Are you tired of slow-setting, crack-prone wall finishes? Conventional plasters often create dusty work environments, waste time, and deliver inconsistent results. Gypsum plaster offers a solution to these persistent construction problems.

Gypsum plaster1 is a versatile finishing material made from calcium sulfate dihydrate (gypsum) that's applied to interior walls and ceilings to create smooth surfaces. It offers superior fire resistance, excellent thermal insulation, faster setting time, and creates healthier indoor environments compared to traditional cement plaster.

As a manufacturer with six production lines of building materials, I've seen firsthand how the right plaster choice impacts everything from construction timelines to the final building quality. Let me guide you through why gypsum plaster has become increasingly popular among contractors and developers worldwide.

What Is Gypsum Plaster and How Does It Differ From Traditional Plaster?

Do you know the material that's revolutionizing interior wall finishes? Many builders struggle with traditional cement plasters that crack, take days to cure, and create dusty, difficult working conditions.

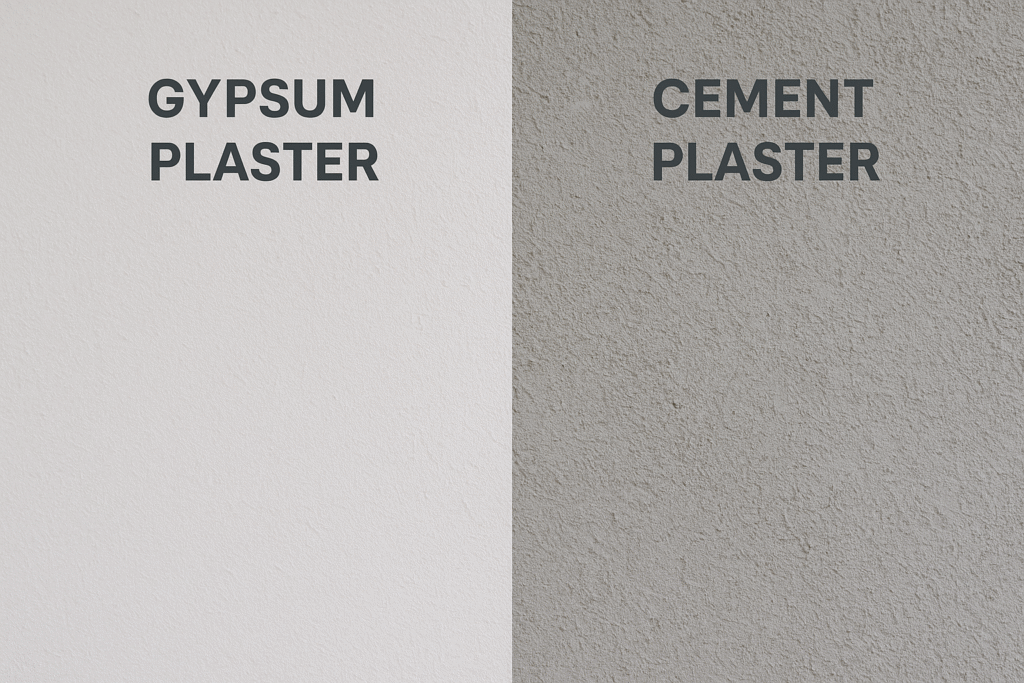

Gypsum plaster is a specialized wall finishing material made from calcined gypsum (calcium sulfate hemihydrate) that, when mixed with water, creates a workable paste that sets into a hard, smooth surface. Unlike cement plaster which contains sand and Portland cement, gypsum plaster offers better workability, faster setting times, and superior finish quality.

Gypsum plaster1 has ancient origins, dating back to Egyptian pyramids and beyond. Today's formulations have evolved significantly while maintaining the core benefits of the natural mineral. Based on my experience supplying HPMC cellulose products that enhance gypsum plaster performance, I can tell you that understanding the differences between plaster types is crucial for construction professionals.

The fundamental distinction lies in composition and performance. Traditional cement plaster consists mainly of Portland cement, sand, and water, creating a rigid, strong but brittle finish. Gypsum plaster, in contrast, contains primarily calcined gypsum with additives like lime and our cellulose products for improved workability.

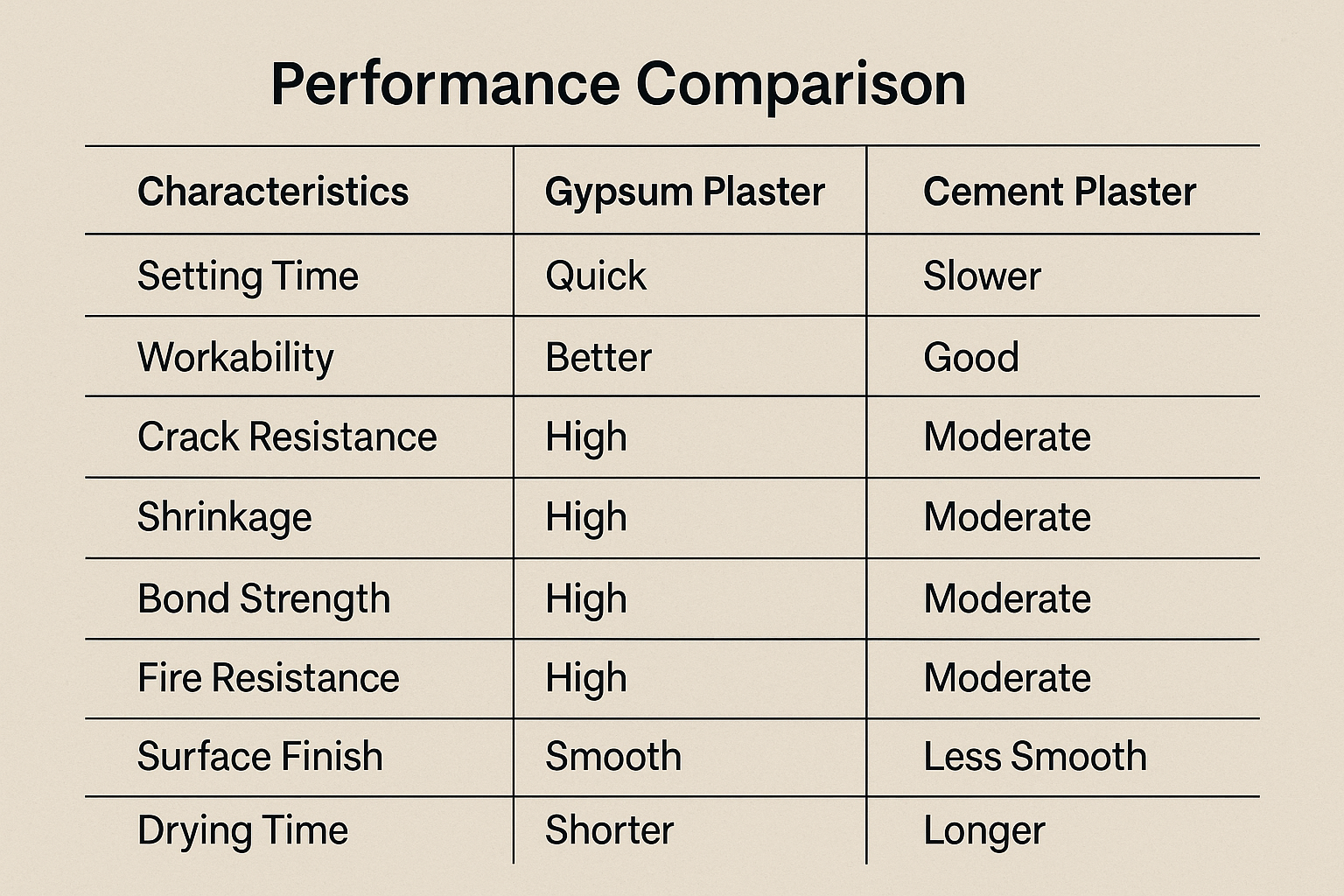

| Feature | Gypsum Plaster | Cement Plaster |

|---|---|---|

| Base Material | Calcium sulfate hemihydrate | Portland cement and sand |

| Setting Time | 30-60 minutes | 24-48 hours |

| Shrinkage | Minimal (0.2-0.3%) | Significant (up to 0.7%) |

| Surface Finish | Very smooth | Relatively rough |

| Workability | Excellent | Good |

| Weight | Lighter | Heavier |

| Environmental Impact | Lower (requires less energy) | Higher |

When I visited construction sites in Saudi Arabia last year, contractors consistently mentioned how gypsum plaster's quick setting time - typically under an hour - dramatically improved their workflow compared to cement plaster's day-long curing process. This time advantage translates directly to cost savings and faster project completion.

What is Gypsum Plaster Commonly Used For in Modern Buildings?

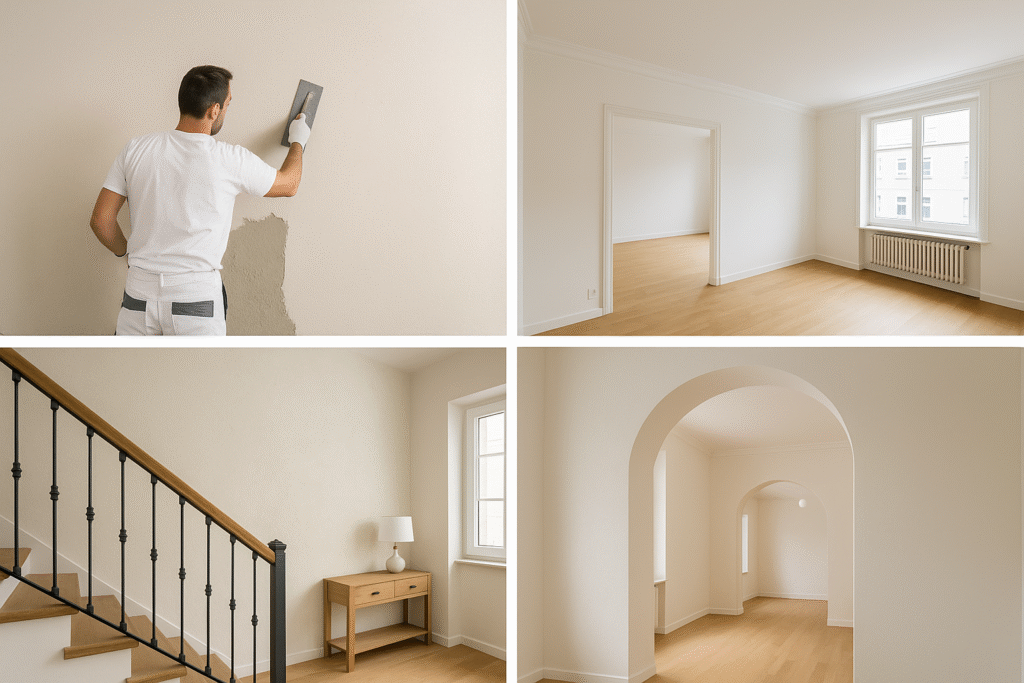

Have you ever wondered why some interior walls look flawlessly smooth while others show every imperfection? The secret often lies in the choice of plaster, with many construction professionals struggling to achieve consistent, high-quality finishes.

Gypsum plaster is primarily used for interior wall and ceiling finishes in residential and commercial construction. It creates smooth surfaces ready for painting, provides acoustic and thermal insulation, offers fire resistance, and works exceptionally well in moisture-controlled environments2 like bedrooms, living rooms, offices, and theaters.

From my decades working with global construction material suppliers, I've witnessed gypsum plaster's versatility across numerous applications. One project in Dubai particularly stands out - a luxury hotel where the interior designer demanded perfectly smooth walls with zero imperfections. Only gypsum plaster could deliver the required finish quality.

The applications of gypsum plaster extend beyond basic wall coating. Modern construction frequently uses specialized gypsum formulations for specific purposes:

Common Applications of Gypsum Plaster

- Interior Wall Finishing: Creates the smooth, paintable surfaces in residential and commercial spaces

- Decorative Moldings: Forms intricate ceiling roses, cornices, and architectural details

- Acoustic Treatment: Specialized acoustic gypsum plasters reduce sound transmission

- Fire Protection: High-performance gypsum plasters provide additional fire resistance to structural elements

- Renovation Work: Ideal for restoring historic buildings and bringing old walls back to life

When working with our clients in developing markets like Pakistan and Iran, we've noticed increasing demand for specialty gypsum plasters that incorporate our HPMC cellulose products. These enhanced formulations offer superior water retention, making them easier to apply even in challenging climate conditions.

| Application | Benefits of Gypsum Plaster | Recommended Additives |

|---|---|---|

| Living Spaces | Thermal regulation, healthy indoor air | Standard HPMC |

| Bathrooms (non-wet areas) | Moisture resistance, mold prevention | Water-resistant HPMC |

| Decorative Work | Extended working time, fine detail capability | Long-open-time HPMC |

| Historic Restoration | Compatibility with traditional materials | Custom formulations |

| Commercial Spaces | Durability, sound dampening | High-viscosity HPMC |

What are the Key Advantages of Gypsum Plaster Over Traditional Options?

Is your construction project falling behind schedule due to slow-setting wall finishes? Many builders face costly delays and quality issues when using traditional cement plasters, impacting timelines and client satisfaction.

Gypsum plaster offers significant advantages including faster setting and drying times (typically 30-60 minutes vs. 24+ hours for cement), better thermal insulation (R-value of 0.5-0.65 per inch), superior fire resistance (up to 4 hours protection), reduced cracking, lighter weight (30-45% lighter), and environmentally friendly production requiring less energy.

Having supplied hydroxypropyl methylcellulose3 to gypsum manufacturers across Saudi Arabia, UAE, and India for over a decade, I've collected countless testimonials about gypsum plaster's advantages. One large-scale housing developer in Riyadh reported completing interior finishing 40% faster after switching to gypsum plaster systems.

The advantages of gypsum plaster extend far beyond just setting time, creating a compelling case for its use in modern construction:

Performance Advantages

Gypsum plaster's thermal regulation properties significantly impact building energy efficiency. With thermal conductivity values between 0.17-0.3 W/mK (compared to cement plaster's 0.72-1.4 W/mK), gypsum-finished rooms maintain more stable temperatures. During summer visits to our clients in Saudi Arabia, I've personally experienced how gypsum-plastered buildings feel noticeably cooler than those with cement finishes.

Fire safety represents another critical advantage. Gypsum contains approximately 21% chemically combined water that releases during fire exposure, absorbing heat energy and slowing fire spread. This provides valuable extra evacuation time in emergency situations. Many building codes now recognize this benefit with favorable fire ratings for gypsum-based systems.

Application Advantages

From a contractor's perspective, gypsum plaster's workability makes a tremendous difference in application quality and speed. Our hydroxypropyl methylcellulose3 additives enhance this workability further, allowing smoother application with less physical effort. Workers report less fatigue and fewer repetitive strain injuries when working with properly formulated gypsum products.

The environmental footprint comparison also favors gypsum:

| Environmental Factor | Gypsum Plaster | Cement Plaster |

|---|---|---|

| Production Energy | 30-45% less | Higher energy demand |

| CO₂ Emissions | Lower (0.12-0.38 kg/kg) | Higher (0.8-0.9 kg/kg) |

| Recyclability | Highly recyclable | Limited |

| Raw Material Source | Often from by-products | Primarily virgin materials |

| Water Usage | Lower | Higher |

What are the Disadvantages of Gypsum Plastering to Consider?

Have you invested in gypsum plaster only to face unexpected limitations? Many contractors enthusiastically adopt gypsum plaster without understanding its constraints, leading to application failures in inappropriate environments.

The main disadvantages of gypsum plastering include poor performance in wet areas (bathrooms, exteriors), higher material costs (20-40% more than cement plaster), limited availability in some regions, the need for skilled applicators, less impact resistance than cement plaster, and incompatibility with certain substrates like green concrete.

During my visits to construction sites across developing countries, I've witnessed both successful applications and disappointing failures of gypsum plaster. A large hotel project in Vietnam stands out - they inappropriately used standard gypsum plaster in bathroom shower areas, resulting in costly remediation work when the plaster deteriorated within months.

To make informed decisions about gypsum plaster use, construction professionals should carefully consider these limitations:

Moisture Sensitivity

Traditional gypsum plaster's greatest weakness is its vulnerability to prolonged moisture exposure. When saturated, gypsum can lose up to 50% of its strength. This makes standard formulations unsuitable for:

- Exterior applications

- Shower areas

- Swimming pool enclosures

- Kitchens with high humidity

For these applications, special water-resistant formulations or cement-based alternatives are necessary. Our company provides specialized cellulose additives that improve water resistance in modified gypsum plasters, but even these enhanced formulations have limitations in continuously wet environments.

Cost and Availability Considerations

The economic equation varies significantly by region:

| Region | Gypsum Availability | Price Premium vs. Cement Plaster | Market Maturity |

|---|---|---|---|

| Middle East | High | 10-20% | Well-established |

| South Asia | Moderate | 25-35% | Growing rapidly |

| Southeast Asia | Limited | 30-45% | Emerging |

| Africa | Very limited | 40-60% | Early adoption |

In emerging markets, the initial cost difference can be substantial. However, when calculating total installed cost including labor savings and faster project completion, gypsum often becomes more competitive. I recommend clients conduct a holistic cost analysis rather than focusing solely on material price.

Technical Limitations

Gypsum plaster requires specific conditions for optimal performance:

- Substrate moisture content below 6%

- Ambient temperatures between 5-40°C during application

- Protection from freezing for 48 hours after application

- Proper substrate preparation including primers for certain surfaces

Additionally, the skill requirements differ from traditional plastering. Workers familiar only with cement plaster techniques require training for proper gypsum application, which presents a transition challenge for many construction companies.

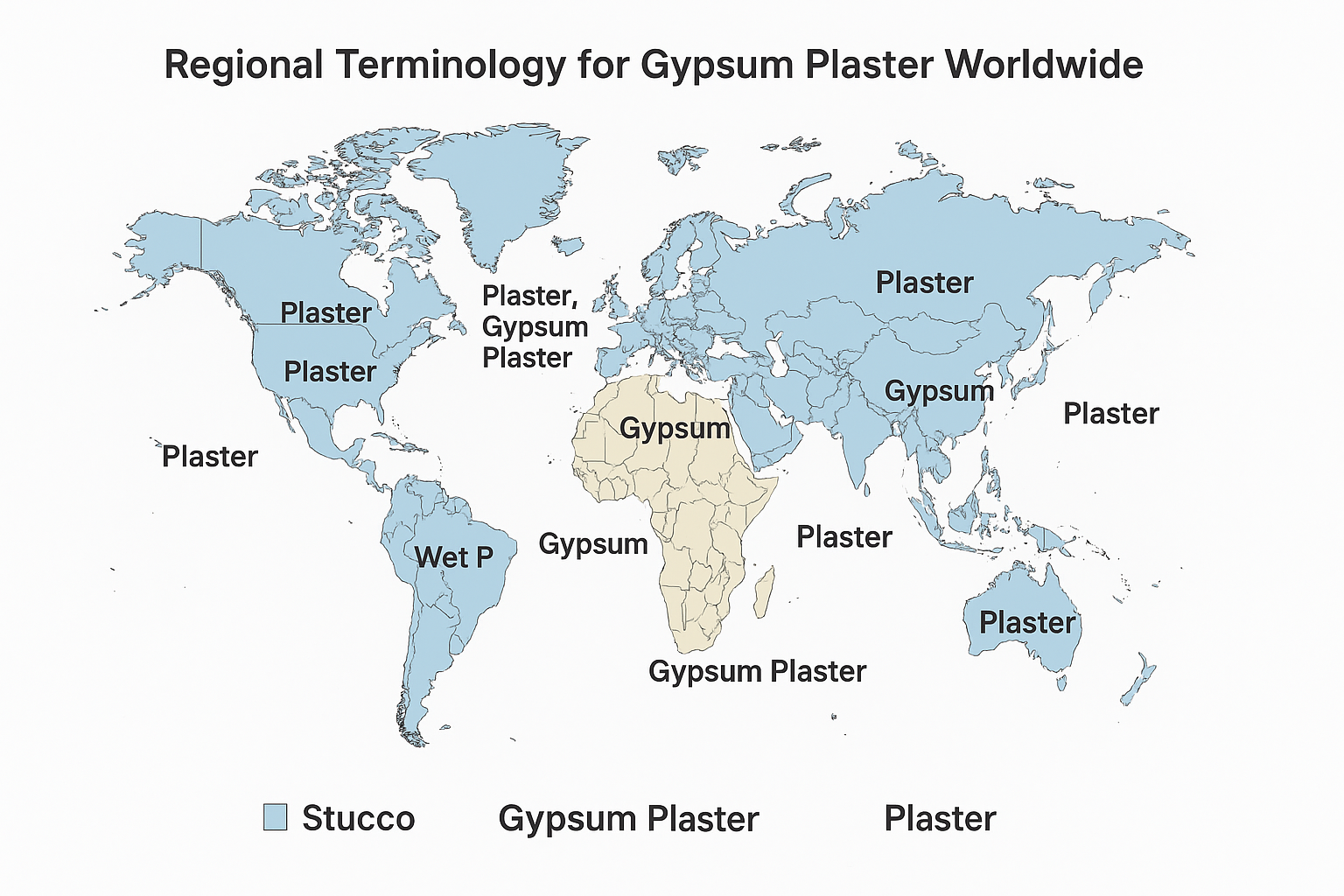

What are Alternative Names for Gypsum Plaster1 in Different Regions?

Do you find yourself confused when hearing different terms for seemingly similar plaster products? Many construction professionals struggle with regional terminology variations, leading to miscommunication and potentially incorrect material specifications.

Gypsum plaster is also known as plaster of Paris, calcined gypsum, and hemihydrate plaster in scientific contexts. Regional terms include POP (India), drywall mud (North America), gyprock (Australia), and gypsum render. Specialized types carry names like Keenes cement (hardened gypsum plaster) and finish plaster.

As I travel to meet clients across our export markets, I've collected an interesting vocabulary of terms for what's essentially the same material. During a trade show in Delhi, I was initially confused when contractors continuously asked about "POP" until I realized they were referring to Plaster of Paris, their local term for gypsum plaster.

Understanding regional terminology variations is essential for effective communication in the global construction industry. Here's a comprehensive breakdown of alternative names for gypsum plaster and their contexts:

Regional Terminology Map

Different regions have developed unique terminology for gypsum-based plastering materials, often reflecting historical development and local construction practices:

| Region | Common Term | Context and Usage |

|---|---|---|

| India & Pakistan | POP (Plaster of Paris) | General term for most gypsum plaster applications |

| North America | Drywall compound/Joint compound | Primarily for finishing drywall seams |

| UK | Gypsum plaster/Thistle (brand name) | Standard term in British construction |

| Australia & NZ | Gyprock (brand name) | Brand name that became generic term |

| Middle East | Juss/Jis (Arabic) | Traditional term in Gulf countries |

| France | Plâtre | Original source of "plaster of Paris" term |

| China | Shí gāo | Literally "stone cream" |

Technical Classifications

Beyond regional variations, technical classifications create another layer of terminology:

- Beta Gypsum Plaster: Regular construction gypsum produced at normal pressure

- Alpha Gypsum Plaster: Premium product produced under pressure, stronger and denser

- Anhydrous Gypsum: Completely dehydrated form used in specialized applications

- Keenes Cement: Hardened gypsum plaster treated with aluminum sulfate

- Finish Plaster: Fine-textured final coat gypsum

- Basecoat Plaster: First application layer, often with coarser texture

When advising clients on which of our cellulose products to use, I must first understand exactly which type of gypsum plaster they're manufacturing. A formulation optimized for standard beta gypsum plaster might perform poorly in an alpha gypsum system with different water demand and setting characteristics.

Historical terminology adds further complexity. "Plaster of Paris" originated because high-quality gypsum was historically mined from Montmartre in Paris. Similarly, "stucco" sometimes refers to gypsum plaster in interior applications but more commonly indicates cement-based exterior finishes in modern construction.

Conclusion: Why Choose Gypsum Plaster Over Cement Plaster?

Gypsum plaster offers faster setting times, superior finish quality, better thermal and acoustic properties, lighter weight, and fire resistance benefits that outweigh its limitations in wet areas and slightly higher costs. For most interior applications, it represents the optimal balance of performance, aesthetics, and efficiency.