Tile adhesive failures can cost contractors thousands in repairs and damage their reputation. Without the right binding agents, even premium tiles can crack, fall off, or develop moisture problems.

Redispersible Polymer Powder (RDP)1 is an essential additive in modern tile adhesives that improves adhesion, flexibility, and water resistance. It forms a polymer film during cement hydration, creating strong bonds between tiles and substrates while enhancing mortar workability and durability against environmental stresses.

I've spent years helping clients solve tile adhesive problems. The difference between a successful installation and a costly failure often comes down to one critical component: redispersible polymer powder. Let me share what makes this additive so important and how it transforms ordinary cement into high-performance tile adhesive.

What Is Redispersible Polymer Powder (RDP)1?

Many contractors struggle with adhesives that crack, separate, or fail to bond properly. These issues usually trace back to missing or low-quality polymer modification in the mortar mix.

RDP is a spray-dried polymer emulsion that redisperses in water when mixed with cement mortar. It consists of fine powder particles containing vinyl acetate, ethylene, and other copolymers that form a flexible film throughout the cement matrix, significantly improving adhesion and flexibility.

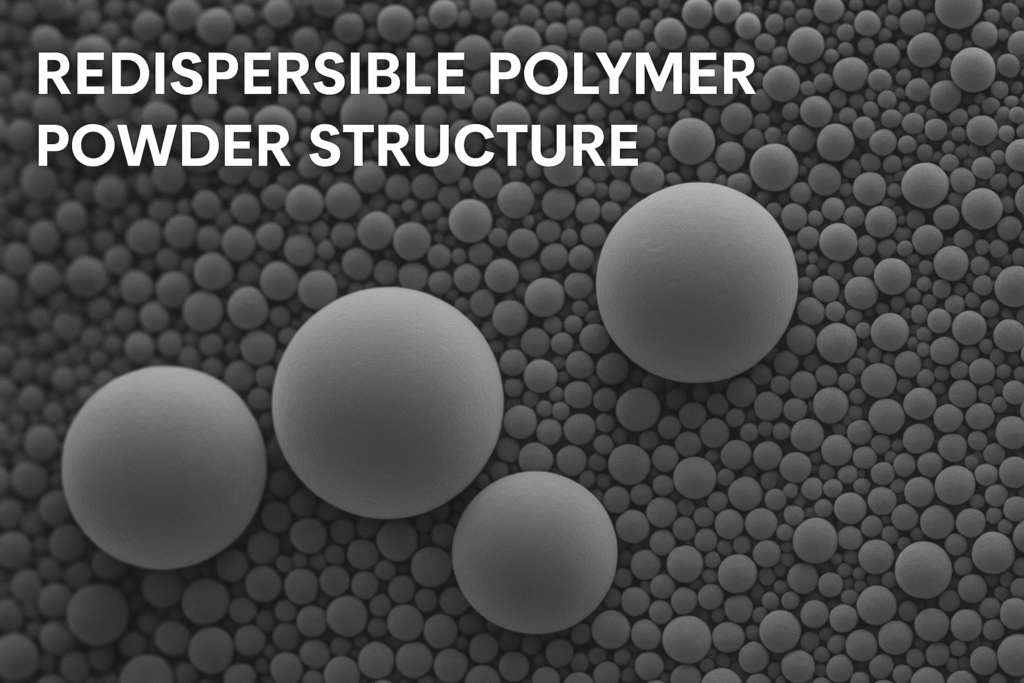

RDP works through a fascinating process I've seen firsthand in our labs. When water is added to dry mortar containing RDP, the polymer particles disperse and form a latex emulsion similar to its original state before drying. As water evaporates from the mortar, these polymer particles form an interconnected film network throughout the cement matrix.

This film formation is critical - it creates polymer bridges between cement particles and aggregates. During my factory tours with customers, I demonstrate this by comparing the microstructure of standard cement mortar with RDP-modified mortar under a microscope. The difference is remarkable!

The polymer film doesn't just sit between cement particles; it actively interacts with them in what we call the "polymer-cement co-matrix." This structure combines the rigidity and compressive strength of cement with the flexibility and adhesive properties of polymers.

Different RDP formulations serve specific purposes. For example, our VAE (vinyl acetate-ethylene) copolymers provide excellent balance between cost and performance, while our acrylic-modified versions offer superior water and alkali resistance for bathroom and exterior applications.

Benefits of Redispersible Polymer Powder in Fresh Mortar

I've watched skilled tilers struggle with difficult-to-spread adhesives. Poor workability leads to inconsistent coverage, weak spots, and tiles that eventually come loose – problems that could have been easily prevented.

RDP dramatically improves fresh mortar workability by acting as a lubricant between particles, increasing open time (the period when adhesive remains workable), enhancing water retention to prevent premature drying, and reducing slump to help tiles stay in place during installation.

During my demonstrations for customers at our KEHAO2 testing facility, I often conduct side-by-side comparisons that clearly showcase these benefits. When we add our RDP to a standard cement mix, the transformation in handling properties is immediate and obvious.

The air-entraining effect of RDP creates microscopic bubbles that act like tiny ball bearings between cement particles. This significantly reduces internal friction, making the mortar smoother and more buttery under the trowel. Tilers can cover more area with less effort, and the mortar spreads more evenly across the substrate.

Water retention is another critical factor, especially in hot or dry environments. Regular mortar can lose water quickly, reducing open time and creating weak bonds. Our RDP forms a protective film that slows water evaporation from the fresh mix. In our tests, mortar with 3% KEHAO2 RDP shows up to 65% better water retention than unmodified mortar.

| Property | Without RDP | With KEHAO RDP |

|---|---|---|

| Open time | 10-15 minutes | 20-30 minutes |

| Water retention | Poor (40-50%) | Excellent (75-90%) |

| Slip resistance | Low | High |

| Workability | Stiff, difficult to spread | Smooth, buttery consistency |

This extended open time is crucial on large jobs, allowing installers to apply adhesive over larger areas without worrying about premature skinning or drying. The anti-sagging properties are equally important for wall applications, preventing heavy tiles from sliding downward during setting.

Performance of RDP in Hardened Mortar

I've investigated countless tile failure cases where bonding problems caused expensive damage. In almost every case, insufficient polymer modification was the root cause of adhesion failure, especially on difficult substrates.

RDP significantly enhances hardened mortar properties by increasing tensile and flexural strength, improving adhesion to difficult substrates like glass and metal, providing crucial crack resistance during substrate movements, and enhancing water resistance to prevent moisture damage.

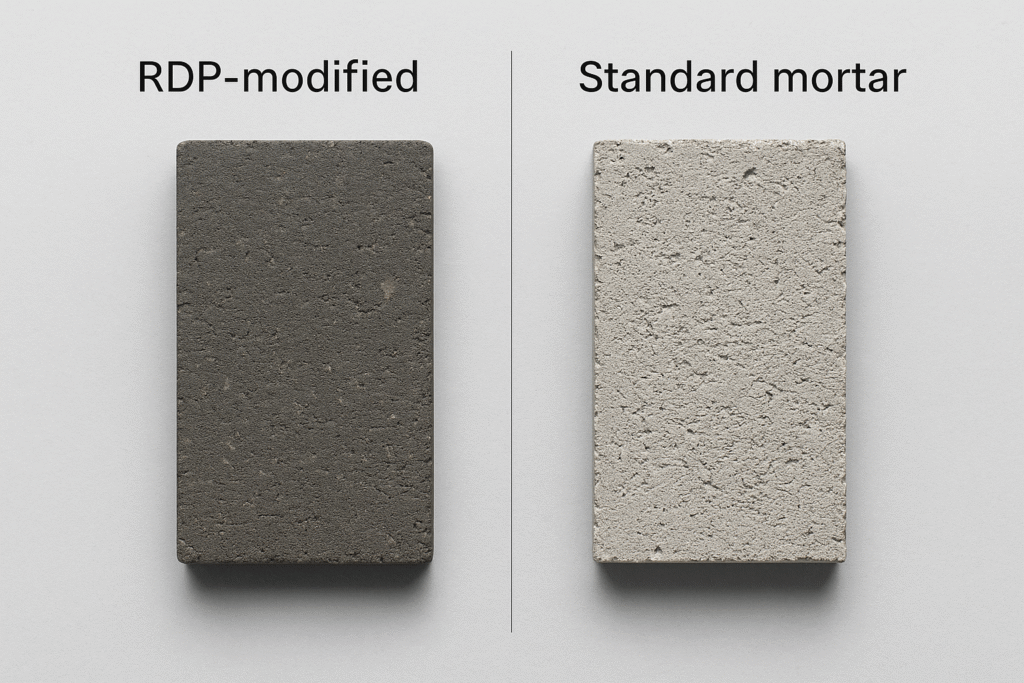

The performance enhancements of RDP in hardened mortar are truly remarkable. During factory demonstrations, I often conduct a simple but dramatic test: I prepare two identical tile installations - one with standard mortar and one with our KEHAO RDP-modified mortar. After curing, we apply progressive force until failure. The difference is striking.

The polymer film formed by our RDP creates strong adhesive bonds not just between the mortar and tile, but within the mortar matrix itself. This three-dimensional reinforcement dramatically increases tensile strength - typically by 30-50% compared to unmodified mortars. This is crucial because while cement has excellent compressive strength, it's relatively weak under tension.

Flexibility is another critical improvement. Traditional cement mortars are rigid and prone to cracking when subjected to structural movements, temperature fluctuations, or vibrations. Our RDP creates elasticity within the mortar that allows it to absorb these movements without fracturing. This flexibility is measured by deformation under load, and our premium RDP can increase this parameter by up to 200%.

| Property | Standard Mortar | KEHAO RDP-Modified Mortar |

|---|---|---|

| Adhesive strength (MPa) | 0.5-0.8 | 1.5-2.0 |

| Flexural strength (MPa) | 3-4 | 5-7 |

| Deformation capability | Very limited | Moderate to high |

| Water absorption (%) | 10-12 | 3-5 |

Water resistance is particularly important in wet areas like bathrooms and exteriors. The hydrophobic properties of certain polymers in our RDP formulations significantly reduce water absorption, protecting both the adhesive layer and the substrate from moisture damage. In our laboratory tests, RDP-modified mortars show water absorption reduction of 60-70% compared to standard mortars.

Application in Flexible Tile Adhesives

Many projects I've consulted on involve challenging installations – large-format tiles on heated floors, porcelain on existing tile, or exterior facades exposed to extreme weather. Standard adhesives fail quickly in these demanding situations.

Flexible tile adhesives require high RDP content (3-5%) to accommodate substrate movement, thermal expansion, and vibration. These premium formulations are essential for large-format tiles, exterior applications, heated floors, and installations over problematic substrates like wood or existing tile.

The development of truly flexible tile adhesives represents one of the most significant advancements in modern tiling technology. During my visits to major construction projects, I've seen firsthand how these specialized adhesives solve problems that would have been nearly impossible to address a decade ago.

Flexible adhesives typically contain higher percentages of our KEHAO RDP - usually between 3-5% of the total dry mix weight, compared to 1-2% in standard formulations. This increased polymer content creates exceptional deformability measured as "S-class" according to international standards. Class S1 adhesives can deform ≥2.5mm under standardized testing, while S2 (highly deformable) adhesives reach ≥5mm.

The importance of these properties becomes evident when dealing with thermal expansion. Consider a heated floor installation: as the floor heating cycles on and off, the substrate expands and contracts. Without sufficient flexibility in the adhesive layer, tiles will eventually crack or debond. Our high-performance RDP provides the critical elasticity needed to absorb these dimensional changes.

| Application | Challenges | RDP Content Needed | Benefits |

|---|---|---|---|

| Large format tiles (>60cm) | Greater stress from dimensional changes | 3-4% | Prevents cracking, accommodates movement |

| Exterior facades | Temperature extremes, freeze-thaw cycles | 4-5% | Withstands thermal shock, prevents water damage |

| Heated floors | Constant expansion/contraction | 3-4% | Absorbs movement, prevents delamination |

| Non-porous substrates | Poor mechanical bonding | 3-5% | Enhances chemical adhesion |

Another critical application is the installation of new tiles over existing ones. This time-saving approach avoids the mess and expense of removing old tiles, but creates unique challenges. The bond between the new adhesive and the smooth surface of existing tiles is primarily chemical rather than mechanical. Our specially formulated RDP enhances this chemical adhesion3 while providing the flexibility needed to accommodate the different expansion rates of multiple layers.

Why Choose KEHAO2's Redispersible Polymer Powder

I've seen many companies struggle with inconsistent RDP quality that leads to batch variations, application problems, and even product failures. These issues damage reputations and create expensive warranty claims that could have been avoided.

KEHAO produces premium RDP with strict quality control4 across six production lines, offering consistent performance, customizable formulations for specific applications, comprehensive technical support, and reliable logistics to global markets including Saudi Arabia, UAE, India, and Brazil.

When I walk customers through our KEHAO production facilities, they're often amazed by the sophisticated technology behind our RDP manufacturing process. Unlike smaller producers who struggle with batch inconsistencies, our six dedicated production lines operate under stringent quality control protocols that ensure remarkable consistency.

This consistency is critical for formulators and manufacturers. When you're producing thousands of tons of tile adhesive, even slight variations in your RDP can lead to significant performance differences in the final product. Our customers appreciate that KEHAO's products deliver the same performance parameters batch after batch, allowing them to maintain their own quality standards.

Our technical expertise extends beyond just manufacturing. Our R&D team specializes in customizing RDP formulations for specific applications and regional requirements. For instance, we've developed specialized grades for markets with extreme climate conditions like Saudi Arabia and the UAE, where temperatures can fluctuate dramatically between day and night.

| KEHAO RDP Advantage | Customer Benefit |

|---|---|

| Six dedicated production lines | Consistent supply, even during peak demand |

| ISO-certified quality control | Predictable performance in formulations |

| Application-specific grades | Optimized performance for different tile adhesives |

| Technical support team | Formulation assistance and troubleshooting |

| Flexible packaging options | Bulk bags or customized packaging |

Our logistics capabilities are especially valuable for international customers. With regular shipments to Saudi Arabia, UAE, Iran, India, Pakistan, Brazil, Mexico, Georgia, Sri Lanka, Singapore, Philippines, and Vietnam, we understand the complexities of international trade. We handle all documentation requirements, offer flexible payment terms, and ensure timely delivery.

Additionally, we provide comprehensive technical documentation, including detailed product specifications, safety data sheets in multiple languages, and application guidelines. Many customers also benefit from our formulation recommendations specific to local raw materials and regional requirements.

When you choose KEHAO2, you're not just buying a chemical product - you're partnering with experts committed to your success. Our technical team is available for consultation throughout your product development process, helping you create tile adhesives that meet or exceed local standards while optimizing your production costs.

Conclusion

RDP transforms ordinary tile adhesives into high-performance products by enhancing workability, adhesion, flexibility and water resistance. KEHAO's premium RDP, backed by consistent quality and technical support, helps manufacturers create reliable tile adhesives for today's demanding applications.

-

Explore how RDP enhances tile adhesive performance, ensuring durability and flexibility. ↩ ↩

-

Learn about KEHAO's commitment to quality and innovation in tile adhesive solutions. ↩ ↩ ↩ ↩

-

Understanding chemical adhesion can improve your installation techniques and outcomes. ↩

-

Learn why consistent quality is crucial for reliable tile adhesive products. ↩