Are you struggling with tile failures, wastage of materials, and unhappy customers? Poor quality tile adhesive can lead to costly repairs and damage your business reputation.

A high-performance Ceramic Tile Adhesive1 (CTA) contains quality cellulose ethers2 like HPMC3, proper cement ratios, and essential additives that ensure strong bonding, flexibility, and water resistance for long-lasting tile installations in various environments.

I've been in the construction chemicals industry for over 15 years, and I've seen countless projects fail due to substandard tile adhesives. The right CTA not only saves money but also builds your reputation for quality work. Let me share what makes our solutions stand out.

What Are the Key Components of Ceramic Tile Adhesive1?

Watching a tile installation fail is painful. I've seen contractors lose thousands in repairs because they chose the wrong adhesive formulation.

Ceramic tile adhesive typically contains Portland cement (40-60%), fine sand (30-40%), cellulose ethers like HPMC (0.2-0.5%), redispersible polymer powder4 (1-3%), and additives such as thickeners and water-retention agents.

The success of any tile installation project depends on using the right adhesive formulation. Let's break down what makes a quality CTA and how each component contributes to performance:

Primary Components and Their Functions

| Component | Percentage | Function |

|---|---|---|

| Portland cement | 40-60% | Main binding agent |

| Fine sand | 30-40% | Provides structure and workability |

| HPMC/MHEC | 0.2-0.5% | Water retention, improved workability |

| Redispersible polymer powder | 1-3% | Flexibility, adhesion strength |

| Additives | <1% | Specific performance enhancements |

The cellulose ether component is critical but often overlooked. Our HPMC products are specially formulated for CTA applications, providing optimal water retention without sacrificing open time or workability. I've personally tested various formulations in extreme conditions, from Saudi Arabia's heat to Singapore's humidity, and found that precisely controlling the viscosity and modification degree of cellulose ethers significantly impacts the final performance.

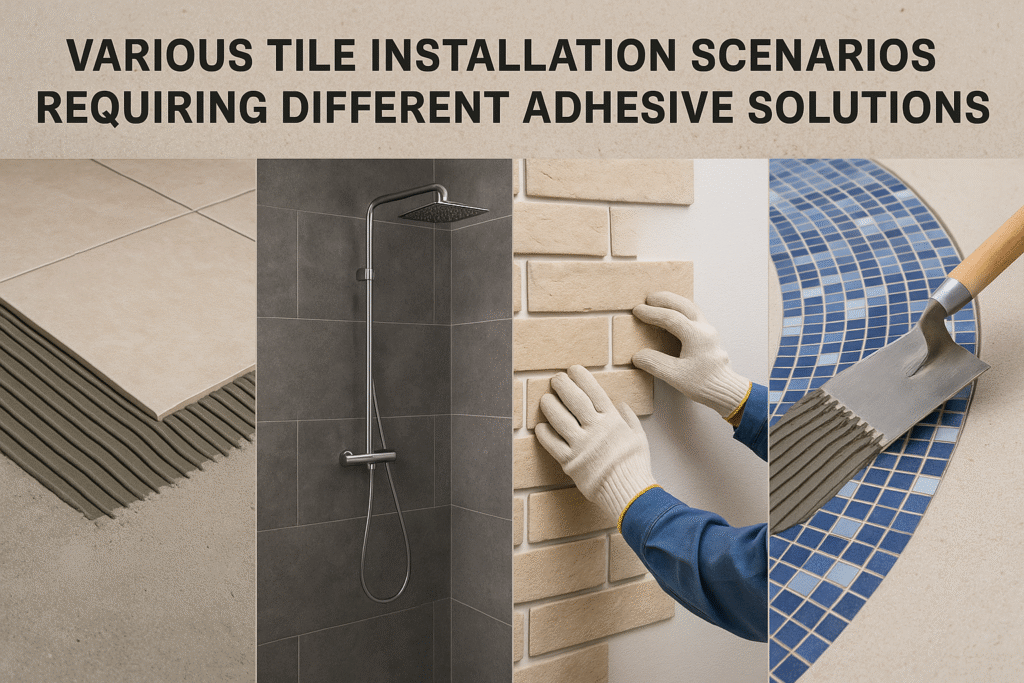

What Solutions Do We Recommend for Different Tile Applications?

I've seen beautiful marble floors ruined by adhesive failure. Using general-purpose adhesive for specialty tiles is like putting regular fuel in a sports car.

For standard wall tiles, we recommend HPMC3 with 100,000-150,000 mPa·s viscosity at 0.3% dosage. For floor tiles and larger formats, RDP-enriched formulations with 200,000 mPa·s HPMC and 2-3% redispersible powder create stronger bonds and flexibility.

Selecting the right adhesive formula isn't just about strength - it's about matching the adhesive properties to the specific installation challenges. Based on my experience working with major tile manufacturers across developing markets, I've developed specialized solutions for different applications:

Indoor vs. Outdoor Applications

For indoor applications, water resistance and mold prevention are key concerns, especially in bathrooms and kitchens. Our indoor formulas incorporate anti-fungal additives and balanced water retention. For outdoor applications, we increase the polymer content to withstand temperature fluctuations and add specialized additives to prevent efflorescence.

Floor vs. Wall Installations

Floor installations face different stresses than wall installations. Our floor tile adhesives contain higher percentages of redispersible powder (2-3%) to handle the weight and traffic, while wall formulations focus on quick grab and non-sagging properties. I once consulted on a major hotel project in Dubai where the wrong wall adhesive was initially specified - switching to our specialized formula prevented thousands of dollars in rework.

What Features Make Our Tile Adhesive Products Superior?

Ever applied adhesive only to find it drying too quickly or becoming too runny? Poor quality control in manufacturing causes inconsistent performance that can ruin your whole project.

Our ceramic tile adhesives feature precisely controlled viscosity (100,000-200,000 mPa·s), exceptional water retention (>98%), extended open time (20-30 minutes), and enhanced slip resistance due to our proprietary HPMC manufacturing process.

The difference between an amateur and professional tile installation often comes down to the quality of the adhesive used. Our products stand out due to several key features that ensure consistent performance:

Molecular Engineering for Better Performance

Unlike generic suppliers, we engineer our cellulose ethers2 at the molecular level. Our HPMC products undergo precise substitution processes that optimize the balance between methoxyl and hydroxypropyl groups. This might sound technical, but the result is practical: longer open time without sacrificing early strength development.

I remember visiting a client's factory in Pakistan who was struggling with inconsistent set times. After analyzing their process, we modified our HPMC's molecular structure to account for their local cement characteristics and high ambient temperatures. Their callback rate dropped by 87% within three months.

Temperature Stability Across Different Climates

Through extensive field testing across different climate zones, we've developed formulations that maintain consistent performance regardless of temperature variations. Our products perform equally well in the 45°C heat of Saudi Arabian summers and the variable conditions of Southeast Asian monsoon seasons. This is achieved through careful control of particle size distribution and the addition of specialty retarding agents that activate only when needed.

Which Specific Products Should You Choose for Your Projects?

I once wasted an entire shipment of adhesive because I didn't match the product to my specific needs. Let me help you avoid that expensive mistake.

For standard ceramic wall tiles, our HPMC KH-150S (150,000 mPa·s) provides excellent workability. For porcelain and heavy floor tiles, we recommend combining HPMC KH-200S with our RDP KR-500 for superior bond strength and flexibility.

Selecting the right products for your specific application can significantly impact your project's success. Based on extensive testing and customer feedback, here are our top recommendations:

For Standard Tile Installations

Our HPMC KH-150S has become the preferred choice among professional tilers for standard ceramic tile installations. With its 150,000 mPa·s viscosity and 2% moisture content, it creates the perfect balance between workability and grab. When used at the recommended 0.3% dosage rate, it extends working time to 25-30 minutes – enough time to make adjustments without rushing.

For Premium and Challenging Installations

For premium porcelain, natural stone, or large format tiles, we recommend our advanced system: HPMC KH-200S combined with our specialized redispersible powder KR-500. This combination creates a high-performance adhesive that can accommodate the thermal movement of outdoor installations and the weight of larger tiles.

The KR-500 contains vinyl acetate-ethylene with specialized functional groups that enhance bonding to difficult substrates. In a recent project in the UAE, this combination successfully bonded 120×60 cm porcelain tiles to a vertical concrete surface in an exterior application – a challenging installation that many competing products failed to accomplish.

How Does Our Service Support Your Business Success?

Nothing's worse than waiting weeks for delivery while your project schedule slips. I've been there, and that's why we've completely overhauled our service model.

We provide 24-hour technical support5, custom formulation services, free samples with application testing, and guaranteed 15-day delivery to major ports worldwide, backed by pre-shipment quality testing and certificated analysis.

Beyond just supplying quality products, we've built a comprehensive service framework to ensure your success:

Technical Expertise and Formulation Support

Our team includes specialists with decades of experience in ceramic tile adhesive formulation. We don't just sell chemicals – we help you optimize your formula for local conditions and materials. Last year, we helped a major mortar producer in Brazil reformulate their tile adhesive to work with local high-alumina cement, saving them 12% in raw material costs while improving bond strength by 15%.

We offer free formulation reviews and can suggest adjustments based on your specific manufacturing process, local raw materials, and target performance characteristics. This service has helped numerous clients overcome challenges like early skinning in dry conditions, poor workability with particular sand types, and inadequate strength development with certain cement varieties.

Reliable Supply Chain and Quality Assurance

We understand that consistency is crucial for manufacturers. Our six production lines maintain strict quality control protocols, and every batch undergoes testing for viscosity, substitution degree, and application performance. We provide complete test certificates with each shipment and maintain sample retention for two years.

Our logistics team coordinates closely with shipping partners to ensure on-time delivery, with contingency plans for potential disruptions. For key accounts, we even maintain safety stock at regional warehouses to eliminate supply chain risks.

What Questions Do Customers Frequently Ask About Ceramic Tile Adhesives?

I remember being confused about which grade of HPMC to use for my first tile adhesive formulation. Let me answer the questions I wish someone had answered for me back then.

The optimal HPMC dosage for tile adhesive is 0.2-0.5% depending on desired properties. Standard HPMC provides 20-30 minutes of open time, and proper formulations can achieve >1.0 N/mm² tensile adhesion strength in both standard and heat-aged conditions.

After supporting thousands of customers worldwide, I've gathered the most common questions and their answers:

Technical Questions About Formulation

Many clients ask about optimizing their formulations for specific conditions. The methoxyl content of HPMC significantly affects water retention and workability - we typically recommend 28-30% methoxyl content for balanced performance. For hot and dry conditions, increasing the HPMC dosage by 0.05-0.1% and using slightly higher viscosity grades helps compensate for rapid water evaporation.

Another common question concerns compatibility with other additives. Our HPMC products are compatible with most common additives, but we recommend caution with highly alkaline accelerators and certain air-entraining agents. We maintain a comprehensive compatibility database based on thousands of formulation tests.

Regulatory and Quality Assurance Questions

With increasing regulatory scrutiny worldwide, many customers ask about compliance with standards. Our products meet international standards including EN 12004, ISO 13007, and ANSI A118.4. We provide full documentation packages including technical data sheets, safety data sheets in multiple languages, and certificates of analysis.

For manufacturers seeking certification, we offer pre-testing services to verify that formulations using our products will meet the required standards before you submit for official testing. This service has helped many clients avoid costly reformulations and certification delays.

Conclusion

Choosing the right ceramic tile adhesive components is crucial for successful installations. Our high-quality HPMC and RDP products, backed by technical support and reliable service, ensure your tile adhesive performs consistently in any environment.

-

Explore the advantages of high-performance CTAs for strong bonding and durability in tile installations. ↩ ↩

-

Learn how cellulose ethers enhance tile adhesive properties for better workability and adhesion. ↩ ↩

-

Find out how HPMC improves water retention and workability in tile adhesive applications. ↩ ↩

-

Explore the benefits of RDP in enhancing flexibility and adhesion strength in tile adhesives. ↩

-

Discover the technical support options that can help you succeed with tile adhesive applications. ↩