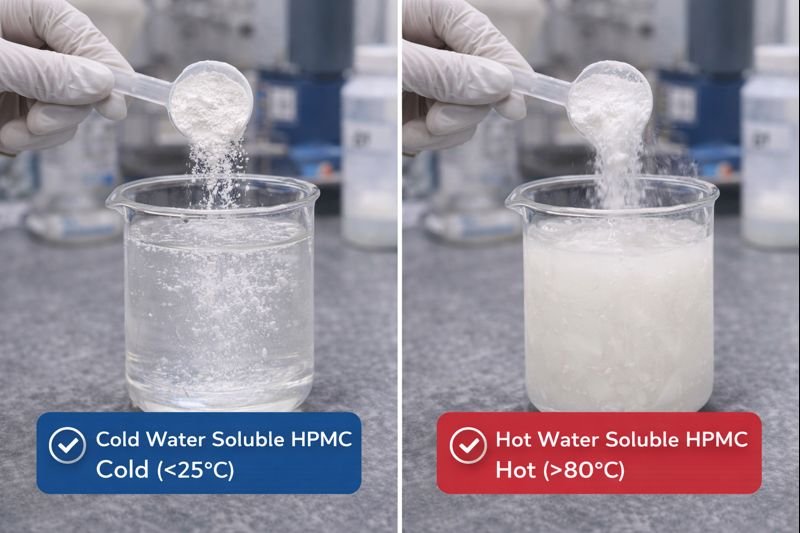

Are you struggling with clumping HPMC1 in your tile adhesive production2? This common problem causes quality issues and wasted materials. Many manufacturers pay premium prices for cold-water soluble HPMC without knowing there's a more cost-effective solution.

The most cost-effective HPMC1 choice depends on your mixing process. For professional dry mortar production with proper equipment, hot-soluble HPMC offers equivalent performance at lower costs because thorough dry-mixing prevents clumping issues that normally require cold-soluble varieties.

Understanding the right type of hydroxypropyl methylcellulose (HPMC1) for your tile adhesive production can save thousands in unnecessary costs. I've worked with countless mortar factories facing this exact dilemma, and the answer isn't what most suppliers will tell you. Let me explain why the production process matters more than the HPMC type.

What is the Role of HPMC1 in Tile Adhesive?

Pain point: Tile adhesive without proper cellulose ethers3 often slumps, dries too quickly, or fails to bond properly. These failures cost contractors time and money, and damage your reputation.

HPMC serves as a critical water retention agent in tile adhesives, ensuring proper cement hydration. It also improves workability, extends open time, enhances slip resistance, and increases adhesion strength by forming a consistent gel structure throughout the mortar.

https://placehold.co/600x400 "Tile adhesive application showing HPMC benefits")

https://placehold.co/600x400 "Tile adhesive application showing HPMC benefits")

HPMC transforms ordinary tile adhesive into a high-performance product through multiple mechanisms. Let me break down exactly how it works and why the dissolution method matters so much for your production line.

Key Functions of HPMC in Tile Adhesives

| Function | Benefit | HPMC Mechanism |

|---|---|---|

| Water Retention | Prevents premature drying | Forms gel network that holds water |

| Workability | Easier application | Increases viscosity and lubrication |

| Extended Open Time | More tiles placed before setting | Controls water evaporation rate |

| Anti-Sagging | Prevents tile slippage | Thixotropic effect stabilizes mortar |

| Adhesion Strength | Better bonding to surfaces | Improves cement hydration and polymer film formation |

The true secret lies in the mixing process. In a factory setting, HPMC is thoroughly mixed with cement and sand particles in large mixers. Each HPMC particle becomes physically separated by countless cement and sand particles. When cold water is added on-site, these HPMC particles can't clump together because they're already dispersed, effectively solving the clumping problem that cold-soluble HPMC is designed to address.

How to Get Tile Adhesive to Dry Faster?

Problem: Construction delays often happen when tile adhesive takes too long to dry. This extends project timelines and increases labor costs, especially in humid environments.

To accelerate tile adhesive drying, adjust the water-cement ratio, ensure proper ventilation, maintain optimal room temperature (70-75°F/21-24°C), select appropriate HPMC viscosity4, and consider adding accelerating admixtures. However, never sacrifice proper curing time for speed.

The drying time of tile adhesive depends on several factors that can be optimized through both formulation and application techniques. When I consult with mortar producers, I recommend a systems approach rather than focusing solely on one component like HPMC.

The main factors affecting drying time5 include environmental conditions, water content, adhesive thickness, and formulation components. While HPMC is crucial for water retention during curing, selecting the right viscosity grade is key - higher viscosity grades typically slow drying time while lower viscosity grades allow faster water evaporation.

For manufacturers looking to optimize drying time5 without compromising quality, I recommend these strategies:

- Formulation adjustments: Balance cement-to-sand ratio and polymer content

- HPMC selection: Choose lower viscosity grades (5,000-30,000 mPa·s) for faster drying applications

- Accelerating additives: Consider calcium formate6 or lithium carbonate in small amounts

- Application guidelines: Provide clear instructions on proper thickness and environmental conditions

From my experience testing various formulations, a well-balanced tile adhesive with properly selected HPMC can reduce drying time by 15-30% while maintaining adhesion strength and workability. The type of HPMC (hot or cold soluble) doesn't significantly impact drying time when properly formulated and mixed.

When Tiling Over Underfloor Heating, Which of These Adhesives is it Preferable to Use S1 or S2?

Concern: Using the wrong adhesive over underfloor heating can lead to cracking, tile detachment, and system failure. Homeowners face expensive repairs and contractors risk their reputation.

For tiling over underfloor heating, S2 classified adhesives are preferable to S1 because they offer superior deformability (≥5mm vs ≥2.5mm deflection) to accommodate thermal expansion/contraction cycles. S2 adhesives contain higher polymer content and often use specially modified HPMC to maintain flexibility.

The classification of tile adhesives as S1 or S2 refers to their deformability according to EN 12004 standards, which is crucial for underfloor heating applications. The continuous heating and cooling cycles create significant stress on the adhesive bond, making flexibility the most critical factor.

Understanding S1 vs S2 Classification

| Property | S1 Adhesive | S2 Adhesive | Impact on Underfloor Heating |

|---|---|---|---|

| Transverse Deformation | ≥2.5mm to <5mm | ≥5mm | Higher deformation capacity handles thermal movement better |

| Polymer Content | 2-5% | 5-8% | More polymer means more flexibility |

| HPMC Content | 0.2-0.3% | 0.3-0.4% | Higher HPMC improves water retention during extended working time |

| Cost | Lower | 15-25% higher | Investment in prevention vs. repair |

| Application Thickness | Standard | Can be applied thicker | Helps level irregular heating systems |

From my work with several large mortar factories, I've observed that the HPMC requirements differ slightly between S1 and S2 formulations. For S2 adhesives, manufacturers typically select HPMC with higher viscosity (50,000-100,000 mPa·s) and sometimes with specific modifications to enhance compatibility with higher polymer content.

Whether using hot or cold soluble HPMC matters less than ensuring the right viscosity and modification for the polymer system. The cost difference between hot and cold soluble HPMC becomes less significant in S2 adhesives since they're already premium products where performance takes priority over raw material costs.

What is Type 4 Tile Adhesive?

Issue: Selecting the wrong adhesive classification for specific tiling projects leads to installation failures. Many contractors don't understand the differences between adhesive types, resulting in costly mistakes.

Type 4 tile adhesive7 refers to ready-mixed paste adhesives classified under EN 12004 as D2, offering high adhesion strength and flexibility without needing on-site mixing. Unlike cementitious adhesives, these don't contain HPMC but use other cellulose derivatives and polymer dispersions for water retention.

The classification of tile adhesives follows European standards (EN 12004), which categorizes products based on their chemical composition and performance characteristics. Type 4 specifically refers to ready-mixed, paste-based adhesives that offer different advantages compared to the powder-form cementitious adhesives (Types 1-3) that contain HPMC.

While Type 4 (dispersion) adhesives don't typically contain HPMC, they use other types of cellulose derivatives like hydroxyethyl cellulose (HEC) or cellulose ethers with different modifications. The main binding agent in these adhesives is a polymer dispersion rather than cement.

For manufacturers who produce both cementitious adhesives and ready-mixed pastes, it's important to understand the different roles of various cellulose ethers3:

Cellulose Ethers in Different Adhesive Types

| Adhesive Type | Primary Cellulose Ether | Function | Concentration |

|---|---|---|---|

| Cementitious (C1/C2) | HPMC | Water retention, workability | 0.2-0.4% |

| Ready-mixed (D1/D2) | HEC | Thickening, anti-settling | 0.3-0.6% |

| Reaction Resin (R1/R2) | None typically | N/A | N/A |

When consulting with our customers who produce multiple adhesive types, I emphasize that while the cost-saving principles of using hot-soluble HPMC apply to cementitious products, the selection criteria for cellulose ethers in ready-mixed products follow different rules. The dispersion systems in Type 4 adhesives typically require cellulose ethers3 with different solubility parameters and compatibility with the polymer emulsions.

Conclusion

For professional tile adhesive manufacturing with proper dry-mixing equipment, hot-soluble HPMC offers equivalent performance at significantly lower costs than cold-soluble varieties. The premium pricing of cold-soluble HPMC is only justified for on-site mixing scenarios, not factory production.

FAQ

Q: How much cost difference exists between hot and cold soluble HPMC?

A: Cold-soluble HPMC typically costs $2000-3000 more per ton than hot-soluble varieties due to the additional surface treatment process.

Q: What mixing equipment ensures proper HPMC dispersion?

A: High-shear mixers, gravity-free mixers, and ploughshare mixers provide excellent HPMC dispersion in dry mortar production.

Q: Does HPMC viscosity affect tile adhesive performance?

A: Yes, higher viscosity HPMC (75,000-100,000 mPa·s) improves sag resistance and water retention but may slow drying time compared to lower viscosity grades.

Q: How long should customers mix tile adhesive with HPMC?

A: For best results, instruct customers to mix 3-5 minutes, let stand for 5 minutes, then briefly remix before application.

Q: Can the same HPMC be used for different tile adhesive classes?

A: While possible, optimizing HPMC viscosity and modification type for specific formulations (C1, C2, S1, S2) yields better performance and potentially lower overall costs.

-

Understanding HPMC's role can help you optimize your tile adhesive formulations and reduce costs. ↩ ↩ ↩ ↩

-

Explore expert insights on improving tile adhesive production efficiency and quality. ↩

-

Discover how cellulose ethers contribute to the performance of various adhesive types. ↩ ↩ ↩

-

Learn how viscosity affects the performance characteristics of your tile adhesives. ↩

-

Understanding drying time factors can help you optimize your adhesive formulations. ↩ ↩

-

Discover how calcium formate can be used to enhance drying times in tile adhesives. ↩

-

Understand the advantages of Type 4 adhesives for specific tiling projects. ↩