Buildings without proper insulation drain money through energy loss and maintenance costs. EIFS systems solve these problems by creating an energy-efficient, protective outer shell for structures.

EIFS (Exterior Insulation and Finish System)1 is important because it provides superior thermal insulation, weatherproofing, design flexibility, and energy efficiency to buildings. This multi-layered system creates a seamless exterior that can reduce heating and cooling costs by up to 40% while protecting the building structure.

I've been working with construction materials for over a decade, and I've seen firsthand how EIFS transforms buildings. Not only does it provide aesthetic appeal, but it also offers functional benefits that make it a popular choice worldwide. Let me share what makes EIFS so significant in modern construction.

What Are The Advantages Of EIFS System?

Builders face challenges with energy efficiency, weather resistance, and aesthetic limitations. EIFS addresses these issues with a comprehensive solution that outperforms traditional cladding systems.

The advantages of EIFS include superior thermal insulation, moisture resistance, design flexibility, impact resistance, and cost-effectiveness. The system creates a continuous insulation barrier that eliminates thermal bridging, while its seamless finish prevents water infiltration and allows for virtually unlimited design possibilities.

EIFS brings multiple benefits that make it stand out in the construction industry. One of the primary advantages is energy efficiency. Because the insulation is placed on the exterior of the wall, it creates a continuous thermal barrier that significantly reduces heat transfer. This results in lower heating and cooling costs - something I've consistently heard from our clients after installation.

The system's design flexibility is remarkable. With EIFS, architects can create complex shapes, curves, and details that would be impossible or prohibitively expensive with other materials. This versatility has made it popular for both new construction and renovations.

Another key advantage is durability. When properly installed and maintained, EIFS can last for decades. The system includes reinforcing mesh that provides impact resistance, and high-quality components like our hydroxypropyl methylcellulose (HPMC)2 and redispersible polymer powder (RDP)3 ensure the adhesive and base coats maintain their integrity over time.

| EIFS Advantage | Description | Benefit |

|---|---|---|

| Energy Efficiency | Continuous exterior insulation | 30-40% reduction in energy costs |

| Design Flexibility | Can create various textures and shapes | Unlimited architectural possibilities |

| Durability | Resistant to impacts and weather | Lower maintenance costs |

| Moisture Protection | Water-resistant barrier | Prevents structural damage |

| Lightweight | Less structural load than brick or stone | Suitable for more building types |

Is EIFS Still Used Today?

Many wonder if EIFS has fallen out of favor due to past issues. The reality is that EIFS has evolved significantly and remains a top choice for builders worldwide.

EIFS is widely used today with annual global market growth of approximately 6%. Modern EIFS systems incorporate drainage planes, water-resistant barriers, and improved installation techniques that address earlier concerns. The system continues to evolve with better components and installation standards.

The evolution of EIFS technology has been remarkable. I remember when first-generation EIFS faced challenges with moisture management. Today, these issues have been completely addressed with advanced drainage systems and improved weather barriers. The industry responded to early problems by developing what's now called "drainage EIFS" or "EIFS with drainage," which allows any water that might penetrate the system to escape safely.

Current EIFS installations follow much stricter guidelines and use higher quality materials. As a manufacturer of key EIFS components, we've invested significantly in research and development to improve our HPMC and RDP products, ensuring they contribute to the system's overall performance and longevity.

The statistics show EIFS popularity remains strong. In commercial construction, EIFS continues to be chosen for its energy efficiency benefits, which have become even more important as energy codes become stricter. The system meets or exceeds most international building energy codes, including the International Energy Conservation Code (IECC) and ASHRAE standards.

Installation techniques have also improved dramatically. Certified installer programs ensure proper application, and quality control measures have become standard in the industry. This has led to greater confidence among architects, builders, and property owners in specifying EIFS for their projects.

What Is Exterior Insulation And Finish System (EIFS)?

When clients ask about EIFS, they're often confused about what makes up this system. Understanding its components is essential to appreciating its function and benefits.

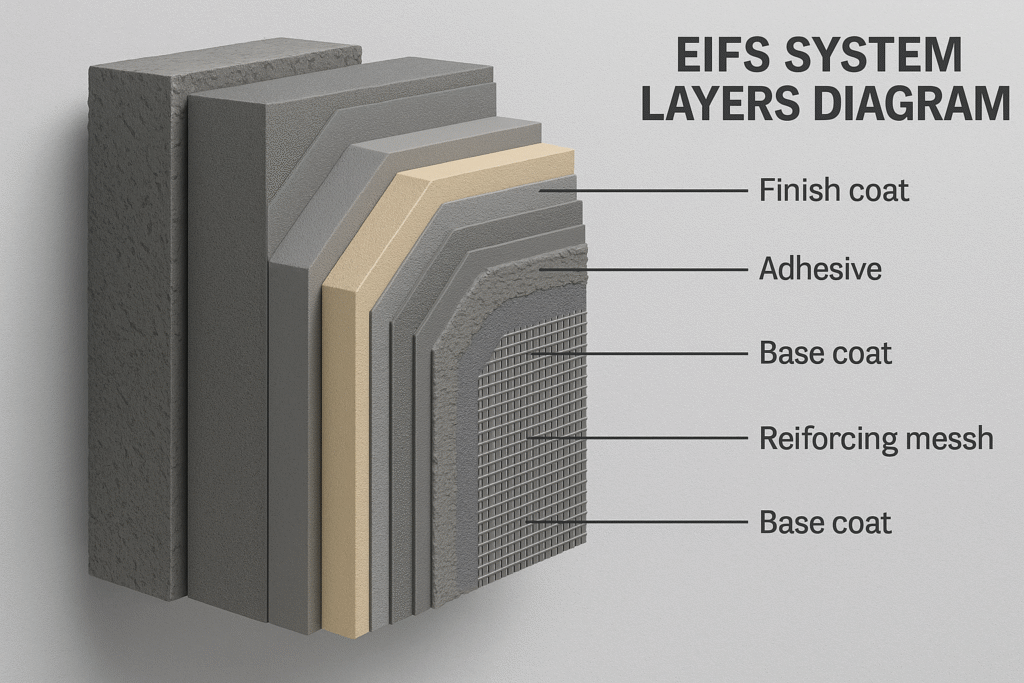

EIFS is a multi-layered exterior wall cladding system consisting of insulation board attached to the substrate, a base coat reinforced with fiberglass mesh, and a textured finish coat. The system creates a continuous insulation envelope around the building while providing an attractive, weather-resistant exterior finish.

Diving deeper into the EIFS structure reveals the importance of each layer and the materials that make them effective. The system typically consists of six key components, each serving a specific purpose:

-

Adhesive Layer: This first layer attaches the insulation board to the substrate. Our high-quality HPMC plays a crucial role here, providing excellent adhesion and workability. The adhesive must be strong enough to hold the system in place for decades while allowing some flexibility for normal building movement.

-

Insulation Board: Usually made from expanded polystyrene (EPS), this layer provides the thermal insulation. The thickness can be adjusted based on the desired R-value and energy performance requirements. This is where EIFS gets its superior insulation properties.

-

Base Coat: Applied over the insulation, this layer embeds the reinforcing mesh. Our specially formulated RDP significantly enhances this layer's flexibility, crack resistance, and adhesion properties. The base coat must be strong yet flexible to resist building movement and prevent cracking.

-

Reinforcing Mesh: Typically fiberglass, this mesh provides impact resistance and structural integrity to the system. Different weights of mesh can be used depending on the required impact resistance.

-

Primer: Sometimes used before the finish coat to improve adhesion and color uniformity.

-

Finish Coat: The outermost layer that provides color and texture. This acrylic-based coat is often enhanced with our HPMC to improve workability and water retention during application.

The synergy between these layers creates a system that's greater than the sum of its parts. When properly installed, EIFS provides thermal efficiency that few other cladding systems can match, while also offering aesthetic flexibility and weather resistance.

What Is A Disadvantage Of EIFS?

No building system is perfect, and honest assessment includes recognizing limitations. EIFS has specific challenges that should be considered during planning and installation.

The main disadvantages of EIFS include potential moisture-related issues if improperly installed, higher initial cost compared to some cladding systems, susceptibility to impact damage, and requirements for specialized installation expertise. However, most of these concerns can be mitigated through proper design, installation, and maintenance.

Understanding EIFS limitations helps my clients make informed decisions and take appropriate precautions. The most significant concern has historically been moisture management. If water penetrates the system and becomes trapped, it can lead to structural damage and mold growth. However, this issue primarily stems from improper installation rather than inherent system flaws.

Modern EIFS includes drainage planes specifically designed to channel any water that might penetrate the exterior finish back to the outside. These drainage EIFS systems have largely addressed the moisture concerns of earlier generations. Still, proper flashing details around windows, doors, and other penetrations remain critical.

Another consideration is impact resistance. While reinforcing mesh provides good durability, EIFS can be damaged by hard impacts. Areas with high traffic or potential for contact may require higher-grade mesh or alternative materials at ground level. Some manufacturers offer high-impact resistant systems specifically for these vulnerable areas.

Installation expertise presents another challenge. EIFS requires experienced professionals who understand the proper application techniques. Cutting corners during installation can compromise the entire system's performance. This is why we provide comprehensive technical support and training for contractors using our HPMC and RDP products in EIFS applications.

Maintenance requirements should also be considered. While EIFS generally requires less maintenance than many other cladding systems, periodic inspection and cleaning are necessary to ensure continued performance. Small damages should be repaired promptly to prevent water infiltration.

Our Service

When customers choose our products, they're often seeking more than just materials. They need confidence that their EIFS system will perform as expected.

We provide high-quality HPMC and RDP specifically engineered for EIFS applications, ensuring optimal adhesion, workability, water resistance, and durability. Our technical team offers comprehensive support including formulation assistance, on-site troubleshooting, and customized solutions for specific project requirements.

At Kehao, we understand that EIFS performance depends greatly on the quality of its components. Our hydroxypropyl methylcellulose (HPMC)2 and redispersible polymer powder (RDP)3 are engineered specifically for demanding EIFS applications, with properties that ensure optimal system performance.

We've invested significantly in research and development to create products that address the specific needs of EIFS manufacturers. Our HPMC provides excellent water retention, which is crucial during application as it prevents premature drying and ensures proper cement hydration. This results in stronger adhesion between system components and the building substrate.

Our RDP enhances flexibility and crack resistance in the base coat, creating a more durable system that can withstand building movement and temperature fluctuations without compromising. This is particularly important in regions with extreme weather conditions or seismic activity.

What sets our service apart is our technical support approach. We don't just sell products; we partner with our customers to ensure optimal results. Our technical team provides formulation assistance, helping customers adjust their mixtures to achieve the perfect balance of workability, setting time, and final properties. We also offer on-site troubleshooting when issues arise, and our laboratory can perform specialized testing to address specific project requirements.

Quality control is another cornerstone of our service. Each batch of our HPMC and RDP undergoes rigorous testing to ensure consistency and performance. We provide detailed technical data sheets and certificates of analysis with every shipment, giving our customers confidence in the materials they're using.

Frequently Asked Questions

People often come to me with questions about EIFS. These common inquiries reflect the considerations when choosing an exterior cladding system.

EIFS typically lasts 20-30 years when properly installed and maintained. Installation costs range from $7-$9 per square foot, approximately 30% less than brick veneer. Modern drainage EIFS systems have resolved most historical moisture issues, and proper installation by certified professionals is key to avoiding problems.

In my years working with EIFS materials, I've encountered numerous questions from contractors, architects, and building owners. Understanding these common concerns helps clarify the value and limitations of EIFS systems.

Regarding durability, I always emphasize that component quality significantly impacts system longevity. Our premium HPMC and RDP contribute to stronger adhesive and base coats, which translates to more durable installations. While the typical lifespan is 20-30 years, I've seen properly maintained systems perform well beyond this timeframe.

Fire resistance is another common concern. EIFS typically carries a fire rating that meets building codes, but the specifics depend on the exact composition and testing certification. Most systems include fire retardants in the insulation layer, and the cement-based components provide additional protection.

Maintenance requirements are relatively minimal compared to other exterior finishes. Regular inspection (typically annual) and cleaning with mild detergent are usually sufficient. Any damaged areas should be repaired promptly to maintain the integrity of the weather-resistant barrier.

Regarding installation, I strongly recommend using certified EIFS professionals. The system requires specific techniques and attention to detail, particularly around openings and penetrations. Proper installation is the single most important factor in preventing potential issues.

Weather performance varies by system design, but properly installed EIFS performs exceptionally well in diverse climates. The system can withstand freeze-thaw cycles, high temperatures, and UV exposure without degradation. Our specially formulated HPMC and RDP enhance resistance to these environmental stresses.

Finally, sustainability concerns are increasingly important. EIFS contributes to energy efficiency, reducing a building's carbon footprint throughout its lifecycle. Additionally, the reduced material weight compared to masonry systems means lower transportation energy costs and less structural material required.

Conclusion

EIFS delivers exceptional energy efficiency, design flexibility, and durability when properly installed with quality components. Our high-performance HPMC and RDP ensure EIFS stability and longevity, making it a smart investment for modern buildings worldwide.

-

Explore the comprehensive benefits of EIFS, including energy efficiency and design flexibility, to understand its significance in modern construction. ↩

-

Discover how HPMC enhances the performance of EIFS and contributes to its durability. ↩ ↩

-

Learn about RDP and how it improves the flexibility and crack resistance of EIFS systems. ↩ ↩