Modern construction projects face challenges with durability, adhesion, and flexibility that traditional cement just can't solve. Without the right additives, buildings crack, surfaces fail to bond, and structures deteriorate prematurely.

Redispersible polymer powder1 (RDP) is essential in construction because it enhances mortar and concrete with improved flexibility, adhesion, workability, and water resistance. When mixed with water, RDP redisperses into polymer particles that form a film during curing, creating stronger, more durable building materials.

I've been supplying RDP to construction companies for years, and I've seen firsthand how this seemingly simple white powder transforms ordinary building materials into high-performance products. The difference between projects using quality RDP and those without is striking. Let me show you why this powder has become indispensable in modern construction.

What Are the Key Advantages of Redispersible Polymer Powder?

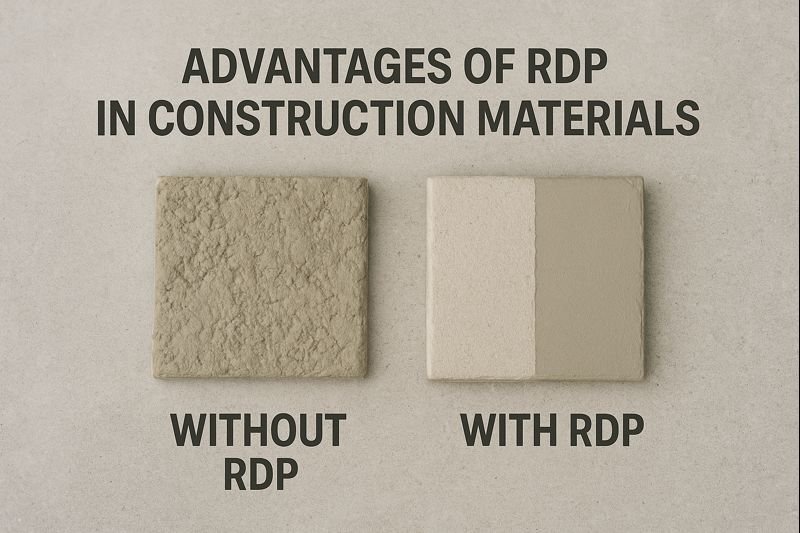

Construction projects constantly struggle with material cracking, poor adhesion, and water damage. These issues lead to costly repairs and shortened building lifespans, creating headaches for both contractors and property owners.

Redispersible polymer powder1 provides crucial benefits including improved adhesion strength, flexibility, water resistance, workability, and durability. These advantages result in reduced cracking, better bonding to difficult substrates, enhanced water repellency, and extended service life for mortar applications.

Comparing Standard Mortar vs. RDP-Enhanced Mortar

When we look deeper at how RDP transforms construction materials, the differences become clear. I often demonstrate this to my clients using simple comparison tests. RDP-modified mortars show significantly improved performance across multiple properties.

The polymers in RDP create a three-dimensional network within the cement matrix. This network acts as a reinforcement, similar to how rebar strengthens concrete, but on a microscopic scale. When the mortar dries, these polymer particles form continuous films that bridge potential crack sites and create flexible bonds between cement particles.

Here's a breakdown of the performance differences:

| Property | Standard Mortar | RDP-Enhanced Mortar |

|---|---|---|

| Adhesion Strength | Low-Medium | High (2-5× stronger) |

| Flexibility | Brittle | Elastic |

| Water Resistance | Poor | Excellent |

| Freeze-Thaw Resistance | Poor | Good |

| Workability | Basic | Improved |

| Durability | Standard | Extended |

I've had clients who initially balked at the added cost of RDP, but after seeing side-by-side comparisons of material performance, they quickly recognized the long-term value and reduced maintenance costs. The upfront investment pays dividends through extended service life and fewer failures.

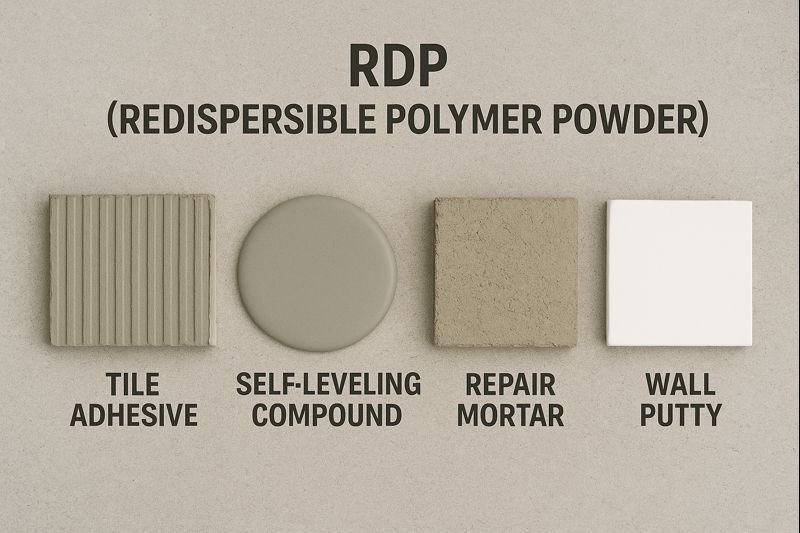

How Is Redispersible Polymer Powder Used in Construction Materials?

Many builders struggle with specialized applications requiring properties that traditional cement-based products can't deliver. Without proper additives, tiles fall off walls, waterproofing fails, and repairs don't last.

Redispersible polymer powder1 is used in tile adhesives2, self-leveling compounds3, repair mortars4, exterior insulation finishing systems5 (EIFS), waterproofing membranes, and decorative finishes. It's typically added at 1-5% concentration to cement mixtures to achieve specific performance characteristics for each application.

Selection Guide for RDP Types in Different Applications

Choosing the right type of RDP can be confusing for many of my customers. Not all redispersible powders are created equal, and selecting the wrong type can lead to project failures. I've developed this guide based on years of helping clients match their application needs to the right RDP formulation.

The chemical composition of RDP varies widely, with options including vinyl acetate-ethylene (VAE), vinyl acetate-versatate (VA/VeoVa), ethylene-vinyl chloride (E/VC), and acrylic-based powders. Each type offers specific benefits tailored to different construction applications.

For exterior applications exposed to harsh weather, I recommend VA/VeoVa or acrylic-based RDPs because they resist hydrolysis and UV degradation. For interior tile adhesives, VAE types often provide the best balance of properties and cost-effectiveness. Projects requiring extreme water resistance, like swimming pools or bathrooms, benefit from specialized hydrophobic RDP formulations.

Particle size also matters significantly. Finer particles (typically 80-120 μm) disperse more uniformly and create more continuous polymer films. This results in better performance but often at a higher price point. For less demanding applications, standard grades (120-250 μm) usually provide adequate performance at lower cost.

| Application | Recommended RDP Type | Typical Dosage |

|---|---|---|

| Tile Adhesive | VAE | 2-5% |

| Self-leveling Compound | VAE/Acrylic | 1-3% |

| External Wall Insulation | VA/VeoVa | 3-6% |

| Waterproofing | Hydrophobic Acrylic | 5-10% |

| Repair Mortar | VAE/Acrylic | 3-7% |

| Decorative Render | VA/VeoVa | 2-5% |

What Role Does Redispersible Polymer Powder Play in Modern Mortar Formulations?

Traditional mortars lack the performance properties required for modern construction techniques and materials. Without polymer modification, mortars fail prematurely when used with non-porous substrates, thin applications, or in challenging environments.

In modern mortars, redispersible polymer powder serves as a critical binder that improves adhesion to difficult substrates like glass, metal, and existing concrete. It reduces water demand while maintaining workability, prevents shrinkage cracking, and creates mortars that can withstand movement from thermal expansion and building settlement.

The Science Behind RDP's Effect on Mortar Properties

The interaction between RDP and cement creates fascinating changes at the microscopic level. As someone who's worked with these materials for years, I find the chemistry behind these improvements particularly interesting. Let me explain how RDP transforms ordinary mortar into a high-performance building material.

When water is added to a dry mixture containing cement and RDP, two simultaneous processes begin. The cement starts its hydraulic hardening process, while the polymer particles redisperse into the water, forming a latex similar to liquid polymers. As the mixture dries, the dispersed polymer particles come closer together and eventually coalesce to form continuous films and membranes within the cement matrix.

This creates a co-matrix system where both cement hydration products and polymer films contribute to the final properties. The polymer films act as elastic bridges between the brittle cement components, improving flexibility and crack resistance. They also create polymer membranes that reduce water permeability and enhance durability against freeze-thaw cycles.

The RDP concentration dramatically affects the final properties. At low concentrations (1-2%), RDP mainly improves workability and adhesion. At moderate levels (3-5%), it significantly enhances flexibility and water resistance. At higher concentrations (above 5%), it fundamentally changes the mortar's behavior, creating highly flexible, water-resistant materials suitable for waterproofing applications.

I've conducted tests showing how different RDP dosages affect key properties:

| RDP Dosage | Adhesion Improvement | Flexibility | Water Permeability Reduction |

|---|---|---|---|

| 1% | 30-50% increase | Minimal | 10-20% |

| 3% | 100-200% increase | Moderate | 40-60% |

| 5% | 200-300% increase | Significant | 70-80% |

| 10% | 300-400% increase | High | 90%+ |

Conclusion

Redispersible polymer powder1 has revolutionized construction materials by enhancing adhesion, flexibility, and durability. Its ability to transform ordinary mortars into high-performance building products makes it indispensable in modern construction projects worldwide.

-

Explore how RDP enhances construction materials, improving durability and performance. ↩ ↩ ↩ ↩

-

Explore the types of tile adhesives that ensure strong and lasting bonds. ↩

-

Discover how self-leveling compounds improve flooring and surface finishes. ↩

-

Explore effective strategies for using repair mortars in construction projects. ↩

-

Learn how EIFS can improve energy efficiency and aesthetics in buildings. ↩