Many customers struggle with CMC powder clumping1 in their industrial mixers, causing production delays and wasting expensive materials. I've seen this problem repeatedly at factories across Saudi Arabia and UAE.

To dissolve CMC powder correctly, use a three-step process: first disperse CMC in cold water with high-speed agitation, then allow it to hydrate completely for 30-60 minutes, and finally adjust the pH to 7-9 for optimal viscosity development. This prevents clumping and ensures uniform distribution.

After 15 years in the cellulose derivatives business, I've visited countless factories struggling with CMC dissolution issues. The difference between proper and improper dissolution can dramatically impact your final product quality. Let me share the knowledge that has helped our clients improve their production processes.

How to Dissolve CMC Powder Properly Without Clumping?

When adding CMC powder directly to water, many operators face immediate clumping issues. The outer layer hydrates too quickly, forming a gel barrier that prevents water from reaching the inside.

To dissolve CMC powder properly, first create a vortex in cold water using high-speed agitation (300-400 RPM), then slowly add CMC powder to the vortex edge, not the center. Maintain agitation for 30-60 minutes until completely hydrated. For industrial use, consider using a venturi-style powder induction system2.

The 3-Step Method for Perfect CMC Dissolution

When I visit our customers' facilities in places like India or Brazil, I often demonstrate this three-step method that has transformed their production processes:

Step 1: Proper Dispersion

Start with cold water (15-25°C) in your mixer. The lower temperature slows initial hydration, giving you time to properly disperse the powder. Create a strong vortex with your mixer running at 300-400 RPM. Add CMC powder slowly at the edge of the vortex, never dumping it in the center. For industrial scale operations, I recommend using powder induction systems that avoid direct contact between powder and water until the last moment.

Step 2: Complete Hydration

After adding all the CMC powder, reduce mixing speed to 150-200 RPM and allow 30-60 minutes for complete hydration. The time depends on CMC grade3, concentration, and temperature. High-viscosity grades require longer hydration times. During a recent project in Pakistan, we found that increasing hydration time from 30 to 50 minutes reduced final product defects by 23%.

Step 3: pH Adjustment

For optimal viscosity, adjust the pH to 7-9 using food-grade sodium hydroxide or citric acid. This final step ensures maximum viscosity development and stability.

| CMC Grade | Recommended Water Temperature | Typical Hydration Time | Optimal pH Range |

|---|---|---|---|

| Low viscosity | 15-20°C | 30-40 minutes | 7.0-8.0 |

| Medium viscosity | 15-25°C | 40-50 minutes | 7.5-8.5 |

| High viscosity | 20-25°C | 50-60 minutes | 8.0-9.0 |

What is the Purpose of CMC Powder in Industrial Applications?

Plant managers often ask me why CMC is so difficult to dissolve compared to other additives. The same properties that make it challenging are what make it valuable.

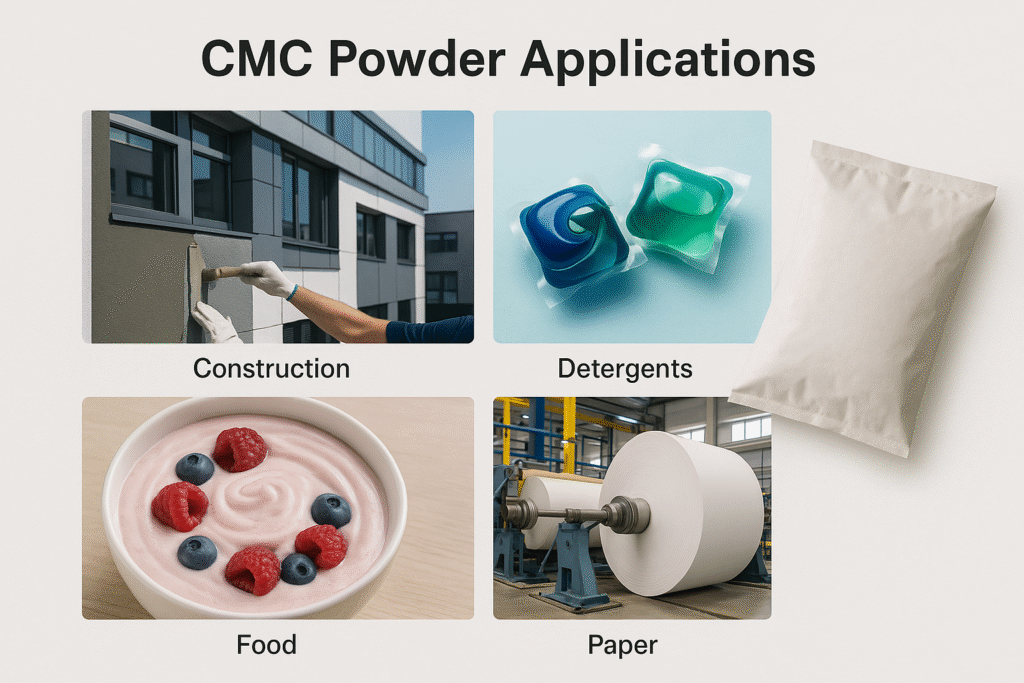

CMC (Carboxymethyl cellulose) powder serves as a thickener4, stabilizer, water-retention agent, and rheology modifier in industries like construction, paints, pharmaceuticals, food, and oil drilling. Its ability to form viscous solutions at low concentrations makes it economical while providing excellent binding, thickening, and suspension properties.

Key Functions of CMC Across Different Industries

Working with customers across multiple sectors, I've seen firsthand how versatile CMC powder can be. In construction mortars, CMC improves water retention, workability, and adhesion. This translates to longer open times and better bonding with substrates.

In paint formulations, our customers value CMC for its thickening effects and anti-settling properties. It prevents pigment sedimentation during storage and provides the right viscosity for application. Unlike some synthetic thickeners, CMC offers excellent stability across various pH levels.

For the pharmaceutical and personal care industries, the binding and film-forming properties of CMC are essential. It creates stable gel structures that can be used as carriers for active ingredients. In one project with a Saudi Arabian pharmaceutical manufacturer, switching to our high-purity CMC improved their tablet binding uniformity by 18%.

| Industry | Primary CMC Function | Typical Dosage Range |

|---|---|---|

| Construction | Water retention, workability | 0.2-0.5% |

| Paints | Thickening, anti-settling | 0.3-1.0% |

| Food | Stabilizer, texture modifier | 0.1-1.0% |

| Pharmaceuticals | Binder, film-former | 0.5-5.0% |

| Oil drilling | Fluid loss control | 0.5-2.0% |

How to Prepare CMC Solution for Different Applications?

Many technical managers struggle with adapting general CMC dissolution guidelines to their specific production requirements and equipment.

To prepare CMC solution, first determine the required concentration (typically 0.5-2% for industrial applications). For dry-mix applications, blend CMC with other powder ingredients before adding water. For wet-mix systems, pre-disperse CMC in high-shear mixers before adding to the main batch. Always conduct small-scale trials to optimize your specific process.

Application-Specific Preparation Methods

Over the years, I've helped develop custom CMC preparation protocols for various industries. Here's what I've learned works best:

For Construction Applications

When working with customers in the construction industry, especially mortar manufacturers in the Middle East, I recommend a two-stage mixing process. First, dry-blend the CMC powder with cement and aggregates before introducing water. This method physically separates the CMC particles, preventing immediate clumping when water is added.

For ready-mix applications, prepare a concentrated CMC solution (2-3%) separately using high-shear mixers, then add this pre-hydrated solution to the main batch. During a recent project in Iran, we helped a customer implement this method, resulting in a 30% reduction in mixing time and more consistent final properties.

For Paint and Coating Systems

Paint manufacturers require particularly uniform CMC solutions. For these applications, I suggest using medium-viscosity grades with lower degrees of substitution for better compatibility with paint components. Start by creating a slurry of CMC in glycol or alcohol (which doesn't hydrate the CMC) before adding to water under high shear. This approach prevents the formation of "fish eyes" and yields smooth, lump-free solutions.

For Food and Pharmaceutical Applications

These industries demand higher purity CMC and more precise preparation methods. Use de-ionized or distilled water at controlled temperatures, and consider adding a non-hydrating solvent like ethanol (10-20% of the water amount) during the dispersion phase to slow initial hydration and improve distribution.

| Application | Pre-Treatment | Mixing Equipment | Special Considerations |

|---|---|---|---|

| Dry mortars | Dry-blending with cement | Powder blender | Protected from moisture during storage |

| Liquid paint | Pre-dispersion in glycol | High-shear mixer | Temperature control important |

| Pharmaceuticals | Co-milling with excipients | Controlled shear mixer | Sterile conditions may be required |

| Oil drilling | Step-addition method | Multi-stage mixer | Salt compatibility testing needed |

Can CMC Dissolve in Cold Water Effectively?

During technical consultations, clients often debate whether to use hot or cold water for CMC dissolution, especially when working with high-viscosity grades.

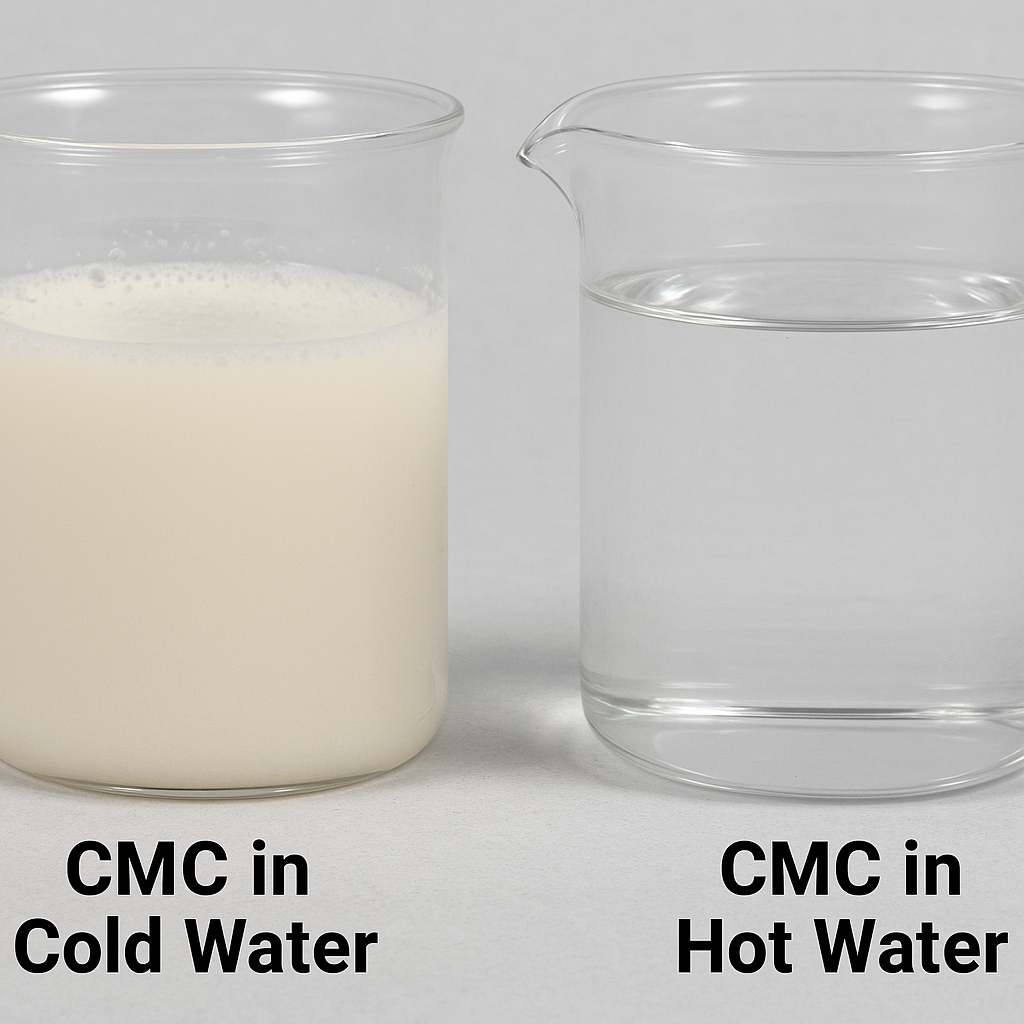

Yes, CMC dissolves effectively in cold water, and cold water (15-25°C) is actually preferred for initial dissolution. Cold water slows the initial hydration rate, allowing better powder dispersion before viscosity increases. Hot water (>40°C) causes rapid surface hydration, leading to clumping and "fish eyes" that are difficult to dissolve completely.

Temperature Effects on CMC Dissolution

Through numerous field tests across our customer base, I've gathered concrete data on how temperature affects CMC dissolution. Cold water dissolution offers several advantages that aren't immediately obvious:

While cold water slows initial hydration, it ultimately leads to more complete dissolution and higher final viscosity. This counter-intuitive fact has helped many of our customers improve their processes. In a controlled study we conducted for a customer in Vietnam, the same CMC grade dissolved in 20°C water achieved 12% higher final viscosity compared to dissolution at 45°C, despite taking longer to reach complete hydration.

Temperature also affects the stability of the final solution. CMC solutions prepared with cold water tend to have better long-term stability and consistent rheological properties. For applications where the CMC solution will be stored before use, this becomes particularly important.

For high-viscosity grades5 (>1500 mPa·s), the difference becomes even more pronounced. When I teach operators at customer sites, I often demonstrate this by preparing two identical samples - one with cold water and one with hot. The difference in final quality is visible even to the untrained eye.

| Water Temperature | Initial Dissolution Speed | Final Solution Quality | Recommended For |

|---|---|---|---|

| Cold (15-20°C) | Slower | Higher viscosity, fewer lumps | High-viscosity grades, precision applications |

| Room temp (20-25°C) | Moderate | Good balance of speed and quality | Most industrial applications |

| Warm (25-35°C) | Faster | Reduced final viscosity | Low-viscosity grades, time-sensitive production |

| Hot (>40°C) | Very fast but prone to clumping | Lowest quality, many undissolved particles | Not recommended |

Conclusion

Proper CMC dissolution requires careful attention to temperature, mixing technique, and hydration time. By following the three-step process and adapting it to your specific application, you'll achieve consistent, high-quality CMC solutions that deliver optimal performance in your products.

-

Understanding the causes of clumping can help you implement effective solutions in your production process. ↩

-

This system can improve your CMC mixing efficiency and prevent clumping during the process. ↩

-

Understanding CMC grades helps you select the right type for your specific industrial needs. ↩

-

Exploring CMC's thickening properties can help you improve product consistency and quality. ↩

-

Understanding these challenges can help you optimize your dissolution process for better results. ↩