Middle Eastern weather poses serious challenges for construction materials. High temperatures and extreme aridity can quickly degrade hydroxypropyl methylcellulose (HPMC)1, leading to costly project failures and product rejections.

To test HPMC stability in Middle Eastern conditions, manufacturers must evaluate thermal degradation, viscosity retention, pH stability, water retention, and gelation temperature. These parameters ensure the material can withstand temperatures exceeding 45°C while maintaining performance in mortars and paints.

As a manufacturer with six production lines and years of exporting to Saudi Arabia, UAE, and other Middle Eastern countries, I've seen firsthand how proper stability testing can make or break a project. Our customers, like large mortar factories and paint manufacturers, need HPMC that performs consistently even when stored in warehouses that reach extreme temperatures.

How to Test HPMC Quality and Stability?

The scorching Saudi Arabian sun can degrade untested HPMC in mere weeks. Without proper stability checks, mortar mixtures can fail prematurely, causing expensive rework and damaging business relationships.

To test HPMC quality, conduct viscosity measurement using rotational viscometers at different temperatures (20°C, 35°C, and 45°C), check particle size distribution through sieve analysis, and perform moisture content testing using loss-on-drying method at 105°C for 3 hours.

Testing HPMC quality requires more than basic checks. I remember visiting a client's facility in Dubai where they were experiencing inconsistent mortar performance despite using what they thought was high-quality HPMC. Upon running a complete battery of tests, we discovered their supplier had provided material with unstable viscosity performance across temperature ranges.

Basic Quality Testing Methods

| Test | Method | Acceptable Results for Middle East |

|---|---|---|

| Viscosity | Brookfield viscometer at 20°C (2% solution) | Remains within ±10% of specified value after heat exposure |

| Particle Size | Laser diffraction or sieve analysis | 100 mesh >98% passing |

| Moisture Content | Loss on drying (105°C, 3 hours) | ≤5% |

| Appearance | Visual inspection | White to off-white powder |

| Ash Content | Muffle furnace (800°C) | ≤5% |

Advanced Stability Testing Methods

| Test | Method | Middle East Requirements |

|---|---|---|

| Heat Stability | Oven storage (45°C, 30 days) followed by viscosity testing | <15% viscosity change |

| UV Stability | Xenon arc chamber exposure | Minimal color change and viscosity retention |

| Humidity Cycling | Exposure to 80% RH and 30% RH cycles | No caking or performance loss |

What is the pH Stability of HPMC?

Many customers I've worked with in Saudi Arabia and UAE have experienced mortar failures because their HPMC broke down in highly alkaline conditions. Poor pH stability can turn an otherwise good product into a complete disaster in cement applications.

HPMC shows optimal pH stability2 between 3-11, making it suitable for both acidic and alkaline construction applications. In cement mortars (pH 12-13), high-quality HPMC should maintain >80% of its original viscosity. Testing involves measuring viscosity of HPMC solutions at different pH levels using buffer solutions.

https://placehold.co/600x400 "pH meter measuring HPMC in various buffer solutions")

https://placehold.co/600x400 "pH meter measuring HPMC in various buffer solutions")

pH stability is crucial for Middle Eastern construction projects. I recall a major project in Riyadh where a competitor's HPMC failed because it wasn't tested for pH stability in the highly alkaline desert soil conditions. The mortar began to fail within weeks of application, causing costly repairs.

The pH stability of HPMC depends largely on its manufacturing process and degree of substitution. Our testing protocol examines HPMC performance across multiple pH environments to ensure consistent performance. We prepare buffer solutions ranging from pH 2 to pH 14 and measure how the HPMC maintains its viscosity and water retention capabilities over time.

pH Stability Testing Methods

| pH Range | Test Condition | Expected Performance for Middle East |

|---|---|---|

| 2-4 (Acidic) | 2% HPMC solution in buffer, 24h | >85% viscosity retention |

| 5-8 (Neutral) | 2% HPMC solution in buffer, 24h | >95% viscosity retention |

| 9-11 (Moderately Alkaline) | 2% HPMC solution in buffer, 24h | >90% viscosity retention |

| 12-14 (Highly Alkaline) | 2% HPMC solution in buffer, 24h | >80% viscosity retention |

What is the Water Retention Mechanism of HPMC in Cement Mortar?

Water evaporates extremely quickly in Middle Eastern climates, often causing mortar to dry before proper cement hydration. This leads to weak bonds and crumbling mortar—a problem I've seen ruin entire building façades in Dubai and Jeddah.

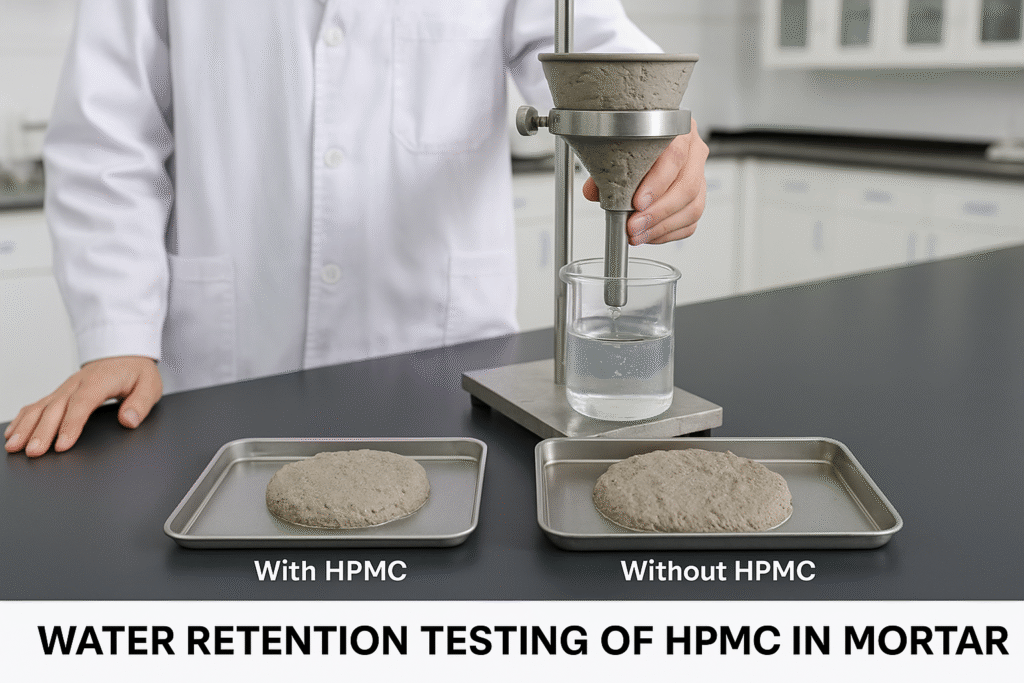

HPMC improves water retention in cement mortar through formation of a reversible hydrogel network that physically traps water molecules. This slows evaporation and ensures proper cement hydration. Water retention is tested using the DIN 18555 method, with good HPMC retaining >95% water after 30 minutes in Middle Eastern conditions.

Understanding the water retention mechanism of HPMC has helped us develop products specifically for the harsh Middle Eastern climate. The mechanism works on multiple levels, which is why proper testing is essential. At the molecular level, HPMC chains form hydrogen bonds with water molecules, temporarily binding them within the mortar matrix. This slows water evaporation significantly, especially important when ambient temperatures exceed 40°C as commonly experienced in places like Saudi Arabia and the UAE.

We test water retention capacity of our HPMC using standardized methods like DIN 18555 or ASTM C1506. The test involves preparing a standard mortar mixture3 with a specific amount of HPMC, placing the mixture on a filter paper under standardized suction, and measuring the amount of water retained after a set period (typically 15-30 minutes). For Middle Eastern applications, we recommend HPMC that can maintain at least 95% water retention after 30 minutes even at temperatures of 35-40°C.

Water Retention Enhancement Factors

| Factor | Impact | Testing Method |

|---|---|---|

| Molecular Weight | Higher = Better water retention | Viscosity correlation |

| Degree of Substitution | Optimal DS = Better performance | Specialized laboratory analysis |

| Concentration | 0.2-0.5% typically optimal | Comparative water retention tests |

| Temperature Resistance | Must work at 40°C+ | Hot room testing |

What is the Gelation Temperature of HPMC?

On several construction sites in Iran and Saudi Arabia, I've witnessed HPMC products that gelled prematurely during mixing due to heat, causing lumps and unworkable mixtures. This is always due to inadequate testing of gelation temperature.

The gelation temperature4 of HPMC is the point where the polymer transitions from a soluble state to a gel state, typically between 55-90°C depending on grade. For Middle Eastern applications, HPMC with gelation temperatures above 75°C is preferred. Testing involves observing the cloud point in a heated water bath.

Gelation temperature is a critical parameter that directly impacts the application window for mortar and paint products in hot climates. When the ambient temperature approaches the gelation temperature of HPMC, the polymer begins to lose solubility and forms a gel structure. This transformation dramatically affects workability and application properties of the final product.

For our Middle Eastern customers, we've developed specialized testing protocols that simulate real-world application conditions. The standard test involves heating a 2% aqueous solution of HPMC at a controlled rate (typically 1°C per minute) and observing the point at which the solution becomes cloudy, indicating the onset of gelation. For more precise measurements, we use differential scanning calorimetry (DSC) to detect the exact temperature at which the phase transition occurs.

Factors Affecting Gelation Temperature

| Factor | Effect | Importance in Middle East |

|---|---|---|

| Methoxyl Content | Higher content = Lower gelation temperature | Critical for summer applications |

| Hydroxypropyl Content | Higher content = Higher gelation temperature | Desired for hot climates |

| Molecular Weight | Minimal effect on gelation temperature | Less relevant for this property |

| Salt Presence | Can lower gelation temperature | Important in coastal areas |

What is the Thermal Degradation of HPMC?

Last year, a major distributor in the UAE returned an entire container of HPMC because it had degraded during shipping. The material had been stored in a container that reached temperatures above 60°C for several days, causing chemical breakdown.

Thermal degradation of HPMC begins at approximately 190-200°C with main decomposition occurring at 300-400°C. However, long-term exposure to temperatures above 50°C can cause gradual degradation. Testing involves thermogravimetric analysis (TGA) and measuring viscosity retention after heat aging.

Thermal degradation is particularly concerning for HPMC destined for Middle Eastern markets, where temperatures during transport, storage, and application can be extreme. While catastrophic decomposition occurs at much higher temperatures, long-term exposure to temperatures commonly found in uncontrolled warehouses (40-60°C) can lead to gradual degradation of the polymer chains, resulting in reduced performance.

Our comprehensive thermal stability testing program simulates these real-world conditions. We conduct accelerated aging tests where HPMC samples are stored at elevated temperatures (45°C, 55°C, and 65°C) for periods ranging from 7 to 90 days. After aging, we measure critical properties including viscosity retention, water retention capability, and mechanical performance in standard mortar formulations. These tests help us predict how the material will perform after months of storage in Middle Eastern conditions.

Thermal Stability Testing Protocol

| Test Condition | Duration | Acceptance Criteria |

|---|---|---|

| 45°C / 20% RH | 90 days | <10% viscosity loss |

| 55°C / 20% RH | 30 days | <15% viscosity loss |

| 65°C / 20% RH | 7 days | <20% viscosity loss |

| Temperature cycling (25-55°C) | 10 cycles | No lumping, <10% performance change |

Conclusion

Proper HPMC testing for Middle Eastern conditions must evaluate thermal stability, pH resistance, water retention, and gelation temperature4. By implementing these comprehensive test methods, manufacturers and buyers can ensure HPMC will perform reliably even in extreme desert environments.

-

Explore the versatile applications of HPMC in construction and its importance in enhancing material performance. ↩

-

Discover the importance of pH stability in construction materials and its role in preventing failures. ↩

-

Understand the components of a standard mortar mixture and their importance in construction. ↩

-

Learn about gelation temperature and its impact on the workability of construction materials. ↩ ↩