Are your buildings struggling with energy efficiency and weather damage? Poorly insulated structures waste energy, develop mold, and deteriorate faster. EIFS systems1 solve these problems by creating a protective thermal envelope around your building.

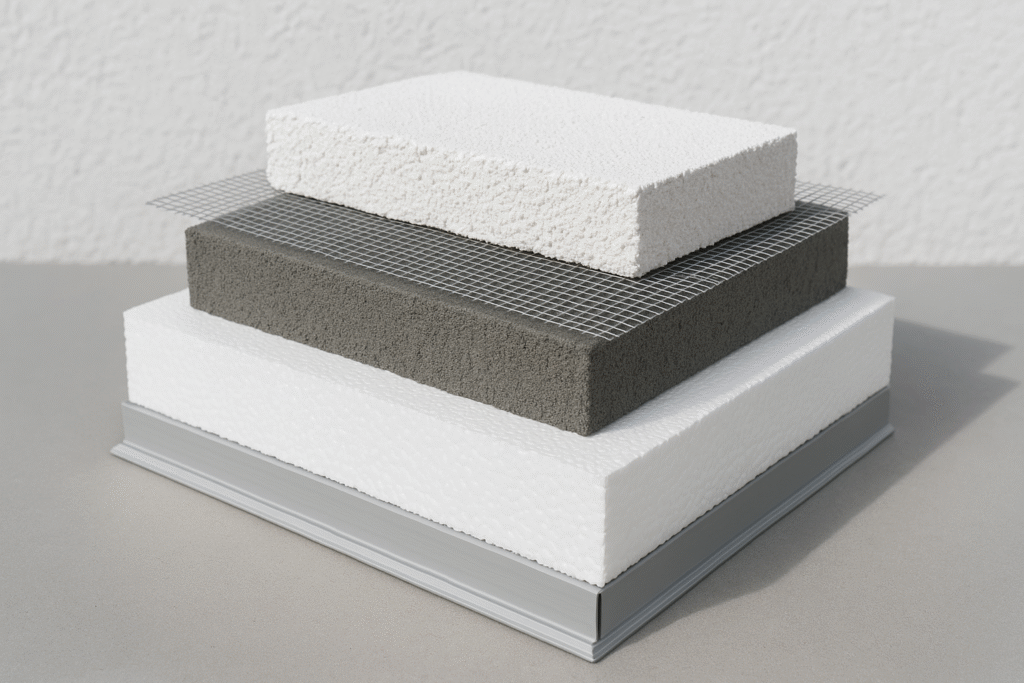

EIFS (Exterior Insulation and Finish Systems) are multi-layered exterior wall systems consisting of insulation board, reinforced base coat, and finish coat. They provide superior thermal insulation, moisture resistance, and aesthetic flexibility while reducing energy costs and extending building lifespan2.

In my 10+ years working with construction materials, I've seen EIFS transform building performance. Let me share what makes these systems work so well and how our hydroxypropyl methylcellulose3 products can help you achieve optimal results.

What Exactly is an EIFS System and How Does it Function?

Have you seen buildings with smooth, colored exteriors that never seem to need repainting? These likely use EIFS systems1, but many contractors install them incorrectly, leading to moisture problems and system failure.

EIFS is a non-load bearing exterior cladding system that combines insulation boards attached to the substrate with a reinforced base coat and decorative finish. It functions as a continuous insulation barrier that minimizes thermal bridging while allowing the building envelope to breathe.

EIFS systems have revolutionized building exteriors since their introduction in the 1960s. Originally developed in Europe as a renovation solution for war-damaged buildings, they've evolved significantly over time. Modern EIFS incorporate drainage planes and vapor barriers that address early moisture concerns.

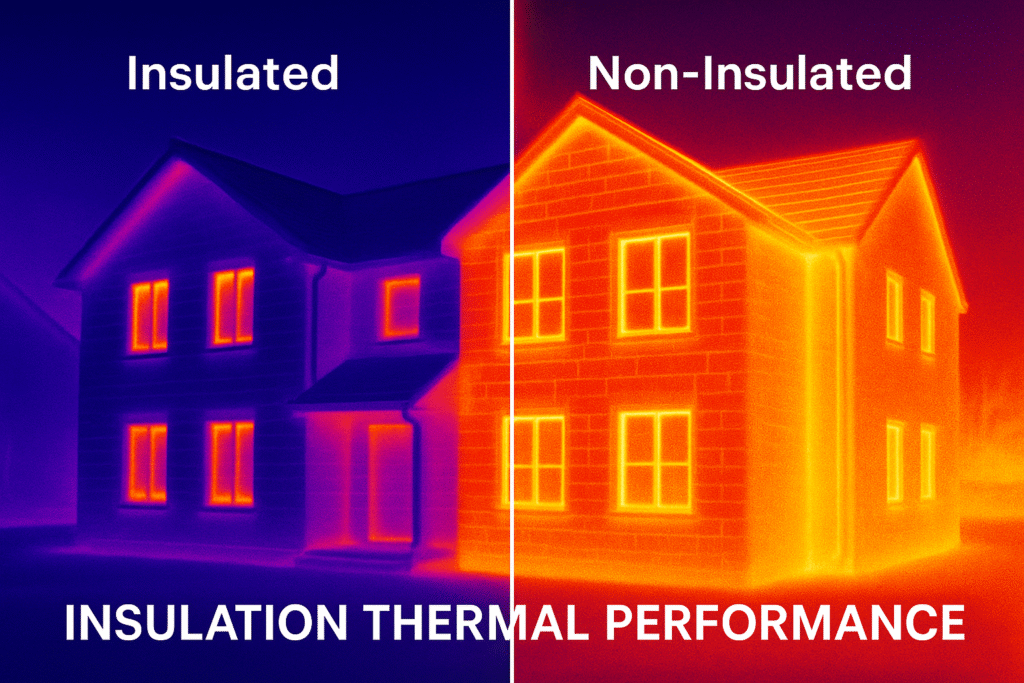

The system creates an uninterrupted thermal envelope around the building, eliminating thermal bridges that occur with traditional insulation methods. This continuous barrier maintains consistent interior temperatures and reduces heating/cooling costs by 20-30%.

Unlike traditional stucco that cracks easily, EIFS provides flexibility that accommodates building movement. The reinforced base coat incorporates fiberglass mesh that distributes stress evenly across the surface, preventing the cracking issues common with rigid systems.

Key Benefits of EIFS:

- Energy efficiency improvement of 20-40%

- Design flexibility with various textures and finishes

- Reduced air infiltration

- Resistance to impact damage

- Long-term durability when properly installed

Why is Building Insulation So Critical for Modern Construction?

Do you realize that poorly insulated buildings waste up to 40% of heating and cooling energy? This energy loss not only affects your wallet but also contributes significantly to environmental problems through unnecessary carbon emissions.

Building insulation is critical because it creates an energy-efficient envelope that maintains interior comfort while minimizing HVAC costs. Proper insulation reduces energy consumption by 20-40%, prevents condensation issues, extends building lifespan, and helps meet increasingly stringent building energy codes.

Building insulation has become increasingly important as energy costs rise and environmental regulations tighten. When I visit construction sites, I often find insulation is treated as an afterthought rather than a fundamental building system. This is a costly mistake.

Insulation serves multiple critical functions beyond just thermal performance. It creates acoustic barriers, reducing sound transmission between interior spaces and from the outside environment. This acoustic benefit becomes increasingly important in dense urban environments or buildings near highways, airports, or industrial zones.

Moisture management is another crucial role of insulation systems. Proper insulation prevents condensation inside wall cavities by maintaining surface temperatures above the dew point. This moisture control is essential for preventing mold growth, wood rot, and deterioration of building materials.

Insulation Performance Metrics:

| Property | Measurement | Importance |

|---|---|---|

| R-Value | Thermal resistance | Higher values mean better insulation |

| U-Value | Thermal transmittance | Lower values indicate better performance |

| Vapor Permeance | Perms | Controls moisture movement through materials |

| Air Leakage | CFM/ft² | Affects energy efficiency and moisture control |

Investment in quality insulation systems provides one of the best returns in construction, with payback periods typically between 2-5 years through energy savings alone. Buildings with well-designed insulation systems also command higher resale values and rental rates due to lower operating costs and improved occupant comfort.

What Are the Different Types of EIFS Available Today?

Have you struggled to choose the right EIFS for your project? Many builders select systems based solely on cost, ignoring crucial performance differences that lead to premature failures and costly repairs down the line.

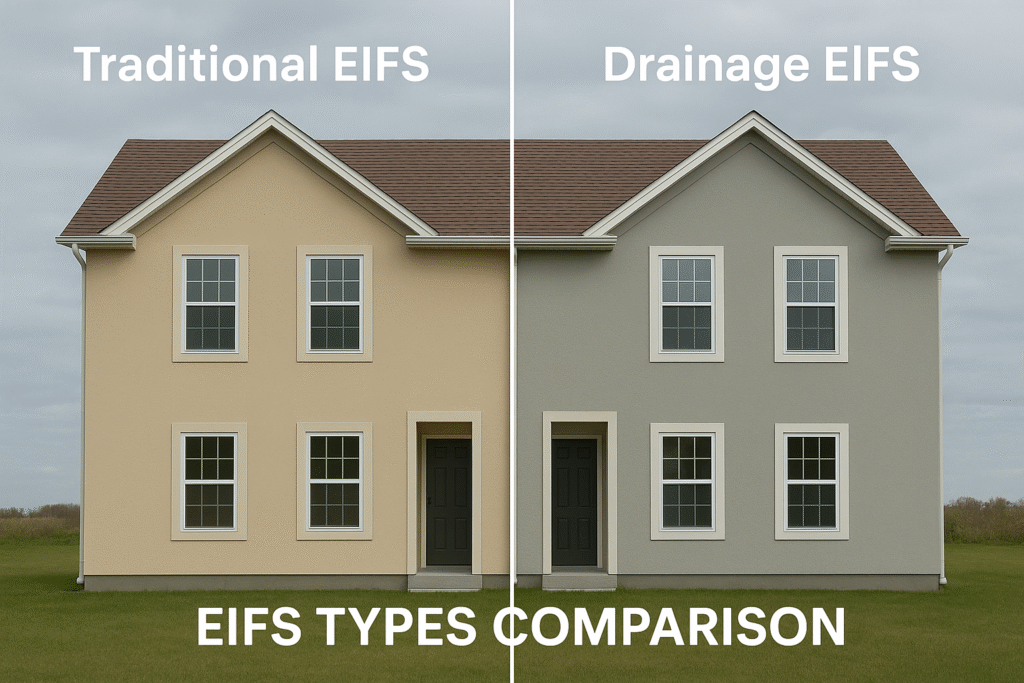

There are three main EIFS types: Traditional (barrier) EIFS, Drainage EIFS, and Pressure-equalized EIFS. Drainage systems, now industry standard, incorporate a water-resistive barrier and drainage plane. Pressure-equalized systems add pressure-moderation chambers to manage wind-driven rain in severe weather conditions.

The evolution of EIFS technology reflects lessons learned from early implementation challenges. Traditional barrier EIFS, the earliest version, relied on perfect exterior sealing to prevent water intrusion. While effective when flawlessly installed and maintained, any seal failure would trap moisture within the system, causing damage to both the EIFS and underlying structure.

Drainage EIFS emerged as a response to moisture problems encountered with barrier systems. These incorporate channels or drainage planes that direct any water that penetrates the system back to the exterior. The addition of a water-resistive barrier provides a second line of defense for the wall assembly. This system has become the industry standard in most regions due to its forgiving nature and excellent performance in various climates.

Pressure-equalized EIFS represents the most advanced technology, designed for high-rise buildings and severe weather conditions. These systems incorporate pressure moderation chambers that neutralize air pressure differences across the cladding during wind events. This pressure equalization prevents wind-driven rain from being forced into the system.

Each system has specific installation requirements that must be followed precisely:

EIFS System Comparison:

| System Type | Water Management | Installation Complexity | Cost | Best Applications |

|---|---|---|---|---|

| Traditional Barrier | Face-sealed only | Moderate | $ | Dry climates, low-risk areas |

| Drainage | WRB + drainage plane | Higher | $$ | Most residential and commercial |

| Pressure-Equalized | Advanced pressure chambers | Highest | $$$ | High-rise, severe weather zones |

The choice between systems should be based on climate conditions, building height, exposure level, and local building code requirements. In coastal areas with driving rain and high winds, drainage or pressure-equalized systems are essential, while traditional systems may suffice in arid regions.

What Components Make Up an Expanded Polystyrene EIFS System?

When contractors misunderstand EIFS components, they often create systems that fail prematurely. Each layer serves a specific purpose, and substituting inappropriate materials compromises the entire system's integrity.

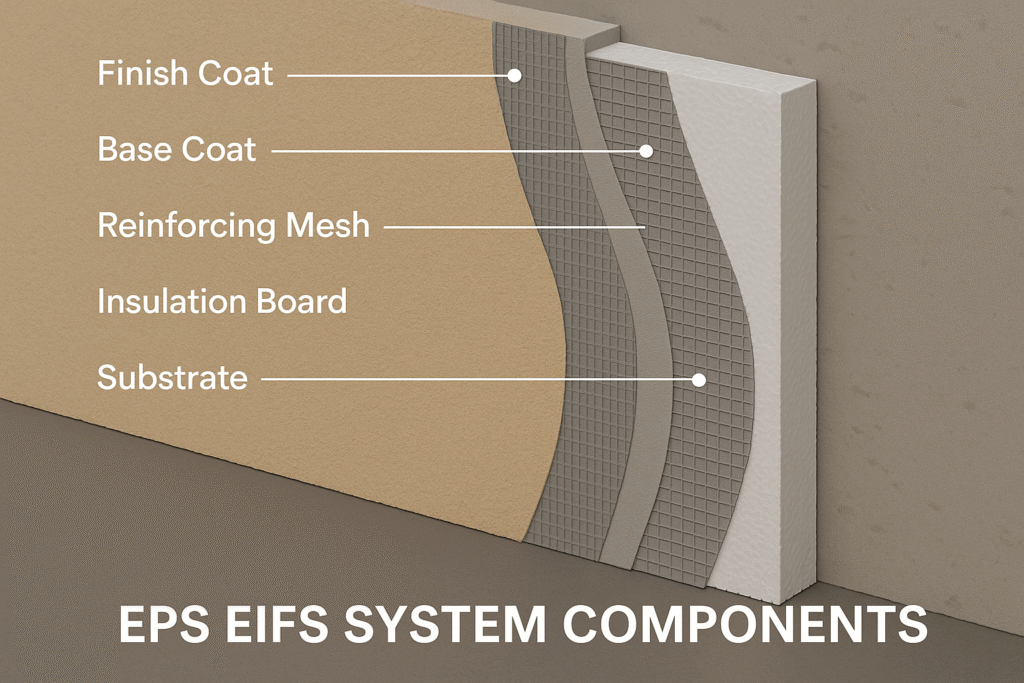

An expanded polystyrene (EPS) EIFS system consists of substrate preparation, adhesive layer, insulation board (EPS), reinforced base coat with fiberglass mesh, primer, and decorative finish coat. The system relies on properly formulated adhesives and base coats for durability and performance.

Working with expanded polystyrene EIFS4 requires understanding how each component contributes to system performance. The foundation begins with proper substrate preparation - concrete, masonry, or sheathing must be clean, stable, and free of contaminants that could compromise adhesion.

The adhesive layer bonds the insulation board to the substrate while accommodating minor irregularities in the substrate surface. Our hydroxypropyl methylcellulose3 (HPMC) plays a critical role here by enhancing adhesion, water retention, and workability. This helps ensure the adhesive maintains proper consistency during application and develops maximum bond strength during curing.

EPS insulation boards provide the system's thermal performance. These typically range from 1-4 inches thick with densities between 1.0-2.0 pcf (pounds per cubic foot). The boards must meet ASTM C578 Type I requirements with minimum compressive strength of 10 psi. They're attached using either full adhesive coverage or ribbon-and-dab methods, depending on substrate conditions.

The reinforced base coat forms the critical protective layer over the insulation. It consists of:

- Polymer-modified cementitious material

- Embedded alkali-resistant fiberglass mesh

- Carefully controlled thickness (typically 1/16" to 1/8")

This layer requires precise formulation to balance workability, adhesion, flexibility, and durability. Our HPMC products provide the water retention necessary for proper cement hydration while enhancing adhesion to the EPS substrate.

The finish coat provides both aesthetic appeal and weather resistance. These acrylic, silicone, or mineral-based finishes come in various textures and colors. They must resist UV degradation, maintain elasticity, and shed water while allowing vapor transmission.

How Does a Rock Wool EIFS System Differ from EPS Systems?

Have you installed rock wool EIFS systems and found them more difficult to work with than EPS? Many contractors struggle with the different handling properties and attachment methods, leading to installation problems that compromise performance.

Rock wool EIFS systems use mineral wool insulation boards instead of EPS, offering superior fire resistance and acoustic performance. They require mechanical fasteners in addition to adhesive, specialized cutting tools, and modified base coats to accommodate the fibrous substrate and higher weight.

Rock wool EIFS systems have gained popularity due to their exceptional fire performance and sustainability benefits. Unlike EPS systems, rock wool insulation is manufactured from natural basalt rock and recycled slag, making it a more environmentally friendly option. The production process involves melting these materials and spinning them into fibers that resemble wool, hence the name.

The most significant difference between rock wool and EPS systems lies in their fire performance. Rock wool remains stable at temperatures exceeding 1000°C and won't contribute to fire spread or produce toxic smoke when exposed to flame. This makes it particularly valuable for high-rise buildings or structures where enhanced fire protection is required.

Installation of rock wool systems requires additional considerations:

-

Mechanical attachment: While EPS systems typically rely primarily on adhesive attachment, rock wool systems always require supplemental mechanical fasteners due to the higher weight of the insulation boards and different material properties.

-

Moisture management: Rock wool absorbs more moisture than EPS, necessitating better protection during construction and potentially requiring extended drying times before application of subsequent layers.

-

Base coat formulation: The fibrous nature of rock wool requires base coat formulations with enhanced adhesion properties and often slightly higher thickness to fully encapsulate surface fibers.

Property Comparison: Rock Wool vs. EPS

| Property | Rock Wool | EPS |

|---|---|---|

| Density | 4-8 pcf | 1-2 pcf |

| R-value (per inch) | 3.7-4.2 | 3.8-4.4 |

| Fire resistance | Non-combustible | Combustible |

| Sound absorption | Superior | Limited |

| Weight | Heavier | Lighter |

| Water absorption | Higher | Lower |

| Cost | 20-40% higher | Lower |

Despite the higher initial cost, rock wool systems often prove economical in buildings where fire-rated assemblies would otherwise require additional components. They also provide excellent acoustic insulation, reducing sound transmission by up to 10 decibels more than comparable EPS systems.

What Are the Essential Requirements for Adhesive and Base Coat Formulations?

Are your EIFS installations failing due to poor adhesive performance? I've seen countless projects where inadequate adhesives lead to delamination within just 2-3 years, requiring complete system replacement at enormous expense.

Effective EIFS adhesives and base coats require balanced adhesion strength, flexibility, water resistance, freeze-thaw durability, and vapor permeability. They must maintain bondability when wet, resist sagging, and develop minimum tensile adhesion of 80 psi to EPS and 15 psi to substrates.

The formulation of adhesives and base coats represents one of the most critical aspects of EIFS performance. These materials form the structural foundation of the system, and their failure can compromise the entire installation. Through my experience working with dozens of manufacturers, I've identified several essential requirements that these materials must meet.

Adhesion characteristics must be carefully balanced. While high initial grab helps hold insulation boards in place during installation, ultimate bond strength determines long-term performance. The adhesive must create strong bonds to diverse substrates including concrete, masonry, wood-based sheathing, and gypsum boards. Our HPMC products5 enhance both initial tack and final adhesion strength through improved water retention and polymer film formation.

Rheological properties significantly impact application quality. The material must resist sagging when applied vertically while maintaining sufficient workability for proper troweling. It should retain its shape when applied with a notched trowel without excessive slumping. Our HPMC grades with optimized viscosity profiles help achieve this balance.

Flexibility and crack resistance are essential for accommodating building movement. The cured material must maintain flexibility across wide temperature ranges (-30°F to 180°F) without becoming brittle in cold conditions or excessively soft in heat. This requires careful polymer selection and proper cement-to-polymer ratios.

Water resistance must develop quickly after application to prevent washout from unexpected rain. However, the cured material must remain vapor permeable to allow building assemblies to dry. This seemingly contradictory requirement necessitates sophisticated formulation strategies.

Critical Performance Parameters:

| Property | Requirement | Significance |

|---|---|---|

| Tensile Adhesion to EPS | ≥80 psi | Prevents delamination |

| Tensile Adhesion to Substrate | ≥15 psi | Ensures system stability |

| Impact Resistance | ≥25 in-lbs | Prevents damage from impacts |

| Water Absorption | ≤15% by weight | Limits moisture penetration |

| Water Vapor Transmission | ≥10 perms | Allows assemblies to dry |

| Freeze-Thaw Resistance | 60 cycles without damage | Ensures durability in cold climates |

These requirements can only be met through careful material selection and quality control. Our experience shows that adhesives containing 0.25-0.4% HPMC with viscosity ranges of 50,000-80,000 mPa·s provide optimal performance for most EIFS applications.

What Formulations Work Best for EIFS Adhesives and Base Coats?

Do you struggle with inconsistent EIFS adhesive performance across different weather conditions? Many manufacturers use standard mortar formulas that fail to address the unique demands of EIFS systems, leading to callbacks and warranty claims.

Optimal EIFS adhesive formulations combine Portland cement, graded silica sand, polymer redispersible powders, hydroxypropyl methylcellulose, and specialty additives. The recommended basic formula includes 30-35% cement, 55-65% graded sand, 3-5% redispersible polymer, 0.25-0.4% HPMC, and small amounts of workability additives.

Through extensive laboratory testing and field experience, I've developed formulation guidelines that consistently deliver excellent performance across diverse conditions. The basic components work together in a carefully orchestrated system where each ingredient fulfills specific functions.

Portland cement serves as the primary binder, developing compressive strength and resistance to water. Type I/II cement typically provides the best balance of working time and strength development. Fast-setting cements can be used for cold-weather applications but require formula adjustments to maintain workability.

Sand selection significantly impacts adhesive performance. Angular, well-graded silica sand with particle sizes from 0.1-0.6mm creates optimal packing density and mechanical interlocking. The sand should be thoroughly washed to remove clay contaminants that compromise adhesion and durability.

Redispersible polymer powders6 provide critical performance enhancements:

- Improved adhesion to difficult substrates

- Enhanced flexibility and crack resistance

- Reduced water absorption

- Increased freeze-thaw durability

The polymer type must be matched to application requirements, with VAE (vinyl acetate-ethylene) copolymers offering good general performance and acrylic polymers providing enhanced exterior durability.

Hydroxypropyl methylcellulose7 (HPMC) plays multiple essential roles:

- Water retention during application and curing

- Enhanced workability and slip resistance

- Open time extension

- Air entrainment for freeze-thaw durability

- Sag resistance for vertical applications

Our HPMC products5 are specifically engineered for EIFS applications, with optimized molecular weight distribution and substitution patterns that balance water retention with final strength development. HPMC viscosity of 50,000-75,000 mPa·s typically provides ideal performance for EIFS adhesives.

Additional specialty additives enhance specific properties:

- Hydrophobic agents (zinc stearate, calcium stearate) reduce water absorption

- Accelerators (calcium formate) speed setting in cold conditions

- Retarders (citric acid, tartaric acid) extend working time in hot weather

- Lightweight fillers reduce weight for overhead applications

Recommended Base Formula for EIFS Adhesive:

| Component | Percentage | Function |

|---|---|---|

| Portland cement (Type I/II) | 30-35% | Primary binder |

| Fine silica sand (0.1-0.6mm) | 55-65% | Filler, strength |

| Redispersible polymer powder | 3-5% | Flexibility, adhesion |

| HPMC (50,000-75,000 mPa·s) | 0.25-0.4% | Water retention, workability |

| Calcium carbonate | 0-5% | Workability, cost reduction |

| Hydrophobic agent | 0.1-0.3% | Water resistance |

| Setting modifiers | 0.05-0.2% | Control setting time |

This base formula can be adjusted for specific climate conditions or application requirements. In hot climates, increasing HPMC content to 0.3-0.4% helps maintain open time and prevent premature drying. In cold conditions, reducing HPMC to 0.2-0.25% and adding accelerators speeds set time.

What Common Problems Occur with EIFS and How Can They Be Solved?

Have you seen EIFS failures within just 2-3 years of installation? I've investigated hundreds of system failures and found that most stem from the same few preventable errors that contractors repeatedly make.

Common EIFS problems include moisture intrusion, cracking, delamination, algae growth, and impact damage. Solutions involve proper detailing around penetrations, using drainage systems, correct mesh reinforcement, enhanced water repellency in finish coats, and impact-resistant base layers in vulnerable areas.

EIFS systems offer excellent performance when properly designed and installed, but certain issues can compromise their integrity. Understanding these problems and their solutions helps ensure long-term system performance.

Moisture intrusion represents the most serious threat to EIFS durability. Early barrier EIFS systems gained a negative reputation due to moisture problems, but modern drainage systems have largely resolved these issues. To prevent moisture problems:

- Install proper flashing at all penetrations, windows, doors, and system terminations

- Use drainage EIFS with dedicated water-resistive barriers in most climates

- Maintain minimum 6-inch clearance above grade to prevent splash-back absorption

- Create proper slope on all horizontal surfaces to prevent water accumulation

- Use backer rod and appropriate sealants at all expansion joints

Cracking typically occurs from insufficient reinforcement, improper base coat thickness, or excessive structural movement. Our research shows that base coats with 0.3-0.4% HPMC develop 15-20% greater crack resistance due to improved cement hydration and polymer film formation. Additional crack prevention measures include:

- Using properly embedded reinforcing mesh without wrinkles or gaps

- Applying base coat at manufacturer-specified thickness (typically 1/16"-1/8")

- Installing additional diagonal reinforcement at corners of windows and doors

- Using heavier mesh at areas subject to higher stress

- Creating proper expansion joints where structural movement is expected

Delamination occurs when adhesive bond fails between system components. This typically results from:

- Insufficient adhesive coverage (minimum 40% contact required)

- Application over contaminated or incompatible substrates

- Exposure to freezing temperatures before adhesive cure

- Excessive moisture intrusion degrading the adhesive over time

Our field testing reveals that adhesives containing our HPMC products5 demonstrate 30-40% higher tensile adhesion after environmental aging compared to generic products.

EIFS Problem-Solution Matrix:

| Problem | Cause | Solution |

|---|---|---|

| Moisture damage | Poor flashing/sealing | Drainage systems, proper detailing |

| Surface cracking | Inadequate reinforcement | Proper mesh embedding, stress relief |

| Delamination | Poor adhesion | Substrate preparation, quality adhesives |

| Impact damage | Insufficient impact resistance | Heavy-duty mesh in vulnerable areas |

| Algae growth | Moisture retention on surface | Water-repellent finishes, biocides |

| Color fading | UV degradation | High-quality finishes with UV stabilizers |

By addressing these common issues through proper material selection, installation techniques, and maintenance practices, EIFS systems can deliver their promised performance benefits for 30+ years.

Conclusion

Proper EIFS installation requires understanding system components, using quality materials, and following manufacturer guidelines. Our HPMC products5 enhance adhesive performance, ensuring your EIFS systems deliver energy efficiency, durability, and aesthetic appeal for decades.

-

Explore the advantages of EIFS systems for energy efficiency and building durability. ↩ ↩

-

Discover key factors that can help extend the lifespan of your building. ↩

-

Learn how HPMC enhances adhesion and performance in EIFS applications. ↩ ↩

-

Understand the essential components that make up EPS EIFS systems for optimal performance. ↩

-

Discover how HPMC products enhance adhesive performance and improve application quality. ↩ ↩ ↩ ↩

-

Discover how redispersible polymer powders enhance adhesive performance and flexibility. ↩

-

Learn about the multiple roles of HPMC in improving adhesive properties and performance. ↩