Ever struggled with product inconsistency or application failures? The wrong CMC viscosity can sabotage your entire production line, costing you thousands in wasted materials and delayed shipments.

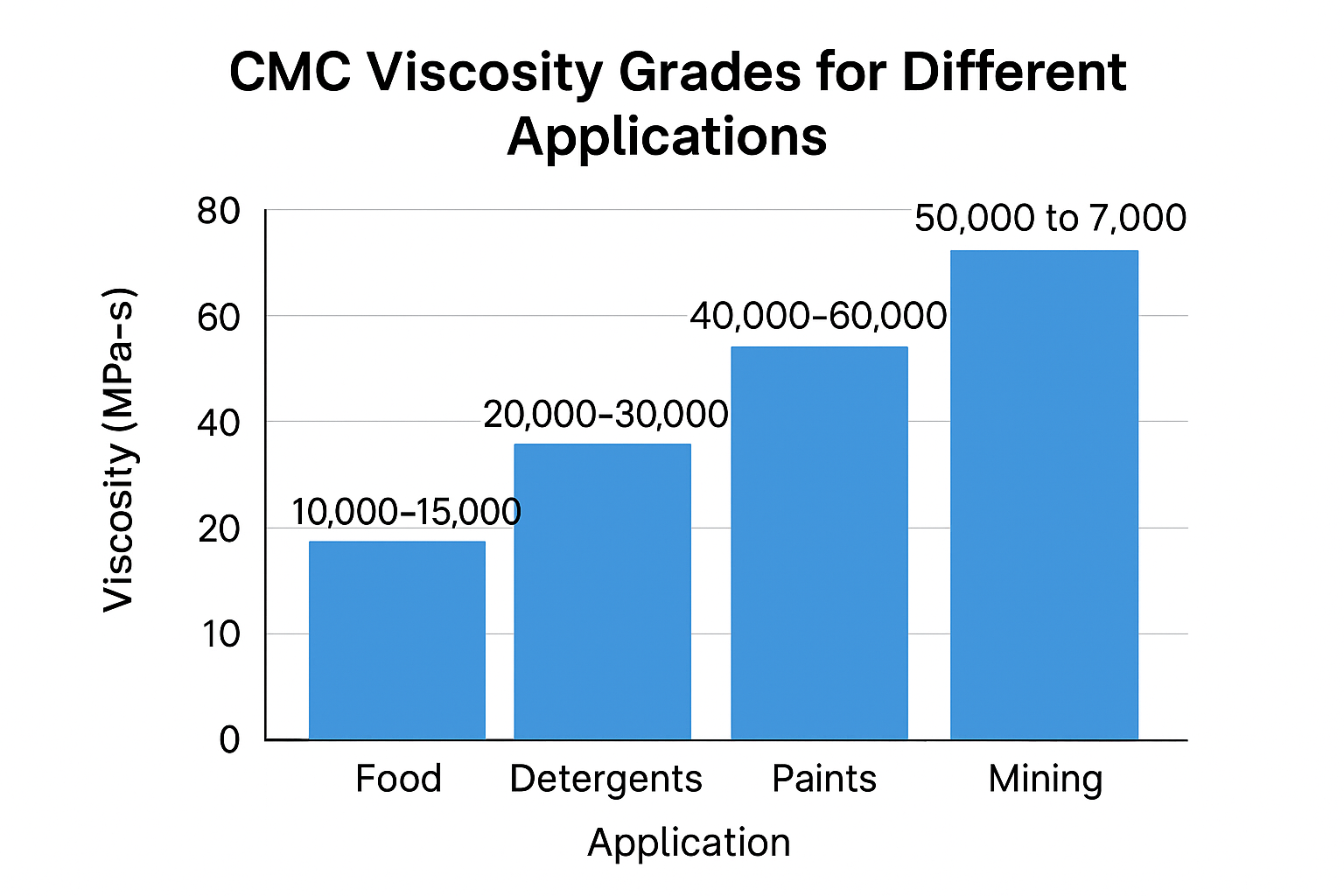

Choosing the right CMC viscosity1 depends primarily on your application requirements. For paints, higher viscosity grades (800-2000 mPa·s) provide better suspension and anti-sagging properties, while detergents typically need lower viscosity CMC (100-800 mPa·s) for improved flowability and dissolution rate.

At Kehao, I've seen countless clients struggle with this decision. Getting the viscosity right isn't just about product performance—it directly impacts your production efficiency and bottom line. Let me break down exactly how to make this critical choice for your specific needs.

What is the Viscosity of CMC and Why Does It Matter?

Have you ever measured CMC incorrectly and watched your entire batch fail quality control? The financial impact of these errors can be devastating, especially for large-scale production.

The viscosity of CMC typically ranges from 50 to 2500 mPa·s for a 1% solution, determined using a Brookfield viscometer at 25°C. This property directly affects thickening power, stabilization capacity, and suspension ability in your formulations.

Viscosity is arguably the most critical property when selecting the right CMC for your application. From my 15 years working with manufacturers across Saudi Arabia and the UAE, I've observed that viscosity profoundly impacts not just the end product performance but also processing efficiency.

The viscosity of CMC is influenced by several factors:

| Factor | Impact on Viscosity | Consideration for Selection |

|---|---|---|

| Degree of Substitution (DS)2 | Higher DS = Higher viscosity | DS 0.7-0.9 for paints; DS 0.5-0.7 for detergents3 |

| Molecular Weight | Higher MW = Higher viscosity | 250,000-400,000 Da for high-viscosity needs |

| Solution pH | Optimal at pH 7-9 | Adjust formula pH to maximize CMC performance |

| Temperature | Decreases with heat | Consider your processing temperature |

| Salt Content | Decreases with electrolytes | Important for detergent applications |

I remember visiting a client's paint factory in Pakistan where they were using low-viscosity CMC (200 mPa·s) in their premium wall paint. Their products were settling during storage and showing poor brush resistance. After switching to our 1500 mPa·s grade, their product stability improved dramatically, eliminating customer complaints and returns.

What is the Percentage of CMC in Detergent?

Are your detergent formulations suffering from poor stability or inadequate soil suspension? Many manufacturers I've consulted were using incorrect CMC percentages, leading to inconsistent product performance.

Modern detergent formulations4 typically contain between 0.5% to 2% CMC, depending on the detergent type and desired properties. Liquid detergents generally require lower percentages (0.5-1%) while powder formulations often need 1-2% for optimal performance.

The percentage of CMC in detergent formulations has a direct impact on multiple product properties that can make or break your product's market success. Through my experience supplying to major detergent manufacturers in India and the Middle East, I've identified the critical relationships between CMC percentage and product performance.

The optimal percentage depends heavily on the detergent type and target properties:

| Detergent Type | CMC Percentage Range | Primary Function |

|---|---|---|

| Laundry Powder | 1.0-2.0% | Anti-redeposition, soil suspension |

| Liquid Laundry | 0.5-1.0% | Viscosity control, stability |

| Dishwashing Liquid | 0.2-0.8% | Thickening, improved cling |

| Industrial Cleaners | 1.0-3.0% | Suspending ability for heavy soils |

Additionally, the viscosity grade selection correlates with your percentage use:

- Lower percentages (0.5%) with high-viscosity CMC (1500+ mPa·s) for premium liquid detergents

- Higher percentages (1.5-2%) with medium-viscosity CMC (400-800 mPa·s) for standard powder detergents

Last month, I consulted with a detergent manufacturer in Brazil who was experiencing product separation and poor soil suspension. By adjusting their CMC percentage from 0.3% to 1.2% and switching to our medium-viscosity grade (650 mPa·s), they significantly improved product stability and cleaning performance.

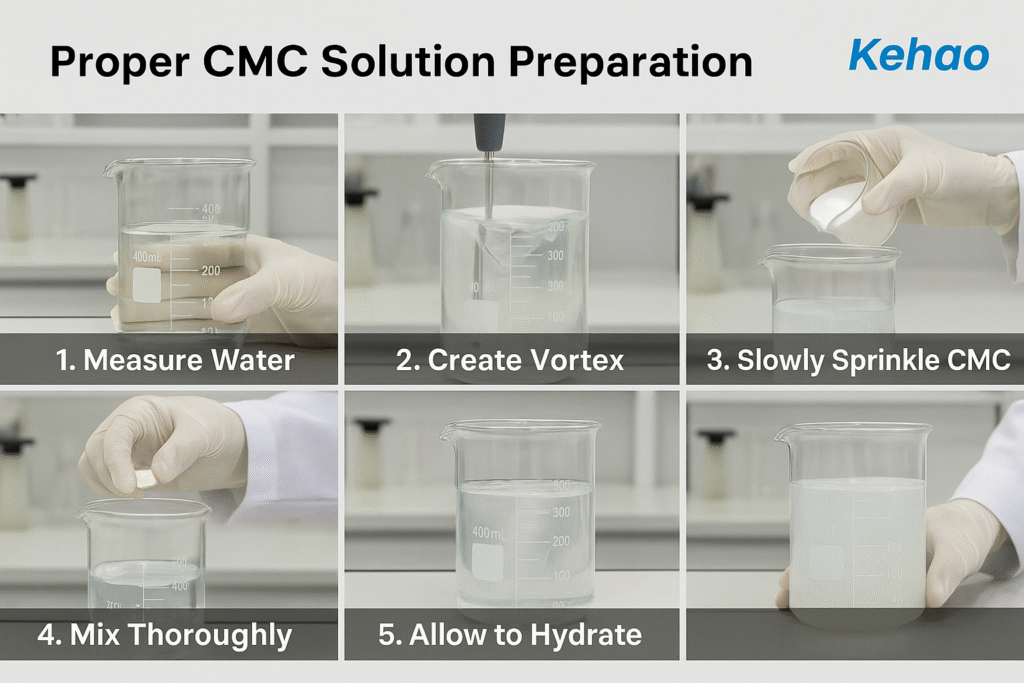

How to Make 1% CMC Solution?

Have you struggled with undissolved lumps or inconsistent viscosity readings when preparing CMC solutions? This common issue has frustrated many of my clients before they learned the proper technique.

To make a 1% CMC solution5, gradually add 10g of CMC powder to 990g of water while stirring vigorously. For best results, use room temperature water initially, create a vortex while adding the powder, and continue stirring for 30-60 minutes until completely dissolved.

Preparing a proper 1% CMC solution is fundamental for both quality control testing and actual application in your production process. I've observed that many manufacturing issues stem from improper CMC dispersion and dissolution, which can dramatically affect final product performance.

The key to success lies in understanding the hydration mechanism of CMC and following a systematic preparation approach:

Step-by-Step Preparation Process:

-

Temperature Selection

- Cold water (15-20°C): Slower dissolution but prevents lumping

- Warm water (30-40°C): Faster dissolution but requires more careful powder addition

- Hot water (>50°C): Not recommended as it can cause uneven hydration

-

Dispersion Method Options

| Method | Advantages | Disadvantages | Best For |

|---|---|---|---|

| High-Shear Mixing | Fast, efficient | Equipment cost | Large scale production |

| Pre-blend with compatible dry ingredient | Prevents lumping | Dilutes concentration | Powder formulations |

| Slurry in non-solvent (glycerin/alcohol) | Excellent dispersion | Additional ingredients | Premium applications |

- Dissolution Time

- Low viscosity CMC (50-300 mPa·s): 15-30 minutes

- Medium viscosity CMC (300-1000 mPa·s): 30-45 minutes

- High viscosity CMC (1000+ mPa·s): 45-60 minutes

I remember visiting a paint manufacturer in Vietnam who struggled with inconsistent CMC performance. Their problem wasn't the CMC itself but their preparation method—adding CMC too quickly to still water. After implementing our staged addition process with proper agitation, their quality control results became much more consistent, saving them thousands in reformulation costs.

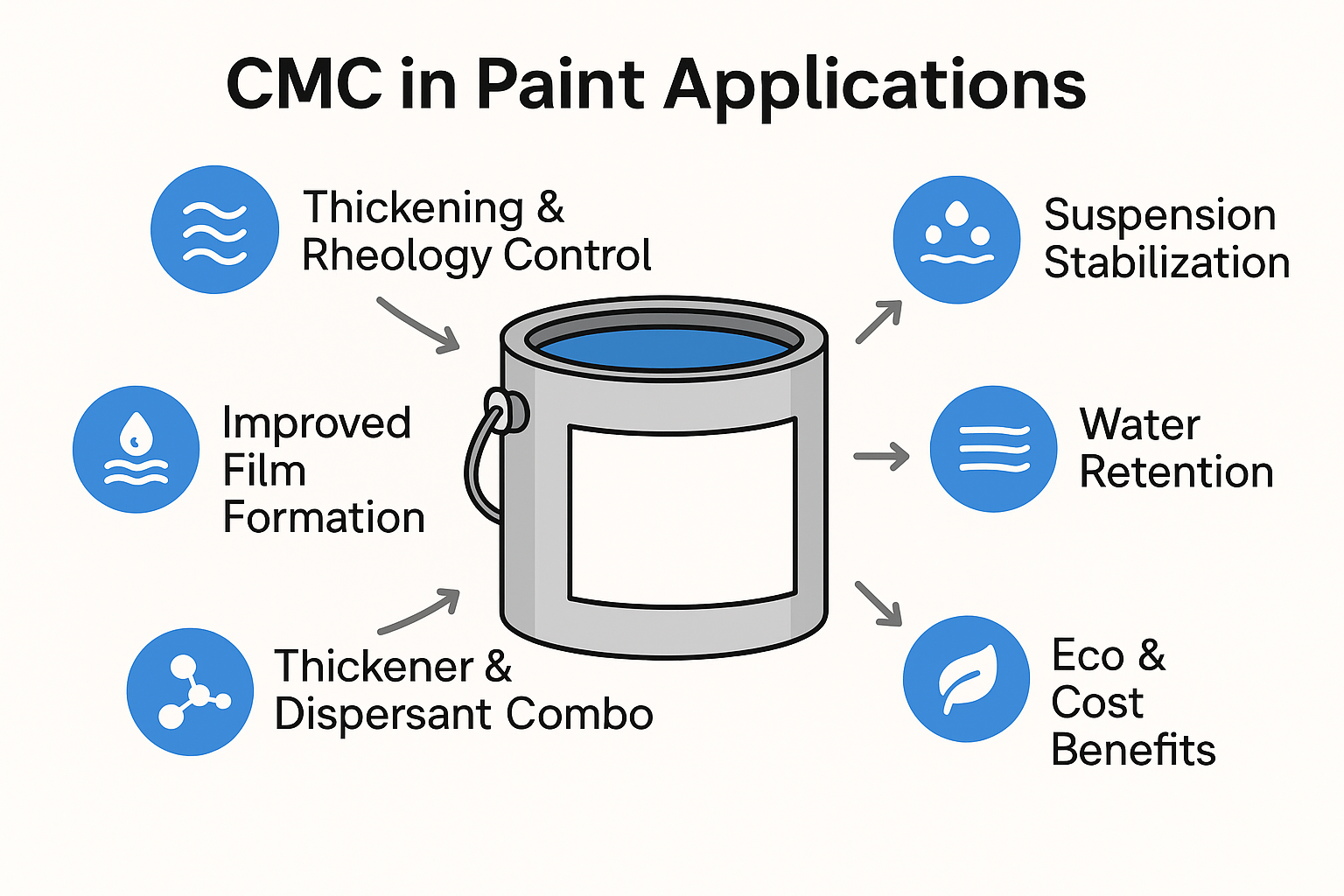

What is the Use of CMC in Paint?

Is your paint experiencing poor stability, inadequate viscosity, or brushability issues? These common problems often trace back to improper CMC selection or usage.

CMC serves multiple critical functions in paint formulations6: it acts as a thickener to provide proper application viscosity, a protective colloid to stabilize pigment suspensions, a water retention agent to improve working time, and an anti-sagging agent for vertical surface applications.

In my two decades working with paint manufacturers across developing markets, I've seen firsthand how CMC dramatically influences paint performance across various property dimensions. The right CMC can transform a mediocre paint into a premium product, while the wrong choice can render even expensive formulations unusable.

Paint applications generally require specific CMC characteristics:

| Paint Type | Recommended CMC Viscosity | Typical Usage Level | Key Benefits |

|---|---|---|---|

| Interior Wall Paint | 1000-1500 mPa·s | 0.3-0.5% | Sag resistance, leveling |

| Exterior Paint | 1200-2000 mPa·s | 0.4-0.7% | Water retention, weatherability |

| Primer | 800-1200 mPa·s | 0.2-0.4% | Stabilization, hiding power |

| Textured Paint | 1500+ mPa·s | 0.5-0.8% | Pattern maintenance, workability |

The interaction between CMC and other paint components is also critical:

- With titanium dioxide: Prevents flocculation and improves coverage

- With latex binders: Enhances stability and prevents coagulation

- With colorants: Improves dispersion and color development

For high-quality paints, we typically recommend our high-purity CMC with low salt content and high degree of substitution (DS 0.85-0.95). This prevents interference with other additives while providing maximum thickening efficiency.

One of my clients in Georgia switched from a standard CMC to our premium high-viscosity grade for their premium interior paint line. The result was a 30% improvement in sagging resistance and significantly better leveling properties, allowing them to market their product at a higher price point with genuine performance advantages.

Conclusion

Selecting the right CMC viscosity is crucial—high viscosity (800-2000 mPa·s) for paints and lower (100-800 mPa·s) for detergents. Consider your specific application requirements, proper preparation methods, and optimal usage percentages for best results.

-

Understanding CMC viscosity is essential for optimizing product formulations and ensuring quality control. ↩

-

Understanding DS is crucial for selecting the right CMC for specific applications. ↩

-

Find out how CMC improves the effectiveness of detergents and their performance. ↩

-

Learn about the optimal CMC percentages for various types of detergents. ↩

-

Find step-by-step instructions for preparing a consistent CMC solution. ↩

-

Explore how CMC enhances the performance and stability of paint products. ↩