Are your latex paints experiencing stability issues, poor thickness control, or application problems? These common paint challenges can frustrate manufacturers and end-users alike, significantly impacting product performance and customer satisfaction.

Hydroxyethyl cellulose (HEC)1 is a critical additive in latex paints that functions as a thickener, water retention agent, and stabilizer. It improves paint consistency, prevents sagging during application, extends working time by slowing water evaporation, and enhances the overall stability of the paint formulation.

Understanding HEC's role in paint formulations can transform your product quality. I've worked with numerous paint manufacturers across Saudi Arabia, UAE, and other countries who have significantly improved their paint performance by optimizing their HEC usage. Let me share what I've learned about this essential ingredient.

What Makes Hydroxyethyl Cellulose Essential for Latex Paint Formulations?

Are you wondering why nearly every quality latex paint contains HEC? Paint formulators face constant challenges balancing viscosity, stability, and application properties while keeping costs manageable.

Hydroxyethyl cellulose serves as a multifunctional additive in latex paints, providing thickening, suspension, stabilization, and water retention properties. Its non-ionic nature ensures compatibility with other paint components while its water solubility makes it ideal for waterborne systems without affecting the paint's finish quality.

The importance of HEC in paint formulations cannot be overstated. In my years working with paint manufacturers, I've seen firsthand how this versatile cellulose ether transforms paint properties. HEC creates a three-dimensional network within the paint system that provides crucial rheological properties. This network suspends pigments and prevents settling during storage, ensuring your paint maintains consistent quality over time.

HEC also significantly affects paint application behavior. The pseudoplastic (shear-thinning) nature of HEC solutions means the paint flows easily during brushing or rolling but quickly regains viscosity when at rest. This prevents undesirable dripping and sagging on vertical surfaces. Additionally, HEC enhances the paint's leveling characteristics, helping to eliminate brush marks for a smoother finish.

Water retention is another critical function of HEC. In hot or dry conditions, paint can dry too quickly, leading to application problems and poor film formation. HEC's hygroscopic nature slows water evaporation, extending working time and improving film coalescence.

| HEC Function | Benefit to Paint |

|---|---|

| Thickening | Controls viscosity and provides proper consistency |

| Suspension | Prevents pigment settling and separation |

| Water Retention | Extends open time and improves application |

| Stabilization | Enhances shelf life and freeze-thaw stability |

| Flow Control | Improves leveling and reduces sags/runs |

How Does HEC Viscosity Grade Affect Latex Paint Performance?

Have you tried different HEC grades in your paint formulations only to get inconsistent results? The selection of the right viscosity grade can make the dramatic difference between a premium paint and an average one.

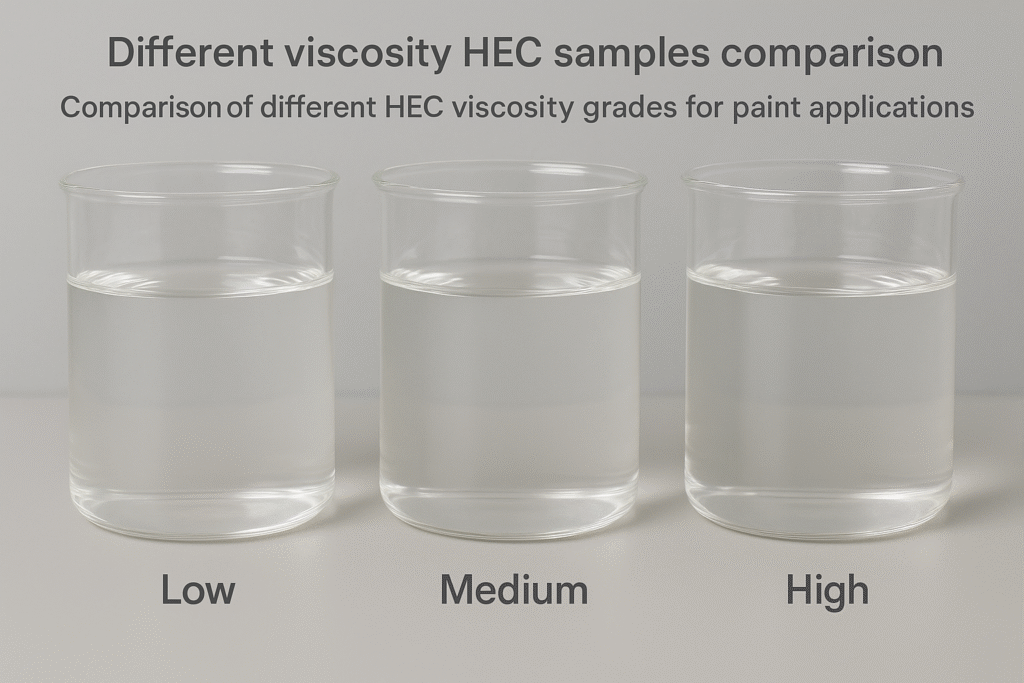

HEC viscosity grade2 directly influences paint thickness, application properties, and stability. Low-viscosity grades (30,000-60,000 mPa·s) provide good flow and leveling, medium grades (80,000-120,000 mPa·s) balance flow with sag resistance, while high-viscosity grades (150,000+ mPa·s) offer excellent thickening power and suspension properties.

The viscosity grade of HEC is arguably the most important specification when formulating latex paints. Based on my experience working with various paint manufacturers, I've observed that selecting the appropriate HEC viscosity grade requires careful consideration of the paint's intended use and desired properties.

Low-viscosity HEC grades like our KEHAO HEC-30000 and HEC-50000 products are excellent for primers and flat paints where enhanced flow and substrate penetration are priorities. These grades provide good thickening at lower concentrations while maintaining excellent flow characteristics. They're particularly valuable in formulations where a balance of cost-effectiveness and basic thickening is needed.

Medium-viscosity grades such as KEHAO HEC-100000 represent the most versatile option. They offer an optimal balance of thickening efficiency, anti-sag properties, and good flow. These grades are my most recommended starting point for most latex paint formulations, especially semi-gloss and eggshell finishes where both application ease and finish quality are important.

High-viscosity HEC grades like KEHAO HEC-150000 and HEC-200000 provide maximum thickening power and excellent suspension properties. I often recommend these for high-build paints, textured finishes, and premium quality paints where superior pigment suspension and sag resistance are critical. These grades are also excellent for spray applications where high viscosity at rest but good atomization under shear is required.

| HEC Viscosity Grade | Recommended Paint Types | Key Benefits |

|---|---|---|

| Low (30,000-60,000 mPa·s) | Primers, Flat/Matte Paints | Better flow, Good penetration, Economic usage |

| Medium (80,000-120,000 mPa·s) | Semi-gloss, Eggshell, General Purpose | Balanced properties, Good leveling, Versatile |

| High (150,000+ mPa·s) | High-build, Textured, Premium Paints | Superior sag resistance, Excellent suspension, High thickening power |

What Makes KEHAO HEC Products Ideal for Latex Paint Applications?

Are you struggling with inconsistent paint quality due to varying additive performance? Finding a reliable HEC supplier can eliminate many formulation headaches, but how do you identify truly superior products?

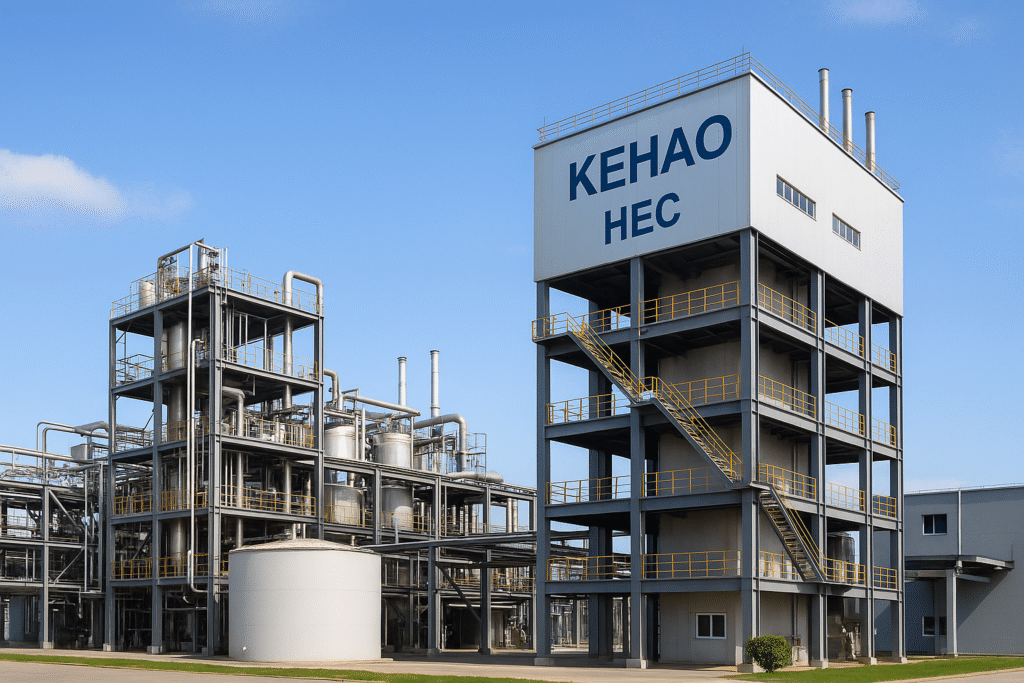

KEHAO HEC products3 offer consistent viscosity between batches, excellent compatibility with latex emulsions, enhanced biostability, and optimized particle size for quick dissolution. Our specialized grades for paint applications undergo rigorous quality control to ensure they meet precise specification requirements for viscosity, substitution degree, and purity.

At KEHAO, we've developed our HEC product line specifically to address the challenges faced by paint manufacturers. Through my interactions with customers across Saudi Arabia, UAE, Iran, India, and other markets, I've gathered valuable feedback that has helped us refine our products to meet specific regional requirements.

Our HEC manufacturing process employs advanced technology that ensures molecular weight consistency between production batches. This translates to predictable viscosity performance in your paint formulations, eliminating the need for constant reformulation adjustments. During my visits to customer facilities, many have commented that this consistency is what makes KEHAO HEC their preferred choice.

Paint stability often depends on the compatibility between the cellulose ether and the latex emulsion. KEHAO HEC products3 are engineered with an optimized degree of substitution that enhances compatibility with various acrylic and styrene-acrylic emulsions commonly used in paint formulations. This reduces the risk of flocculation and other stability issues that can plague paint during storage.

Another advantage of KEHAO HEC is our specialized bio-stable grades for paint applications. Traditional cellulose ethers can be susceptible to enzymatic degradation, leading to viscosity loss during storage. Our bio-stable grades incorporate advanced enzyme resistance technology without sacrificing performance or increasing formulation complexity.

| KEHAO HEC Grade | Viscosity (2% solution) | Recommended Paint Applications |

|---|---|---|

| KEHAO HEC-30000 | 30,000-40,000 mPa·s | Primers, Economical flat paints |

| KEHAO HEC-50000 | 50,000-60,000 mPa·s | Interior flat paints, General purpose |

| KEHAO HEC-100000 | 90,000-110,000 mPa·s | Semi-gloss, Eggshell, Most popular grade |

| KEHAO HEC-150000 | 140,000-160,000 mPa·s | Premium paints, Better sag resistance |

| KEHAO HEC-200000 | 190,000-210,000 mPa·s | High-build formulations, Textured finishes |

Conclusion

HEC is a vital component in latex paint formulations, providing critical thickening, stabilization, and application properties. By selecting the right KEHAO HEC grade for your specific paint requirements, you can achieve optimal performance while maintaining cost efficiency.