Is your mortar factory struggling with product performance issues? Poor adhesion, cracking, and water resistance problems can destroy your reputation and cost you clients. VAE redispersible polymer powder1 offers a proven solution.

VAE redispersible polymer powder1 is widely chosen by mortar factories because it significantly improves adhesion, flexibility, workability, and water resistance of cementitious mortars. It forms polymer films during hydration that enhance bond strength between mortar and substrates while reducing cracking and improving durability.

I've been in the construction materials industry for over 15 years, and I've seen firsthand how the right additives can transform ordinary mortar into exceptional building products. When clients visit our factory in China, their first question is almost always about our VAE redispersible polymer powder. Let me share why this material has become essential for modern mortar production.

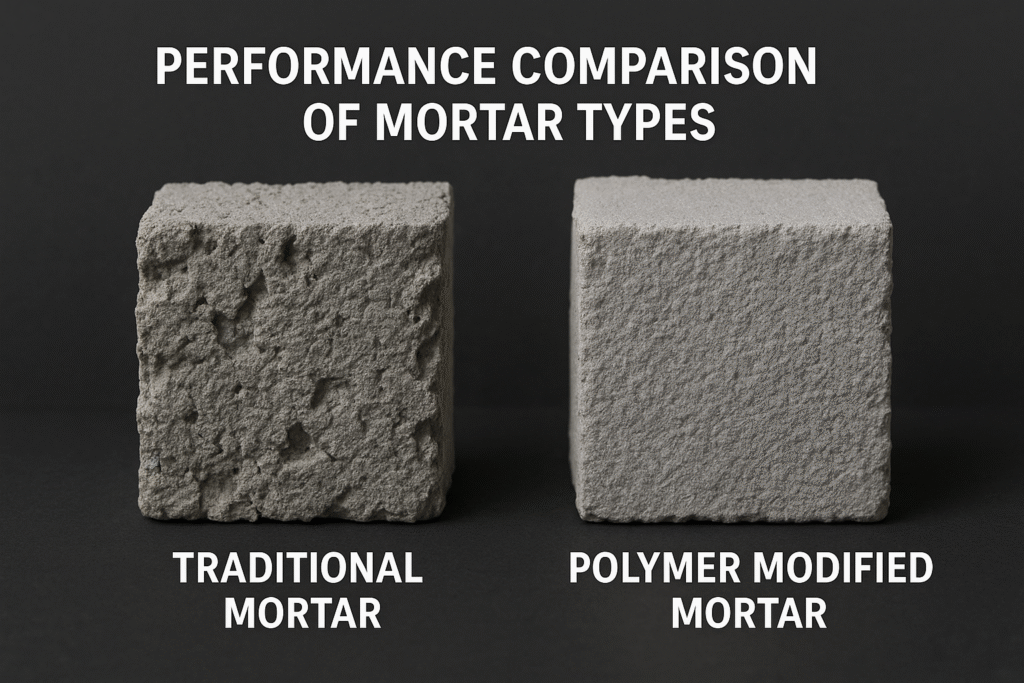

What Are the Advantages of Polymer Modified Cementitious Mortar?

Are you tired of customers complaining about mortar failure? Poor adhesion and cracking not only harm your reputation but also lead to expensive callbacks and material waste.

Polymer modified cementitious mortar offers superior bonding strength to various substrates, enhanced flexibility that prevents cracking, improved water resistance, and better workability compared to conventional mortars. These properties extend product lifespan and reduce application failures in both interior and exterior applications.

When I first started producing mortar additives, many manufacturers were skeptical about the benefits of polymer modification. However, the results speak for themselves. Our laboratory tests consistently show that adding just 2-5% of our VAE redispersible polymer powder can increase adhesion strength by up to 300%.

The polymer modification works through a dual hardening process. When water is added to the dry mix, cement hydration begins simultaneously with polymer particle redispersion. As water evaporates, the polymer particles form continuous films that interlock with the cement hydrates. This creates a co-matrix structure that significantly improves the mortar's performance properties.

Key Benefits of Polymer Modification:

| Property | Improvement | Practical Benefit |

|---|---|---|

| Adhesion | 200-300% increase | Better bonding to difficult substrates |

| Flexibility | 150-200% increase | Reduced cracking in variable conditions |

| Water Resistance | 80-90% reduction in water absorption | Enhanced durability in wet environments |

| Workability | Extended open time by 15-20 minutes | Easier application and better productivity |

These improvements translate directly to better performance, fewer callbacks, and enhanced reputation for your mortar products.

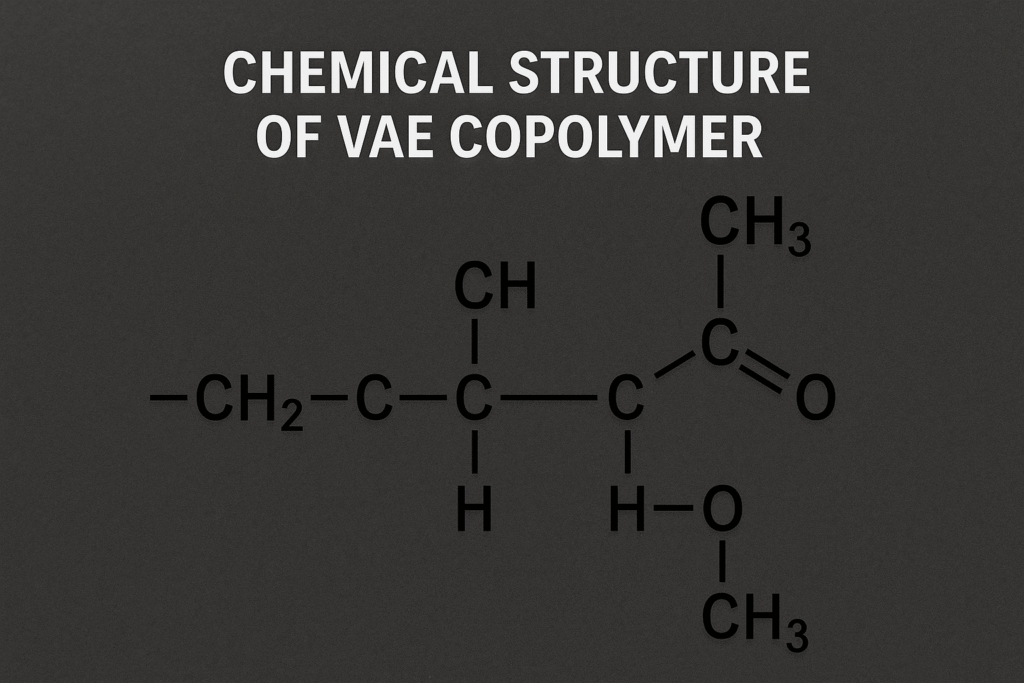

What Is the Chemical Composition of Redispersible Polymer Powder?

Have you wondered what makes redispersible polymer powder so effective? Many mortar manufacturers don't understand the chemistry behind these additives, leading to improper selection and application failures.

Redispersible polymer powder consists primarily of vinyl acetate-ethylene2 (VAE) copolymers that have been spray-dried with protective colloids and anti-caking agents. The base polymer typically contains 70-85% vinyl acetate and 15-30% ethylene, which provides an optimal balance of hardness, flexibility, and water resistance.

In our factory, we carefully control the ratio of vinyl acetate to ethylene based on the intended application. This is crucial because the ethylene content significantly affects the polymer's glass transition temperature (Tg). A higher ethylene content produces a more flexible polymer with a lower Tg, which is ideal for exterior applications subject to temperature fluctuations.

The spray-drying process is equally important. The liquid polymer emulsion is atomized into a hot air stream, causing water to evaporate rapidly while leaving behind discrete polymer particles. Protective colloids (typically polyvinyl alcohol) ensure these particles can later redisperse when water is added to the mortar mix.

Typical Composition of Commercial Redispersible Polymer Powder:

| Component | Percentage | Function |

|---|---|---|

| VAE Copolymer | 80-90% | Primary film-forming agent |

| Protective Colloid | 5-10% | Enables redispersion in water |

| Anti-caking Agents | 3-5% | Prevents clumping during storage |

| Defoamers | 1-2% | Controls air content in mixed mortar |

| Specialty Additives | 1-3% | Application-specific properties |

Understanding this composition helps our customers select the right grade for their specific application, whether it's tile adhesives3, EIFS (External Insulation and Finishing Systems), or self-leveling compounds4.

What Are the Properties of Redispersible Polymer Powder?

Do inconsistent mortar properties damage your reputation with contractors? Without proper additives, your products may perform differently in various temperatures and humidity levels, frustrating your customers.

Redispersible polymer powder offers consistent performance through its unique ability to form polymer films within the cement matrix after rehydration. It provides excellent adhesion to various substrates, flexibility that accommodates substrate movement, water repellency, and improved workability that extends open time for better application results.

At our testing facility, we regularly evaluate different formulations of redispersible polymer powder to ensure optimal performance across various applications. One of the most remarkable properties is the powder's stability. Unlike liquid polymers that have limited shelf life, properly formulated redispersible powders maintain their effectiveness for 12-24 months when stored properly.

The particle size distribution is another critical property we control carefully. Most commercial grades have an average particle size between 80-120 microns, which allows for easy blending with other dry mortar components while ensuring complete redispersion when water is added. Too large particles can create inconsistent mixing, while too fine particles may cause dusting issues during production.

Key Performance Properties:

| Property | Test Method | Typical Value | Impact on Mortar |

|---|---|---|---|

| Film Formation Temperature | DSC Analysis | 0°C to +5°C | Determines minimum application temperature |

| Bulk Density | DIN 53468 | 400-550 g/L | Affects mixing and homogeneity |

| Ash Content | 1000°C Residue | 10-12% | Indicates mineral content |

| MFFT (Minimum Film-Forming Temperature) | ASTM D2354 | 0-5°C | Determines film quality at low temperatures |

| Particle Size | Laser Diffraction | D50: 80-120 μm | Affects dispersion quality |

These properties directly influence the performance of the final mortar product, which is why we offer extensive technical support to help customers select the optimal grade for their specific application requirements.

What Are the Ingredients in Polymer Powder?

Have you been disappointed by generic polymer additives that don't deliver the performance you need? Many suppliers don't disclose their formulations, leaving mortar manufacturers with suboptimal products.

Polymer powder ingredients include base polymers (typically vinyl acetate-ethylene copolymers), protective colloids like polyvinyl alcohol, mineral anti-caking agents such as calcium carbonate or silica, and specialized additives like defoamers and hydrophobic agents. The precise formulation varies based on the intended application and performance requirements.

In our production facility, we've developed specialized formulations for different applications. For example, our tile adhesive grade contains additional cellulose ethers to improve water retention and open time, while our exterior insulation grade includes hydrophobic additives to enhance water resistance.

The base VAE polymer accounts for the majority of the formulation, but the supporting ingredients play crucial roles in functionality. Protective colloids, primarily polyvinyl alcohol (PVA), surround the polymer particles during spray drying and facilitate redispersion when water is added to the mortar. Without proper protective colloids, the polymer would form irreversible agglomerates that wouldn't disperse effectively.

Anti-caking agents prevent the powder from forming lumps during storage, especially in humid conditions. We typically use finely ground calcium carbonate or silica, which also contribute beneficial mineral content to the final mortar formulation.

Application-Specific Ingredients:

| Application | Special Ingredients | Purpose |

|---|---|---|

| Tile Adhesives | Cellulose ethers, quartz filler | Water retention, slip resistance |

| EIFS Mortars | Hydrophobic agents, lightweight fillers | Water resistance, workability |

| Self-Leveling Compounds | Superplasticizers, accelerators | Flow properties, setting time |

| Repair Mortars | Fibers, shrinkage reducers | Crack resistance, dimensional stability |

| Waterproofing Mortars | Silanes, siloxanes | Enhanced water repellency |

By understanding these ingredient combinations, we can help our customers develop formulations that meet specific performance requirements for their target markets.

What Is the Formula for RDP Powder?

Are you struggling to create the perfect dry mortar formula? Without understanding how redispersible polymer powder interacts with other ingredients, you might be wasting money on ineffective formulations.

The basic formula for RDP powder in a dry mortar mix varies by application but typically includes 1-5% VAE polymer powder, 20-40% cement, 50-70% graded aggregates, and small percentages of additives like cellulose ethers, accelerators or retarders, and air-entraining agents. This balanced formulation ensures optimal performance properties.

When I consult with mortar manufacturers, I always emphasize that there's no one-size-fits-all formula. Every application has unique requirements. For example, a tile adhesive formula might contain 3-5% RDP powder for excellent adhesion, while a render might need only 1-2% for water resistance and workability.

The cement type and quality significantly impact how much RDP is needed. Higher quality Portland cements often require less polymer modification to achieve target properties. Similarly, the aggregate gradation affects the formula—well-graded aggregates with appropriate fines content typically require less polymer to achieve workability targets.

Sample Formulations for Common Applications:

| Component | Tile Adhesive | EIFS Basecoat | Self-Leveling Compound |

|---|---|---|---|

| Portland Cement | 25-35% | 20-30% | 25-40% |

| Graded Aggregates | 55-65% | 60-70% | 50-60% |

| RDP Powder | 3-5% | 2-3% | 1-2% |

| Cellulose Ether | 0.2-0.3% | 0.2-0.3% | 0.05-0.1% |

| Specialty Additives | < 1% | < 1% | 3-5% |

These formulations provide a starting point, but we always recommend laboratory testing to optimize for local materials and climate conditions. Our technical team conducts over 500 formulation tests annually to help customers develop products tailored to their specific markets.

How to Make Redispersible Polymer Powder?

Have you wondered what goes into manufacturing high-quality RDP? Many mortar producers don't understand the complexity of the production process, leading them to undervalue quality differences between suppliers.

Redispersible polymer powder is manufactured through a multi-stage process: first creating a liquid polymer emulsion through emulsion polymerization, then spray-drying the emulsion with protective colloids to form a redispersible powder. The process requires specialized equipment and precise control of temperature, pressure, and formulation parameters.

At our production facility in China, we've invested heavily in state-of-the-art manufacturing equipment. The process begins with reactor vessels where vinyl acetate and ethylene monomers undergo emulsion polymerization in the presence of initiators and emulsifiers. This creates a stable polymer emulsion with precisely controlled particle size and composition.

The critical step is spray drying, where the liquid emulsion is mixed with protective colloids (mainly polyvinyl alcohol) and then atomized into a hot air chamber. The water evaporates almost instantly, leaving behind discrete polymer particles coated with the protective colloid. The temperature control during this process is crucial—too hot, and the polymer may thermally degrade; too cool, and the powder may contain excessive moisture.

After spray drying, the powder undergoes classification to ensure consistent particle size distribution. Anti-caking agents are added at this stage to prevent agglomeration during storage and transportation. The final product is tested for key properties such as redispersibility, minimum film formation temperature, and ash content before packaging.

Key Manufacturing Parameters:

| Process Stage | Critical Parameters | Quality Impact |

|---|---|---|

| Emulsion Polymerization | Temperature, monomer ratio, initiator concentration | Polymer composition, stability |

| Spray Drying | Inlet/outlet temperature, atomization pressure, feed rate | Redispersibility, moisture content |

| Classification | Air flow, separation settings | Particle size distribution |

| Final Blending | Mixing time, additive incorporation | Flowability, anti-caking properties |

| Quality Control | Redispersion test, film properties, bulk density | Performance consistency |

Our production capacity of 50,000 tons annually allows us to serve mortar manufacturers across multiple continents while maintaining strict quality control. Each batch undergoes comprehensive testing against our quality standards before release.

Conclusion

VAE redispersible polymer powder1 has revolutionized the mortar industry by enhancing adhesion, flexibility, and water resistance. By understanding its composition, properties, and proper formulation, you can create superior mortar products that outperform your competition.

-

Explore how VAE redispersible polymer powder can enhance your mortar's performance and durability. ↩ ↩ ↩

-

Understand the significance of vinyl acetate-ethylene in enhancing mortar properties. ↩

-

Learn about the essential characteristics that make tile adhesives effective. ↩

-

Discover the advantages of using self-leveling compounds in construction. ↩