Choosing the wrong mortar mix can lead to building failures, wasted materials, and costly repairs. Many contractors struggle with selecting appropriate formulations for specific applications, risking project integrity and reputation.

Drymix mortar1 is a pre-mixed powder consisting of cement, sand, and additives like HPMC2 that requires only water addition before use. The right formula depends on your application - whether for tile adhesives3, renders, EIFS systems4, or repair mortars - and must match your project's specific requirements for workability, adhesion, and durability.

I've been supplying hydroxypropyl methylcellulose and other additives to mortar factories across Asia and the Middle East for over 15 years. During this time, I've learned that understanding mortar applications is crucial for both manufacturers and end-users. Let me share what I've discovered about key applications and how to optimize each formula.

What Are The Key Dry Mix Applications That Require Special Formulations?

Poor formulation choices can ruin entire batches of mortar, causing adhesion failures and material wastage. I've seen projects delayed for weeks due to improper mortar selection.

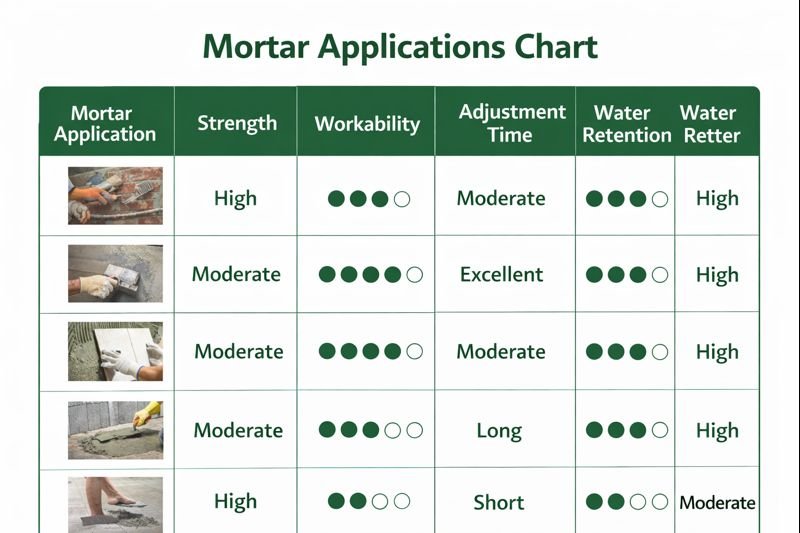

The main dry mix mortar applications include tile adhesives3, self-leveling compounds5, renders/plasters, repair mortars, EIFS/ETICS systems, grouts, and waterproofing mortars6. Each requires specific additives like HPMC, RDP, and cellulose ethers in different concentrations to achieve the required performance characteristics.

Tile Adhesives

Tile adhesives represent one of the most common dry mix applications worldwide. The optimal formulation typically includes:

| Component | Standard Content (%) | Function |

|---|---|---|

| Portland cement | 25-35 | Binding agent |

| Graded sand | 60-70 | Filler |

| HPMC (hydroxypropyl methylcellulose) | 0.2-0.5 | Water retention, workability |

| Redispersible polymer powder | 1-5 | Flexibility, adhesion |

| Additives (retarders, accelerators) | 0.1-0.5 | Setting time control |

For premium tile adhesives, I recommend using HPMC with viscosity between 50,000-100,000 mPa·s for vertical applications to prevent slippage. Based on my experience with clients in Saudi Arabia and UAE, local environmental conditions affect the ideal water retention values - higher humidity regions require less water retention while drier climates need more. This balance is crucial for proper adhesive curing, especially in outdoor applications where temperature fluctuations can compromise adhesion if the formulation isn't optimized.

How to Make Mortar Mix That Ensures Consistent Quality?

Many mortar manufacturers I've visited struggle with batch-to-batch consistency. Quality variations can destroy customer trust and lead to expensive product recalls.

To make quality mortar mix, use precise weighing systems for all components (±0.1% accuracy), employ high-speed mixers (>800 RPM) for proper dispersion of additives, implement strict quality control protocols including water demand testing, open time verification, and adhesion strength measurement for each batch.

Raw Material Selection

The foundation of consistent mortar production begins with raw material selection and quality control. I've seen firsthand how variations in cement quality or improper sand gradation can dramatically affect the final product performance.

For optimal production, implement these practices:

| Material | Quality Parameters | Testing Frequency |

|---|---|---|

| Cement | Setting time, fineness | Every delivery |

| Sand | Particle size distribution, moisture content | Daily |

| Cellulose ethers (HPMC) | Viscosity, substitution degree | Every batch |

| Redispersible powder | Particle size, minimum film forming temperature | Every delivery |

During my visits to production facilities in India and Pakistan, I noticed that manufacturers who implemented automated dosing systems reduced formulation errors by up to 90%. Additionally, climate-controlled storage for moisture-sensitive additives like HPMC and redispersible polymer powder7 significantly extended shelf life and maintained consistent performance. The investment in proper raw material handling pays dividends in reduced customer complaints and improved reputation in the market.

What Does A Complete Drymix Mortar Application Guide Include?

Incomplete application instructions lead to product failures in the field. I've consulted with contractors who wasted entire pallets of material due to improper mixing or application techniques.

A complete drymix mortar application guide must include specific substrate preparation requirements, exact water ratios (typically 0.18-0.25 L/kg), proper mixing instructions (usually 3-5 minutes at specified speeds), application methods and thickness ranges, and curing conditions including temperature limits (usually 5-35°C) and protection needs.

Application Methods By Mortar Type

Different mortar formulations require specific application techniques to achieve optimal performance. Based on my experience with clients across developing markets, application expertise varies significantly among contractors.

For construction professionals, here's a comprehensive overview:

| Mortar Type | Application Methods | Tools | Layer Thickness | Special Considerations |

|---|---|---|---|---|

| Tile Adhesives | Thin-bed method | Notched trowel | 2-5mm | Proper open time observation |

| Renders | Single or multi-layer | Trowel, spray machine | 10-20mm | Require mesh reinforcement for layers >15mm |

| Self-Leveling | Pour and spread | Gauge rake, spike roller | 3-30mm | Requires proper ventilation during curing |

| EIFS Adhesive | Spot-and-dab or full surface | Notched trowel | 5-10mm | Edge protection critical |

When I consulted with a large mortar factory in Brazil last year, we discovered that nearly 40% of their customer complaints stemmed from application errors rather than product defects. By developing detailed application guides with visual aids and conducting regular contractor training sessions, they reduced installation-related issues by over 60%. This demonstrates the crucial role communication plays in successful product implementation, regardless of formulation quality.

How Does EIFS Adhesive Mortar Differ From Standard Mortars?

Using standard mortar for EIFS installation often results in system failures, energy efficiency loss, and moisture ingress. Many contractors don't realize EIFS requires specialized formulations.

EIFS adhesive mortar differs from standard mortars through higher polymer content (typically 3-5% redispersible powder), specific rheological additives for vertical hold, enhanced flexibility (elongation >1%), and improved freeze-thaw stability. These properties ensure proper bonding between insulation boards and various substrates while accommodating thermal movements.

EIFS Adhesive Performance Requirements

EIFS (External Insulation and Finish Systems) adhesives face unique challenges compared to other mortar applications. Based on my work with EIFS manufacturers in Georgia and Vietnam, these systems require carefully balanced formulations.

The critical performance parameters include:

| Property | Requirement | Role of Additives |

|---|---|---|

| Adhesion strength to EPS | >0.08 MPa | Redispersible powder provides polymer film formation |

| Adhesion strength to concrete | >0.25 MPa | HPMC improves wet adhesion and ultimate bond strength |

| Open time | >20 minutes | Cellulose ethers control water retention |

| Sag resistance | <0.5mm on vertical surface | HPMC controls rheology |

| Flexibility | Elongation >1% | Polymer content creates flexibility |

In my experience, EIFS adhesive failures often stem from inadequate polymer content or improper HPMC grade selection. When we helped a manufacturer in the UAE reformulate their EIFS adhesive, increasing the RDP content from 2.5% to 4% and switching to a higher viscosity HPMC (75,000 mPa·s instead of 30,000 mPa·s) improved adhesion strength by nearly 40%. This modification successfully eliminated delamination issues they had been experiencing on high-rise projects, where wind loads placed additional stress on the adhesive bond.

What Makes EIFS Surface Mortar Special Compared To Traditional Renders?

Traditional renders often crack and deteriorate when used in EIFS systems. The unique stress patterns in these systems demand specialized surface mortar formulations.

EIFS surface mortar (base coat) contains 5-7% polymer content (vs. 1-2% in traditional renders), fibers for crack resistance, lower modulus of elasticity for movement accommodation, higher impact resistance (>10J), and must maintain flexibility while providing proper embedment for reinforcing mesh.

EIFS Surface Mortar Formulation

The base coat in an EIFS system serves as critical protection for the insulation while providing the foundation for the decorative finish. Drawing from my experience with mortar factories in Singapore and Philippines, I've observed that successfully formulated EIFS surface mortars balance several competing properties.

A typical high-performance EIFS base coat contains:

| Component | Content (%) | Function |

|---|---|---|

| Portland cement | 30-35 | Structural integrity |

| Fine graded sand | 55-60 | Filler, workability |

| Redispersible polymer powder | 5-7 | Flexibility, adhesion |

| HPMC | 0.3-0.5 | Workability, water retention |

| Polypropylene fibers | 0.1-0.3 | Crack resistance |

| Lightweight fillers | 2-5 | Reduced weight, workability |

I remember consulting with a manufacturer in Mexico who was experiencing excessive cracking in their EIFS installations. By incorporating 0.2% polypropylene fibers8 and increasing their polymer content from 3% to 6%, they virtually eliminated cracking issues. Additionally, switching from standard cellulose ether to HPMC with higher methoxyl content improved water resistance in their rainy coastal region. This highlights how regional climate conditions should influence formulation decisions - there's no truly universal formula that works optimally everywhere.

How To Find a Professional HPMC Supplier For Your Mortar Formulations?

Many mortar manufacturers waste time and money on inconsistent HPMC products. Poor-quality HPMC leads to production delays, quality issues, and customer complaints.

To find a professional HPMC supplier, verify manufacturing capabilities (dedicated production lines indicate specialization), request technical specifications showing viscosity ranges and modification types, check quality certifications (ISO 9001 minimum), evaluate technical support capabilities, and test samples in your actual formulations before committing to bulk orders.

Evaluating HPMC Quality For Mortar Applications

As a manufacturer with six production lines, I've learned that not all HPMC products are created equal, despite similar specifications on paper. Subtle differences in manufacturing processes create significant performance variations.

When selecting an HPMC supplier, consider these critical factors:

| Evaluation Criteria | Importance | What To Look For |

|---|---|---|

| Particle size distribution | Critical | Consistent sizing ensures proper dissolution |

| Viscosity stability | High | Less than 5% variation between batches |

| Modification type | Critical | Methoxyl/hydroxypropyl ratio affects water retention |

| Technical support | Medium | Supplier should offer formulation assistance |

| Supply reliability | High | Production capacity and inventory practices |

| Quality control | Critical | Regular testing protocols and documentation |

During my interactions with mortar manufacturers across developing markets, I've observed that manufacturers who conduct thorough evaluation of HPMC samples in their specific formulations avoid costly reformulation later. A client in Pakistan once shared how switching suppliers based solely on price led to inconsistent open time in their tile adhesive, resulting in substantial customer complaints. When they returned to a supplier with proven quality, despite paying 15% more, they ultimately saved money through reduced waste and improved customer satisfaction.

Conclusion

Selecting the right drymix mortar formulation for each specific application is crucial for project success. By understanding the unique requirements of tile adhesives, EIFS systems, and other applications, and partnering with reliable HPMC suppliers, you can ensure consistent quality and optimal performance.

-

Explore the versatility of Drymix mortar and its essential role in construction projects. ↩

-

Learn about HPMC's critical function in enhancing mortar performance and workability. ↩

-

Discover effective practices for using tile adhesives to ensure strong and lasting installations. ↩ ↩

-

Find out how EIFS systems improve energy efficiency and aesthetics in building design. ↩

-

Understand the benefits and application techniques of self-leveling compounds for smooth surfaces. ↩

-

Learn about the essential characteristics of waterproofing mortars for effective moisture control. ↩

-

Discover how redispersible polymer powder enhances flexibility and adhesion in mortar formulations. ↩

-

Discover the benefits of using polypropylene fibers for enhanced crack resistance in mortars. ↩