The pharmaceutical industry faces constant challenges in drug formulation and delivery. Poor stability, inconsistent release profiles, and inadequate bioavailability threaten product effectiveness and patient outcomes. Cellulose derivatives1 offer versatile solutions to these pressing problems.

Cellulose derivatives1 serve numerous critical functions in pharmaceutical manufacturing, including as thickeners, stabilizers, binders, coating agents, and controlled-release matrices. Their biocompatibility, biodegradability, and chemical versatility make them ideal for enhancing drug formulations and improving therapeutic outcomes.

As a supplier with over a decade of experience in cellulose derivatives, I've seen firsthand how these remarkable polymers have revolutionized pharmaceutical development. Let me walk you through the key applications that make cellulose derivatives indispensable in modern medicine manufacturing.

How Do Cellulose Derivatives Function As Thickening And Stabilizing Agents?

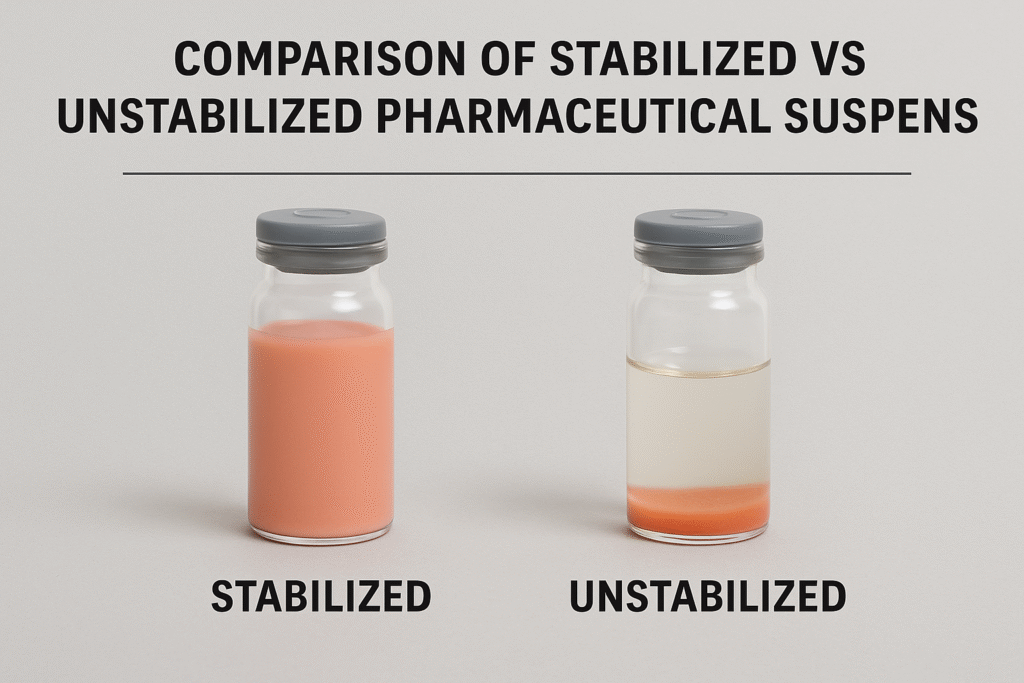

Pharmaceutical suspensions and emulsions often suffer from sedimentation and phase separation. Without proper stabilization, these formulations quickly become unusable, wasting resources and potentially endangering patients.

Cellulose derivatives like HPMC and CMC function excellently as thickening and stabilizing agents by increasing viscosity, preventing particle sedimentation, and maintaining uniform drug distribution throughout the formulation's shelf life.

Diving deeper into this application, I've observed notable differences in how various cellulose derivatives perform as stabilizers. Hydroxypropyl methylcellulose (HPMC)2 is particularly effective in aqueous systems due to its amphiphilic nature - it contains both hydrophilic and hydrophobic groups that enable it to interact with different components in formulations.

When we supply HPMC to pharmaceutical manufacturers, they typically use concentrations between 0.5-5% to achieve optimal viscosity. The molecular weight of the HPMC significantly impacts its thickening capability - our high-molecular-weight grades can increase viscosity dramatically even at low concentrations.

For suspensions containing insoluble drug particles, the stabilizing mechanism is fascinating: HPMC forms a protective colloid around particles, creating steric hindrance that prevents particles from coming together and agglomerating. This property is crucial for maintaining uniform dosing in liquid medicines.

| Cellulose Derivative | Concentration Range | Primary Stabilizing Mechanism | Best For |

|---|---|---|---|

| HPMC | 0.5-5% | Steric stabilization | Aqueous suspensions |

| CMC | 0.1-1% | Electrostatic repulsion | Ionic formulations |

| HEC | 0.3-3% | Viscosity enhancement | Topical preparations |

What Makes Cellulose Derivatives Effective In Bioadhesive And Mucoadhesive Drug Delivery Systems?

Traditional drug delivery systems often suffer from poor retention at target sites. Medications are quickly cleared from mucosal surfaces, reducing therapeutic efficacy and wasting expensive active ingredients.

Cellulose derivatives excel in bioadhesive and mucoadhesive drug delivery due to their ability to form hydrogen bonds with mucin glycoproteins, prolonging drug contact time with absorption sites and significantly improving bioavailability.

In my experience working with pharmaceutical developers, the mucoadhesive properties of cellulose derivatives have revolutionized drug delivery across multiple routes of administration. Carboxymethyl cellulose (CMC)3 stands out in this application because of its exceptional binding capacity to mucosal tissues.

The mechanism behind this remarkable property involves the formation of physical entanglements between cellulose polymer chains and the glycoprotein networks in mucus. Additionally, the numerous hydroxyl and carboxyl groups in CMC form hydrogen bonds with similar groups in the mucin molecules.

I recall working with a customer developing a buccal film for delivering a peptide drug with poor oral bioavailability. By incorporating our high-viscosity CMC at 2-3%, they achieved residence times exceeding 4 hours on the buccal mucosa, compared to just 20-30 minutes with standard formulations. This dramatic improvement translated to sustained drug release and reduced dosing frequency.

Different cellulose ethers exhibit varying degrees of mucoadhesion based on their chemical substitution patterns:

| Cellulose Derivative | Mucoadhesive Strength | Best Application | Key Advantage |

|---|---|---|---|

| CMC | Very High | Buccal/vaginal delivery | Forms ionic bonds with mucin |

| HPMC | Moderate | Ocular delivery | Non-irritating, comfortable |

| HEC | Moderate-Low | Nasal delivery | Rapid hydration |

How Do Cellulose Derivatives Enhance Pharmaceutical Coating Processes?

Pharmaceutical coating is plagued by challenges including poor film uniformity, extended processing times, and coating defects. These issues compromise both aesthetics and functional properties of dosage forms.

Cellulose derivatives like HPMC and ethylcellulose are ideal film-forming agents for pharmaceutical coatings, providing moisture protection, taste masking, improved appearance, and controlled drug release properties.

The film-forming capability of cellulose derivatives has transformed pharmaceutical coating operations across the industry. HPMC in particular has become the gold standard for aqueous film coating due to its exceptional properties. Over my years supplying to pharmaceutical companies, I've seen a dramatic shift from organic solvent-based coatings to water-based HPMC systems, driven by safety and environmental concerns.

When HPMC forms a film on tablet surfaces, it creates a continuous polymer network through hydrogen bonding between adjacent molecules. The mechanical strength of these films is remarkable – our pharmaceutical-grade HPMC can produce coatings that resist mechanical stress during packaging and transport while still disintegrating appropriately upon administration.

For controlled-release applications, ethylcellulose is often the polymer of choice. Its hydrophobic nature creates a diffusion barrier that regulates drug release over extended periods. By adjusting the polymer concentration and coating thickness, manufacturers can target specific release profiles ranging from 6 to 24 hours.

A critical consideration in coating applications is viscosity control. Too high viscosity makes spraying difficult, while too low viscosity leads to uneven coating. Our technical team typically recommends HPMC with viscosity ranges of 3-15 cP (2% solution) for optimal spray application in modern coating pans.

| Coating Type | Preferred Cellulose Derivative | Coating Level | Key Function |

|---|---|---|---|

| Immediate Release | Low-viscosity HPMC | 2-4% w/w | Appearance, moisture protection |

| Enteric | HPMC-AS | 5-10% w/w | Acid resistance |

| Extended Release | Ethylcellulose | 8-15% w/w | Controlled diffusion |

What Role Do Cellulose Derivatives Play As Gelling Agents?

Topical and transdermal pharmaceutical formulations frequently suffer from poor consistency, limited drug stability, and inadequate skin contact time. These issues reduce therapeutic efficacy and patient compliance.

As gelling agents, cellulose derivatives create stable, transparent gels with tunable rheological properties. They provide excellent drug dispersion, enhanced skin contact, and controlled release profiles ideal for topical and transdermal delivery systems.

The gelling mechanism of cellulose derivatives fascinates me even after years in the industry. When we supply hydroxypropyl methylcellulose to gel manufacturers, it undergoes a remarkable transformation in water. At low temperatures, HPMC hydrates slowly, but as temperature increases, the polymer chains uncoil and form a three-dimensional network through hydrogen bonding and hydrophobic interactions.

This temperature-responsive behavior creates interesting possibilities for pharmaceutical applications. For example, some of our customers formulate ophthalmic solutions that are liquid at room temperature for easy administration but gel upon contact with the warmer eye surface (around 35°C), increasing residence time and drug absorption.

The concentration of cellulose derivative critically determines gel properties. For HPMC, concentrations below 2% typically produce flowing gels suitable for eye drops or nasal sprays. At 2-5%, we see moderately firm gels ideal for topical applications like anti-inflammatory creams. Concentrations above 5% create rigid gels used for specialized applications like wound dressings.

I worked with a dermatological product manufacturer who was struggling with drug crystallization in their anti-fungal gel. By switching to our specially modified HPMC grade with optimized substitution pattern, they achieved both improved stability and enhanced skin penetration due to the polymer's interaction with keratin structures.

| Gel Property | Controlling Factor | Typical Range | Application |

|---|---|---|---|

| Viscosity | Concentration, MW | 5,000-100,000 mPa·s | Flow control |

| Clarity | Purity, dissolution | >95% light transmission | Consumer acceptance |

| Mucoadhesion | Substitution type | 1-5 N/cm² adhesive strength | Extended contact |

| Texture | Particle size, hydration | Varies by application | User experience |

Why Are Cellulose Derivatives Preferred As Fillers In Solid Dosage Forms?

Pharmaceutical tablets and capsules often struggle with poor flow properties, inadequate compressibility, and inconsistent disintegration. These manufacturing challenges lead to weight variation, dose inconsistency, and quality control failures.

Microcrystalline cellulose (MCC)4 is an exceptional pharmaceutical filler due to its superior compressibility, flow properties, and disintegration characteristics, enabling the production of robust tablets with consistent weight and drug content.

The physical properties of microcrystalline cellulose make it uniquely valuable in tablet formulation. Its partially crystalline structure provides mechanical strength while its porous nature facilitates compression and disintegration. Through our work with tablet manufacturers, I've gained deep appreciation for how MCC's properties can be manipulated to solve formulation challenges.

MCC acts through a fascinating compression mechanism known as plastic deformation. Unlike brittle excipients that fracture during compression, MCC particles deform and create extensive hydrogen bonding between adjacent surfaces. This results in exceptionally strong tablets even at relatively low compression forces - typically 10-15 kN compared to 20-30 kN for other fillers.

The disintegration mechanism of MCC is equally interesting. When a tablet containing MCC contacts water, capillary action draws water into the tablet matrix through microscopic pores. This creates internal pressure that, combined with the disruption of hydrogen bonds, causes rapid disintegration. Our pharmaceutical-grade MCC can produce tablets with disintegration times as short as 30-60 seconds.

Different grades of MCC offer tailored performance characteristics:

| MCC Grade | Particle Size | Bulk Density | Best Application |

|---|---|---|---|

| MCC 101 | 50 μm | 0.26-0.31 g/cm³ | Direct compression |

| MCC 102 | 100 μm | 0.28-0.33 g/cm³ | Wet granulation |

| MCC 200 | 180 μm | 0.30-0.36 g/cm³ | Improved flow properties |

For challenging applications like low-dose, high-potency drugs, we recommend specialized MCC grades with controlled particle size distribution to minimize segregation and ensure content uniformity.

How Do Cellulose Derivatives Improve The Granulation Process?

Traditional pharmaceutical granulation often suffers from poor batch-to-batch consistency, extended processing times, and high moisture sensitivity. These issues lead to manufacturing inefficiencies and product quality problems.

Cellulose derivatives function as superior binders in pharmaceutical granulation by forming strong bridges between particles, improving flow properties, enhancing compressibility, and enabling consistent drug release from the final dosage forms.

The binding mechanism of cellulose derivatives in granulation is a fascinating process I've observed across numerous pharmaceutical manufacturing facilities. When a solution of HPMC or CMC is added to powder blends during wet granulation, these polymers form solution bridges between adjacent particles. As the solvent evaporates during drying, these bridges solidify into strong solid bonds.

For hydroxypropyl methylcellulose, the hydroxypropyl substituents enhance water penetration into the powder bed, while the methoxyl groups provide binding strength upon drying. We typically recommend using HPMC concentrations between 2-5% in binding solutions, though this can vary based on drug properties and manufacturing equipment.

Low-viscosity grades (3-15 mPa·s) are generally preferred for spray applications in fluid bed granulators, while higher viscosity grades work well in high-shear mixers where stronger binding is needed. The molecular weight of the cellulose derivative directly correlates with granule strength – higher molecular weights produce more robust granules resistant to breakage during subsequent processing.

In one memorable case, I worked with a manufacturer who was struggling with tablet capping issues for a hygroscopic drug product. By switching from povidone to our specialized low-substitution HPMC binder, they achieved granules with better compressibility and significantly reduced moisture uptake, solving their capping problem entirely.

| Processing Method | Recommended Cellulose Derivative | Concentration | Key Advantage |

|---|---|---|---|

| High-shear wet granulation | Medium-viscosity HPMC | 3-5% | Dense, strong granules |

| Fluid bed granulation | Low-viscosity HPMC | 2-4% | Uniform distribution |

| Twin-screw wet granulation | CMC or HPMC | 2-3% | Continuous processing |

| Dry granulation | MCC co-processed | N/A | Improved compressibility |

Conclusion

Cellulose derivatives remain the backbone of pharmaceutical formulation, offering unmatched versatility across multiple applications. From stabilizing suspensions to controlling drug release, these natural polymers deliver solutions that improve manufacturing efficiency and enhance therapeutic outcomes.

-

Explore how cellulose derivatives are revolutionizing drug formulation and delivery in the pharmaceutical industry. ↩ ↩

-

Explore the versatile applications of HPMC in drug formulations and coatings. ↩

-

Learn how CMC improves drug delivery and stability in various formulations. ↩

-

Discover why MCC is a preferred filler for producing robust and consistent tablets. ↩