Choosing the wrong mortar can lead to structural failures, costly repairs, and project delays. Many builders waste time and money using inappropriate mortar1 types for their specific construction needs.

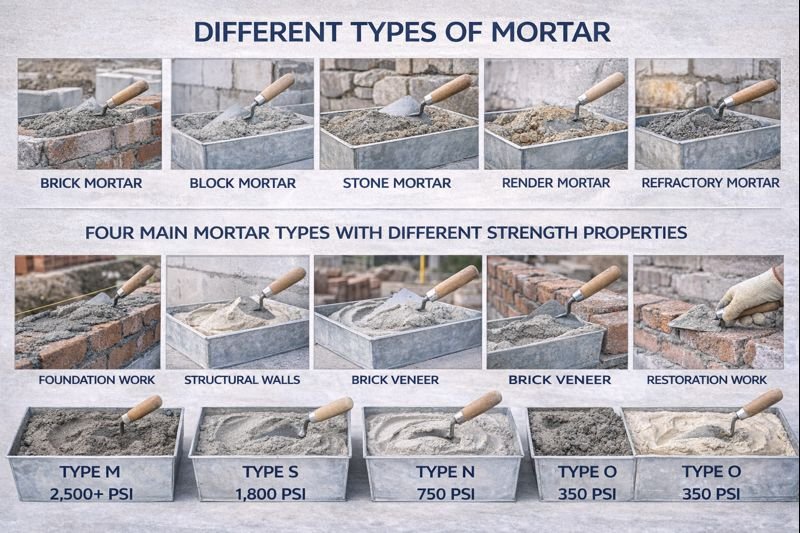

Mortar is a workable paste used to bind building blocks such as stones, bricks, and concrete masonry units, fill gaps, and seal joints. Different types (M, S, N, and O) offer varying compressive strength and are designed for specific applications based on load-bearing requirements and exposure conditions.

Understanding mortar types isn't just about strength—it's about matching the right product to your specific project requirements. Let me walk you through the main mortar types and how to choose wisely for different construction scenarios.

What Are The Different Types of Mortar Available Today?

Ever started a project only to discover you're using the wrong mortar type? This mistake can compromise structural integrity and waste valuable resources on unnecessary repairs.

The four main types of mortar are Type M (high strength), Type S (medium-high strength), Type N (medium strength), and Type O (low strength). Each type contains different proportions of portland cement, lime, and sand, designed for specific construction applications.

Mortar selection directly impacts building durability, water resistance, and overall project success. The right choice depends on several factors including location, load requirements, and exposure conditions.

Type M Mortar: When Would You Need High-Strength Mortar?

Have you ever wondered why some structures remain standing for centuries while others deteriorate within decades? The secret often lies in using the right mortar type for heavy-duty applications.

Type M mortar2 offers the highest compressive strength (2,500+ PSI) among all mortar types, making it ideal for below-grade applications, heavy loads, and structures subject to severe weather conditions or earth pressure like retaining walls and foundations.

Type M mortar contains the highest ratio of portland cement compared to other types, typically mixed in proportions of 1 part portland cement, 1/4 part lime, and 3 parts sand. This high cement content gives it exceptional strength but reduces workability.

When working with Type M mortar, I've noticed it's particularly suitable for hard stone masonry where high compressive strength is essential. However, this type has lower bonding properties compared to mortars with higher lime content. It's also more rigid and less able to accommodate building movement, which makes it unsuitable for areas with significant temperature fluctuations or seismic activity.

In my experience working with international clients, Type M mortar is especially popular in regions with extreme weather conditions like the Middle East, where structures must withstand intense heat and occasional heavy rains. However, without proper application techniques, even this high-strength mortar can fail prematurely. Always ensure proper mixing ratios and curing conditions for optimal performance.

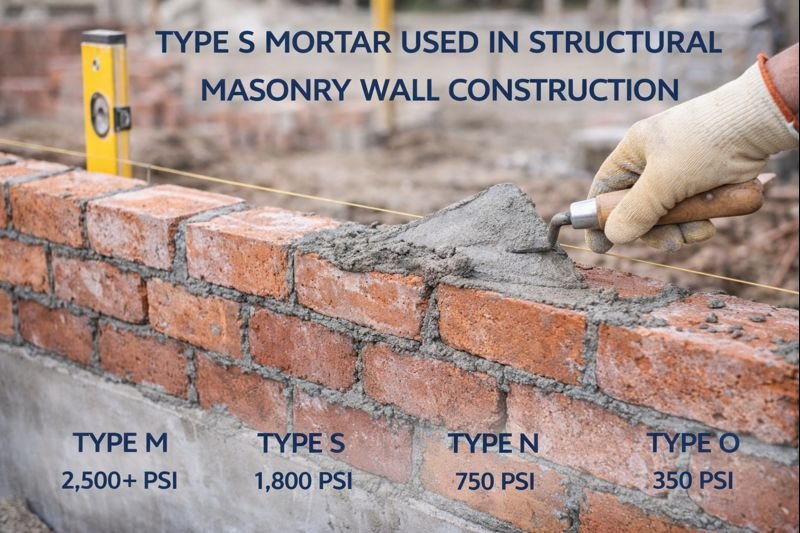

Type S Mortar: What Makes It Ideal For Structural Applications?

Have you struggled with mortar that cracks or fails under moderate stress? Many contractors face this issue when they don't match mortar strength to the actual structural demands of their projects.

Type S mortar provides medium-high compressive strength (1,800-2,500 PSI) and high tensile bond strength, making it perfect for at-grade and below-grade applications, including masonry foundations, retaining walls, manholes, sewers, and hardscape installations.

Type S mortar strikes an excellent balance between strength and workability, containing more lime than Type M but less than Types N and O. The standard mix ratio is typically 1 part portland cement, 1/2 part lime, and 4-1/2 parts sand.

One of the main advantages of Type S mortar is its superior tensile bond strength. This property makes it particularly valuable for applications that must withstand high lateral forces, such as those experienced during earthquakes or high winds. The added lime content improves workability while maintaining impressive strength.

I've found Type S mortar to be particularly valuable when working on projects in seismic zones. For instance, when consulting with clients in earthquake-prone regions like India or Pakistan, I often recommend Type S because it provides the necessary structural integrity while allowing minimal movement accommodation. The mortar's versatility also extends to hardscape applications like patios and outdoor kitchens, where it resists moisture infiltration and freeze-thaw cycles effectively. However, proper water content during mixing is crucial—too wet, and strength is compromised; too dry, and workability suffers.

Type N Mortar: Why Is It Called General-Purpose Mortar?

Do you know which mortar type professional masons reach for most often? When versatility matters more than maximum strength, Type N is usually their go-to choice.

Type N mortar is a medium-strength mortar (750-1,800 PSI) that balances good workability with adequate compressive strength, making it the most common choice for above-grade exterior and interior load-bearing walls under normal loading conditions.

Type N mortar contains more lime than Types M and S, with proportions typically being 1 part portland cement, 1 part lime, and 6 parts sand. This higher lime content improves workability and flexibility while providing sufficient strength for most residential and commercial applications.

I consider Type N the workhorse of mortars. Its popularity stems from its excellent balance of strength, workability, and economy. The increased lime content creates mortar that's easier to work with and accommodates slight building movements and thermal expansion better than higher-strength alternatives.

During my visits to construction sites across Saudi Arabia and the UAE, I've observed Type N mortar being used extensively in brick veneer applications, where it adheres well to the backing and facing materials while allowing for some movement. It's particularly effective in warm climates because its water retention properties help prevent premature drying during hot weather installation. However, I always caution against using Type N for below-grade applications or in areas with severe freeze-thaw cycles, where its moderate strength may be insufficient. For optimal results, always follow manufacturer guidelines regarding mixing and curing times, especially when working in extreme temperature conditions.

Type O Mortar: When Would You Use Low-Strength Mortar?

Ever wondered why historic restoration specialists don't use modern high-strength mortars? Using excessively strong mortar on soft, historic masonry can actually cause more harm than good.

Type O mortar is a low-strength mortar (350-750 PSI) designed primarily for interior applications and repointing or repair work on historic structures where the original masonry units are soft and require a more flexible, breathable mortar.

Type O has the highest lime content of all mortar types, with typical proportions of 1 part portland cement, 2 parts lime, and 9 parts sand. This high lime content creates a soft, workable mortar with excellent water retention and self-healing properties.

In my restoration consulting work, I've seen firsthand how crucial proper mortar selection is when dealing with historic structures. Type O mortar's lower strength actually becomes an advantage in these scenarios because it allows the mortar—rather than the irreplaceable historic bricks or stones—to take the stress and deteriorate first.

The high lime content in Type O makes it particularly suitable for structures built before the 20th century, when masonry units were typically softer than modern materials. During a recent project consulting for the restoration of a century-old building in Georgia, we specifically recommended Type O mortar because its flexibility and breathability closely matched the original lime mortars used in construction. This compatibility prevented the damage often seen when harder, modern mortars are inappropriately used with soft historic masonry. However, Type O requires more careful attention to curing conditions, as its higher lime content means it cures through carbonation rather than hydration, a slower process that requires protection from rapid drying and freezing.

Conclusion

Choosing the right mortar1 type is crucial for project success. Consider the application environment, required strength, and material compatibility when selecting between Types M, S, N, or O for optimal performance and durability in your construction project.