Buying hydroxypropyl methylcellulose (HPMC)1 can drain your budget fast if you don't know the insider tricks. Many manufacturers pay 15-25% more simply because they don't understand what truly affects performance.

To save costs when purchasing high-quality HPMC, focus on key chemical parameters rather than marketing claims. Prioritize methoxyl content (28-30%) and hydroxypropoxyl content (7-12%) over viscosity ratings. Buy during industry low seasons (March-April, September-October) and request batch-specific testing reports to ensure quality.

I've been in this business for years, and I've seen countless customers get trapped by misleading specifications and fancy packaging. Let me share some industry insider knowledge that will help you make smarter purchasing decisions and potentially save thousands on your next HPMC order.

Which HPMC Grade Is Best For Your Application?

Many suppliers will push their most expensive products, claiming "premium" quality. But is higher viscosity or price really better for your specific needs?

The best HPMC grade depends entirely on your application. For tile adhesives2, a 100,000 mPa·s viscosity is often excessive - a 15,000-40,000 mPa·s product with proper methoxyl content (28-30%) will perform better at lower cost. For renders and plasters, lower viscosity grades (400-4,000 mPa·s) often provide optimal workability.

Diving deeper into HPMC grade selection requires understanding the relationship between chemical structure and performance. I've worked with hundreds of formulations and discovered that substitution degree matters more than simple viscosity numbers. When comparing products, always ask for both methoxyl and hydroxypropoxyl content percentages - these determine water retention, cement compatibility, and open time in mortars.

Here's a comparison table of HPMC grades and their optimal applications:

| Viscosity Range | Best Applications | Cost-Saving Potential |

|---|---|---|

| 100-400 mPa·s | Liquid detergents, paints with good flow | 15-20% vs. higher viscosity |

| 4,000-15,000 mPa·s | Wall putties, self-leveling compounds | 10-15% with proper methoxyl content |

| 15,000-60,000 mPa·s | Tile adhesives, plasters | Focus on substitution degree, not just viscosity |

| 100,000+ mPa·s | Special high-sag applications | Often unnecessarily expensive |

Don't be fooled by suppliers pushing the highest viscosity grades - in many cases, they're trying to maximize their margins, not your product performance.

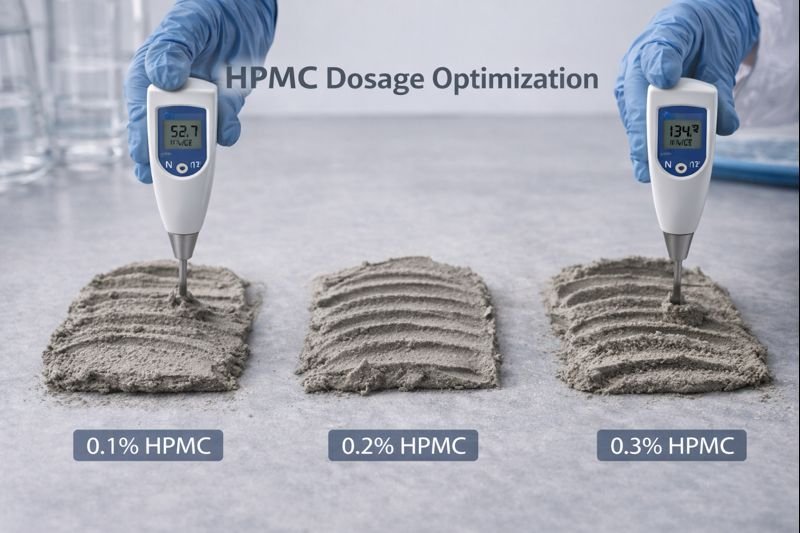

What Is The Optimal Usage Rate For HPMC?

Plant managers often worry they're using too little HPMC, risking performance issues. Others use too much, wasting money. What's the right balance?

The optimal HPMC usage rate typically ranges from 0.2-0.5% for most construction applications. For tile adhesives, 0.25-0.3% is usually sufficient with quality HPMC. For renders and plasters, 0.1-0.2% often provides adequate water retention and workability. Using high-quality HPMC allows reducing dosage by up to 20%.

Determining the perfect usage rate requires understanding the interaction between HPMC and other components in your formula. I've helped dozens of customers optimize their formulations, finding that many were overdosing HPMC by 15-30% due to working with inconsistent quality material.

The key is systematic testing. Start with the standard recommended dosage, then create test batches with incremental reductions of 5-10%. Measure critical parameters like:

Water Retention Testing

- Standard method: DIN 18555-7 or EN 1015-8

- Target: >90% for tile adhesives, >85% for renders

- If values remain above these thresholds, you can likely reduce dosage further

Open Time Assessment

- Test according to EN 1346 for tile adhesives

- Monitor for significant drops in adhesion strength

I've found that many formulators can reduce HPMC usage by 10-15% without performance loss by simply switching to a product with proper substitution degree3 and consistent quality. The savings compound significantly at scale - for a plant producing 10,000 tons of dry mix annually, this could mean $20,000-40,000 in direct material cost reduction.

What Are The Key Benefits Of HPMC Worth Paying For?

With dozens of suppliers claiming their HPMC is "premium quality," how do you know which benefits actually matter for your application?

The core benefits of quality HPMC include water retention (prevents rapid drying), workability improvement (easier application), and sag resistance (prevents slipping). However, not all products deliver equally on these promises. Key differentiators worth paying extra for include consistent particle size distribution4, low gel content, and proper chemical substitution pattern.

Understanding which HPMC benefits truly matter requires looking beyond marketing claims to chemical functionality. In my experience consulting with major mortar producers, I've found three aspects worth paying premium for:

1. Substitution Pattern Regularity

The distribution of methoxyl and hydroxypropoxyl groups along the cellulose chain dramatically affects performance. Uniform substitution (measured by HPLC analysis) provides more predictable water retention and cement compatibility. This isn't listed on most specification sheets, but it's worth requesting this data or specific testing.

2. Manufacturing Process Quality

HPMC produced through proper reactor-controlled processes results in fewer gel particles and more consistent performance. You can often detect this through simple dissolution testing:

| Quality Indicator | Premium HPMC | Standard HPMC | Low-Quality HPMC |

|---|---|---|---|

| Dissolution time (20°C) | <20 minutes | 20-40 minutes | >40 minutes |

| Gel particles visible | None | Few | Many |

| pH of 2% solution | 6.0-8.0 | 5.5-8.5 | Variable |

3. Batch-to-Batch Consistency

This is perhaps the most valuable yet overlooked benefit. Inconsistent HPMC forces constant formula adjustments and can lead to customer complaints. Request multiple batch certificates to compare consistency - variations in viscosity exceeding 10% between batches indicate poor process control.

I've found that paying 5-8% more for HPMC with excellent batch consistency often saves 12-15% in overall production costs through reduced quality control issues and fewer customer complaints.

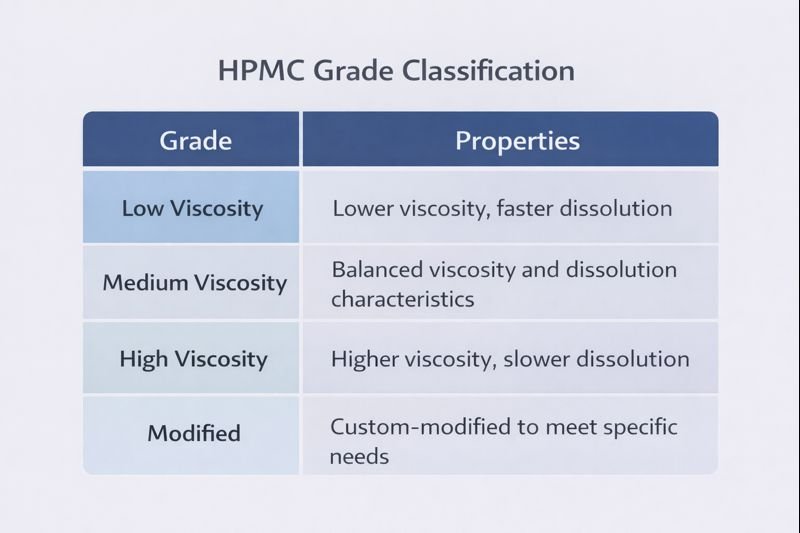

What Different Grades Of HPMC Are Available?

Many buyers get confused about HPMC grades, often paying for specifications they don't need. What's the real difference between all these grades?

HPMC grades vary primarily by viscosity (from 100 to 200,000 mPa·s), methoxyl content (19-30%), and hydroxypropoxyl content (4-12%). Higher methoxyl content improves water retention while higher hydroxypropoxyl content enhances compatibility with other ingredients. Construction applications typically use grades with 20,000-40,000 mPa·s viscosity.

Diving deeper into HPMC grades requires understanding both the chemical and physical properties that define performance. In my experience working with hundreds of formulations, the most important distinctions go well beyond simple viscosity ratings.

Chemical Substitution Classifications

The methoxyl (MO) and hydroxypropoxyl (HP) content percentages create distinct performance profiles:

| Grade Type | MO% | HP% | Characteristics | Best Applications |

|---|---|---|---|---|

| Low MO/Low HP | 19-24% | 4-7% | Faster dissolution, lower water retention | Paints, liquid products |

| Medium MO/Medium HP | 25-27% | 7-10% | Balanced properties, good workability | General construction |

| High MO/Medium HP | 28-30% | 7-10% | Excellent water retention, delayed dissolution | Tile adhesives, EIFS |

| High MO/High HP | 28-30% | 10-12% | Maximum compatibility, good low-temperature performance | Special applications |

Physical Form Classifications

Beyond chemical structure, physical characteristics significantly impact both performance and price:

-

Particle Size Distribution: Finer grades (>95% passing 100 mesh) dissolve faster but cost 5-8% more to produce

-

Surface Treatment: Some grades receive special treatments to control dissolution rate:

- Hot-water soluble types (dissolve only above 60°C)

- Delayed-dissolution types (treated to prevent lumping)

-

Gel Temperature: The temperature at which HPMC forms a gel in water:

- Low gel temp (<50°C): Better for cool climate applications

- High gel temp (>65°C): Better for hot climate applications

I've found that choosing the right grade combination can save 10-15% on material costs while improving performance. For example, many tile adhesive manufacturers wrongly believe they need the highest viscosity grades, when a medium-viscosity product with proper substitution pattern would perform better at lower cost.

What Is The Charge Structure Of HPMC And How Does It Impact Pricing?

Price negotiations for HPMC can be challenging if you don't understand the factors that legitimately affect costs. What drives HPMC pricing, and how can you use this knowledge to negotiate better?

HPMC is non-ionic (uncharged) in nature, but pricing is charged based on multiple factors: viscosity grade (higher usually costs more), substitution degree (higher methoxyl costs more), purity level, packaging type, and order volume. Seasonal demand fluctuations create 8-12% price variations throughout the year, with March-April and September-October typically offering lower prices.

Diving deeper into HPMC pricing structures reveals several opportunities for cost savings. As someone who has negotiated hundreds of contracts with suppliers, I've identified key leverage points that most buyers miss.

Production Cost Structure

Understanding how HPMC is produced reveals why certain specifications cost more:

| Cost Component | Percentage of Total | Negotiation Opportunity |

|---|---|---|

| Raw materials (cellulose) | 45-55% | Limited - commodity pricing |

| Processing chemicals | 15-20% | Moderate - affects substitution degree |

| Energy & conversion | 15-20% | High - affects viscosity & purity |

| Packaging & logistics | 10-15% | Very high - simplify packaging |

Seasonal Buying Strategy

HPMC production is relatively stable year-round, but demand fluctuates significantly:

-

Peak Demand Periods:

- May-July: Construction peak in Northern Hemisphere

- November-January: Pre-season stocking

-

Low Demand Periods (best for negotiation):

- March-April: Winter construction slowdown

- September-October: Post-peak inventory balancing

I've consistently secured 8-12% discounts by placing larger orders during these low-demand periods and negotiating "futures" contracts with suppliers.

Volume vs. Specification Optimization

Many buyers focus solely on volume discounts, missing the bigger opportunity in specification optimization:

- Reducing viscosity requirements by 25% (e.g., from 100,000 to 75,000 mPa·s) can save 5-8% without performance impact

- Accepting wider viscosity tolerance ranges (±10% instead of ±5%) can reduce costs by 3-5%

- Bulk packaging vs. paper bags can save 3-4% on overall costs

I've helped numerous clients save 15-20% on HPMC costs by combining seasonal buying with specification optimization - without compromising product performance.

Conclusion

Saving on HPMC purchases comes down to understanding the real performance drivers - methoxyl and hydroxypropoxyl content matter more than viscosity alone. Buy during industry low seasons, verify quality through proper testing, and optimize your grade selection based on actual application needs, not marketing claims.

FAQ

Q: Can I mix different HPMC grades to optimize costs?

A: Yes, blending high and lower-grade HPMC can work, but requires careful testing to ensure consistent performance.

Q: How important is the country of origin for HPMC quality?

A: Manufacturing process matters more than country. Both Chinese and European producers make excellent HPMC if using proper reactor technology.

Q: How can I verify HPMC quality quickly?

A: Check dissolution time in room temperature water, solution clarity, and perform a basic pH test - quality HPMC should dissolve without lumps and have pH between 6-8.

-

Explore this resource to understand HPMC's applications and benefits in various industries. ↩

-

Explore the optimal HPMC grades for tile adhesives to improve performance and reduce costs. ↩

-

Understand how substitution degree affects the performance characteristics of HPMC. ↩

-

Learn how particle size distribution influences the dissolution and effectiveness of HPMC. ↩