Importing lower-quality HPMC can lead to project failures, unhappy customers, and wasted money. Many of my clients faced these exact problems before learning proper testing methods.

To identify premium HPMC1 through laboratory testing, importers should check viscosity, moisture content, ash content, pH value, particle size, and gel temperature. These parameters reveal the quality and suitability of HPMC for specific applications like mortars, paints, or construction products.

As an HPMC1 manufacturer with six production lines2, I've seen many importers struggle with inconsistent product quality. Let me share the testing methods we use at our factory in China to ensure our hydroxypropyl methylcellulose meets international standards. These tests will help you verify quality before making large purchases.

How to Test HPMC1?

Pain point: Many importers receive HPMC that doesn't perform as claimed, causing production delays and financial losses. I hear this complaint almost weekly from new clients.

To test HPMC properly, measure viscosity using a rotational viscometer at 2% concentration and 20°C, check moisture content (should be <5%), determine ash content (<5%), measure pH (neutral 5.5-8.0), analyze particle size distribution, and evaluate gel temperature according to application requirements.

Testing HPMC requires specific equipment and procedures. From my 15 years in the industry, I've found that many importers don't realize how critical proper testing is. Let me break down each test method:

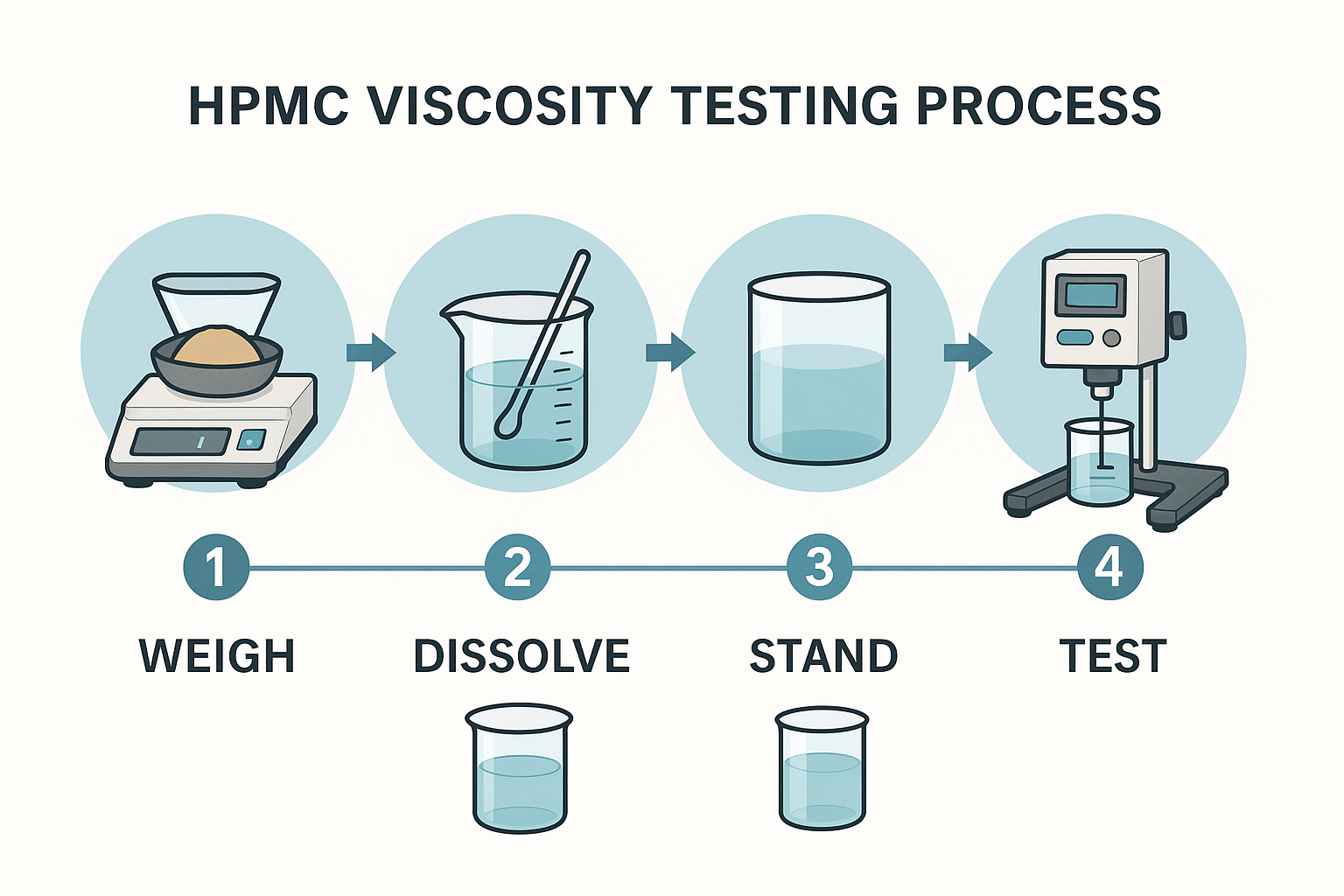

Viscosity Testing

Viscosity is the most important property of HPMC. We measure it using a Brookfield viscometer at a 2% concentration in water at 20°C. The viscosity range typically falls between 100-200,000 mPa·s depending on the grade.

Testing procedure:

- Weigh 2g of HPMC powder

- Disperse in 98g of hot water (80°C)

- Cool to 20°C while stirring

- Measure with viscometer at appropriate RPM

Moisture Content Testing

We use an infrared moisture analyzer to ensure moisture content remains below 5%. Too much moisture can cause clumping and reduced shelf life.

Ash Content Analysis

Ash content indicates the level of inorganic materials. Premium HPMC should have ash content below 5%. Higher levels suggest impurities or additives.

pH Value Measurement

Quality HPMC has a neutral pH between 5.5-8.0. We test using a calibrated pH meter on a 2% solution.

Particle Size Distribution

Using laser diffraction analysis, we ensure consistent particle size distribution. This affects dissolution rate and performance in final applications.

What is the Difference Between HPMC Grades?

Problem: Selecting the wrong HPMC grade leads to application failures and wasted resources. I've seen clients lose thousands of dollars purchasing inappropriate grades.

The main differences between HPMC grades3 lie in viscosity (from 100 to 200,000 mPa·s), methoxyl content (19-30%), hydroxypropyl content (4-12%), and gel temperature (specific to each grade). These properties determine performance in various applications like tile adhesives, renders, paints, or pharmaceuticals.

Understanding HPMC grade differences is essential for importers. I've helped many clients select the right specifications for their particular applications. Here's a detailed breakdown of the key differences between HPMC grades:

Viscosity Variations

HPMC grades are primarily classified by their viscosity. In our factory, we produce grades ranging from 100 mPa·s to 200,000 mPa·s. Low-viscosity grades (100-4,000 mPa·s) are typically used in tile adhesives and self-leveling compounds. Medium-viscosity grades (4,000-75,000 mPa·s) work well in renders and plasters. High-viscosity grades (above 75,000 mPa·s) are ideal for specialty applications like pharmaceutical capsules or as thickeners in specific formulations.

Methoxyl and Hydroxypropyl Content

These chemical parameters significantly affect HPMC1 performance. Higher methoxyl content (28-30%) provides better water retention and adhesion, while higher hydroxypropyl content improves solubility in cold water. For construction applications, we typically recommend methoxyl content around 19-24% and hydroxypropyl content of 7-12%.

Gel Temperature

Different applications require specific gel temperature ranges. For example:

- Hot climate construction: Higher gel temperature (70-90°C)

- Cold climate construction: Lower gel temperature (40-60°C)

- Pharmaceutical applications: Precisely controlled gel temperature

Application-Specific Modifications

Some grades include special modifications for specific uses:

- Surface-treated grades for dry-mix mortars (improved dispersibility)

- Delayed solubility grades for cement-based products

- Extended workability grades for plasters and renders

What is the HS Code for HPMC?

Problem: Incorrect HS code classification can result in import delays, higher duties, and legal complications. I've helped many clients resolve these costly customs issues.

The Harmonized System (HS) code for HPMC (Hydroxypropyl Methylcellulose) is 3912.39. This code falls under "Cellulose and its chemical derivatives, not elsewhere specified, in primary forms," specifically covering "Other" cellulose ethers that don't fit into more specific categories.

Proper HS code classification for HPMC is crucial for smooth customs clearance. In my experience working with exporters shipping to over 15 countries, there are several important points to understand about HPMC classification:

Primary HS Code Classifications

The main HS code for HPMC is 3912.39, but depending on the specific end-use or chemical modification, other codes might apply:

- 3912.39.00: Standard HPMC for most applications

- 3912.31.00: For pharmaceutical-grade HPMC (in some countries)

- 3905.99.90: Occasionally used for specially modified HPMC

Country-Specific Variations

Different countries may have slightly different sub-classifications for HPMC. For example:

- US Tariff Classification: 3912.39.0090

- EU Combined Nomenclature: 3912.39.85

- China Customs Code: 3912.39.00

Import Duty Considerations

Import duties vary significantly by country. In my experience, Saudi Arabia charges about 5% duty on HPMC imports, while India charges 7.5%. Some countries offer preferential rates under trade agreements. For instance, HPMC exported from China to ASEAN countries often qualifies for reduced rates under the China-ASEAN Free Trade Agreement.

Documentation Requirements

When importing HPMC, you'll typically need:

- Commercial Invoice

- Packing List

- Certificate of Origin

- Bill of Lading/Airway Bill

- Material Safety Data Sheet (MSDS)

- Product Specification Sheet

What is the Appearance of HPMC?

Problem: Counterfeit or low-quality HPMC looks similar to premium grades, making visual identification challenging. Many clients initially struggle to distinguish quality differences.

HPMC1 typically appears as a white to off-white fine powder with a neutral odor. Premium HPMC has consistent particle size, flows freely without clumping, shows no discoloration, and dissolves clearly in water without leaving residue. Lower quality HPMC may have yellowish tints, irregular particle sizes, or leave undissolved particles.

Visual inspection is your first line of defense against substandard HPMC. In my factory, we perform rigorous appearance checks before any chemical testing. Here's what to look for when inspecting HPMC:

Color and Texture Characteristics

Premium HPMC should be uniformly white to slightly off-white. Any yellowing or gray tints indicate oxidation, contamination, or poor manufacturing processes. The texture should be fine and consistent, with a silky feel between your fingers. Coarse or irregular textures suggest poor grinding or processing.

Flowability and Moisture Indicators

High-quality HPMC flows smoothly when poured, without excessive dust or static cling. If you notice significant clumping or moisture absorption, this indicates improper drying or storage. Our factory maintains strict humidity controls during production and packaging to prevent these issues.

Simple Visual Tests

You can perform these quick tests without specialized equipment:

- Water Dissolution Test: Sprinkle a small amount on cold water. Premium HPMC will hydrate gradually and form a clear gel without lumps.

- Hot Water Test: Quality HPMC will not dissolve in hot water (above gel temperature) but will disperse evenly.

- Uniform Distribution Test: Spread a thin layer on dark paper. Check for consistent particle size and no foreign particles.

- Compression Test: Press a small amount between fingers. It should compress slightly and return to powder form without sticking excessively.

Packaging Inspection

Even packaging can reveal quality indicators. Premium HPMC is typically packed in moisture-resistant multi-layer bags with proper labeling including:

- Batch number

- Production date

- Grade specification

- Manufacturer information

- Net weight (usually 25kg per bag)

Conclusion

Testing HPMC1 properly involves checking viscosity, moisture content, particle size, and more. Choose the right grade based on viscosity and chemical content. Remember the correct HS code is 3912.39, and premium HPMC appears as a uniform white powder with consistent properties.