Many tile installers struggle with adhesives that fail prematurely, causing expensive callbacks and damaged reputation. Poor water retention and inadequate open time1 are often to blame, leading to weak bonds and falling tiles.

HPMC (Hydroxypropyl Methylcellulose)2 is the key additive that improves tile adhesive performance by enhancing water retention, extending open time, and increasing bonding strength. It typically comprises 0.2-0.5% of the formulation but dramatically improves workability, sag resistance, and overall adhesion quality.

At Kehao, we've spent years perfecting our HPMC formulations specifically for ceramic tile adhesives. Our customers consistently report that the right HPMC grade can transform an average adhesive into a premium product. Let me share what makes this additive so crucial for your tile adhesive formulations.

What Key Performance Benefits Does HPMC Provide in Tile Adhesive?

Tile installers often face the frustration of adhesives drying too quickly in hot conditions, making proper tile placement impossible. Without sufficient water retention3, even the best application techniques can't prevent bond failure.

HPMC enhances tile adhesives by improving water retention (keeping mortar workable longer), extending open time (allowing more time for tile placement), increasing sag resistance (preventing heavy tiles from slipping), boosting adhesion strength, and improving workability for smoother application.

HPMC transforms the performance of ceramic tile adhesives through several crucial mechanisms. When added to the formulation, HPMC forms a protective colloid that slows water evaporation and absorption into porous substrates. This water retention capability is particularly valuable in hot, dry conditions where premature drying is a common problem.

In my experience working with customers across Saudi Arabia and the UAE, this extended working time is critical. It allows installers to cover larger areas before placing tiles, increasing efficiency while ensuring proper adhesion. One Saudi customer recently told me they were able to increase their installation area by 30% per mixing batch after switching to our premium HPMC grade.

Water retention isn't just about convenience—it directly impacts bond strength. When adhesive retains moisture longer, cement hydration becomes more complete, resulting in stronger crystalline structures and better mechanical properties. Additionally, HPMC improves the rheological properties of the adhesive, making it thixotropic (flowing under pressure but resisting flow when static), which prevents heavy tiles from sagging on vertical surfaces.

How Are Tile Adhesives Classified and What HPMC Grades Are Recommended?

Contractors often select the wrong adhesive class for specific applications, leading to installation failures. The confusion about which HPMC grade matches each adhesive class causes manufacturers to formulate products that don't meet performance standards.

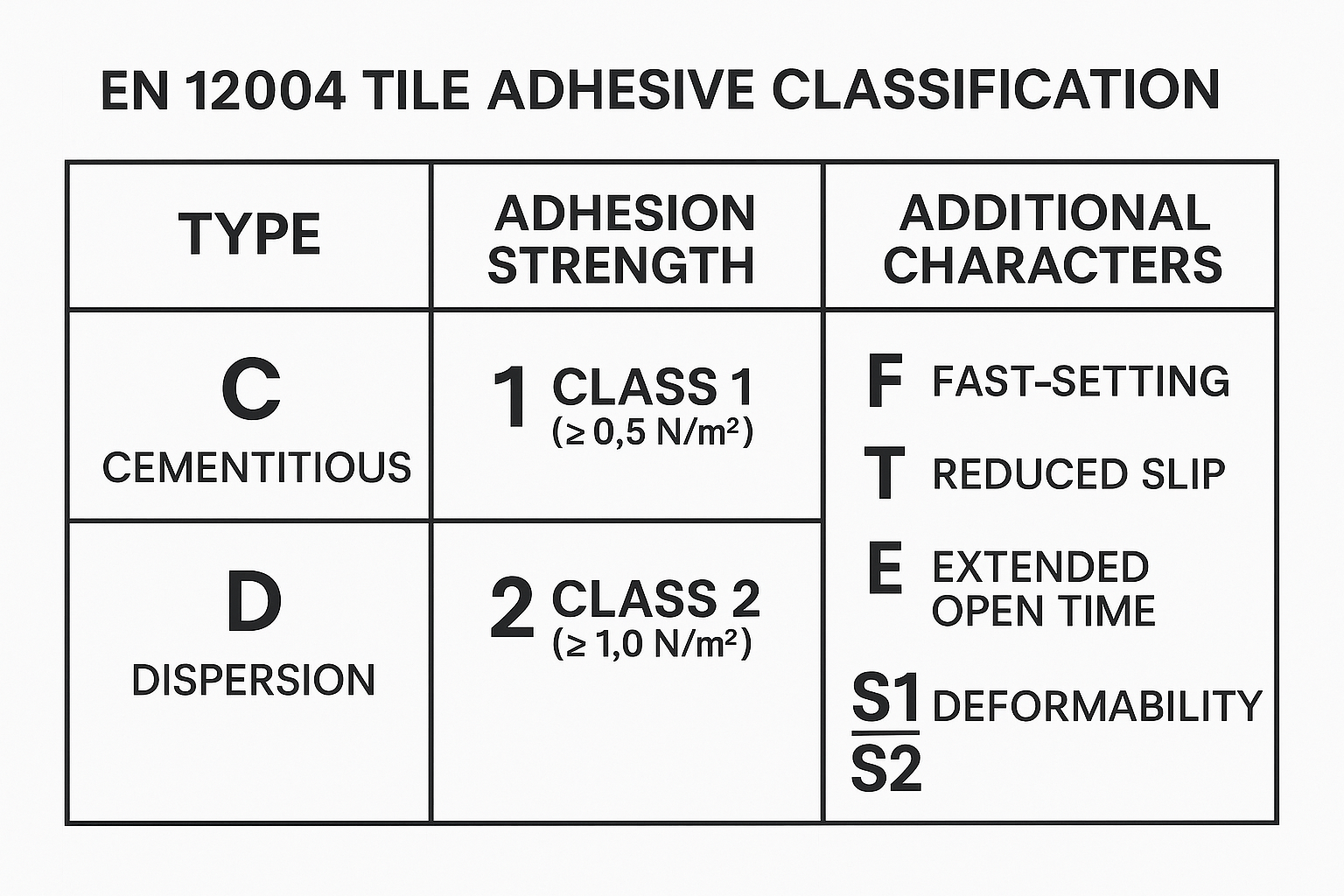

Tile adhesives are classified according to EN 12004 standards as C1 (normal)4, C2 (improved)5, and specialty types including fast-setting (F), slip-resistant (T), and extended open time (E) versions. For C1 adhesives, HPMC with 100,000-150,000 viscosity is suitable, while C2 adhesives require 150,000-200,000 viscosity grades.

The European Standard EN 12004 provides a comprehensive classification system that helps manufacturers and end-users match adhesives to specific project requirements. Understanding these classifications is essential for selecting the appropriate HPMC grade. Below is a detailed breakdown of tile adhesive classes and the recommended HPMC specifications:

| Adhesive Class | Description | Recommended HPMC Viscosity | Recommended HPMC Methoxyl Content | Typical Dosage |

|---|---|---|---|---|

| C1 (Normal) | Standard cementitious adhesive with ≥0.5 N/mm² tensile strength | 100,000-150,000 mPa·s | 19-24% | 0.2-0.3% |

| C2 (Improved) | Enhanced adhesive with ≥1.0 N/mm² tensile strength | 150,000-200,000 mPa·s | 19-24% | 0.3-0.5% |

| C2F (Fast-setting) | Rapid-hardening with high early strength | 100,000-150,000 mPa·s | 27-30% | 0.2-0.4% |

| C2T (Slip-resistant) | Reduced slip for heavy tiles | 200,000-250,000 mPa·s | 19-24% | 0.3-0.5% |

| C2E (Extended open time) | Longer working time (≥30 min) | 150,000-200,000 mPa·s | 19-24% | 0.3-0.5% |

| C2TE (Premium) | Combined slip resistance and extended open time | 200,000-250,000 mPa·s | 22-27% | 0.4-0.6% |

I've observed that many manufacturers in developing markets start with basic C1 formulations, but quickly upgrade to C2 grades as their customers demand better performance. The difference in HPMC quality and grade significantly impacts the final product performance, with higher viscosity grades typically delivering better overall results for premium adhesives.

What Are the Key Factors Influencing HPMC Performance in Tile Adhesives?

Many manufacturers struggle with inconsistent adhesive performance despite using the same HPMC percentage. The mystery lies in not understanding how viscosity, substitution, and particle size affect the final properties of the adhesive.

HPMC performance in tile adhesives is primarily influenced by molecular weight (determines viscosity and water retention), methoxyl content (affects dissolution temperature and workability), hydroxypropyl substitution (impacts flexibility), particle size (determines dissolution speed), and purity (ensures consistent performance).

When selecting the optimal HPMC grade for tile adhesives, manufacturers must consider several technical parameters that significantly impact performance. From my years of supporting customers across various climate conditions, I've found that these factors require careful balancing to achieve optimal results.

Viscosity is perhaps the most critical parameter, as it directly correlates with water retention capability. Higher viscosity HPMC (150,000-200,000 mPa·s) provides better water retention, which is essential for achieving proper cement hydration and stronger bonds. However, there's a practical limit—extremely high viscosity can make the adhesive difficult to mix and apply.

The methoxyl content determines the thermal gelation properties of HPMC. Products with lower methoxyl content (19-24%) work well in standard conditions, while higher methoxyl content (27-30%) is beneficial in cold weather applications as it lowers the gelation temperature. In the hot climate of countries like Saudi Arabia and the UAE, I typically recommend medium methoxyl content (22-27%) to balance workability with water retention.

Particle size distribution significantly impacts dissolution speed. Fast-dissolving grades with smaller particle sizes (less than 100 μm) reduce mixing time but may cause lumping if not properly dispersed. Slower-dissolving grades with larger particles provide more consistent performance but require longer mixing times. For most tile adhesive applications, we recommend a balanced particle size distribution to ensure both ease of mixing and consistent performance.

The purity6 of HPMC also plays a crucial role. Impurities can interfere with cement hydration and introduce inconsistencies in the adhesive's performance. At Kehao, our advanced production processes ensure HPMC with minimal gel content and impurities, leading to more predictable and consistent adhesive performance.

What Are KEHAO's Recommended Products for Tile Adhesives?

Selecting the wrong HPMC grade wastes money and results in poor product performance. Manufacturers are often overwhelmed by technical specifications without clear guidance on which products suit their specific formulation needs.

Kehao recommends KH-100M for standard C1 adhesives, KH-150M for general-purpose C2 applications, KH-200M for premium C2TE adhesives requiring extended open time and slip resistance, and KH-75000SD for fast-setting adhesives in humid conditions. All products are available with customized packaging and complete technical support.

Based on extensive field testing and customer feedback across diverse climatic conditions, I've developed specific recommendations tailored to different tile adhesive applications. Our product range is designed to meet the specific challenges faced by manufacturers in developing markets.

For manufacturers just entering the tile adhesive market, our KH-100M grade offers an excellent balance of performance and cost-effectiveness. With a viscosity of 100,000 mPa·s and standard methoxyl content, it provides sufficient water retention for basic C1 adhesive formulations. We've seen several customers in India and Pakistan successfully use this grade as they establish their market presence.

For improved adhesives, our KH-150M grade delivers enhanced water retention and workability. This product has been particularly successful in the Middle East, where its balanced properties help compensate for the challenges of hot, dry installation conditions. One major customer in Iran reported a 40% reduction in callback complaints after switching to this grade.

Our premium offering, KH-200M, is specially designed for high-performance C2TE adhesives. With carefully controlled viscosity and substitution patterns, it delivers exceptional open time extension and sag resistance. This grade has become increasingly popular among our customers in Brazil and Mexico who serve the high-end tile installation market.

For specialized applications, we offer KH-75000SD, featuring rapid dissolution and unique anti-sagging properties. This product works particularly well in formulations that include redispersible powder, creating synergistic effects that enhance overall adhesive performance.

All Kehao products undergo rigorous quality testing, including viscosity measurement, gel content analysis, and application performance testing. We provide complete technical documentation, including safety data sheets and application guidelines, to support our customers' formulation efforts.

What Are the Market Trends and Conclusions for HPMC in Tile Adhesives?

Manufacturers often stick with outdated formulations, missing opportunities to differentiate their products. Market demands are shifting toward higher performance adhesives, but many producers lack the technical knowledge to make this transition.

The tile adhesive market is trending toward higher-performance C2 formulations, eco-friendly products with reduced cement content, and specialized solutions for large-format tiles. HPMC remains the essential additive for achieving these performance goals, with premium grades delivering the water retention and workability demanded by modern installation practices.

The tile adhesive market continues to evolve rapidly, with several clear trends emerging in recent years. Based on our global market analysis and customer interactions, I've observed a significant shift toward higher-performance products, even in price-sensitive markets. This trend is driven by the increasing prevalence of large-format tiles, which place greater demands on adhesive performance.

In developing markets like Vietnam and the Philippines, where traditional cement-sand mixtures were once standard, we're seeing accelerated adoption of factory-prepared dry-mix adhesives containing HPMC. This shift is creating substantial growth opportunities for HPMC suppliers who can provide consistent quality and technical support.

Sustainability has also emerged as a key consideration. Manufacturers are increasingly looking for ways to reduce the cement content in their formulations while maintaining performance standards. Higher-efficiency HPMC grades that deliver superior water retention at lower dosage rates are helping achieve this goal, reducing both the carbon footprint and the cost of the final product.

Another notable trend is the growing demand for multi-functional adhesives that can handle a variety of installation challenges. Rather than offering multiple specialized products, many manufacturers prefer to develop premium "universal" adhesives that work well across different substrates and tile types. These formulations typically rely on high-performance HPMC grades combined with other additives like redispersible powder.

From our perspective at Kehao, success in this evolving market requires more than just supplying quality HPMC. Our approach includes comprehensive technical support, helping customers optimize their formulations and troubleshoot application issues. This consultative approach has proven particularly valuable for customers in developing markets who may have limited R&D resources.

Frequently Asked Questions (FAQ)

What is the recommended dosage of HPMC in tile adhesives?

The typical dosage ranges from 0.2-0.5% of the dry mix weight, with higher dosages used in premium formulations requiring extended open time and enhanced slip resistance.

How does HPMC viscosity affect tile adhesive performance?

Higher viscosity HPMC (150,000+ mPa·s) provides better water retention and sag resistance, while lower viscosity grades offer improved workability and easier mixing. The optimal choice depends on specific application requirements.

Can HPMC replace other additives in tile adhesive formulations?

While HPMC provides multiple benefits, it works best in combination with other additives like redispersible powder for flexibility and strength. HPMC primarily addresses water retention and workability, not adhesion strength directly.

How should HPMC be incorporated into dry-mix tile adhesives?

For best results, HPMC should be pre-blended with other dry ingredients before adding cement to prevent lumping. Proper dispersion is critical for achieving consistent performance.

What HPMC grade is best for fast-setting tile adhesives?

Fast-setting adhesives typically require HPMC with higher methoxyl content (27-30%) and moderate viscosity (75,000-100,000 mPa·s) to balance quick setting with sufficient workability.

Conclusion

HPMC is the cornerstone additive for high-performance tile adhesives, with the right grade dramatically improving water retention3, workability, and bonding strength. By selecting the appropriate Kehao HPMC product for your specific formulation needs, you can develop competitive adhesives that meet or exceed international standards.

-

Learn about open time and its significance in tile installation, ensuring proper placement and adhesion. ↩

-

Explore how HPMC enhances tile adhesive performance, ensuring better water retention and bonding strength. ↩

-

Understanding water retention can help you choose the right adhesive for your projects, preventing bond failures. ↩ ↩

-

Learn about C1 adhesives and their applications to ensure proper performance in your projects. ↩

-

Discover the benefits of C2 adhesives for improved performance in tile installations. ↩

-

Learn how purity affects the performance and reliability of tile adhesives in various applications. ↩