Uneven fiber distribution in mortar can lead to uncontrolled cracking and structure failure. Many manufacturers struggle with proper dispersion testing, risking costly product failures and reputation damage.

To test PP fiber dispersion1 uniformity in laboratory settings, use either the wet sieving method for field testing or hardened section analysis for precise evaluation. Both methods verify whether fibers are evenly distributed throughout the mixture to ensure consistent crack resistance performance.

Testing fiber dispersion isn't just a technical requirement—it's essential for ensuring product quality. Without proper testing, you can't guarantee the performance of your fiber-reinforced products2. Let me share the most practical methods I've used in our factory testing labs.

Is Wet Sieving the Most Practical Method for Testing PP Fiber Dispersion?

Fresh mortar samples often show inconsistent fiber content across batches. Many quality control teams lack a standardized approach to verify proper dispersion, leading to unpredictable performance in the field.

The wet sieving method is indeed the most practical field test for fiber dispersion. By washing random mortar samples through a standard sieve, you can collect, dry and weigh the retained fibers, then compare weights between samples to verify uniform distribution.

How to Perform the Wet Sieving Test

The wet sieving method remains my go-to test for everyday quality control. It's straightforward yet effective for monitoring dispersion uniformity across production batches.

Equipment Required:

| Equipment | Specification |

|---|---|

| Standard Test Sieve | 0.075mm mesh (No. 200) |

| Sampling Tools | Trowel or scoop |

| Drying Oven | Set at 105±5°C |

| Precision Scale | 0.01g accuracy |

| Wash Bottle | For directing water flow |

Step-by-Step Procedure:

- Take at least three random samples (approximately 1kg each) from different locations in your freshly mixed mortar batch

- Carefully wash each sample through the standard sieve using clean water

- Continue washing until the water runs clear (all cement and sand particles have passed through)

- Collect all PP fibers retained on the sieve

- Dry the collected fibers in the oven until constant weight is achieved

- Weigh each dried fiber sample on the precision scale

- Calculate the coefficient of variation between the samples

I consider dispersion acceptable if the coefficient of variation is below 15% between samples. This method has helped us identify mixing problems before products leave our facility, saving countless customer complaints.

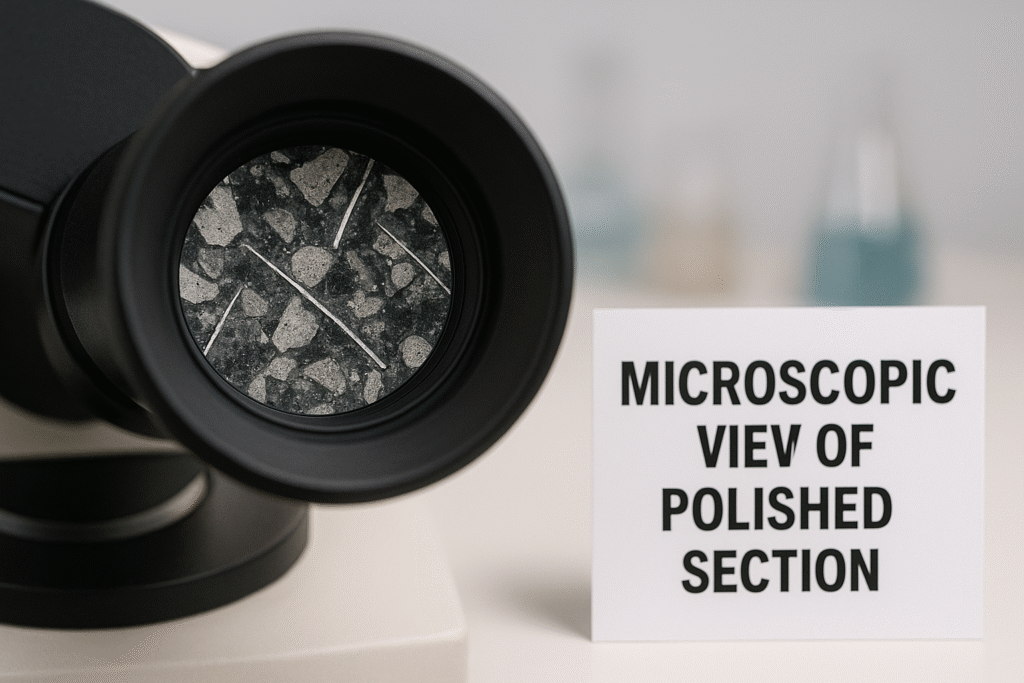

Can Hardened Section Analysis Provide More Precise Fiber Distribution Data?

Visual inspection of hardened mortar often misses critical dispersion problems. Engineers need quantifiable data to validate mix designs, but traditional testing methods may not provide sufficient precision for critical applications.

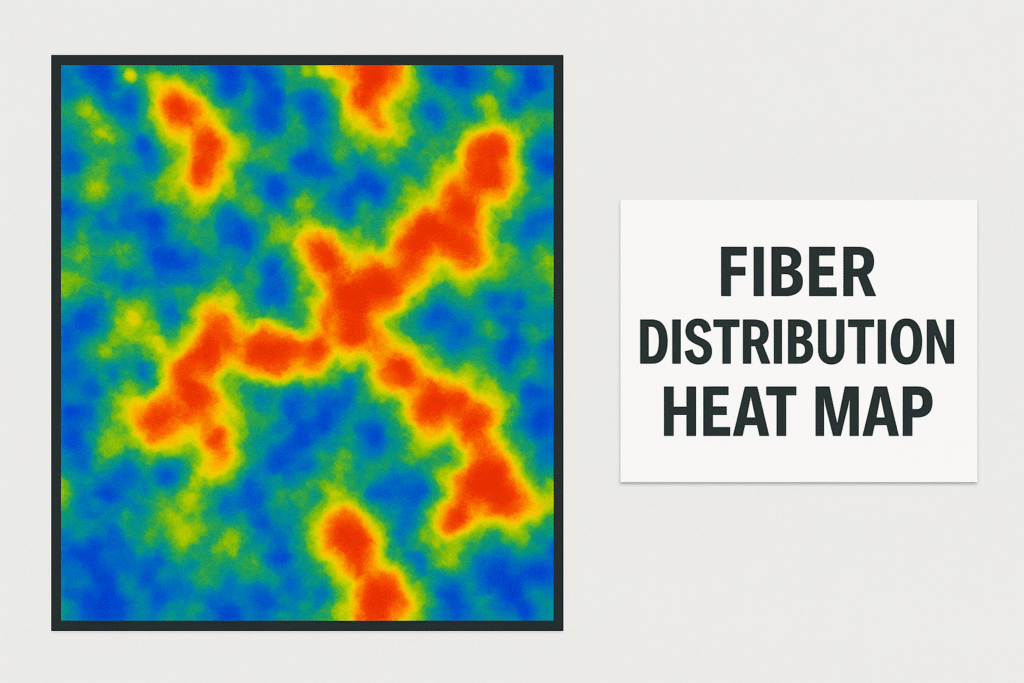

Hardened section analysis offers more precise fiber distribution data by examining polished cross-sections of cured specimens under microscopy. This method allows direct observation, counting of fibers per unit area, and even heat-map generation using image analysis software.

Advanced Techniques for Hardened Section Analysis

I've found hardened section analysis particularly valuable when developing new fiber-reinforced products or troubleshooting performance issues in existing formulations.

Required Equipment:

| Equipment | Purpose |

|---|---|

| Concrete Saw | For cutting specimens |

| Polishing Equipment | To prepare smooth surfaces |

| Stereomicroscope | For fiber observation |

| Image Analysis Software | For quantitative assessment |

| Digital Camera | To document findings |

Analysis Procedure:

- Cast standard test specimens using your fiber-reinforced mortar mix

- Allow complete curing under controlled conditions (typically 28 days)

- Cut specimens into thin slices perpendicular to the primary stress direction

- Polish cut surfaces to achieve a smooth, reflective finish

- Examine under stereomicroscope at 10-40x magnification

- Count fiber occurrences per unit area across multiple fields of view

- Use image analysis software to generate fiber distribution maps

The true value of this method lies in its ability to visualize fiber orientation as well as distribution. In our lab, we've used it to optimize mix designs for specific applications, ensuring fibers align properly to resist expected stress patterns.

What's the Core Logic Behind Effective Fiber Dispersion Testing?

Manufacturers often focus solely on total fiber content rather than distribution. This oversight can lead to localized weaknesses despite meeting overall specification requirements for fiber percentage.

The core logic of fiber dispersion testing is sample consistency verification. Any randomly selected portion of the mixture should contain approximately the same fiber content as the overall design mix. This ensures uniform reinforcement throughout the material for effective crack control.

Understanding the Statistical Approach to Fiber Dispersion

When I talk with our quality control team, I emphasize that we're essentially applying statistical sampling principles to verify material homogeneity. This conceptual framework helps them understand why proper dispersion matters.

Key Statistical Considerations:

| Parameter | Significance |

|---|---|

| Sample Size | Must be representative but practical |

| Number of Samples | More samples increase confidence |

| Standard Deviation | Measures consistency between samples |

| Coefficient of Variation | Normalized measure of dispersion |

| Confidence Intervals | Statistical reliability of results |

To visualize this concept, imagine dividing your mortar into a three-dimensional grid. Each cell in this grid should contain approximately the same number of fibers to ensure uniform crack resistance. When we test random samples, we're essentially checking if this theoretical grid exists in practice.

I've worked with our team to develop acceptance criteria based on application requirements. For structural applications, we typically require a coefficient of variation below 10%, while for non-structural uses, we might accept up to 20% variation. This tiered approach balances quality control with practical manufacturing constraints.

Regular testing using either method helps identify issues with mixing equipment, procedures, or fiber types. For example, we once discovered that changing the mixing sequence significantly improved dispersion uniformity without any additional cost—a finding that would have been impossible without systematic testing.

Conclusion

Proper dispersion testing is essential for quality fiber-reinforced products. Whether using wet sieving for quick checks or hardened section analysis for detailed studies, consistent sampling ensures your products deliver reliable crack resistance throughout.