stress on the building structure, which is especially important in high-rise constructions or renovations of older buildings.

-

Fast Setting Time: While traditional cement putties might take 24-48 hours to fully cure, gypsum-based products can often be ready for sanding within 2-4 hours. This dramatically speeds up project timelines.

-

Thermal Insulation: Gypsum naturally provides better thermal insulation than cement products, helping to maintain more consistent indoor temperatures and potentially reducing energy costs.

-

Crack Resistance: The flexibility of gypsum putty allows it to better accommodate minor structural movements without cracking, leading to a longer-lasting finish.

-

Environmentally Friendly: Many gypsum products contain recycled materials and require less energy to produce than Portland cement alternatives.

| Property | Gypsum Putty | Traditional Cement Putty |

|---|---|---|

| Weight | 8-12 kg/m² | 18-25 kg/m² |

| Setting Time | 2-4 hours | 24-48 hours |

| Shrinkage | Minimal | Moderate to High |

| Workability | Excellent | Good |

| Dust During Sanding | Low | High |

How does gypsum putty compare to traditional wall putty?

Have you ever wondered why some professionals still use cement-based putties despite the advantages of gypsum? The answer lies in specific application requirements and regional availability, but the differences are worth understanding.

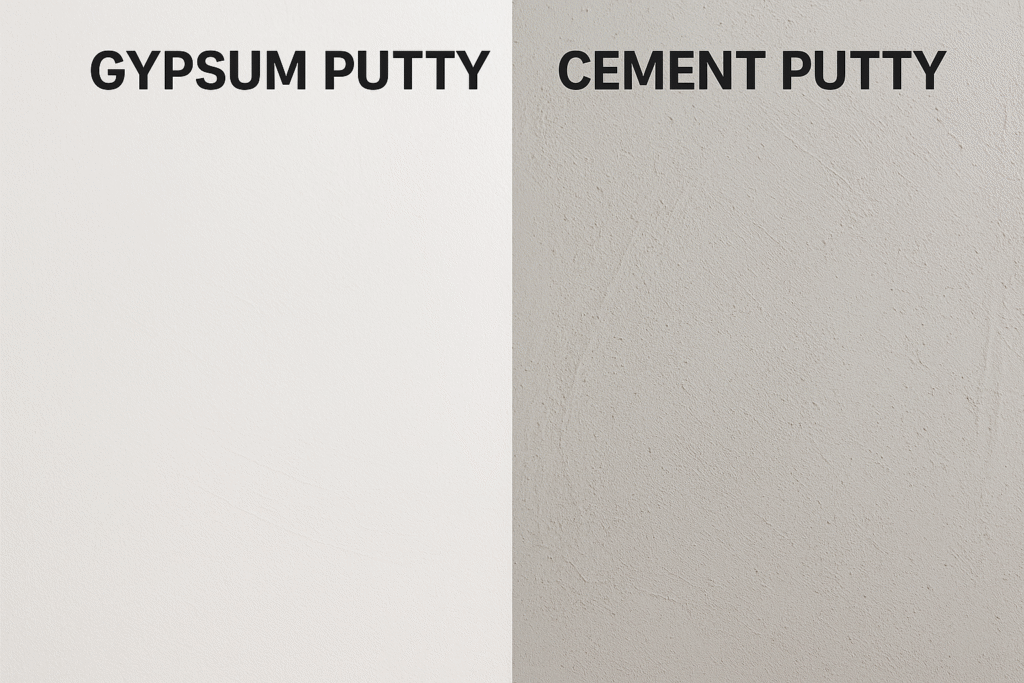

Gypsum putty offers superior workability, faster drying times, and lighter weight compared to traditional cement putties. However, cement-based options may provide better water resistance and durability in high-moisture environments, though they're heavier and take longer to cure.

Detailed Comparison with Traditional Options

I've supplied both gypsum and traditional putties to construction projects across different climates, and I've noticed distinct patterns in their performance. It's important to understand these differences when selecting materials for your project:

Material Composition:

- Gypsum putty consists primarily of calcined gypsum (CaSO₄·½H₂O), polymers, and specialized additives.

- Traditional cement putties typically contain Portland cement, lime, sand, and various additives.

Application Differences:

The application experience differs significantly between these materials. Gypsum putty has a creamier consistency that glides smoothly onto surfaces, while cement putties have a grittier texture requiring more effort to achieve a smooth finish. In my experience, contractors can cover approximately 30-40% more area in the same time period when using gypsum putties.

Durability Considerations:

While gypsum putty excels in interior applications, it's important to note that traditional cement-based putties still maintain advantages for exterior or high-moisture environments. However, modern enhanced gypsum formulations with water-resistant additives (such as those containing HPMC and RDP) are narrowing this gap.

Cost Analysis:

Though gypsum putty may have a higher initial cost (approximately 10-20% more per kg), the total project cost often ends up lower due to:

- Reduced labor time

- Less material needed per square meter

- Faster project completion

What is the application process for gypsum putty?

Is proper application technique really that important for gypsum putty? Yes—the remarkable results and time savings you can achieve depend greatly on following the correct process and using appropriate tools.

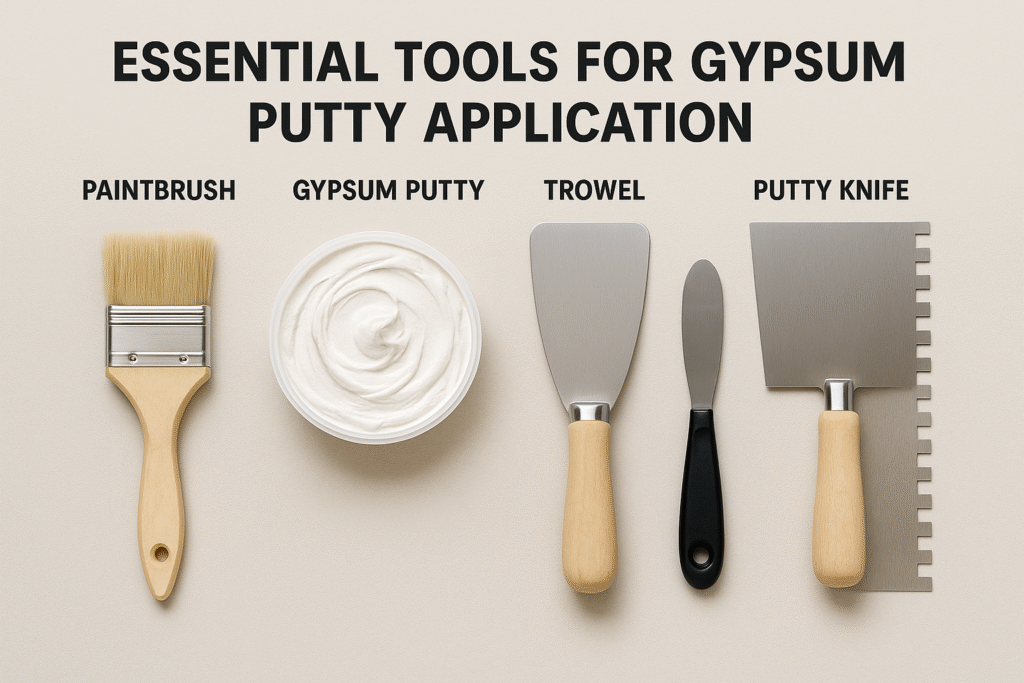

Applying gypsum putty typically involves preparing the surface by cleaning and priming, mixing the putty to the right consistency (if not pre-mixed), applying with a putty knife in thin layers, allowing proper drying time between coats, and finally sanding for a smooth finish ready for painting.

Mastering the Application Process

In my years working with construction materials, I've seen countless projects succeed or fail based on application technique alone. Here's a detailed breakdown of the process that our most successful customers follow:

Step 1: Surface Preparation

The wall surface must be clean, dry, and free from dust, oil, or loose particles. Any existing paint should be scraped off, and cracks should be widened slightly in a V-shape to ensure better filling. I recommend applying a primer specifically formulated for gypsum products, which creates a better bond between the wall and the putty.

Step 2: Mixing (for powder products)

If using powdered gypsum putty, add it gradually to clean water (approximately 40-45% water by weight) and mix thoroughly until achieving a smooth, lump-free consistency. Pre-mixed options save time but typically cost 25-30% more.

Step 3: Application Technique

Apply the first coat thinly (1-2mm) using a wide putty knife or trowel in upward strokes. Cover the entire surface evenly, focusing on filling any imperfections. Allow this layer to dry completely before proceeding—usually 1-2 hours depending on humidity and temperature conditions.

Step 4: Second and Final Coats

Apply subsequent coats even thinner than the first, with each layer covering a wider area than the previous one to feather the edges. Most professional applications require 2-3 coats for optimal results. The final coat should be applied with extra attention to smoothness.

Step 5: Finishing

Once completely dry, sand the surface lightly with fine-grit sandpaper (180-220 grit) attached to a sanding block or pole sander. Wipe away all dust before painting or applying other finishes.

Temperature and humidity significantly impact drying times—optimal conditions are 65-75°F (18-24°C) with 50-60% relative humidity. Working outside these ranges may require adjustments to technique and timing.

What are the use cases and market position of gypsum putty?

Where exactly does gypsum putty fit in today's construction market? Its growing popularity spans from residential renovations to commercial developments, though understanding its ideal applications helps maximize its benefits.

Gypsum putty excels in interior wall finishing for residential buildings, commercial spaces, hotels, hospitals, and educational institutions. It's particularly valuable in renovation projects, high-rise buildings where weight matters, and fast-track construction projects where time savings are critical.

Market Position and Ideal Applications

The global market for gypsum-based products continues to expand, with compound annual growth rates exceeding 5% in many regions. I've observed several key trends and applications worth highlighting:

Residential Construction:

In residential applications, gypsum putty has become particularly popular for:

- New construction where schedule acceleration provides significant cost benefits

- Renovation projects where minimizing dust and disruption is crucial

- Luxury apartments where perfect wall finishes are expected

- Historic renovations where adding minimal additional weight to structures is important

Commercial Applications:

The commercial sector has embraced gypsum putty for:

- Office complexes requiring rapid tenant improvements

- Hotels and restaurants where construction schedules directly impact revenue generation

- Healthcare facilities where air quality during construction and renovation is strictly controlled

- Educational institutions with tight renovation windows between academic terms

Regional Market Variations:

I've noticed significant regional differences in adoption rates. In the Middle East and parts of Asia, gypsum putty has achieved dominant market position with 60-70% market share in interior applications. In contrast, some European markets still favor traditional lime or cement-based products, though this is gradually changing as labor costs increase.

Value Chain Position:

Gypsum putty occupies an interesting position in the construction value chain—it represents a relatively small percentage of total project cost (typically 1-3%) but can significantly impact both construction schedules and final aesthetic quality. This positions it as a high-leverage material where small additional investments can yield substantial returns in project outcomes.

Emerging Trends:

The newest developments in the market include:

- Pre-colored gypsum putties eliminating the need for paint in some applications

- Ultra-lightweight formulations for specialized applications

- Antimicrobial versions for healthcare and food service environments

- Quick-setting varieties that can be painted within hours rather than days

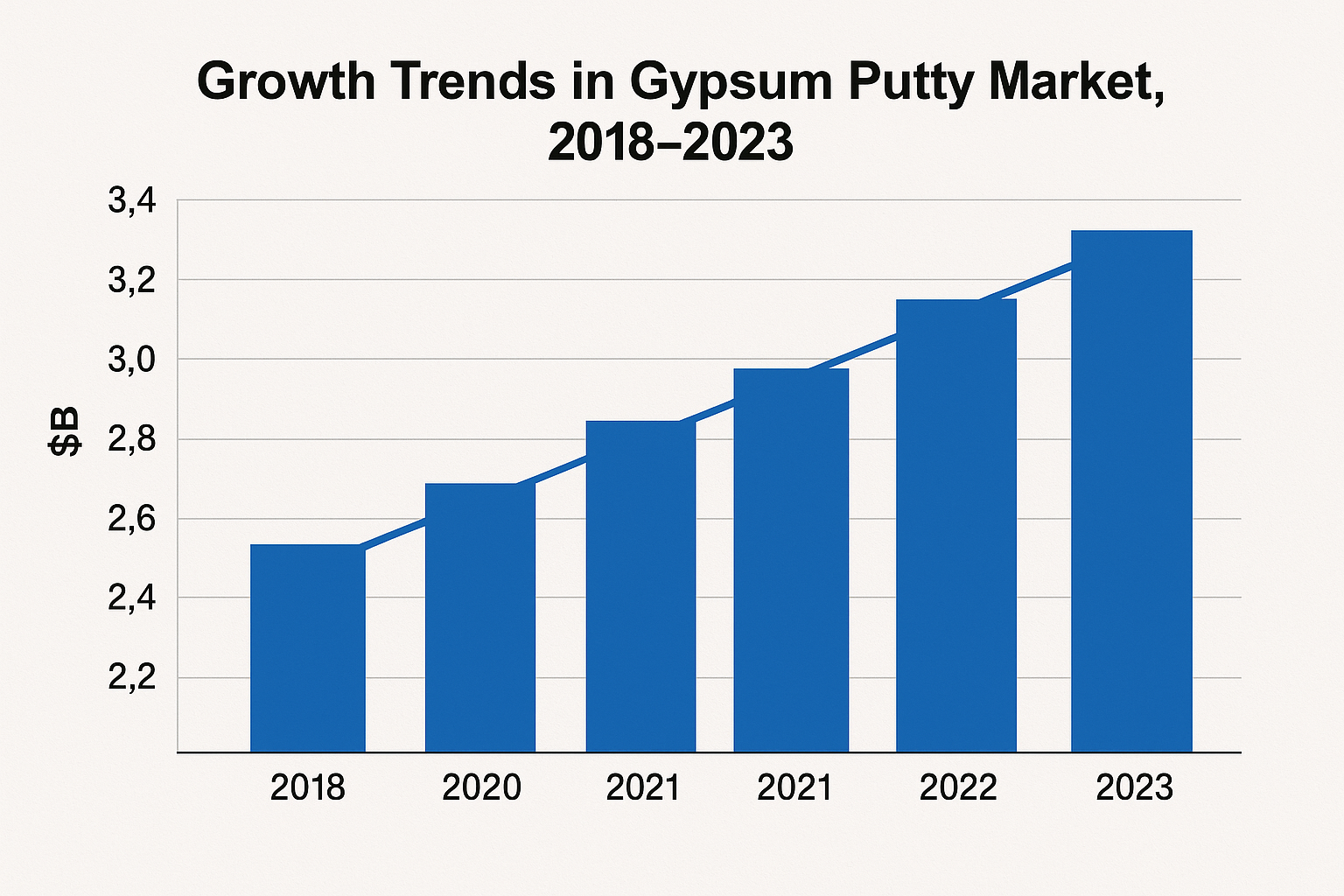

What do statistics tell us about gypsum putty usage?

Are the trends in gypsum putty adoption backed by hard numbers? The data reveals compelling patterns in market growth, efficiency gains, and environmental impact that support its increasing popularity.

Market research shows gypsum-based construction products growing at 5.8% CAGR globally, with labor time savings of 20-30% compared to traditional methods. Environmental assessments indicate 25-35% lower carbon footprint, while weight reduction typically ranges from 60-65% versus cement-based alternatives.

By the Numbers: The Gypsum Putty Revolution

Having analyzed both industry reports and our own sales data, I can share some remarkable statistics about gypsum putty adoption and performance:

Market Growth and Adoption:

The global market for gypsum-based construction products2 reached approximately $3.8 billion in 2022, with putty and finishing compounds representing about 22% of this total. Regional growth varies significantly, with the Asia-Pacific region leading at 7.2% CAGR, followed by the Middle East at 6.5%. Our own sales data mirrors these trends, with our gypsum-based products showing 34% growth over the past three years.

Performance Metrics:

Controlled studies comparing traditional cement putties to gypsum alternatives show:

- Average project completion time reduction of 22.7% when using gypsum putty

- Labor cost savings of 18-25% per project due to faster application and reduced drying time

- Material usage efficiency improvement of approximately 15% due to better coverage rates and less waste

Environmental Impact:

Life cycle assessments comparing gypsum to cement-based products show significant environmental advantages:

- Carbon footprint reduction of 25-35% per square meter of wall surface

- Energy consumption during manufacturing reduced by approximately 40%

- Water usage during production decreased by 30-45%

Weight and Structural Implications:

For a typical 10-story residential building, switching from traditional cement putty to gypsum products can:

- Reduce the total dead load by approximately 35-40 tons

- Potentially allow for reduced structural element sizing

- Decrease foundation requirements by 3-5% in new construction

Contractor Adoption Rates:

Survey data from construction professionals indicates:

- 78% of contractors who try gypsum putty continue to use it for future projects

- 65% report customer satisfaction improvements after switching

- 82% cite faster project completion as their primary motivation for adoption

These statistics tell a compelling story of a material that delivers measurable benefits across multiple dimensions—from project economics to environmental sustainability.

Frequently Asked Questions (FAQ) about gypsum putty?

What are the most common questions people ask about gypsum putty? From waterproofing concerns to mixing methods, understanding these answers can help you make informed decisions for your projects.

The most frequent questions about gypsum putty concern its water resistance, suitable surfaces for application, mixing ratios, shelf life, and compatibility with different paint types. Each has a straightforward answer based on material properties and best practices.

Answering Your Common Questions

After speaking with thousands of customers over the years, these are the questions that come up most frequently, along with the answers I typically provide:

Q: Is gypsum putty waterproof?

A: Standard gypsum putty is not waterproof by nature, though it has some water resistance. For areas with high moisture exposure, I recommend specialized water-resistant formulations containing hydrophobic additives like HPMC (hydroxypropyl methylcellulose) and RDP (redispersible polymer powder). These modified versions can withstand occasional water contact but are still best used for interior applications.

Q: How long does gypsum putty take to fully cure?

A: While the surface may feel dry within 2-4 hours, complete curing typically takes 24-48 hours depending on layer thickness, humidity levels, and ventilation. I always advise customers to wait at least 24 hours before painting, even when using quick-setting formulations. Rushing this process can lead to paint adhesion issues later.

Q: Can gypsum putty be applied over painted surfaces?

A: Yes, but proper preparation is crucial. The existing paint must be well-adhered, clean, and lightly sanded to provide a good mechanical key. For glossy surfaces, I recommend applying a bonding primer specifically designed for gypsum products before applying the putty to ensure proper adhesion.

Q: What's the shelf life of gypsum putty3 products?

A: Powdered gypsum putty products typically have a shelf life of 9-12 months when stored in dry conditions. Pre-mixed putties usually last 12-18 months if kept properly sealed. Always check the package for specific manufacturer recommendations, and inspect for hardening or unusual consistency changes before use.

Q: Can gypsum putty be used outdoors?

A: Standard gypsum putty is not recommended for direct outdoor exposure. For semi-protected exterior applications like covered porches, specially formulated exterior-grade gypsum products with enhanced water resistance and freeze-thaw stability are available, though they typically cost 35-45% more than standard formulations.

Q: How do I achieve the smoothest possible finish with gypsum putty?

A: The smoothest finishes come from applying multiple thin layers rather than one thick layer, using wide (8-12 inch) taping knives for the final coat, ensuring proper drying between layers, and sanding with progressively finer grit sandpaper (finishing with 220 grit). Some professionals also dampen their sanding sponges slightly for final smoothing.

Conclusion

Gypsum putty offers substantial benefits for modern construction, including lighter weight, faster application, and excellent finishes. With proper application techniques and quality formulations containing additives like HPMC, it provides an efficient, environmentally-friendly solution for wall finishing across various projects.

-

Explore the advantages of gypsum putty, including its lightweight properties and quick drying time, which can enhance your construction projects. ↩ ↩

-

Explore this link to understand the advantages and applications of gypsum-based construction products in modern building. ↩

-

Get insights into the shelf life of gypsum putty and how to store it for optimal use. ↩