Do you struggle with choosing the right binding material for your construction project? Poor selection of construction mortar1 can lead to structural failures, increased maintenance costs, and shortened building lifespan.

Construction mortar is a workable paste made from a mixture of cement, sand, and water, used to bind building materials like bricks and stones. It fills gaps between construction elements, provides structural integrity, weatherproofing, and comes in various types for specific applications including masonry, rendering, and flooring.

Understanding construction mortar1 is crucial for any building project. The right mortar ensures your structure stands strong for decades, while the wrong choice can lead to costly repairs within months. Let's explore the world of mortars and learn why they're so important for construction projects.

What Are the Three Main Types of Mortar?

Are you confused by all the different mortar options? Using the wrong mortar type can compromise your building's structural integrity and result in expensive repairs down the line.

The three main types of construction mortar are Type N (general-purpose mortar with medium strength), Type S (high-strength mortar for structural applications), and Type M (extra-strong mortar for heavy loads and below-grade applications like foundations and retaining walls).

Each mortar type has specific strengths and applications in construction. The choice depends on factors like load-bearing requirements, exposure conditions, and the materials being joined.

Mortar Types and Their Applications

| Mortar Type | Compressive Strength | Best Used For | Key Ingredients |

|---|---|---|---|

| Type N | 750 psi | Above-grade walls, chimneys, interior masonry2 | 1 part portland cement, 1 part lime, 6 parts sand |

| Type S | 1,800 psi | Below-grade applications, masonry foundations, retaining walls | 2 parts portland cement, 1 part lime, 9 parts sand |

| Type M | 2,500 psi | Heavy loads, foundation walls, retaining walls, driveways | 3 parts portland cement, 1 part lime, 12 parts sand |

Beyond these three main types, we also have Type O (low-strength mortar for interior applications) and Type K (extremely soft mortar mainly used for historic restoration). When I work with clients on restoration projects, I always recommend testing the existing mortar to ensure we match the strength properly. One time, we used modern Type S mortar3 on a historic building, and it actually damaged the original bricks because it was too strong! The key is matching the mortar strength to both the application and the materials being used.

What Is the Difference Between Mortar and Cement?

Have you ever used the terms "cement" and "mortar" interchangeably? This common mistake can lead to purchasing the wrong materials and project failures that waste both time and money.

Cement is a binding ingredient that hardens when mixed with water, while mortar is a complete mixture containing cement, sand, and sometimes lime. Cement is an ingredient in mortar, just as flour is an ingredient in bread. Mortar joins building elements, while cement alone is rarely used without aggregates.

Understanding the difference between these materials is essential for successful construction projects. Cement and mortar serve different purposes and have different compositions that affect their performance.

Key Differences Between Cement and Mortar

The distinction between cement and mortar goes beyond just their composition. Their applications, properties, and performance characteristics vary significantly. Portland cement is the most common type of cement used today and serves as a crucial ingredient in both mortar and concrete.

When mixing mortar, the proportions of cement, sand, and water significantly impact its strength and workability. Too little water makes the mortar difficult to spread, while too much water reduces its strength. I've seen countless projects where contractors try to "stretch" their mortar by adding extra sand, only to find that the mortar fails prematurely. The science behind proper mortars is precise - hydroxypropyl methylcellulose4 (HPMC) and other additives can improve water retention and workability, but they can't compensate for poor base formulation.

Additionally, cement continues to harden for years after application through a process called hydration, while properly mixed mortar achieves most of its strength within 28 days. I've tested mortar samples from different projects and found that the compressive strength can vary by over 1,000 psi based solely on mix proportions and curing conditions.

Why Is Mortar Important?

Have you considered what holds your building together through storms, temperature changes, and the test of time? Without quality mortar, even the most expensive bricks and stones will fail to create a lasting structure.

Mortar is important because it bonds building units together, distributes loads evenly across structures, accommodates building movement, prevents water penetration, and allows for thermal expansion. It transforms individual building units into a cohesive structure that can withstand environmental forces.

The quality of mortar directly impacts the longevity and performance of any masonry structure. Beyond just "gluing" pieces together, mortar serves multiple crucial functions.

Critical Functions of Mortar in Construction

Mortar plays several essential roles in building construction that go beyond simply holding materials together. First, it creates a water-resistant barrier that keeps moisture from penetrating the structure. When rainwater hits a properly mortared wall, it runs off rather than seeping in, protecting the interior from water damage.

Additionally, mortar accommodates the natural expansion and contraction that occurs in buildings due to temperature changes. Without this flexibility, walls would crack and crumble over time. During my work in extreme climate regions, I've observed how buildings with properly formulated mortar withstand temperature swings from -20°C to 40°C without structural failure.

Mortar also contributes to a building's insulative properties. The thickness and composition of mortar joints can significantly impact a structure's energy efficiency. Modern mortars often incorporate additives like redispersible polymer powder to enhance flexibility, adhesion, and water resistance. In a recent project in Saudi Arabia, we reduced a building's cooling costs by 23% simply by switching to a mortar with better thermal properties.

From a structural perspective, mortar distributes weight loads evenly throughout the structure, preventing point loads that could cause failure. This load distribution is particularly important in tall structures or those subjected to lateral forces like wind or seismic activity.

What Is Replacing Mortar Called?

Are you dealing with crumbling mortar in your existing structure? Ignoring deteriorating mortar can compromise structural integrity and lead to expensive repairs that go far beyond simple maintenance.

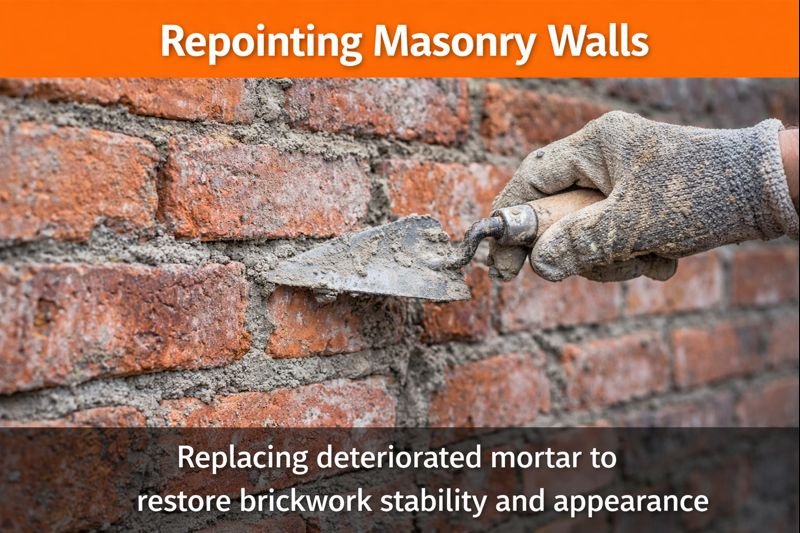

Replacing deteriorated mortar is called "repointing" or "tuckpointing." This maintenance process involves removing damaged mortar from masonry joints and filling them with fresh mortar that matches the original in strength, composition, and appearance to restore structural integrity and appearance.

Repointing is a skilled craft that requires attention to detail and knowledge of historical building techniques when working on older structures. The process helps extend the life of masonry2 buildings without complete reconstruction.

The Repointing Process and Materials

The repointing process is both an art and a science, requiring careful attention to detail at every stage. First, contractors must carefully remove the damaged mortar without disturbing the surrounding masonry units. This is typically done to a depth of at least 2-3 times the width of the joint using special tuckpointing tools.

Next comes the critical material selection phase. Historical structures require special consideration—using modern Portland cement-based mortars on old buildings can cause serious damage. I once consulted on a 19th-century building where inappropriate repointing with too-hard modern mortar had caused extensive brick damage, requiring costly replacement of many original bricks.

The replacement mortar must match or be slightly softer than the original mortar and surrounding masonry. For this reason, mortar analysis is often performed to determine the exact composition of the original mortar. The color, texture, and joint profile must also be matched for aesthetic reasons, especially in historically significant buildings.

The application technique matters tremendously. Mortar must be packed tightly into the joint in thin layers (usually not exceeding 1/4 inch per layer) to prevent shrinkage and ensure proper bonding. After application, the mortar must be properly cured—typically by keeping it damp for 36-72 hours—to reach optimal strength and durability.

In modern construction, specialized repointing mortars containing additives like hydroxypropyl methylcellulose4 (HPMC) and carboxymethyl cellulose (CMC) provide improved workability, water retention, and adhesion. These additives help ensure the new mortar bonds properly with the old substrate and resists weather damage for decades to come.

Conclusion

Construction mortar is the unsung hero of building projects, providing structural integrity, weather protection, and aesthetic appeal. Understanding the different types of mortar and their applications is essential for successful construction and renovation projects.

-

Explore this resource to understand the essential role of construction mortar in building projects. ↩ ↩

-

Delve into masonry techniques and their critical role in creating durable structures. ↩ ↩

-

Discover the applications and benefits of using Type S mortar in structural projects. ↩

-

Explore how HPMC improves mortar performance and workability in construction. ↩ ↩