Ever notice your mortar suddenly losing workability on a hot day? The problem isn't your mixing technique—it's chemistry. Temperature changes can transform your perfectly mixed HPMC solution into a useless mess within minutes.

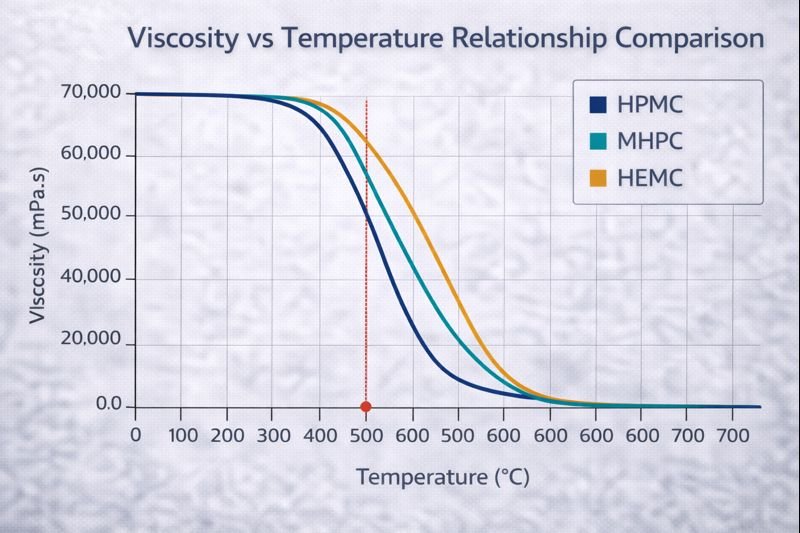

HPMC (hydroxypropyl methylcellulose) viscosity1 is highly temperature-dependent. When temperatures rise above its gel point, HPMC undergoes a phase transition where it loses its thickening properties, releases water, and viscosity drops dramatically, significantly impacting construction material performance.

This temperature sensitivity is critical knowledge for anyone working with HPMC in construction materials, especially in hot weather conditions or high-heat applications. Let me explain why understanding this relationship can save your projects from disaster and how you can select the right HPMC for challenging conditions.

How Is Viscosity Affected By Temperature?

We've all experienced this basic truth: heat something up, and it typically flows more easily. Cold honey barely moves, warm honey pours freely. But HPMC behaves differently, and this unusual property creates both challenges and opportunities.

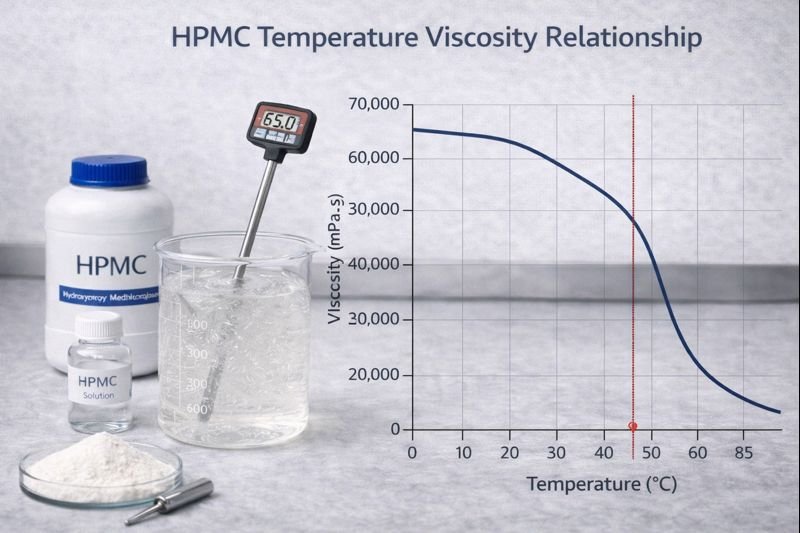

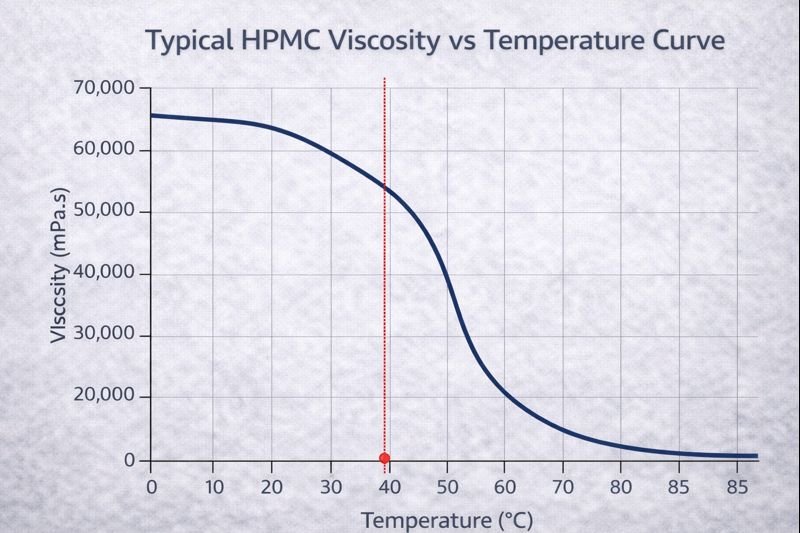

Unlike most liquids that simply thin when heated, HPMC solutions follow a unique pattern. At lower temperatures, HPMC viscosity decreases slightly as temperature rises (normal behavior), but upon reaching its gel temperature, viscosity dramatically drops as the polymer undergoes phase separation.

This gel temperature behavior is what makes HPMC so useful—and sometimes troublesome—in construction applications. I remember visiting a construction site in Dubai during summer where workers couldn't understand why their normally reliable tile adhesive suddenly became unworkable by mid-morning. The issue wasn't product quality but rather using standard HPMC in extreme heat conditions.

The temperature-viscosity relationship2 for HPMC can be broken down into three distinct phases:

HPMC Temperature Response Phases

| Temperature Range | HPMC Behavior | Practical Impact |

|---|---|---|

| Below 20°C | Normal viscosity, good water retention | Slower dissolution, requires more mixing |

| 20-30°C (depends on grade) | Optimal performance range | Ideal working conditions for most applications |

| Above gel point (typically 32-85°C) | Rapid viscosity loss, gel formation | Material becomes unworkable, water retention fails |

For construction professionals, understanding this relationship means knowing that not all HPMC products will perform the same way under temperature stress. The specific gel temperature of your HPMC is a critical specification that should match your application and environmental conditions.

How Does Temperature Affect The Viscosity Of A Polymer?

Working with polymers like HPMC means understanding a fundamental paradox: their behavior often contradicts our everyday experience with liquids. This unique temperature response is why polymer science fascinates me.

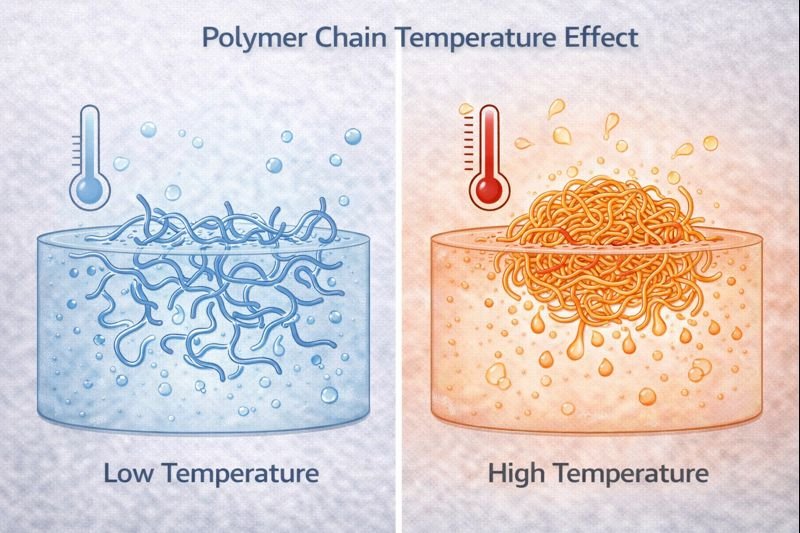

Temperature affects polymer viscosity through molecular movement and interaction. For most polymers, higher temperatures increase molecular motion, reducing viscosity. However, HPMC and similar cellulose derivatives exhibit inverse solubility—they become less soluble and form gels at higher temperatures due to hydrophobic interactions between molecules.

The mechanism behind this behavior is complex but essential to understand if you work with these materials regularly. At lower temperatures, water molecules form hydrogen bonds with the hydroxyl groups on HPMC molecules, creating a stable solution. As temperature rises, these hydrogen bonds weaken while hydrophobic interactions between polymer chains strengthen, eventually causing the polymer to aggregate and separate from water.

This property makes HPMC valuable in applications like construction mortars, where water retention is critical to ensure proper cement hydration. I've tested different grades of HPMC in our laboratory under varying temperature conditions, and the differences in performance can be dramatic:

Polymer Temperature Response Comparison

| Polymer Type | Low Temperature Behavior | High Temperature Behavior | Application Consideration |

|---|---|---|---|

| Standard HPMC | Good viscosity and water retention | Rapid viscosity loss above 50-65°C | Suitable for moderate climates |

| High-gel point HPMC | Good viscosity, slightly higher cost | Maintains performance up to 75-85°C | Essential for hot weather or heat-generating applications |

| HEMC (alternative) | Similar to HPMC but different solubility | Earlier gel point than many HPMC types | Sometimes used in specific formulations |

The practical impact: using standard HPMC in a tile adhesive3 that generates heat through cement hydration in hot weather is asking for trouble. The combined heat can easily exceed the gel point, causing the material to lose water retention precisely when it's most needed.

At What Temperature Does HPMC Degrade?

During a project consultation in Saudi Arabia last year, I was asked this critical question when a client's exterior rendering kept failing in summer conditions. The answer involves understanding both physical and chemical changes in HPMC.

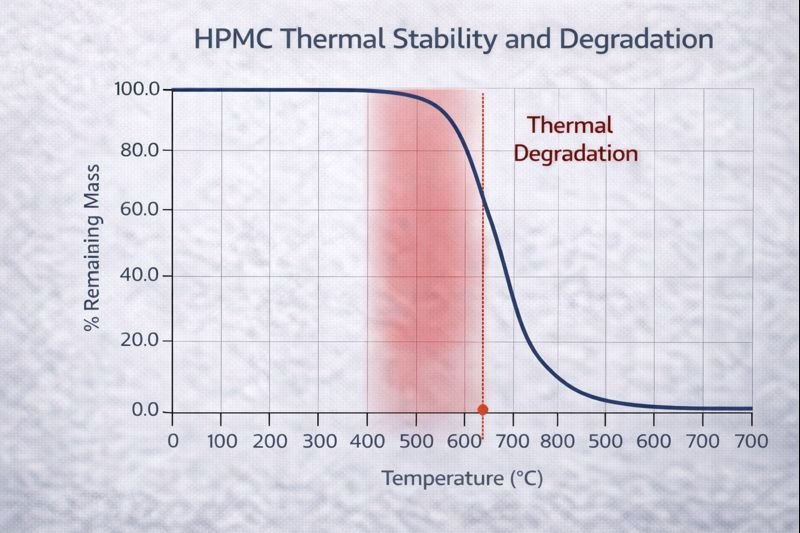

HPMC doesn't chemically degrade at its gel point (typically 32-85°C depending on grade); it merely undergoes a physical phase change. True chemical degradation begins at much higher temperatures—around 190-200°C—when the polymer backbone starts breaking down through thermal decomposition.

This distinction between gel formation (reversible) and true degradation (irreversible) is important for processing and application considerations. When HPMC reaches its gel temperature in a mortar, it loses its effectiveness temporarily, but if temperatures return to normal before the mortar sets, some functionality may be recovered.

However, once chemical degradation occurs (during manufacturing or extreme conditions), the HPMC is permanently damaged. Understanding these temperature thresholds helps in both product selection and application procedures:

HPMC Temperature Thresholds

| Temperature Range | Effect on HPMC | Reversibility | Practical Implications |

|---|---|---|---|

| Below gel point | Normal function | N/A | Optimal working conditions |

| Gel point to ~150°C | Phase separation, gel formation | Potentially reversible | Material becomes unworkable but not chemically altered |

| 150-190°C | Beginning molecular changes | Mostly irreversible | Processing temperature limit in dry manufacturing |

| Above 200°C | Chemical bond breaking, decomposition | Fully irreversible | Complete degradation, material destroyed |

For construction professionals, this knowledge translates to practical guidelines: always store HPMC products in cool, dry places; mix mortars with cool water when working in hot conditions; and consider application timing to avoid the hottest parts of the day in extreme climates.

How Does Temperature Affect The Viscosity Of A Lubricant?

While HPMC isn't a lubricant in the traditional sense, its flow properties and how they compare to lubricants offers valuable insights for formulators and end-users in construction materials.

Unlike lubricants that typically show decreasing viscosity with increasing temperature, HPMC solutions initially follow this pattern but then dramatically reverse when reaching their gel point. This contrasting behavior explains why temperature management is much more critical for HPMC-containing materials than for many other construction chemicals.

This difference becomes particularly relevant when formulating construction materials that might contain both HPMC and traditional flow modifiers or when switching between different types of rheology modifiers in formulations.

I've observed this contrast firsthand when developing formulations for clients. While traditional additives like polycarboxylate superplasticizers show predictable thinning as temperatures rise, HPMC-containing systems can suddenly shift from workable to unusable within a narrow temperature window.

The practical significance lies in understanding these differences when creating robust formulations for variable environmental conditions:

Rheology Modifier Comparison

| Additive Type | Temperature Response | Temperature Sensitivity | Formulation Strategy |

|---|---|---|---|

| HPMC | Inverse solubility above gel point | Highly sensitive to temperature | Select appropriate gel point, consider environmental conditions |

| Synthetic lubricants | Consistent viscosity decrease with temperature | Moderate sensitivity | Often used in conjunction with HPMC for different properties |

| Mineral oils | Linear viscosity decrease | Highly predictable | Not water-compatible like HPMC |

For formulators, the key takeaway is that HPMC isn't just another rheology modifier—its unusual temperature response means that temperature management becomes an integral part of both product design and application guidelines.

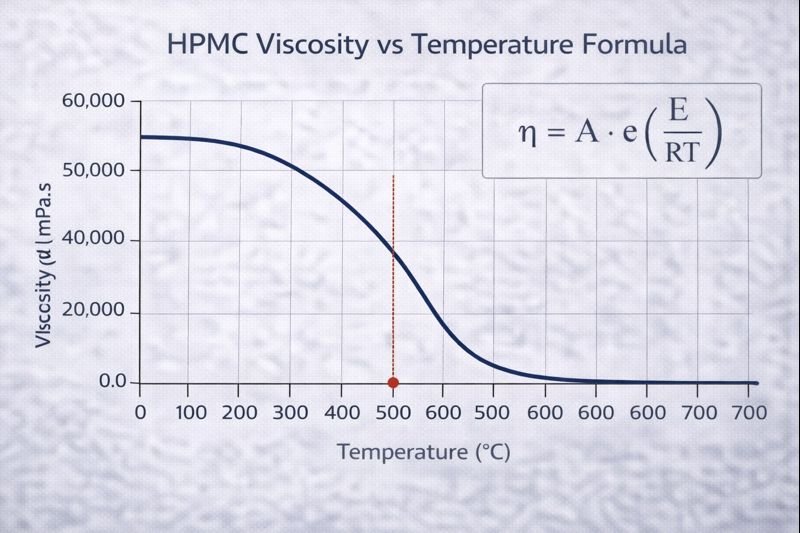

What Is The Relationship Between Temperature And Viscosity Formula?

During technical discussions with clients, I'm often asked about mathematical models for predicting how their HPMC-containing products will behave across temperature ranges. The relationship is more complex than for simple liquids.

For HPMC solutions below their gel point, the Arrhenius equation can approximate viscosity changes: η = A·e^(Ea/RT), where η is viscosity, A is a constant, Ea is activation energy, R is the gas constant, and T is absolute temperature. However, this model breaks down completely near and above the gel temperature, where phase separation occurs.

This mathematical limitation reflects the physical reality—HPMC undergoes a phase transition rather than just molecular speed changes. For practical applications, empirical testing is often more valuable than theoretical models when working near the gel temperature.

I've found that relying solely on viscosity-temperature formulas can lead to serious miscalculations in real-world applications. For example, a tile adhesive3 formulation that works perfectly in laboratory conditions might fail completely on a sun-exposed wall because the combined heat from the sun and cement hydration pushes the local temperature above the gel point.

Temperature-Viscosity Relationship Models

| Model Type | Applicability to HPMC | Reliability | Practical Use |

|---|---|---|---|

| Arrhenius Equation | Only below gel temperature | Good for limited range | Laboratory formulation work |

| Modified Williams-Landel-Ferry | Can be adapted for wider ranges | Requires specific constants | Advanced research applications |

| Empirical Testing Data | Full temperature range | Excellent | Most reliable for practical applications |

For building material manufacturers, this means that while understanding the theoretical relationships is important, there's no substitute for actual testing under real-world temperature conditions for your specific HPMC grade and application.

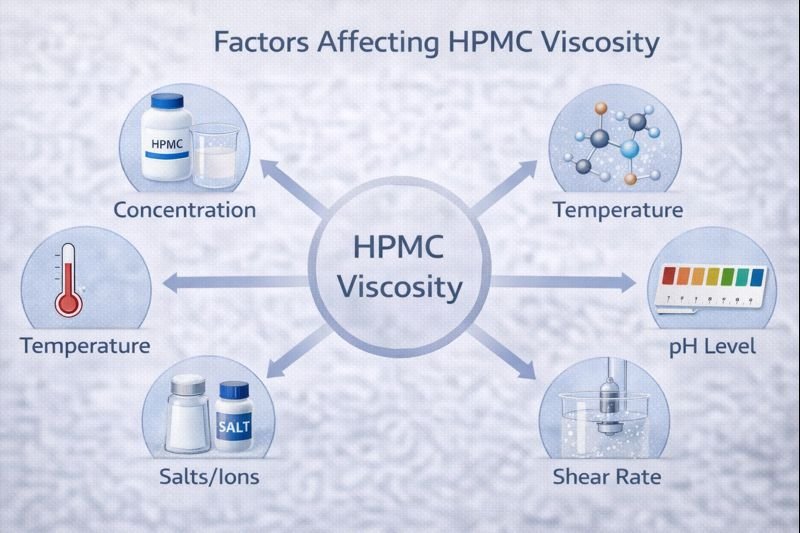

What Are The 5 Factors That Affect Viscosity?

Through years of working with HPMC in various construction applications, I've identified several critical factors beyond temperature that influence viscosity performance. Understanding these interactions helps create more robust formulations.

Beyond temperature, HPMC viscosity is significantly affected by 1) molecular weight/substitution degree, 2) concentration, 3) shear rate (mixing intensity), 4) pH of the solution, and 5) presence of salts or other additives. These factors often interact with temperature effects, either amplifying or mitigating temperature sensitivity.

These factors don't exist in isolation—they create a complex performance matrix that explains why two seemingly similar products can perform very differently in real-world applications.

Let's explore how these factors interact with temperature effects and influence application performance:

HPMC Performance Factors Matrix

| Factor | Interaction with Temperature | Practical Impact | Selection Consideration |

|---|---|---|---|

| Molecular Weight | Higher MW types often have higher gel temperatures | Higher MW provides better water retention but slower dissolution | Match MW to application requirements and climate conditions |

| Substitution Type/Degree | Methoxyl/hydroxypropyl ratio affects gel temperature | Different substitution patterns create different temperature responses | Specialized grades available for extreme temperature applications |

| Concentration | Higher concentrations typically increase temperature sensitivity | More pronounced viscosity changes across temperature range | Balance cost vs. performance needs |

| Shear Forces | High shear during mixing can lower effective viscosity & affect temperature response | Mixing methods become critical in hot weather | Consider application method when selecting grade |

| pH & Additives | Cement alkalinity and additives can shift temperature response | Can either worsen or improve temperature stability | Test complete formulation, not just HPMC alone |

I've seen projects succeed or fail based on understanding these interactions. For instance, a client in the Middle East was experiencing inconsistent tile adhesive3 performance until we identified that the combination of high shear mixing and elevated temperatures was pushing their material beyond its stable range. By adjusting both the HPMC grade and mixing procedures, we resolved the issue.

Conclusion

Temperature dramatically affects HPMC viscosity through its unique gel point property. For reliability in hot conditions, specify high gel temperature HPMC products rather than focusing solely on viscosity. This prevents sudden workability loss, water release, and resulting construction failures.

Frequently Asked Questions

What is HPMC gel temperature?

The temperature at which HPMC undergoes phase separation, losing its thickening properties and water retention capabilities. This can range from 32-85°C depending on the specific grade.

How can I prevent HPMC from gelling in hot weather?

Use high gel temperature HPMC grades, mix with cold water, work during cooler parts of the day, and consider temporary shading for freshly applied materials.

Does HPMC permanently lose its properties after heating?

HPMC undergoes reversible physical changes at its gel point, but permanent chemical degradation only occurs at much higher temperatures (above 190°C).

Can different types of HPMC have different gel temperatures?

Yes, gel temperature varies significantly based on substitution pattern, molecular weight, and manufacturing processes. Specialized high-gel temperature grades are available.

Why does my mortar suddenly become difficult to work with on hot days?

When the temperature exceeds the HPMC gel point, it rapidly loses water retention capability, making the mortar feel dry and difficult to spread.

-

Understanding HPMC viscosity is crucial for construction applications, ensuring optimal performance in varying temperatures. ↩

-

Explore the unique temperature-viscosity relationship of HPMC, crucial for formulating effective construction materials. ↩

-

Understanding the factors affecting tile adhesive performance can prevent failures in hot weather applications. ↩ ↩ ↩