Are you struggling to find a versatile thickening agent that works across multiple industries? Many manufacturers face this exact problem, wasting time and money on ineffective additives. Carboxymethyl cellulose (CMC) might be the solution you're looking for.

Carboxymethyl cellulose (CMC)1 is a water-soluble cellulose derivative that functions as a thickener, stabilizer, and rheology modifier. It's widely used in food, pharmaceuticals, detergents, textiles, and drilling fluids due to its excellent water retention, binding properties, and cost-effectiveness.

As a leading manufacturer of cellulose derivatives for over 15 years, I've seen firsthand how CMC transforms products across industries. Let me share what makes this versatile ingredient so valuable and why it might be exactly what your manufacturing process needs.

What is Carboxymethyl Cellulose and How Does it Work?

Do you know what makes your ice cream smooth or your toothpaste stay on your brush? The answer might surprise you. CMC works behind the scenes in countless everyday products, but few understand its importance.

Carboxymethyl cellulose is a modified cellulose created by reacting cellulose with chloroacetic acid under alkaline conditions. The resulting anionic polymer dissolves readily in water to form viscous solutions that stabilize emulsions, prevent crystallization, and improve texture in various applications.

Let me explain how CMC works at the molecular level. The modification process introduces carboxymethyl groups (-CH₂COOH) to the cellulose backbone, replacing some hydroxyl groups (-OH). This substitution is typically measured as the degree of substitution (DS)2, ranging from 0.4 to 1.5. The DS value directly impacts CMC's properties - higher DS values generally mean better solubility in water.

CMC's structure gives it unique properties that make it invaluable across industries:

| Property | Benefit | Industry Applications |

|---|---|---|

| Water solubility | Creates clear solutions without heat | Food, pharmaceuticals, personal care |

| Thickening ability | Controls viscosity at low concentrations | Detergents, paints, food products |

| Binding capacity | Holds ingredients together | Pharmaceuticals, ceramics, paper |

| Film-forming | Creates protective coatings | Food packaging, pharmaceuticals |

| pH stability | Functions across wide pH range (3-10) | Diverse industrial applications |

When CMC dissolves in water, it forms a three-dimensional network that traps water molecules. This is why just a small amount can significantly increase a solution's viscosity. I've personally seen customers reduce their thickener usage by up to 30% when switching to our high-quality CMC.

What is Carboxymethyl Cellulose Used For in Different Industries?

Have you ever wondered how so many different products maintain their perfect consistency? From foods you eat to medicines you take, CMC plays a crucial but often invisible role in product formulation.

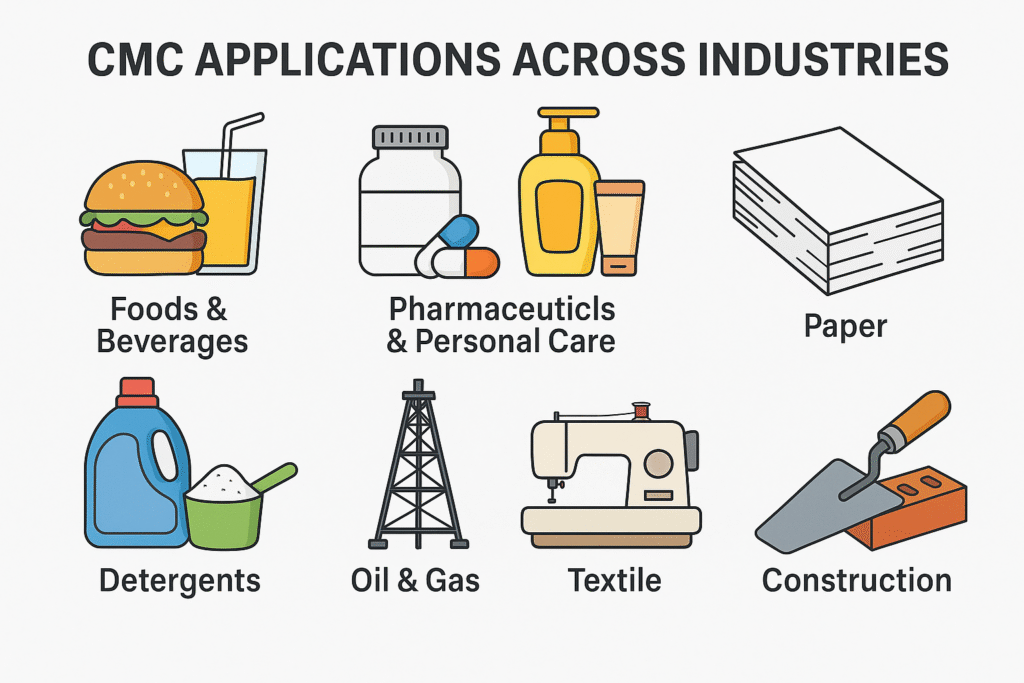

Carboxymethyl cellulose is used as a thickener in foods like ice cream and salad dressings, a stabilizer in pharmaceuticals, a binding agent in detergents, a sizing agent in textiles, and a rheology modifier in oil drilling. Its versatility stems from its ability to control viscosity while maintaining stability across different temperatures and pH levels.

I've worked with clients across various sectors, and the versatility of CMC never ceases to amaze me. Let me walk you through how different industries leverage its unique properties:

Food Industry Applications

CMC has become indispensable in food production. In ice cream, it prevents ice crystal formation during freezing and thawing cycles, creating that smooth texture consumers love. In bakery products, it improves dough stability and increases moisture retention, extending shelf life. Our clients in the beverage industry use CMC to suspend fruit pulp in drinks without settling.

Pharmaceutical and Personal Care Uses

In the pharmaceutical sector, CMC serves as a tablet binder and disintegrant, controlling how medications release active ingredients in the body. For toothpastes, it provides the perfect consistency while helping ingredients remain evenly distributed. I've helped formulate ophthalmic solutions where CMC mimics natural tears, providing relief for dry eyes.

Industrial and Technical Applications

For our industrial clients, CMC functions as:

- A water retention agent in concrete and mortar

- A protective colloid in ceramic glazes

- A sizing agent in textile manufacturing

- A rheology modifier in oil drilling fluids

- An adhesive in paper products

The technical grade CMC3 we produce helps manufacturers optimize their processes while reducing costs. One client in the oil drilling industry reported a 15% improvement in fluid performance after switching to our specialized CMC grade.

Is CMC Safe to Consume in Food Products?

Are you concerned about the safety of food additives in your products? With increasing consumer scrutiny, manufacturers need confidence in the safety profile of every ingredient they use.

Carboxymethyl cellulose is generally recognized as safe (GRAS) by the FDA and approved as food additive E4664 in Europe. Numerous toxicological studies have confirmed its safety at typical consumption levels, showing it passes through the digestive system largely unmetabolized, with no significant absorption into the bloodstream.

Safety is a top priority for my company, which is why we maintain strict quality control protocols for all our CMC products. The safety profile of CMC comes from its molecular structure and behavior in the body. As a modified form of cellulose (which naturally occurs in all plant matter), CMC retains many of cellulose's inert properties.

Regulatory bodies worldwide have extensively evaluated CMC's safety:

| Regulatory Body | Designation | Daily Intake Limit |

|---|---|---|

| FDA (US) | GRAS (Generally Recognized As Safe) | No specific limitation when used according to GMP |

| EFSA (Europe) | E466 | ADI "not specified" (considered safe) |

| JECFA (WHO/FAO) | INS 466 | ADI "not specified" |

| Food Standards Australia New Zealand | Approved food additive | No specific limitation |

| Health Canada | Permitted food additive | Various uses with specific limits |

Our food-grade CMC undergoes rigorous testing to ensure it meets all applicable standards. We provide full documentation including:

- Certificate of Analysis

- Heavy metals testing results

- Microbiological safety reports

- Non-GMO certification

- Kosher and Halal certifications when required

I've worked with food manufacturers who initially had concerns about using CMC but were reassured by both the extensive safety data and our transparent quality assurance processes. One client even featured their use of "plant-derived thickeners" as a selling point after understanding CMC's natural origins.

What Are the Side Effects of Carboxymethylcellulose?

Do you worry about potential adverse reactions to ingredients in your products? Understanding the complete profile of raw materials helps prevent customer complaints and ensures product safety.

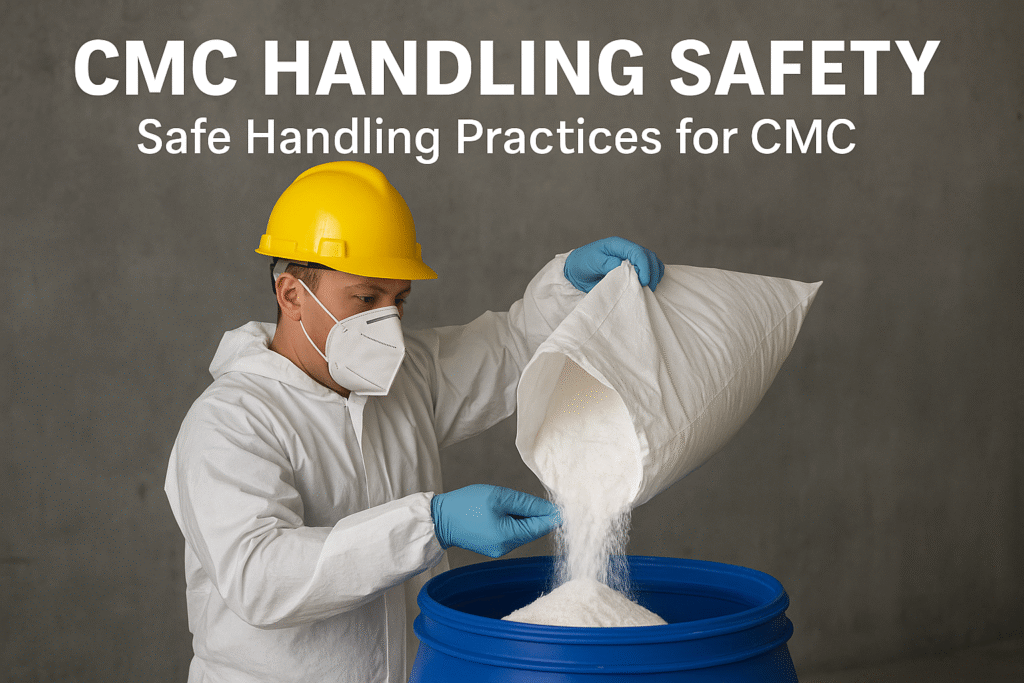

While carboxymethyl cellulose is generally safe, some individuals may experience mild digestive issues like bloating or gas when consuming large amounts. In rare cases, hypersensitivity reactions can occur. Industrial handling may cause mild eye or respiratory irritation, but protective equipment easily prevents these occupational exposures.

Through my years in the industry, I've gathered comprehensive information about the potential side effects of CMC. For food and pharmaceutical applications, the reported issues are minimal, but it's important to be aware of them:

Potential Digestive Effects

At high concentrations, CMC can cause:

- Temporary bloating

- Mild abdominal discomfort

- Changes in stool consistency

These effects result from CMC's water-binding properties in the digestive tract and typically resolve quickly. They're most commonly reported when CMC is used as a fiber supplement rather than as a food additive.

Allergic and Hypersensitivity Reactions

These are extremely rare but may include:

- Skin redness or itching

- Respiratory symptoms in sensitive individuals

- Contact dermatitis (primarily in industrial settings)

Our technical team tracks all reported adverse reactions and can confirm that significant issues are exceedingly uncommon. We've provided consultation to pharmaceutical companies developing CMC-containing products, helping them establish appropriate testing protocols.

Industrial Handling Considerations

For manufacturing personnel, CMC is considered a nuisance dust that requires standard dust control measures:

- Local exhaust ventilation

- Dust masks when handling large quantities

- Eye protection

- Regular cleaning protocols to prevent dust accumulation

We provide comprehensive safety data sheets and handling recommendations with all our CMC products. After implementing our suggested handling procedures, one client reported a complete elimination of respiratory complaints among workers who regularly handle CMC.

What Does Carboxymethyl Cellulose Do for Eyes?

Have you struggled with dry eye solutions that don't last or feel natural? Many ophthalmology products fail to provide lasting relief, frustrating both providers and patients. CMC offers surprising benefits for this specific application.

Carboxymethyl cellulose functions as an effective artificial tear component by mimicking the viscosity of natural tears and forming a protective coating on the eye surface. It increases tear film stability, extends contact time with the ocular surface, and provides sustained moisture relief for dry eye conditions while being non-irritating and compatible with contact lenses.

The ophthalmic applications of CMC represent one of its most specialized and high-value uses. Our pharmaceutical-grade CMC is used in numerous eye care formulations worldwide. Here's how it functions in these critical applications:

CMC's molecular structure makes it ideal for eye care because it:

- Closely matches the rheological properties of natural tears

- Adheres to the corneal surface without blurring vision

- Creates a moisture-retaining film that doesn't quickly wash away

- Remains stable in sterile solutions without preservatives

- Provides lubrication that reduces friction with each blink

In clinical settings, CMC-based eye drops typically outperform other artificial tear formulations in patient satisfaction surveys. Studies have shown that eye drops containing CMC can provide relief for up to 4-6 hours, compared to just 1-2 hours with some alternative formulations.

Our pharmaceutical partners incorporate CMC in various ophthalmic products:

| Product Type | CMC Concentration | Key Benefit |

|---|---|---|

| Artificial tears | 0.5-1.0% | Basic dry eye relief |

| Overnight lubricating gels | 1.0-2.0% | Extended protection during sleep |

| Contact lens rewetting drops | 0.1-0.5% | Compatible with lens materials |

| Post-surgical eye drops | 0.5-1.0% | Promotes corneal healing |

| Prescription dry eye medications | 0.5-1.0% | Delivery vehicle for active ingredients |

I've personally worked with ophthalmology researchers developing new dry eye treatments. The consistent feedback is that CMC provides an excellent balance of viscosity, retention time, and patient comfort compared to alternatives.

Frequently Asked Questions About Carboxymethyl Cellulose

Do you need quick answers to your CMC questions? I've compiled responses to the most common inquiries we receive from potential customers to help you make informed decisions.

Carboxymethyl cellulose is an odorless, white to cream-colored powder derived from plant cellulose. It dissolves in water to form clear solutions, is stable across pH 3-10, and comes in various viscosity grades5. CMC is biodegradable, compatible with most ingredients, and available in food, pharmaceutical, and technical grades for different applications.

Over my years in the cellulose derivatives industry, I've answered countless questions about CMC. Here are the most frequent ones, with detailed answers that go beyond the basics:

What's the difference between CMC grades?

CMC varies primarily by:

- Degree of substitution (DS): Higher DS means greater water solubility

- Viscosity: From 10 cPs to 50,000+ cPs (1% solution)

- Purity: Technical, food, and pharmaceutical grades have different specifications

- Particle size: Fine powder vs. granular forms affect dissolution speed

We can customize these parameters to match your specific application requirements. One customer needed a quick-dissolving, high-viscosity CMC for their instant food product, and we developed a specialized grade that reduced their production time by 25%.

How should CMC be stored?

For optimal shelf life (typically 2-3 years), store CMC:

- In a cool, dry place (below 30°C)

- Away from direct sunlight

- In sealed containers to prevent moisture absorption

- Away from strong odors (CMC can absorb odors)

Proper storage prevents clumping and viscosity loss. Our packaging includes moisture barriers and is available in various sizes from 25kg bags to 1000kg super sacks.

Is CMC environmentally friendly?

CMC is:

- Derived from renewable plant sources

- Biodegradable in appropriate environments

- Non-toxic to aquatic organisms at typical concentrations

- Energy-efficient to produce compared to many synthetic polymers

We've documented our environmental practices and provide sustainability information for customers with eco-friendly initiatives. Our production facility has reduced water usage by 40% in recent years through process improvements.

How do I incorporate CMC into my formulation?

For best results:

- Disperse CMC in cold water under high shear

- Allow complete hydration (15-30 minutes depending on grade)

- Add other ingredients after CMC has fully dissolved

- Consider using our pre-dispersed grades for easier incorporation

Our technical team offers free formulation assistance, including sample preparation protocols tailored to your specific equipment and processes.

Conclusion

Carboxymethyl cellulose offers versatility, safety, and performance across industries. From food products to pharmaceuticals and industrial applications, CMC delivers reliable thickening, stabilizing, and binding properties while meeting strict safety standards. Contact us to discover how our CMC can enhance your products.

-

Explore how CMC enhances product quality and efficiency across multiple sectors. ↩

-

Understand how DS affects the properties and applications of CMC. ↩

-

Discover how technical grade CMC optimizes processes in various industries. ↩

-

Explore the safety and regulatory status of food additive E466 in food products. ↩

-

Understand how viscosity grades affect the performance of CMC in applications. ↩