Finding the right HPMC grade for your construction project can feel overwhelming. Low viscosity works great for some applications while high viscosity excels in others, but choosing incorrectly can lead to costly failures and wasted materials.

Low viscosity HPMC1 provides excellent flowability while high viscosity HPMC offers superior thickening and sag resistance. The key difference lies in their molecular weight and chain length, which determines their ability to either promote flow or create structure in construction materials.

As a factory producing all grades of hydroxypropyl methylcellulose for over 15 years, I've seen countless clients struggle with viscosity selection. Let me share what I've learned about these crucial differences and how they impact your construction materials so you can make the right choice every time.

What Is High and Low Viscosity Hydroxypropyl Methylcellulose?

Every time I visit construction sites, contractors ask me why their materials aren't performing correctly. Usually, it's because they're using the wrong HPMC viscosity type without understanding the basic differences.

Low viscosity HPMC1 (typically 4,000-15,000 mPa·s) has shorter polymer chains that provide water retention with minimal thickening effect. High viscosity HPMC2 (30,000-200,000 mPa·s) has longer polymer chains that create significant thickening, making materials resistant to sagging on vertical surfaces.

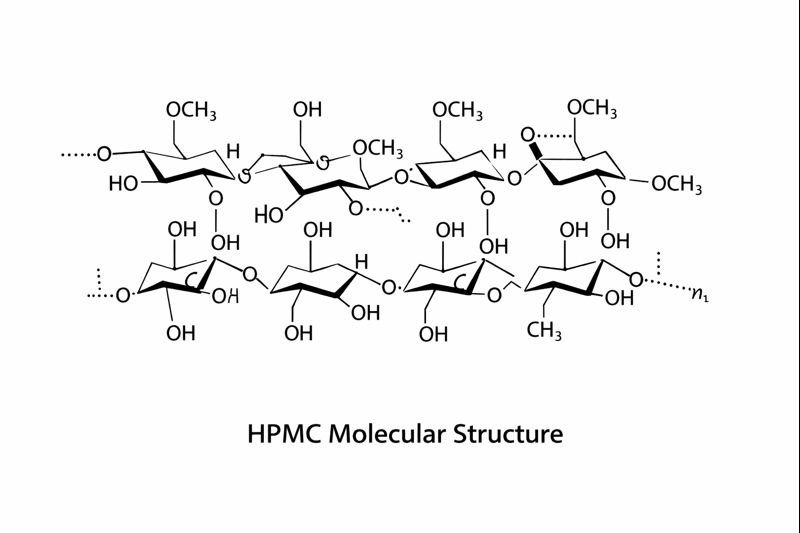

The viscosity of HPMC is directly related to its molecular weight and degree of substitution. During our manufacturing process, we can control these parameters to create specific viscosity grades. Low viscosity HPMC features shorter cellulose chains with fewer hydroxypropyl and methyl substitutions, resulting in a material that dissolves more quickly and creates less structure in solution. This makes it perfect for applications requiring good flowability.

High viscosity HPMC, on the other hand, contains longer polymer chains with more substitution groups. These longer chains create more entanglement in solution, resulting in stronger gelling properties and increased thickening power. This is why high viscosity HPMC excels in applications where materials need to stay in place on vertical surfaces.

Low Viscosity HPMC Applications

- Self-leveling compounds

- Grouts

- Sprayable mortars

- Paint primers

High Viscosity HPMC Applications

- Tile adhesives

- Renders and plasters

- Exterior insulation systems

- Joint compounds

What Is the Difference Between Low Viscosity and High Viscosity?

I once visited a client who was frustrated because his tile adhesive kept sliding down the wall. His supplier had sold him low viscosity HPMC when his application clearly needed high viscosity. This common mistake costs companies thousands in wasted material.

Low viscosity HPMC provides minimal thickening with excellent flowability, making materials spread easily. High viscosity HPMC creates strong internal structure, preventing sagging on vertical surfaces. The difference affects working time, water demand, and application properties of the final construction material.

The performance differences between low and high viscosity HPMC extend far beyond just thickness. In our laboratory testing, we consistently find that viscosity affects multiple properties of construction materials:

Low viscosity HPMC allows particles to move more freely in the mixture, creating a more fluid consistency that's perfect for self-leveling compounds3. This fluidity comes at the cost of structural integrity, making it unsuitable for vertical applications. The shorter polymer chains mean it can incorporate into the mixture more quickly but provides less binding strength overall.

High viscosity HPMC, with its longer polymer chains, creates a network structure that suspends heavy aggregates and prevents sagging. This makes it essential for vertical applications like tile adhesives4 and plasters. The increased molecular entanglement also improves adhesion to substrates and extends open time, giving workers more time to place and adjust materials.

Our testing shows that water retention capability exists in both types, but high viscosity HPMC typically retains water more effectively over longer periods. This is crucial for proper cement hydration in hot or windy conditions where rapid drying can compromise strength development.

| Property | Low Viscosity HPMC | High Viscosity HPMC |

|---|---|---|

| Flow properties | Excellent | Limited |

| Sag resistance | Poor | Excellent |

| Water demand | Lower | Higher |

| Mixing ease | Easier | More difficult |

| Setting time | Quicker | Slower |

| Cost | Lower | Higher |

What Is the Difference Between HPMC Grades?

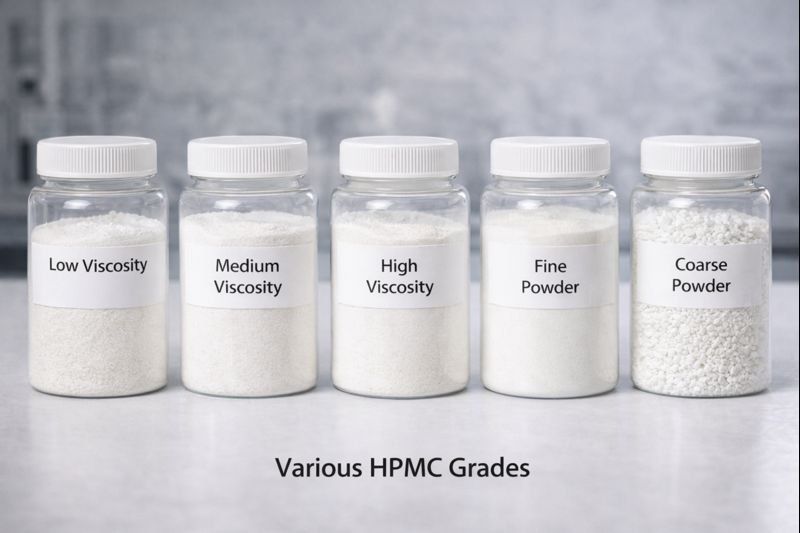

During factory tours, clients often ask me why we have dozens of HPMC grades when they all look like white powder. The answer lies in the specialized performance each grade delivers for specific applications.

HPMC grades differ not only in viscosity but also in methoxyl content, hydroxypropyl content, particle size, and surface treatment. These variations affect solubility, thermal gelation temperature, and compatibility with other construction chemicals, creating products optimized for specific applications.

HPMC grades are differentiated by a complex interplay of chemical and physical properties that we carefully control during our manufacturing process. Beyond viscosity, the most important differentiating factors include:

-

Methoxyl Content: Higher methoxyl content increases organic solubility and lowers the thermal gelation temperature. In our facility, we produce grades ranging from 19-30% methoxyl substitution.

-

Hydroxypropyl Content: This affects water solubility and compatibility with other additives. Our grades range from 4-12% hydroxypropyl substitution.

-

Particle Size Distribution: Finer particles dissolve faster but may create dust issues. Coarser particles reduce dust but take longer to dissolve. We offer grades with mean particle sizes from 50-150 microns.

-

Surface Treatment: Some grades receive special treatment to delay dissolution, preventing lumping during mixing.

Different applications demand specific combinations of these properties. For example, our tile adhesive grades combine high viscosity with carefully balanced methoxyl content to provide excellent sag resistance while maintaining good workability. Our self-leveling grades use low viscosity with optimized particle size for quick dissolution and excellent flow properties.

The manufacturing technology used also affects performance. We use both traditional solvent processes and newer technologies to create grades with special properties for the most demanding applications.

| HPMC Grade Feature | Impact on Construction Material |

|---|---|

| Methoxyl Content | Affects water retention and thermal gelation |

| Hydroxypropyl Content | Influences compatibility with cement and additives |

| Particle Size | Determines dissolution rate and mixing behavior |

| Surface Treatment | Controls dissolution profile and anti-lumping properties |

| Manufacturing Process | Affects purity and performance consistency |

Is High or Low Viscosity Better?

A new client once asked me which viscosity was "better quality" for her mortar production. I explained that asking whether high or low viscosity is better is like asking whether a hammer or screwdriver is better—it depends entirely on what you're trying to build.

Neither high nor low viscosity HPMC is universally better—each excels in specific applications. High viscosity is better for vertical applications requiring sag resistance like tile adhesives. Low viscosity is superior for horizontal applications needing flow properties like self-leveling compounds.

The "better" viscosity depends entirely on matching the HPMC properties to your specific application requirements. Through years of field experience with our customers across different climates and construction practices, I've learned that application success depends on understanding the performance needs of each project.

High viscosity HPMC creates the internal structure needed to prevent heavy materials from sagging on walls. In our laboratory tests, properly formulated tile adhesives with high viscosity HPMC can hold ceramic tiles weighing up to 40kg/m² without slipping. This same property would be disastrous in self-leveling compounds, where flow is essential.

Low viscosity HPMC allows the necessary particle mobility for self-leveling materials to spread evenly across floors. Our testing shows that the right low viscosity grade can help materials achieve a smooth surface with minimal effort, reducing labor costs. This same property would cause vertical applications to fail immediately.

Climate conditions also affect which viscosity works best. In hot, dry environments, water retention becomes more critical, sometimes requiring a medium-viscosity grade that balances workability and water retention. In cold conditions, set time becomes more important, which can influence viscosity selection.

Cost considerations are also important. Higher viscosity grades generally cost more per kilogram, but often require lower dosages to achieve the desired effect. Our technical team works with customers to find the most cost-effective solution for each application, sometimes blending grades to achieve optimal performance at reasonable cost.

| Application | Recommended Viscosity | Key Benefit |

|---|---|---|

| Tile Adhesive | High (40,000-100,000 mPa·s) | Prevents tile slippage |

| Self-Leveling Compound | Low (4,000-15,000 mPa·s) | Enables proper flow |

| Plaster | Medium-High (20,000-40,000 mPa·s) | Balances workability and sag resistance |

| Wall Putty | Medium (15,000-30,000 mPa·s) | Provides smooth application with adequate thickness |

| Exterior Insulation System | High (50,000+ mPa·s) | Holds heavy insulation panels in place |

How Do Liquids With a High Viscosity Differ From Liquids With Low Viscosity?

During product demonstrations, I often show clients two beakers of HPMC solution—one high viscosity, one low. The visual difference is striking and helps explain the fundamental physical properties at work in their formulations.

High viscosity liquids flow slowly, resist deformation, and maintain shape under stress. Low viscosity liquids flow rapidly, spread easily, and conform quickly to container shapes. These differences stem from intermolecular forces and polymer chain entanglement that create internal friction during flow.

The physical differences between high and low viscosity HPMC solutions reveal the fundamental properties that determine their performance in construction materials. In our laboratory, we conduct extensive testing to understand these differences:

High viscosity HPMC solutions exhibit pronounced pseudoplastic behavior, meaning they thin under shear stress (like mixing or spreading) but recover their structure quickly when the stress stops. This property is crucial for tile adhesives, which need to spread easily during troweling but immediately recover structure to hold tiles in place.

The polymer chains in high viscosity solutions create extensive entanglement networks that resist flow and deformation. Under a microscope, these networks appear as complex, interconnected structures that can support heavy particles and prevent sedimentation. This same structure gives high viscosity solutions excellent water retention properties, as water molecules become trapped in the polymer network.

Low viscosity solutions, by contrast, have fewer entanglements and allow for greater molecular mobility. This creates excellent flow properties and allows particles to move more freely within the mixture. In self-leveling compounds, this mobility is essential for achieving a smooth, flat surface with minimal effort.

Temperature sensitivity also differs between high and low viscosity solutions. High viscosity HPMC typically shows more pronounced thermal gelation, forming a gel structure at elevated temperatures. This property can be advantageously used in hot weather applications where additional structure is needed to prevent sagging.

The rate of dissolution also varies significantly. In our production facility, we can demonstrate how low viscosity grades incorporate into water more quickly, creating a uniform solution faster than high viscosity grades. This affects mixing procedures and equipment requirements at construction sites.

| Viscosity Property | High Viscosity HPMC | Low Viscosity HPMC |

|---|---|---|

| Flow Rate | Slow | Fast |

| Structure Recovery | Fast | Slow |

| Particle Suspension | Excellent | Limited |

| Thermal Sensitivity | More Pronounced | Less Pronounced |

| Dissolution Rate | Slower | Faster |

| Shear Thinning | Significant | Minimal |

Conclusion

Choosing between high and low viscosity HPMC comes down to application requirements. High viscosity provides structure and sag resistance for vertical applications, while low viscosity enables flow for horizontal surfaces. Neither is universally "better"—success depends on matching the right grade to your specific project needs.

FAQ

1. Can I mix high and low viscosity HPMC?

Yes, they can be blended to achieve intermediate properties, though factory-produced medium viscosity grades often perform more consistently.

2. Does viscosity affect the amount of HPMC needed in a formula?

Generally, higher viscosity grades can be used at lower dosages to achieve similar thickening effects, potentially offsetting their higher cost.

3. How does temperature affect HPMC viscosity?

HPMC solutions typically show lower viscosity as temperature increases until reaching the thermal gelation point, where viscosity suddenly increases.

4. Do high and low viscosity grades have different storage requirements?

No, both should be stored in cool, dry conditions, protected from moisture.

5. Can viscosity affect the final strength of cement-based materials?

Indirectly, as proper water retention from the appropriate viscosity grade ensures complete cement hydration, improving final strength.

6. How do I know which viscosity grade is right for my application?

Consider whether your application is vertical (typically requiring high viscosity) or horizontal (usually requiring low viscosity), then consult with a cellulose ether specialist for specific recommendations.

-

Explore how Low viscosity HPMC enhances flowability and application efficiency in construction materials. ↩ ↩

-

Learn how High viscosity HPMC provides sag resistance and structural integrity for vertical applications. ↩

-

Explore the role of self-leveling compounds in achieving smooth surfaces in construction. ↩

-

Learn about effective tile adhesive applications and how to prevent common issues. ↩