Fake HPMC1 has flooded the market, costing you money and compromising your projects. Without proper testing knowledge, even experienced buyers fall victim to these sophisticated counterfeits.

To spot fake HPMC, perform these three simple field tests: the iodine test for starch detection (turns blue if adulterated), the water dissolution test (should be clear not cloudy), and the burn test (pure HPMC leaves minimal white ash).

I remember when one of my clients called in a panic after their entire batch of wall putty failed to set properly. After visiting their site, I immediately recognized the problem - they'd purchased counterfeit HPMC2. Today, I'll share the exact field tests we use at Kehao to verify HPMC authenticity, saving you from costly project failures.

Can the Iodine Test Really Reveal Starch Fillers in HPMC1?

The market is flooded with HPMC adulterated with cheap starch fillers. These counterfeits look identical but will destroy your mortar's water retention and adhesion properties.

The iodine test quickly reveals starch adulterants in HPMC. Simply dissolve a small sample in water, add a few drops of iodine tincture (available at any pharmacy), and watch - if it immediately turns blue, your HPMC contains starch fillers.

The iodine test works by exploiting a fundamental chemical reaction3 between starch molecules and iodine. This reaction produces a distinctive blue-black complex that's immediately visible to the naked eye. Dishonest manufacturers often add corn starch, potato starch, or other similar compounds to increase weight and volume while maintaining the powder's appearance.

The implications of starch adulteration are severe for construction applications4. Starch lacks the critical properties that make HPMC1 valuable - water retention, binding strength, and workability. When used in mortar or cement-based products, starch-adulterated HPMC will result in poor adhesion, reduced working time, and potential delamination of applied materials.

For accurate testing, follow these steps:

- Take a small sample (about 1 gram) of your HPMC powder

- Dissolve it in about 100ml of room temperature water

- Let it fully hydrate (usually 15-20 minutes)

- Add 3-5 drops of iodine tincture and stir

- Observe immediately - pure HPMC remains unchanged, while adulterated material turns blue

This simple field test requires no special equipment but offers remarkable reliability in detecting one of the most common HPMC adulterants.

How Does the Water Dissolution Test Reveal HPMC Quality?

Many suppliers sell HPMC contaminated with insoluble fillers. These impurities compromise water retention and create inconsistent mixtures that fail during application.

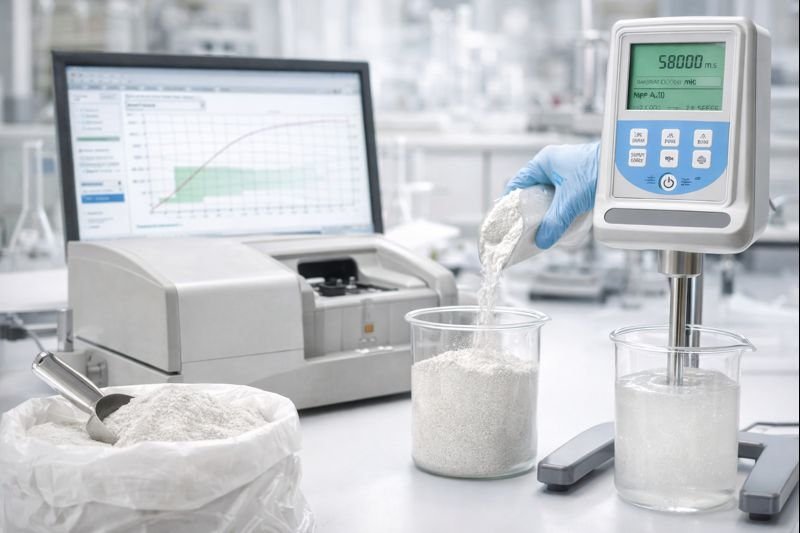

The water dissolution test reveals HPMC purity by examining solution clarity. Place a sample in a clear glass with water and stir thoroughly. Pure HPMC creates a clear, transparent solution, while cloudy or milky solutions indicate fillers and impurities that will undermine performance.

The water dissolution test provides critical insights into your HPMC's overall quality and purity. Pure hydroxypropyl methylcellulose is completely water-soluble and forms a clear solution after proper hydration. Any cloudiness, sediment, or opacity in the solution directly indicates contamination with insoluble materials.

Common adulterants revealed by this test include calcium carbonate, talc, silica, and various inorganic salts. These materials are substantially cheaper than HPMC and are deliberately added to increase weight and reduce production costs. Unfortunately, these fillers dramatically reduce the key performance properties of HPMC in construction applications.

To perform this test correctly:

- Use a clean, clear glass container

- Fill with room temperature water (about 200ml)

- Gradually sprinkle 2-3 grams of HPMC onto the water surface

- Allow complete hydration (30-60 minutes depending on viscosity grade)

- Observe solution clarity against a dark background

- Stir thoroughly and check for settling particles

A quality HPMC1 solution should appear transparent or slightly translucent depending on concentration, but never milky or opaque. It should maintain uniform consistency throughout the liquid with no visible particles or sediment after standing. The presence of floating particles, settling material, or pronounced cloudiness all indicate adulterated product.

This test is particularly valuable because water retention is one of HPMC's most critical functions in construction applications - and this property is directly compromised by insoluble fillers.

Can the Burn Test Accurately Detect Inorganic Fillers in HPMC?

Unethical suppliers often add inorganic materials to increase HPMC weight. These adulterants seriously compromise performance while allowing suppliers to charge premium prices for inferior products.

The burn test effectively identifies inorganic fillers in HPMC. Place a small sample on a heat-resistant surface and ignite it with a lighter. Pure HPMC burns completely, leaving minimal white ash, while adulterated material leaves substantial dark residue or hard chunks.

The burn test leverages a fundamental chemical principle: organic materials like pure HPMC are carbon-based and burn relatively completely, while inorganic compounds like salts and minerals leave substantial residue. This makes it an excellent field method for detecting common HPMC adulterants like sodium chloride (salt), calcium carbonate, and other mineral fillers.

These inorganic materials are often added as "weight enhancers" since HPMC is typically sold by weight. A product adulterated with 30% salt, for example, costs the manufacturer significantly less to produce while maintaining the appearance of genuine HPMC. For buyers, however, this translates to paying premium prices for ineffective material.

For construction applications, these adulterants create serious performance issues. Salt-contaminated HPMC, for instance, can cause efflorescence (white salt deposits) on finished surfaces and accelerate corrosion of metal components embedded in mortar or concrete. Other mineral fillers reduce water retention capacity and compromise adhesion strength.

To conduct a proper burn test:

- Place a small amount (0.5-1g) of HPMC on a clean, heat-resistant surface

- Ignite with a lighter and allow to burn completely

- Examine the remaining ash:

- Pure HPMC leaves minimal (5-10%), lightweight white ash

- Adulterated HPMC produces substantial dark ash, hard residue, or salt-like crystals

- The greater the residue, the higher the adulteration level

This test is particularly valuable because it requires no special equipment beyond a standard lighter and can quickly identify adulterants that might pass visual inspection. At Kehao, we regularly conduct this test as part of our quality control process, ensuring our HPMC meets international purity standards.

Conclusion

These three simple field tests - iodine for starch, water dissolution for clarity, and burn test for inorganics - help you quickly identify fake HPMC. Protect your projects by verifying quality before purchase and working with reputable suppliers.

-

Understanding HPMC's role can help you appreciate its significance in construction applications. ↩ ↩ ↩ ↩

-

Identifying counterfeit HPMC is crucial for maintaining project integrity. ↩

-

Understanding the chemistry behind the iodine test enhances your testing knowledge. ↩

-

Learn about HPMC's essential properties that make it vital for construction projects. ↩