Are you wasting time and money on putty that cracks? This common problem frustrates contractors and homeowners alike, leading to costly repairs and project delays.

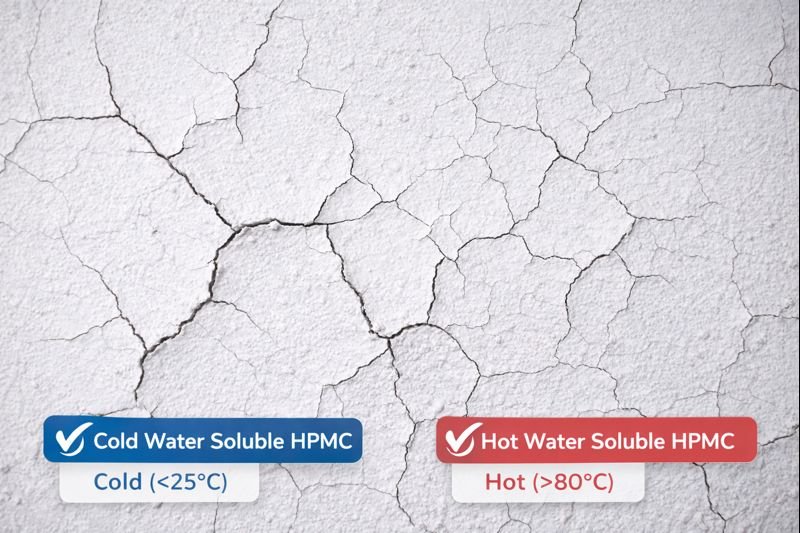

Wall putty cracks primarily occur due to insufficient HPMC (hydroxypropyl methylcellulose)1 dosage, counterfeit products, inappropriate viscosity, improper dissolution, or using the wrong HPMC grade2 for your specific application. Addressing these factors ensures durable, crack-free finishes.

As a manufacturer with six production lines supplying HPMC to over 15 countries, I've seen countless customers struggle with cracking issues. The good news? Most cracking problems have simple solutions once you understand the underlying causes. Let's explore why this happens and how to fix it.

Why is my putty cracking?

You've applied fresh putty, but days later, those frustrating hairline cracks appear. Your reputation is on the line, and redoing the work means lost profits and unhappy clients.

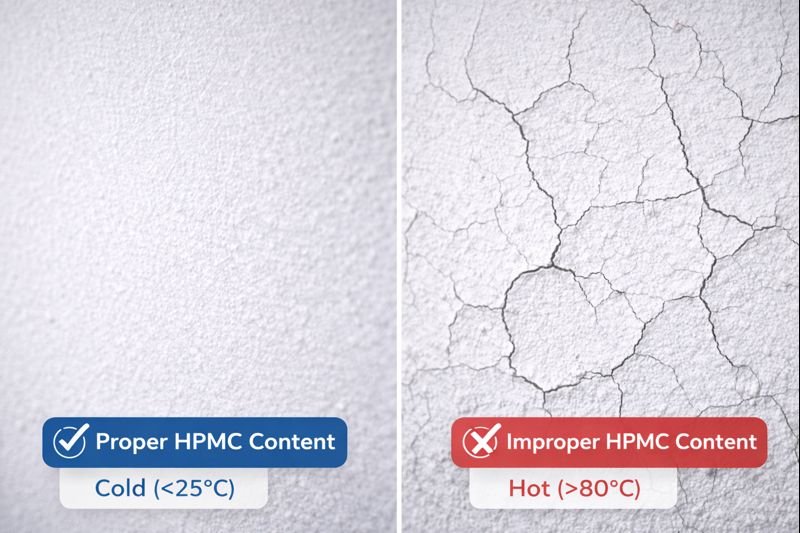

Putty cracks primarily because of insufficient moisture retention during the cement hydration process. When HPMC content is too low (below 0.2%) or counterfeit (salt-adulterated), water evaporates too quickly, preventing proper cement hydration and causing shrinkage cracks.

The #1 Culprit: Insufficient HPMC or Counterfeit Products

Quality HPMC is the backbone of crack-resistant putty powder. I've visited countless construction sites where contractors were bewildered by persistent cracking despite following proper application techniques. In most cases, the problem traced back to either insufficient HPMC dosage or counterfeit products.

Authentic HPMC creates what we call a "water lock" effect - it retains moisture long enough for cement to hydrate completely. For wall putties, I recommend at least 0.3-0.5% HPMC content by weight. Anything less risks premature drying and inevitable cracking. More concerning is the prevalence of salt-adulterated HPMC in the market. These counterfeits appear to have high viscosity initially but provide virtually no water retention.

How can you identify fake HPMC? Authentic products dissolve slowly and form a clear solution. Counterfeit versions typically dissolve too quickly and may leave salt residue. At our factory, we've developed a simple field test: place a small amount in water and observe the dissolution pattern. Authentic HPMC forms a gel-like layer before slowly dissolving, while counterfeits dissolve almost immediately.

| HPMC Quality Indicator | Authentic HPMC | Counterfeit HPMC |

|---|---|---|

| Dissolution time | 5-15 minutes | Under 2 minutes |

| Solution clarity | Clear, consistent | Cloudy or with residue |

| Water retention | 98% or better | Below 90% |

| Price range | $2.50-4.00/kg | Below $2.00/kg |

| Field performance | Consistent workability | Initial good viscosity, poor retention |

How to prevent putty from cracking?

Every failed project costs you time, materials, and customer trust. With putty cracking consistently ranking as a top complaint, finding prevention methods is essential for your business survival.

To prevent putty cracking, use quality HPMC at the correct dosage (0.3-0.5%), choose moderate viscosity grades (50,000-80,000 mPa·s), ensure thorough mixing in dry powder, allow complete dissolution before application, and select application-specific HPMC grades3 with proper surface treatment.

The Viscosity Misconception: Higher Isn't Always Better

One of the most common mistakes I see in our industry is the blind pursuit of high-viscosity HPMC. Last year, I visited a large mortar factory in Saudi Arabia where the production manager proudly showed me their newly purchased "premium" HPMC with viscosity exceeding 100,000 mPa·s. Their reasoning? Higher viscosity means better quality. They were shocked when I suggested this might be causing their cracking issues.

Excessively high viscosity creates problems rather than solving them. When HPMC viscosity is too high, the putty becomes sticky, difficult to apply, and develops high internal stresses during drying. These stresses literally cause the putty to "pull itself apart" as it dries. The ideal viscosity for most wall putty applications falls between 50,000 and 80,000 mPa·s.

What we actually need is optimal water retention, not maximum viscosity. These are different properties! Water retention determines how long moisture remains available for cement hydration. In our laboratory tests, medium-viscosity HPMC often outperforms higher-viscosity variants in preventing cracks because it creates the right balance of workability and moisture retention.

Consider these factors when selecting HPMC viscosity:

- Climate conditions (higher humidity areas can use lower viscosity)

- Substrate porosity (more porous substrates benefit from slightly higher viscosity)

- Application thickness (thicker applications may require higher water retention)

- Working time requirements (longer working times need better water retention)

How to fix wall putty cracks?

You're staring at unsightly cracks in your freshly applied putty. Your client is upset, and you need a solution fast that won't require stripping everything back to the substrate.

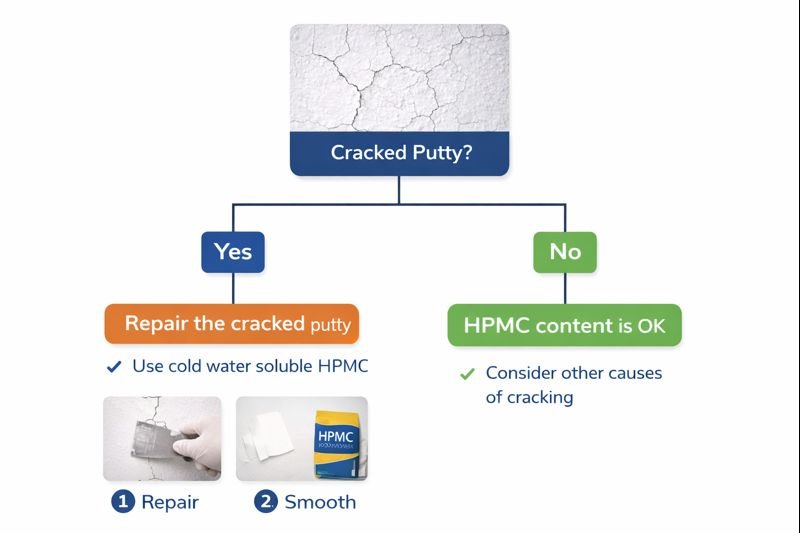

To fix wall putty cracks, first determine if they're surface-level or structural. For hairline cracks, apply a thin layer of quality putty with proper HPMC content (0.4-0.5%) over the affected area after cleaning and priming. For deeper cracks, fill with elastic crack filler before applying the final putty coat.

Beyond Cosmetic Fixes: Addressing Root Causes

Repairing cracked putty goes beyond simply covering the problem. In my experience working with construction professionals across developing markets, temporary fixes often lead to recurring issues and disappointed customers. The key is diagnosing the type of crack before attempting repairs.

Surface cracks (typically under 1mm width) usually stem from formulation or application issues. These can be fixed relatively easily by applying a thin layer of properly formulated putty. However, deeper or recurring cracks may indicate substrate movement, improper surface preparation, or fundamental formulation problems.

I recommend this systematic approach for permanent repairs:

-

Evaluate the substrate: Check for underlying moisture problems, structural movement, or improper initial preparation. Even the best putty will fail on a poor substrate.

-

Identify the crack pattern: Hairline cracks in a map-like pattern usually indicate shrinkage from improper HPMC usage. Single deep cracks often suggest structural movement.

-

Formulate properly: For repairs, increase your HPMC content slightly (0.4-0.5%) and ensure you're using a quality product with proper water retention properties.

-

Consider additives: For particularly problematic areas, add 0.1-0.2% redispersible polymer powder4 to increase flexibility and adhesion. This significantly improves crack resistance in the repair layer.

-

Control application environment: Apply repairs in moderate temperature and humidity conditions, avoiding direct sunlight which accelerates drying and promotes cracking.

| Crack Type | Possible Cause | Recommended Fix |

|---|---|---|

| Hairline map cracks | Insufficient HPMC | Clean, prime, apply properly formulated putty |

| Single deep cracks | Structural movement | Elastic crack filler + reinforced putty |

| Edge cracks | Poor bonding/preparation | Remove loose material, prime, apply modified putty |

| Recurring cracks | Substrate issues | Address substrate problem before repairing putty |

What to do with cracked putty?

Your project deadline is approaching, but the putty has cracked. You're faced with tough decisions: strip it all and start over, attempt repairs, or try to salvage the situation with painting techniques.

When facing cracked putty, assess crack severity before deciding how to proceed. Minor surface cracks can be repaired with proper putty while extensive cracking requires removal and reapplication. Always address the root cause—typically improper HPMC usage—before attempting any fix.

Making Informed Decisions for Different Scenarios

In my 15+ years working with construction materials, I've seen every imaginable putty disaster scenario. The correct approach depends on several factors including crack severity, project timeline, and budget constraints. Let me share the framework I use when advising our customers:

For minor surface cracking (cracks under 0.5mm width covering less than 20% of the surface), repair is usually viable. Start by applying a quality primer to improve adhesion, then use a properly formulated putty with adequate HPMC content. I've found that adding 0.1-0.2% redispersible polymer powder to your repair mix significantly improves flexibility and prevents recurrence.

For moderate cracking (cracks 0.5-2mm width or covering 20-50% of the surface), you're in a gray area. The decision depends largely on project requirements. For high-end projects with strict quality standards, I recommend complete removal and reapplication. For less demanding applications, strategic repair might be acceptable.

For severe cracking (cracks over 2mm wide or covering more than 50% of surface), there's really only one professional option: complete removal and reapplication using properly formulated materials. I've seen contractors try to "hide" severe cracking under paint or textured finishes, but this almost always leads to customer complaints within months.

When deciding whether to repair or replace, consider these factors:

- Project visibility and customer expectations

- Available time and budget constraints

- Root cause identification and elimination

- Likelihood of successful repair

- Long-term performance requirements

Remember that the reputation costs of failed repairs often far exceed the immediate costs of doing the job right the second time.

Conclusion

Using the right amount of quality HPMC (0.3-0.5%), choosing moderate viscosity grades, ensuring proper mixing, and selecting application-specific products will prevent most putty cracking issues. When cracks occur, address the root cause before attempting repairs.

FAQ

Can temperature affect HPMC performance in putty?

Yes, extreme temperatures affect dissolution and water retention properties. In hot climates, use cold water for mixing and consider specialized hot-weather grades of HPMC.

How can I test if my HPMC is authentic?

Real HPMC dissolves slowly (5-15 minutes), forms a clear solution, and creates a gel-like layer before dissolving completely. Counterfeits dissolve quickly and may leave residue.

What's the minimum HPMC percentage needed to prevent cracking?

For most wall putty applications, 0.3% is the absolute minimum, with 0.4-0.5% being optimal for challenging conditions.

Can adding more water help prevent cracking?

No, excessive water actually increases shrinkage and cracking. The solution is proper HPMC content, not more water.

Is there a difference between HPMC for interior vs. exterior putty?

Yes, exterior applications require HPMC with better water resistance, UV stability, and often benefit from additional anti-fungal treatment.

-

Understanding HPMC is crucial for ensuring quality in putty applications and preventing cracks. ↩

-

Selecting the correct HPMC grade is vital for achieving the desired putty performance. ↩

-

Choosing the right HPMC grade for your application can prevent cracking issues. ↩

-

Explore how adding redispersible polymer powder can improve flexibility and adhesion. ↩