Poor water retention in your construction mortar leads to cracking, reduced strength, and failed projects. I've seen contractors waste thousands when cement doesn't properly hydrate in hot climates.

The best HPMC1 grade for water retention in construction materials is MHPC with hydroxypropoxy content of 7-12% rather than standard HPMC. Specifically, HPMC-WH-1502 or HPMC-WH-1003 grades maintain ≥90% water retention even at high temperatures (40°C), ensuring proper cement hydration and preventing strength loss.

After years of supplying HPMC to construction companies across Saudi Arabia, UAE, and other hot-climate regions, I've learned water retention capability isn't just about viscosity. Let me share what truly determines performance and how to select the right grade for your specific application.

What is HPMC Building Material and Why is Water Retention Critical?

Contractors often face rapid water evaporation in mortar, causing incomplete cement hydration, cracking, and structural weakness. This is especially problematic in hot, dry environments where I've seen projects fail.

HPMC1 (Hydroxypropyl Methylcellulose) is a cellulose ether used as an additive in construction materials. It functions as a water-retention agent, thickener, and binder in cement-based products, ensuring proper cement hydration by preventing premature water loss, particularly in dry or hot conditions.

Water retention is perhaps the most critical function of HPMC in construction applications. When cement doesn't retain enough moisture during curing, it can't complete the chemical reactions needed for proper strength development. I've visited countless job sites where this issue causes material failure.

The water retention mechanism is based on HPMC1's unique molecular structure. Unlike what many manufacturers advertise, viscosity alone doesn't determine water retention performance. The ratio of methoxy groups to hydroxypropoxy groups in the HPMC molecule is what truly matters. Higher hydroxypropoxy content (7-12%) creates stronger hydrogen bonds with water molecules, preventing rapid evaporation.

This is why MHPC (Methyl Hydroxypropyl Cellulose) typically outperforms standard HPMC in construction applications. When testing different grades in our lab under high-temperature conditions (40°C), we consistently find that MHPC maintains workability for much longer periods, even when the viscosity measurements are similar.

Which HPMC is Best for Maximum Water Retention?

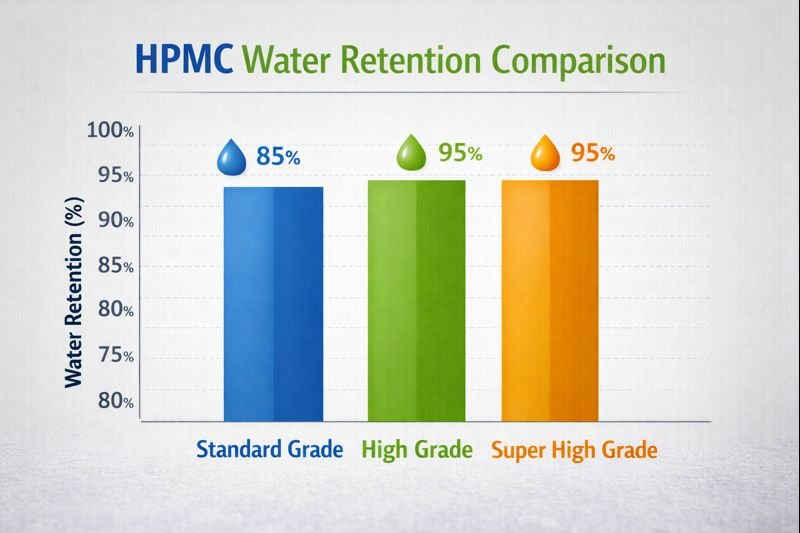

Many suppliers push high-viscosity grades, claiming better performance, but our testing shows this isn't always true. I've seen expensive high-viscosity products fail while properly formulated lower-viscosity options excel.

The best HPMC1 for water retention is HPMC-WH-150 or HPMC-WH-100, which feature moderate viscosity (100-150 mPa·s) but high hydroxypropoxy content (7-12%). These specialized grades maintain ≥90% water retention even at elevated temperatures, significantly outperforming standard HPMC grades with similar viscosity but lower hydroxypropoxy content.

Looking deeper at HPMC selection for optimal water retention, we need to consider both chemical structure and application requirements. In our factory's research lab, we've conducted extensive testing on different HPMC formulations across various temperature conditions.

The hydroxypropoxy substitution level is crucial because it directly impacts the hydrophilic properties of the molecule. Higher hydroxypropoxy content increases the number of potential hydrogen bonding sites, allowing the HPMC molecule to "trap" more water molecules. This molecular interaction prevents water migration and evaporation, even under challenging conditions.

When selecting an HPMC grade, consider these factors:

| Factor | Optimal Range | Impact on Water Retention |

|---|---|---|

| Hydroxypropoxy Content | 7-12% | Higher content = better water retention |

| Methoxy Content | 19-24% | Balances water retention with other properties |

| Viscosity | 100-150 mPa·s | Moderate viscosity optimizes workability while maintaining water retention |

| Particle Size | 80-100 mesh | Finer particles dissolve faster and distribute more evenly |

One important consideration: extremely high water retention can sometimes negatively impact open time in applications like tile adhesives4. This is why we recommend thorough testing of any HPMC grade in your specific formulation rather than relying solely on manufacturer specifications.

What is the Water Retention Mechanism of HPMC in Cement Mortar?

I've worked with contractors who thought adding more water would solve drying issues – it actually weakens the final product! Understanding how HPMC actually works changed their approach completely.

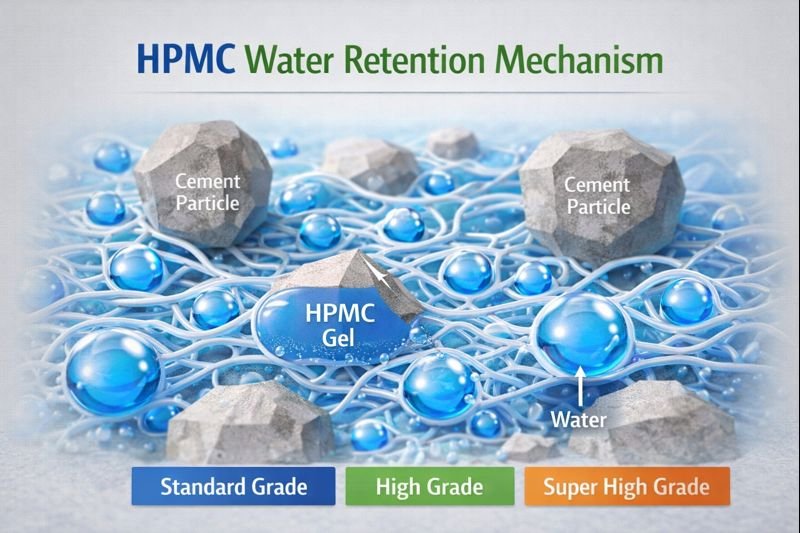

HPMC retains water in cement mortar through three primary mechanisms: forming a protective gel layer that slows evaporation, increasing mixture viscosity to reduce water mobility, and creating hydrogen bonds with water molecules. This multi-faceted approach ensures cement particles have adequate time for complete hydration, critical for developing optimal strength.

When we examine the water retention mechanism at a molecular level, several fascinating processes occur simultaneously. First, when HPMC1 dissolves in the mixing water, it forms a three-dimensional network structure through hydrogen bonding. This network significantly increases the solution's viscosity, physically restricting water movement.

Second, HPMC molecules form a thin protective film around cement particles. This film acts as a barrier, slowing water evaporation from the cement matrix. Under scanning electron microscope analysis in our laboratory, we can actually observe this film formation around cement particles in samples with proper HPMC addition.

Third, the hydroxypropyl groups in HPMC create strong hydrogen bonds with water molecules. These bonds effectively "lock" water within the cement matrix, releasing it gradually as the cement hydrates. This is why the hydroxypropoxy content is so critical – more hydroxypropyl groups mean more potential bonding sites for water molecules.

The practical impact of these mechanisms is significant:

| Benefit | How HPMC Provides This |

|---|---|

| Extended Workability | Slows water loss, keeping mortar workable longer |

| Reduced Cracking | Ensures continuous hydration throughout curing |

| Improved Bonding | Maintains moisture needed for proper adhesion |

| Enhanced Strength | Facilitates complete cement hydration reactions |

| Consistency in Adverse Conditions | Performs reliably even in hot/dry environments |

In our field tests across different climate zones, we've found that proper HPMC addition can extend workability time by 200-300% compared to untreated mortars, particularly crucial in regions like Saudi Arabia where temperatures regularly exceed 40°C.

What is Hydroxypropyl Methylcellulose Used for in Construction?

Many customers initially know HPMC only as a thickener, not realizing its diverse functions can solve multiple application problems simultaneously.

Hydroxypropyl methylcellulose serves multiple functions in construction: it provides critical water retention for proper cement hydration, improves adhesion to substrates, enhances workability and sag resistance, reduces material shrinkage and cracking, and increases open time for applications like tile adhesives and renders.

The versatility of HPMC in construction applications extends far beyond simple water retention. Based on our experience supplying major construction material manufacturers, here's a comprehensive breakdown of how HPMC impacts different construction materials:

-

Tile Adhesives: HPMC significantly improves slip resistance, allowing heavier tiles to adhere without sliding. It extends open time, giving installers more working flexibility. In fast-setting thin-bed adhesives, the right HPMC grade can provide 20-30 minutes of additional working time.

-

Renders and Plasters: HPMC improves workability, allowing smoother application and better finishing. It reduces sagging on vertical surfaces and improves pumpability in machine-applied renders.

-

Self-Leveling Compounds: HPMC controls flow properties, preventing segregation of components while maintaining self-leveling characteristics. It also improves surface appearance by reducing air bubbles.

-

Joint Fillers: HPMC enhances adhesion to joint edges and improves crack resistance. It also provides better sandability after drying.

-

EIFS Systems5 (External Insulation Finishing Systems): HPMC improves adhesion to insulation boards and enhances freeze-thaw stability.

The specific HPMC grade requirements vary by application:

| Application | Recommended HPMC Type | Key Property Requirements |

|---|---|---|

| Tile Adhesives | HPMC-WH-100K | High water retention, moderate viscosity, delayed dissolution |

| Renders | HPMC-WH-150K | High water retention, good workability |

| Self-Leveling | HPMC-WH-100000 | Ultra-high viscosity, controlled flow |

| Joint Compounds | HPMC-WH-15000 | High viscosity, good workability |

| EIFS | HPMC-WH-75K | Balanced water retention and workability |

The 'K' designation indicates a specially treated HPMC with delayed dissolution properties, which is particularly valuable in dry-mix applications where premature lump formation must be avoided.

Does Hydroxypropyl Methylcellulose Dissolve in Water?

A common misconception I hear from new customers is that all HPMC dissolves the same way in water. This misunderstanding leads to application issues and wasted material.

Yes, hydroxypropyl methylcellulose dissolves in water, but the dissolution process depends on temperature and grade. HPMC displays inverse solubility – it dissolves in cold water but forms a gel in hot water above its gel point (typically 65-80°C). Special surface-treated grades offer delayed dissolution to prevent lumping in dry-mix formulations.

The dissolution behavior of HPMC is a fascinating aspect of its chemistry that directly impacts construction applications. When HPMC powder comes into contact with water, individual particles begin to hydrate from the outside. If not properly dispersed, this can lead to the formation of a gel layer around undissolved powder, creating lumps that significantly reduce efficiency.

Understanding the temperature-dependent behavior of HPMC is crucial for proper application. Below its gel temperature, HPMC dissolves to form a clear solution. Above this temperature (typically 65-80°C depending on the specific grade), it forms a thermal gel. This property is particularly relevant in hot-climate installations, where mixing water temperature must be monitored.

To address dissolution challenges, we offer surface-treated HPMC grades with delayed dissolution properties. These grades (designated with 'K' in our product names) are treated with small amounts of glyoxal or other agents that temporarily retard water penetration into the HPMC particles, allowing better dispersion before dissolution begins.

The dissolution process follows these stages:

- Initial Wetting: Water contacts the HPMC particles

- Surface Hydration: Outer layer begins to hydrate

- Swelling: Particles expand as they absorb water

- Dissolution: HPMC molecules separate and dissolve into the water

- Network Formation: Dissolved molecules form a three-dimensional network

For optimal dissolution in construction applications, we recommend these practices:

| Best Practice | Reason |

|---|---|

| Use cold water (<30°C) | Prevents premature gel formation |

| Add HPMC to water (not water to HPMC) | Prevents agglomeration |

| High-shear mixing | Ensures complete dissolution |

| Pre-disperse in dry ingredients | Improves distribution in dry-mix formulations |

| Allow sufficient dissolution time | Ensures complete performance development |

In practical terms, most construction-grade HPMC requires 15-20 minutes for complete dissolution under proper mixing conditions. Inadequate dissolution can compromise water retention performance, so proper mixing protocols are essential for maximizing HPMC effectiveness.

Conclusion

The best HPMC grade for water retention isn't determined by viscosity alone but by hydroxypropoxy content (7-12%). HPMC-WH-150 and HPMC-WH-100 provide optimal performance, maintaining ≥90% water retention even at 40°C. Always conduct standardized testing to verify performance in your specific application.

FAQ

1. How much HPMC should I add to my mortar mix?

Typically 0.2-0.5% by weight of the dry mix, though this varies by application. Start with manufacturer recommendations and adjust based on testing.

2. Can I use the same HPMC grade for all my construction applications?

No, different applications require different properties. Tile adhesives need different characteristics than self-leveling compounds, for example.

3. How do I test water retention properly?

Use standardized methods like EN 13454 or ASTM C1506. Observe the mortar after 24 hours under specified conditions.

4. Does HPMC affect final strength of cement-based materials?

Properly selected HPMC typically improves strength by ensuring complete cement hydration. However, excessive dosage can introduce air and reduce strength.

5. How should I store HPMC products?

Store in cool, dry conditions in sealed containers. HPMC is hygroscopic and will absorb moisture from the air if exposed.

6. Is there a difference between food-grade and construction-grade HPMC?

Yes, construction-grade HPMC is specifically formulated for building applications with different substitution levels and additives than food-grade versions.

-

Explore the versatile applications of HPMC in construction, from water retention to improving adhesion. ↩ ↩ ↩ ↩ ↩

-

Find out why HPMC-WH-150 is recommended for optimal water retention in hot climates. ↩

-

Explore the advantages of HPMC-WH-100 for construction applications requiring high water retention. ↩

-

Learn how HPMC improves adhesion and workability in tile adhesive applications. ↩

-

Explore how HPMC enhances the performance and durability of External Insulation Finishing Systems. ↩