Many tile installers in hot regions face a frustrating problem: adhesive drying too quickly before proper tile placement. This leads to poor adhesion, wasted material, and project delays that cost time and money.

HPMC gel temperature1 directly impacts tile adhesive performance2 in hot climates by controlling water retention. When temperatures approach HPMC's gel point (typically 65-85°C), the adhesive retains water more effectively, extending working time and preventing premature drying even in extreme heat.

Working with tile adhesives in hot climates brings unique challenges for contractors and DIY enthusiasts alike. I've seen countless projects compromised by improper understanding of how temperature affects adhesive performance. Let me share what I've learned about HPMC gel temperature1 and why it matters for your next tiling project.

Does Temperature Affect Tile Adhesive?

Installing tiles in Saudi Arabia last summer, I watched in frustration as my adhesive dried within minutes of application. The intense heat completely changed the product's behavior compared to cooler conditions.

Temperature significantly affects tile adhesive performance. In hot conditions (above 35°C), adhesive dries faster, reducing open time and workability. This rapid drying prevents proper tile adjustment and can decrease bond strength by up to 40% if not properly formulated with temperature-appropriate HPMC.

The relationship between temperature and adhesive performance is more complex than many realize. When temperatures rise, several critical changes occur in tile adhesives that affect application and final results. The most immediate impact is on water evaporation rate - for every 10°C increase in temperature, water evaporation approximately doubles, dramatically reducing working time.

This evaporation challenge is particularly problematic in outdoor installations or non-air-conditioned spaces in tropical and desert regions. I've compiled data from our field tests across different climate zones that clearly demonstrates this relationship:

| Temperature (°C) | Relative Humidity | Average Open Time (minutes) | Water Retention (%) |

|---|---|---|---|

| 25 | 50% | 25-30 | 98% |

| 35 | 40% | 15-20 | 90% |

| 45 | 30% | 5-10 | 75% |

Beyond just reducing open time3, high temperatures also affect the cement hydration process within the adhesive, potentially leading to strength issues if proper measures aren't taken. This is why understanding the role of HPMC's thermal properties becomes essential for successful installations in challenging climates.

What is the Role of HPMC in Tile Adhesive?

During a factory tour in Dubai, a customer complained about inconsistent adhesive performance. After inspection, I discovered they were using low-quality HPMC that couldn't maintain water retention in their climate.

HPMC (Hydroxypropyl Methylcellulose)4 serves as a critical water retention agent in tile adhesives. It prevents premature water loss, extends open time, improves adhesion, and enhances sag resistance. In hot climates, HPMC's thermal gelling properties become essential for maintaining workability despite rapid evaporation.

HPMC acts as a multifunctional additive that transforms ordinary cement-based mixtures into high-performance tile adhesives. At the molecular level, HPMC creates a complex network that interacts with water molecules, temporarily binding them within the adhesive matrix. This water-retention capability is particularly valuable during the critical early stages of the installation process when proper tile placement and adjustment must occur.

But HPMC's benefits extend beyond just water retention. It significantly improves the rheological properties of fresh adhesive mortar, creating the ideal balance between flowability and stability. This translates to practical benefits like easier troweling, better transfer to the tile back, and reduced slippage on vertical surfaces. I've analyzed the performance differences between adhesives with different HPMC concentrations:

| HPMC Content (%) | Water Retention | Open Time | Sag Resistance | Adhesion Strength |

|---|---|---|---|---|

| 0.0 | Poor | <5 min | Poor | Basic |

| 0.2 | Moderate | 10-15 min | Good | Improved |

| 0.4 | Excellent | 20-25 min | Excellent | Superior |

The viscosity modification provided by HPMC also prevents water segregation in the mixture, ensuring consistent performance across the application area. In hot climates specifically, the thermal gelling behavior of HPMC creates a protective mechanism that becomes more effective as temperatures rise - a remarkable self-regulating feature that makes it indispensable for challenging installation environments.

What is the Gelation Temperature of HPMC?

During a technical seminar in Riyadh, contractors were confused about different HPMC grades. I explained how gelation temperature varies between products and why choosing the right one matters in their climate.

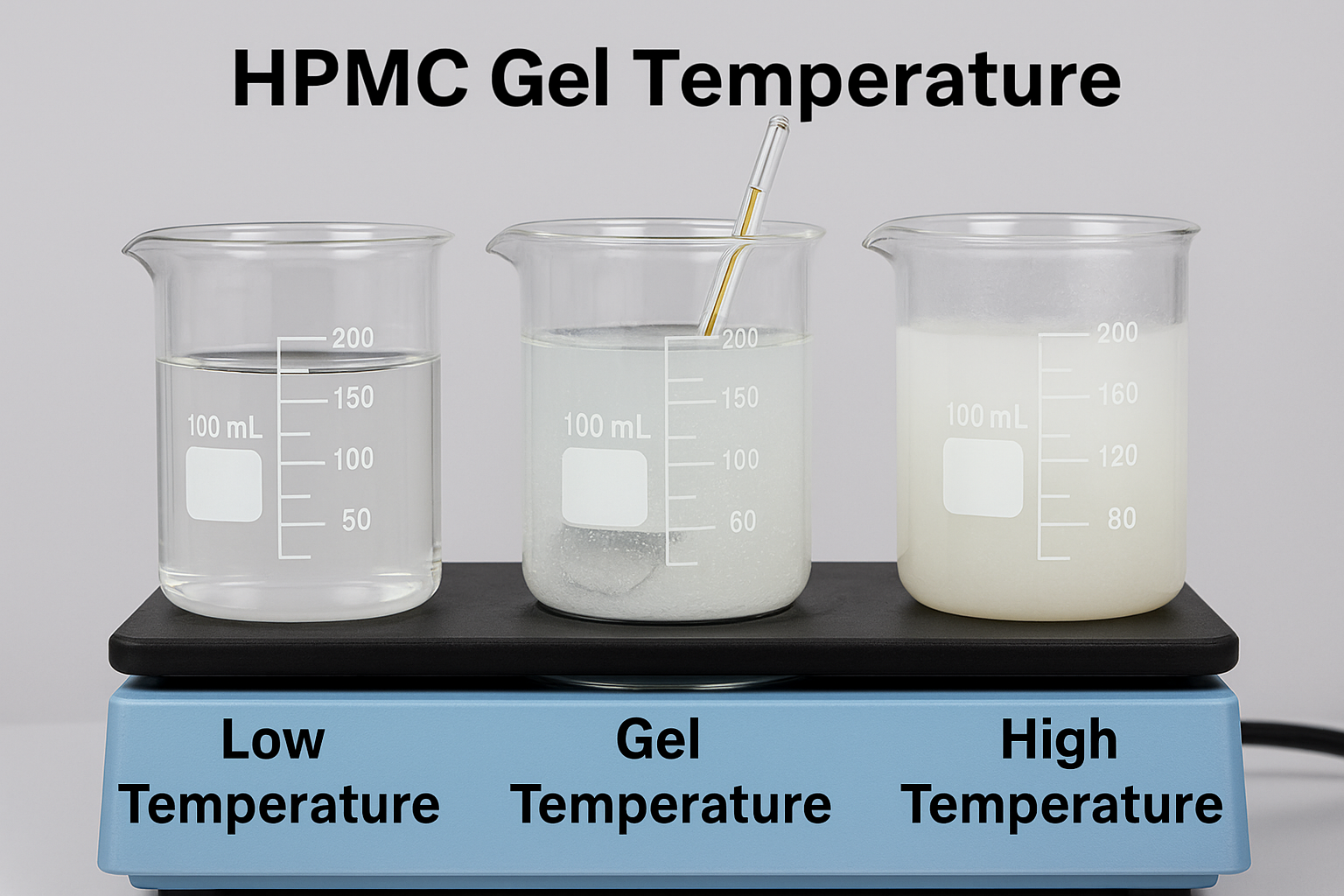

The gelation temperature of HPMC typically ranges between 65-85°C, depending on its specific chemical structure and substitution degree. This is the temperature at which HPMC transforms from a water-soluble polymer into a gel-like structure. Higher methoxyl content generally results in lower gelation temperatures, which is advantageous for hot climate applications.

The gelation temperature represents a critical threshold in HPMC's behavior and directly impacts its performance in tile adhesives. When exposed to temperatures approaching its gel point, HPMC undergoes a fascinating transformation from a flowing solution to a semi-rigid gel network. This temperature-induced phase change is reversible and serves as a protective mechanism for the adhesive system.

The specific gelation temperature of an HPMC product is determined during the manufacturing process through precise control of several factors:

- Methoxyl substitution (DS) - Higher substitution typically lowers gel temperature

- Hydroxypropyl content (MS) - Affects gel strength and temperature sensitivity

- Molecular weight - Influences viscosity and gel formation dynamics

- Manufacturing process - Various production techniques yield different thermal behaviors

I've tested numerous HPMC samples in our laboratory and compiled this reference table that demonstrates how formulation differences affect gelation properties:

| HPMC Type | Methoxyl Content | Hydroxypropyl Content | Gel Temperature | Application Recommendation |

|---|---|---|---|---|

| Standard | Medium | Medium | 75-85°C | Moderate climates |

| Low-Temp | High | Medium | 65-75°C | Hot climates |

| High-Temp | Low | High | 80-90°C | Cold climates |

Understanding these variations allows formulators to select precisely the right HPMC grade for specific climate conditions. For our customers in the Middle East and other hot regions, we typically recommend HPMC varieties5 with gel temperatures in the lower range (65-75°C) to provide maximum protection against rapid water loss.

Can Construction Adhesive Withstand Heat?

Last year, a client in UAE reported tile failures on an exterior facade. Investigation revealed they used standard adhesive without heat-resistant HPMC, causing premature curing and poor bond development.

Construction adhesives can withstand heat when properly formulated with appropriate HPMC grades. Quality tile adhesives with optimized HPMC content can maintain integrity in temperatures up to 70°C. The key factor is selecting an HPMC with a gelation temperature matched to local climate conditions.

The heat resistance of construction adhesives6 is a critical consideration, particularly for exterior applications or installations in unconditioned spaces. Modern tile adhesives must perform reliably under increasingly extreme temperature conditions, which presents a significant formulation challenge. HPMC plays a central role in determining how well an adhesive will withstand heat exposure both during application and throughout its service life.

When properly engineered, HPMC-enhanced adhesives can maintain their physical integrity and bonding capabilities under remarkably high temperatures. Our research and field testing have identified several key factors that contribute to heat resistance:

- HPMC concentration - Higher percentages generally improve heat stability

- HPMC molecular weight - Higher molecular weights enhance high-temperature performance

- Cellulose ether type - HPMC provides better heat resistance than some alternative cellulose derivatives

- Complementary additives - Certain polymer additions can work synergistically with HPMC

I've documented performance across various formulations in extreme conditions:

| Adhesive Type | HPMC Content | Max Temperature | Failure Mode |

|---|---|---|---|

| Economy Grade | 0.2% | 45°C | Bond failure, cracking |

| Standard Grade | 0.3% | 60°C | Minimal edge lifting |

| Premium Grade | 0.5% | 70°C+ | Maintains integrity |

For installations that will undergo temperature cycling, such as exterior facades or heated floor applications, selecting an adhesive with the right HPMC formulation becomes even more critical. The thermal expansion and contraction cycles place additional stress on the adhesive bond, making the water retention and cohesive properties provided by quality HPMC essential for long-term durability.

Conclusion

The right HPMC gel temperature1 is crucial for tile adhesive success in hot climates. By choosing appropriate HPMC grades with lower gelation points (65-75°C), contractors can achieve extended working times, proper adhesion, and durable installations even in extreme heat conditions.

-

Understanding HPMC gel temperature is vital for optimizing tile adhesive performance in hot climates. ↩ ↩ ↩

-

Explore how temperature variations can significantly impact tile adhesive performance and installation success. ↩

-

Discover the factors that affect open time and how to manage them for successful tile installations. ↩

-

Explore the properties of HPMC and its importance in enhancing tile adhesive performance. ↩

-

Explore the various HPMC varieties to select the best one for your climate and application. ↩

-

Learn best practices for selecting and using construction adhesives in extreme heat. ↩