Struggling with unstable detergent formulations? Inconsistent product quality can devastate your brand reputation and bottom line. Leading manufacturers face this challenge daily but have found a reliable solution.

Hydroxyethyl Cellulose (HEC)1 is preferred by top detergent manufacturers because of its exceptional compatibility with complex formulations, stability across wide pH ranges, and ability to maintain consistent viscosity in high-electrolyte environments while enhancing product performance and user experience.

When formulating premium detergents, the thickener you choose impacts everything from shelf stability to consumer satisfaction. I've seen countless manufacturers struggle with product separation and inconsistent performance until they made the switch to HEC. Let's explore why this ingredient has become the gold standard for quality-focused producers.

What Key Advantages Make HEC Stand Out from Other Thickeners?

Production managers face constant pressure to deliver consistent quality while keeping costs manageable. Poor thickener choice often leads to product recalls, customer complaints, and wasted resources.

HEC provides superior stability in complex detergent formulations by maintaining viscosity across broad pH ranges (2-12), resisting degradation in high-salt environments, and creating smooth, non-sticky textures that consumers prefer over products thickened with alternatives.

HEC truly stands apart when we look at what matters most in detergent production. I regularly consult with manufacturers who've tried multiple thickeners before settling on HEC as their preferred choice. The primary advantages that consistently convince them to switch include its exceptional electrolyte tolerance, pH stability, and temperature resistance.

Unlike many alternatives, HEC maintains consistent performance across a broad spectrum of conditions. This translates directly to improved production efficiency since fewer adjustments are needed during manufacturing. The compatibility with both anionic and cationic surfactants also provides formulation flexibility that's hard to match.

Cost-effectiveness is another crucial factor. While the raw material cost of HEC might initially seem higher than some alternatives, the overall formula cost often works out lower because:

| Cost Factor | HEC Advantage |

|---|---|

| Dosage Required | Lower use levels (0.3-2.0%) compared to some alternatives |

| Processing Time | Faster dissolution with proper grades |

| Stability | Fewer rejected batches due to separation or viscosity loss |

| Synergistic Effects | Enhanced performance with salt thickening systems |

For one of my clients, switching to our premium HEC grade reduced their thickener usage by 30% while improving their product's shelf stability from 9 months to over 18 months - a significant competitive advantage in their market.

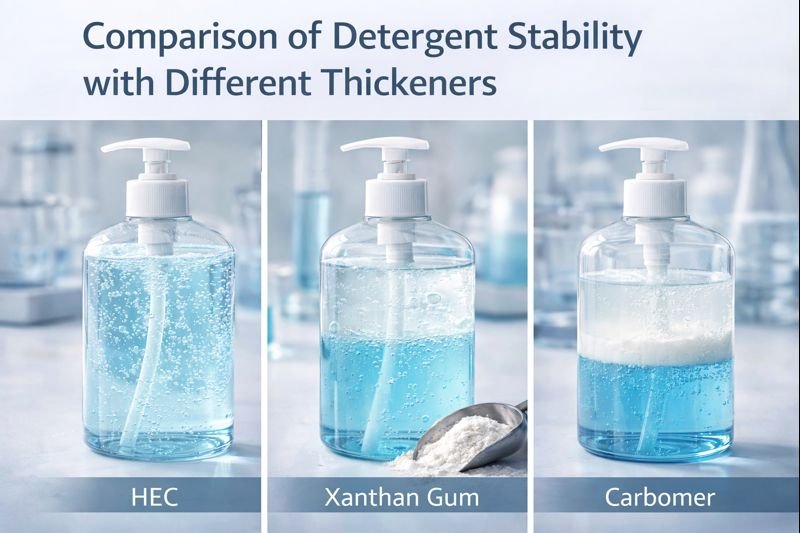

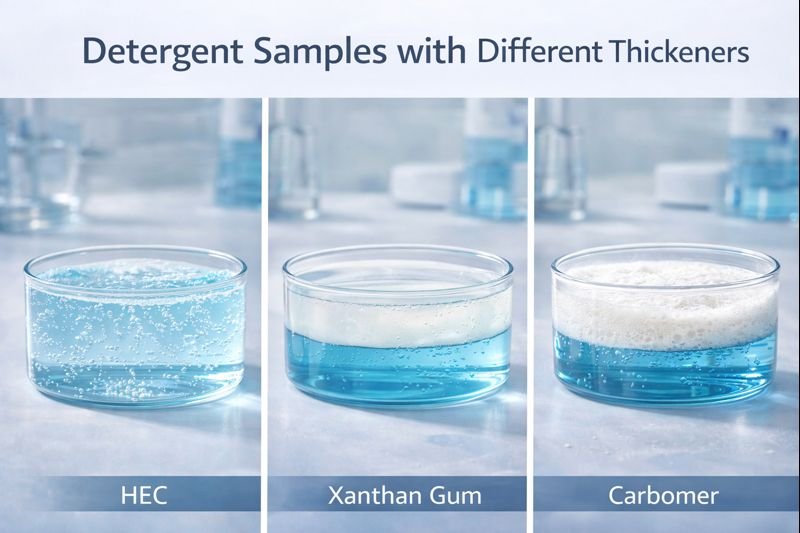

How Does HEC Compare to Other Common Thickeners in Detergents?

Formulating with the wrong thickener wastes time and resources. Many manufacturers find their products separating on store shelves or failing performance tests after using inappropriate thickening agents.

Compared to alternatives, HEC offers better salt tolerance than xanthan gum, superior clarity than carbomers, and more consistent performance across temperature ranges than cellulose gums, making it the most versatile option for complex detergent formulations.

When evaluating thickeners for detergent applications, compatibility with other ingredients becomes paramount. I've worked with numerous formulation teams who previously used carbomers but struggled with incompatibilities when introducing certain fragrances or active ingredients. The switch to HEC eliminated these issues almost immediately.

The performance comparison extends beyond just basic thickening. HEC provides excellent suspension properties for decorative elements or encapsulated fragrances that many manufacturers now incorporate into premium products. This multifunctionality often allows simplification of formulations by reducing the need for additional stabilizers or suspension agents.

Environmental considerations are increasingly important for modern manufacturers. HEC offers biodegradability advantages over some synthetic polymers while maintaining performance consistency that natural gums can't always deliver. This balance of performance and environmental profile has made it particularly attractive for brands positioning themselves as eco-friendly alternatives.

From a processing standpoint, HEC demonstrates remarkable advantages in production efficiency:

| Processing Parameter | HEC Performance | Common Alternatives |

|---|---|---|

| Dissolution Speed | Moderate to fast with proper grades | Often slower, especially with natural gums |

| Dust Generation | Low with granular grades | Can be problematic with powders |

| Shear Stability | Excellent | Variable depending on type |

| pH Adjustment Requirements | Minimal | Often significant |

I recently helped a manufacturer troubleshoot a persistent issue with batch consistency. After analyzing their process, we identified their previous thickener's sensitivity to minor variations in mixing parameters as the culprit. Implementing our specialized HEC grade standardized their results across production runs.

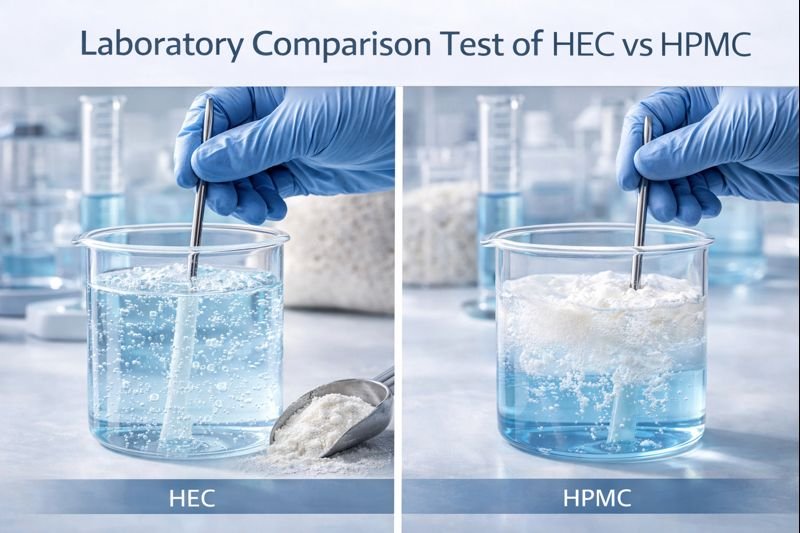

How Does HEC Compare Specifically to HPMC2 in Detergent Applications?

Formulation scientists often debate between HEC and HPMC, unsure which will deliver the most consistent results. Making the wrong choice leads to reformulation costs and production delays.

HEC outperforms HPMC in detergent applications through faster hydration (typically 15-30 minutes versus 1-2 hours), better electrolyte tolerance, and superior performance in cold-water conditions, though HPMC may offer advantages in specific high-temperature applications.

When comparing HEC directly with HPMC (Hydroxypropyl Methylcellulose), several key performance differences become apparent. I've conducted numerous side-by-side comparisons for clients considering both options, and the results consistently show HEC's superiority for most detergent applications.

The hydration kinetics represent perhaps the most significant production advantage. HEC typically reaches full viscosity development in a fraction of the time required for HPMC, which translates directly to faster production cycles and increased plant capacity. For manufacturers running multiple batches daily, this time saving can significantly improve overall output without additional equipment investments.

Solution clarity is another area where HEC typically outperforms HPMC in detergent systems. This becomes particularly important for transparent product formulations where visual appeal is a selling point. The difference becomes even more pronounced in high-electrolyte environments:

| Property | HEC Performance | HPMC Performance |

|---|---|---|

| Salt Tolerance | Maintains clarity up to 20% salt concentration | Often clouds at >10% salt levels |

| Surfactant Compatibility | Excellent with most types | Good but more sensitive to certain anionics |

| Low-Temperature Stability | Maintains viscosity at 4°C | May gel or precipitate at low temperatures |

| Viscosity Retention | Stable over 12+ months | Sometimes decreases over time |

While HPMC does offer some advantages in thermal gelation properties that can be useful for specific applications, this feature is rarely beneficial in typical detergent formulations3 where consistent viscosity across temperature ranges is preferred.

Cost efficiency analysis typically favors HEC when considering the overall formulation cost rather than just the raw material price. At our production facility, we've optimized our HEC manufacturing process specifically for detergent applications, resulting in grades that allow our clients to use lower dosages while achieving superior stability.

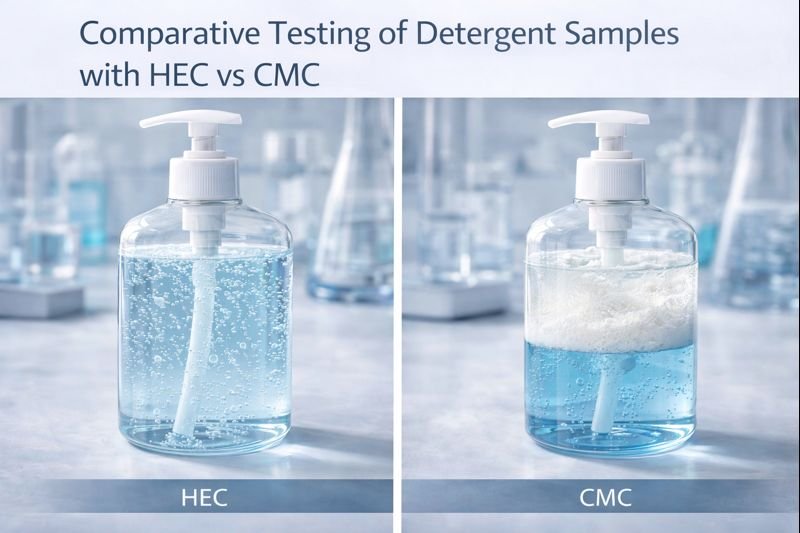

What's the Difference Between Using HEC and CMC4 in Modern Detergents?

Detergent manufacturers frequently struggle to choose between HEC and CMC, risking product stability issues and wasted ingredients if they select incorrectly based on price alone.

HEC differs from CMC by offering ionic neutrality (making it compatible with both cationic and anionic ingredients), greater stability across varying water hardness conditions, and consistent performance regardless of pH fluctuations, though CMC may provide cost advantages in simple formulations.

The fundamental chemical difference between HEC and CMC (Carboxymethyl Cellulose) drives significant performance variations in detergent applications. CMC's anionic nature creates both advantages and limitations that formulators must carefully consider. Through years of testing both materials in various detergent systems, I've developed a clear understanding of when each excels.

CMC has historically been popular in detergents primarily due to its lower cost structure. However, as formulations have become increasingly complex, more manufacturers are recognizing the limitations of this approach. The sensitivity of CMC to calcium and magnesium ions (water hardness) creates inconsistent performance across different regions where water mineral content varies significantly.

Performance stability across product lifecycle presents another critical difference. Our laboratory aging studies consistently demonstrate HEC's superior maintenance of intended viscosity profiles over time. Consider these comparison points from our testing:

| Performance Factor | HEC Results | CMC Results |

|---|---|---|

| Hard Water Stability | Minimal viscosity change | 30-50% viscosity reduction possible |

| Enzyme Compatibility | No significant interaction | May reduce enzyme activity |

| Freeze/Thaw Stability | Maintains properties | Often separates after cycling |

| Fragrance Compatibility | Compatible with most types | May interact with certain fragrances |

The processing requirements also differ significantly. CMC typically requires careful management of dissolution conditions and can form lumps or "fish eyes" if not properly dispersed. Our specialty HEC grades are specifically engineered to minimize these processing challenges, allowing for more straightforward manufacturing protocols.

I recently worked with a major household brand that switched from CMC to our premium HEC grade after experiencing significant regional variations in their product performance. The consistency improvements across different water conditions eliminated customer complaints about product thinning in hard water regions, justifying the slight increase in raw material cost through enhanced brand reputation.

FAQ: Frequently Asked Questions About HEC in Detergent Applications

How does HEC affect the environmental profile of detergents?

Many manufacturers worry about the environmental impact of their ingredients. Using non-biodegradable thickeners can damage brand reputation and violate increasingly strict regulations.

HEC is biodegradable according to OECD guidelines, breaks down into non-toxic components in wastewater treatment processes, and has minimal aquatic toxicity compared to synthetic polymer alternatives, supporting manufacturers' sustainability claims and regulatory compliance.

Can HEC be used in cold-water detergent formulations?

Formulating for cold-water performance presents unique challenges. Many thickeners lose effectiveness at lower temperatures, compromising product quality exactly when consumers expect consistent results.

HEC maintains optimal viscosity and performance in cold water (even below 15°C), unlike some alternatives that stiffen or precipitate at reduced temperatures, making it ideal for cold-water detergents that help consumers reduce energy consumption.

What concentration of HEC is typically needed for effective thickening?

Using too much thickener wastes money; too little leads to unstable products. Finding the optimal dosage is crucial for both product performance and profitability.

Most detergent formulations require 0.3-2.0% HEC for effective thickening, with exact dosage depending on desired viscosity, electrolyte content, and other formula components, typically allowing for 20-40% reduction compared to less efficient thickeners.

Conclusion

HEC stands as the preferred thickener for top detergent manufacturers due to its outstanding stability, compatibility, and performance advantages. By choosing the right HEC grade, you'll achieve consistent product quality while optimizing both production efficiency and formulation costs.

-

Explore how HEC enhances detergent formulations with its unique properties and benefits. ↩

-

Understand the key differences between HEC and HPMC for informed formulation choices. ↩

-

Learn about the critical factors in detergent formulations that affect quality and performance. ↩

-

Explore the performance differences between CMC and HEC in detergent formulations. ↩