Exporting HPMC without proper certifications is like trying to cross borders without a passport. Many manufacturers lose deals and face shipment rejections because they overlook these critical requirements.

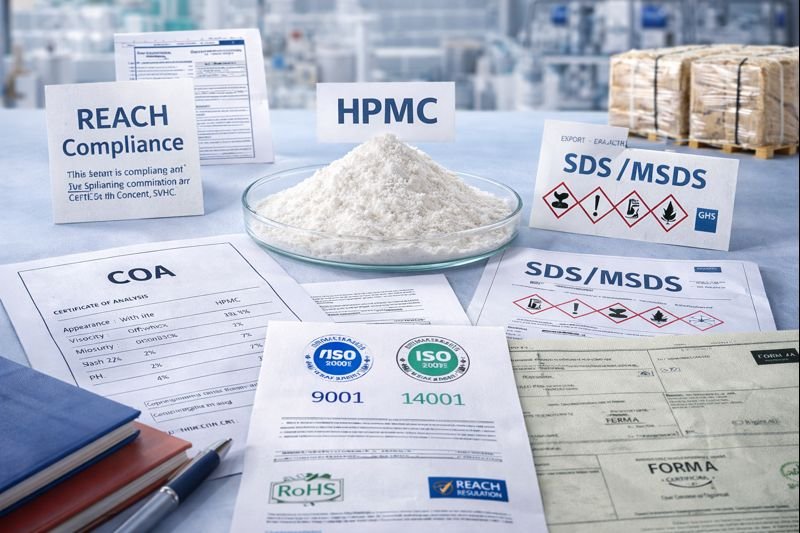

HPMC export certification1 needs depend on both application type and destination market. Construction use requires CE marking2 in Europe, while food applications need FDA compliance3 in the US and Halal certification4 in Muslim countries. Industrial HPMC products must meet ISO 90015 and region-specific chemical regulations.

Understanding certification requirements for hydroxypropyl methylcellulose (HPMC) is essential for successful market entry. I've seen many suppliers lose business opportunities simply because they didn't have the right paperwork. Let me explain what you need to know to avoid these costly mistakes.

Why Is ISO 90015 Certification Considered Just Your "Business Passport"?

Pain point: Many HPMC manufacturers believe having ISO 9001 certification alone guarantees global market access, only to face unexpected barriers.

ISO 9001 is only your starting point for HPMC exports. This quality management certification proves you have consistent production processes but doesn't address specific market requirements. Think of it as your business passport - necessary but insufficient for entry to every destination.

ISO 9001 establishes that your factory follows internationally recognized quality management principles. It covers documentation, traceability, consistency in production, and continuous improvement systems. However, this certification doesn't verify the actual performance of your HPMC or its suitability for specific applications.

I've witnessed several Chinese manufacturers invest heavily in production capacity while neglecting certification requirements. One of our competitors lost a 50-container order to Saudi Arabia because they couldn't provide proper documentation beyond their ISO certificate. The buyer needed application-specific certifications that proved the HPMC would perform correctly in their construction products.

The Difference Between Basic and Application-Specific Certifications

| Certification Type | Purpose | Examples | Limitations |

|---|---|---|---|

| General Business | Verifies management systems | ISO 9001, ISO 14001 | Doesn't verify product performance |

| Product-Specific | Confirms product characteristics | Third-party test reports | May not meet regulatory requirements |

| Market Access | Allows legal entry to markets | REACH (EU), FDA (US) | Often region-specific |

| Application-Specific | Verifies suitability for end use | CE marking, Halal | Must match the customer's application |

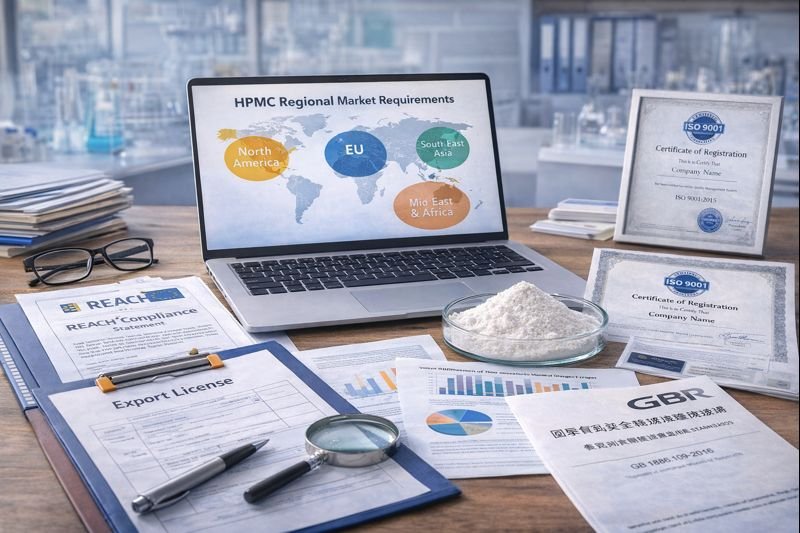

What "Market Visas" Does Your HPMC Need for Different Regions?

Problem: HPMC shipments get stuck at customs or rejected by customers because manufacturers didn't research specific market entry requirements.

Different regions have mandatory chemical registration systems that act as "market visas" for your HPMC. For the EU, REACH registration is non-negotiable - without it, your products won't clear customs regardless of quality or price.

REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe isn't optional - it's a legal requirement for selling chemical substances above one ton annually. The registration involves detailed documentation on the substance's properties, classification, toxicological impact, and safe use guidelines.

Similarly, countries like South Korea (K-REACH), Turkey (KKDIK6), and the UK (UK REACH) have developed their own chemical registration systems. Each requires separate submissions and generates different compliance costs.

I remember when we first entered the European market. Despite having high-quality HPMC, our first shipment was held at Rotterdam port because we hadn't completed REACH registration7. The delay cost us nearly $20,000 in storage fees and almost lost us the customer. We now maintain an updated database of regulatory requirements for each target market and review it before approaching new territories.

Key Chemical Registration Requirements By Region

| Region | Primary Regulation | Key Requirements | Typical Timeline | Approximate Cost |

|---|---|---|---|---|

| European Union | REACH | Registration dosier, tonnage bands | 6-12 months | $20,000-50,000+ |

| United States | TSCA Inventory | Chemical notification | 3-6 months | $10,000-25,000 |

| China | China REACH | New chemical substance notification | 4-8 months | $15,000-30,000 |

| South Korea | K-REACH | Similar to EU REACH | 6-10 months | $15,000-35,000 |

| Middle East | Varies by country | Often GCC standardization | 3-6 months | $5,000-15,000 |

How Does The End Application Determine Certification Requirements?

Challenge: Using industrial-grade HPMC in food or pharmaceutical applications can lead to serious compliance issues and safety concerns.

The end-use application of your HPMC dictates which specific certifications you need. Construction applications require different standards than food-grade or pharmaceutical uses, and mixing these categories can create serious problems.

For construction applications, CE marking under the Construction Products Regulation (CPR) is crucial in Europe. This confirms your HPMC meets standards for use in building materials. In concrete and mortar applications, customers will look for ASTM C1328 compliance in America or EN 934-3 in Europe.

Food-grade HPMC needs FDA compliance in the US, typically following standards in 21 CFR 172.874. In Europe, it must meet E464 food additive regulations. Muslim markets require Halal certification, while Jewish markets may need Kosher certification. Pharmaceutical applications have even stricter requirements, often needing USP/NF or EP compliance.

We once had a Turkish customer who rejected our industrial-grade HPMC because they needed it for food applications. Despite our competitive pricing, they ultimately chose a more expensive supplier who had proper food-grade certifications. This experience taught us to always clarify the end application before quoting prices.

HPMC Certification Requirements By Application

| Application | Required Certifications | Key Performance Parameters | Testing Standards |

|---|---|---|---|

| Construction | CE marking, ISO standardization | Water retention, viscosity, workability | ASTM C1328, EN 934-3 |

| Food | FDA, E464, Halal, Kosher | Purity levels, heavy metal content | 21 CFR 172.874, FCC |

| Pharmaceutical | USP/NF, EP, JP | Substitution type, viscosity precision | USP <1121>, EP 2.2.49 |

| Personal Care | ISO 16128, Natural/Organic standards | Stability, sensory properties | ASTM E640, ISO 29621 |

| Agricultural | EPA registrations, organic certifications | Suspension stability, biodegradability | OECD guidelines |

Why Are Third-Party Test Reports The "Health Check" Buyers Really Need?

Problem: Generic certifications don't prove your HPMC will perform in specific applications, leading to quality disputes and customer dissatisfaction.

Beyond mandatory certifications, serious buyers want detailed third-party test reports that verify your HPMC's actual performance characteristics for their specific application.

Third-party test reports from recognized laboratories like SGS, Intertek, or Bureau Veritas provide objective verification of your product's performance. These reports typically measure critical parameters like water retention, viscosity, gel temperature, particle size distribution, and substitution degree.

Different applications require different performance profiles. For example, construction customers focus on water retention and workability, while pharmaceutical customers prioritize precise viscosity and purity levels. The specific industry standards also vary by region - American buyers often reference ASTM standards, while European customers look for EN standards compliance.

Last year, we competed against a supplier offering HPMC at 15% lower prices for a major Middle Eastern mortar manufacturer. While their price was attractive, we provided comprehensive SGS test reports showing our superior water retention values that would reduce cement consumption in the customer's formula. This performance advantage ultimately won us the contract despite our higher price, as the customer calculated that the formula savings outweighed the raw material cost difference.

Key Performance Parameters in Third-Party Testing

| Parameter | Importance | Testing Method | Application Impact |

|---|---|---|---|

| Water Retention | Critical for mortar workability | EN 459-2, ASTM C1506 | Affects open time and adhesion |

| Viscosity | Determines flow behavior | Brookfield method, Ubbelohde | Impacts application properties |

| Substitution Degree | Defines chemical properties | NMR spectroscopy | Affects solubility and performance |

| Particle Size | Impacts dissolution | Laser diffraction | Determines dissolution speed |

| Gel Temperature | Thermal transition point | Rheology measurements | Important for temperature stability |

Conclusion

The right certifications for HPMC exports depend on both destination market and end application. Basic ISO certification is just your starting point - you need region-specific regulatory approvals and application-specific performance validations to succeed globally.

-

Understanding HPMC export certification is crucial for compliance and successful market entry. ↩

-

CE marking is essential for construction materials in Europe, ensuring compliance with safety standards. ↩

-

FDA compliance is vital for food-grade HPMC to ensure safety and legality in the US market. ↩

-

Halal certification is crucial for accessing Muslim markets, ensuring products meet religious standards. ↩

-

ISO 9001 certification demonstrates quality management but is not enough for market access. ↩ ↩

-

KKDIK is Turkey's chemical regulation, vital for compliance and market access. ↩

-

REACH registration is a legal requirement for chemical substances in the EU, crucial for market entry. ↩