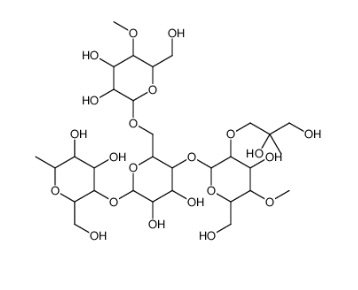

Hydroxypropyl Starch Ether (HPS) is a modified starch product. Think of starch like the kind you find in potatoes or corn. We take this natural starch and chemically modify it to give it special properties that make it more useful for certain applications, especially in construction.

Hydroxypropyl Starch Ether (HPS) is a versatile additive that enhances the performance of a wide range of construction materials. Whether it’s in cement-based products, gypsum-based plasters, paints, or dry-mix mortars, HPS improves workability, water retention, and stability. By ensuring these materials are easier to apply and more durable, HPS contributes to the quality and longevity of construction projects.

Hydroxypropyl Starch Ether (HPS) is a modified starch product. Think of starch like the kind you find in potatoes or corn. We take this natural starch and chemically modify it to give it special properties that make it more useful for certain applications, especially in construction.

Improves Workability: When added to cement or gypsum-based products (like plaster or tile adhesives), HPS makes the mixture easier to work with. It provides a smoother texture and makes spreading or applying the material easier.

Water Retention: HPS helps the mixture retain water longer. This is important because it ensures that the cement or plaster doesn’t dry out too quickly, which can lead to cracks or weak spots. By retaining moisture, HPS helps achieve a stronger final product.

Anti-Sagging: In applications like tile adhesives, HPS prevents the tiles from slipping or sagging after they’ve been placed on the wall. This makes the installation process more reliable and reduces the need for adjustments.

Thickening Agent: HPS acts as a thickening agent, which means it can make mixtures more viscous (thicker) without adding much weight. This property is useful in many different construction and building materials.

Improved Adhesion: It enhances adhesion properties, making it an ideal additive for products requiring strong bonding capabilities.

| Desc | Range |

|---|---|

| Appearance | White or similar white fibrous orgranular powder |

| Hydroxypropyl content,% | 8-12 |

| Methoxy (degree of substitution) | 18-22 |

| Ash Content (%) | <5 |

| water 2% solution viscosity, mPa.s | 400-85000 Brookfield |

| Gel temperature , 'C | 65-75 |

| PH | 5.5-7.5 |

When added to tile adhesives, HPS improves the adhesive’s workability, making it easier to spread and apply. It enhances water retention, allowing the adhesive to maintain its moisture content longer, which gives the installer more time to adjust tiles before the adhesive sets. HPS also provides anti-sagging properties, preventing tiles from slipping down the wall after application. This stability ensures a more secure bond between the tiles and the substrate.

In cement mortars used for masonry, plastering, or repair work, HPS enhances workability and improves the smoothness of the mortar mix. This makes the mortar easier to spread and apply with precision. The water retention capability of HPS also ensures that the mortar cures properly, leading to fewer cracks and stronger, more durable surfaces. By maintaining optimal moisture levels, HPS helps improve the bonding strength between bricks, blocks, or other materials.

HPS in wall putty formulations helps improve adhesion to various substrates, such as concrete, plaster, or drywall. It ensures a smooth finish, which is crucial for aesthetic purposes. By enhancing the putty’s workability and providing good water retention, HPS contributes to a uniform application, reducing the risk of cracks or peeling after the putty dries.

HPS is added to self-leveling compounds to improve flow properties and ensure a smooth, even surface. The water retention capability of HPS helps maintain the right moisture level during application, allowing the compound to self-level correctly without cracking or shrinking as it dries. This leads to a perfectly flat and smooth floor finish, which is essential for subsequent flooring installations like tiles or laminate.

HPS is used in paints to control viscosity and improve the paint’s consistency. It helps in achieving the right thickness, making the paint easier to apply without dripping or sagging. This is especially important for creating smooth, even coats on walls and other surfaces. The presence of HPS also enhances the paint’s ability to adhere to surfaces, providing a durable finish that resists wear and tear.

HPS is commonly added to gypsum plaster to improve its workability and make it easier to apply on walls and ceilings. The water-retaining properties of HPS are crucial in gypsum plasters, as they prevent premature drying and cracking, ensuring a strong, smooth finish. HPS also helps in achieving a consistent texture, which is important for high-quality finishes in interior applications.

Improved Workability:

HPS enhances the smoothness and consistency of cement-based and gypsum-based mixtures. This makes them easier to mix, spread, and apply, whether you’re working with tile adhesives, mortars, or plasters. Workers can achieve a more uniform application with less effort.

Enhanced Water Retention:

HPS has excellent water-retaining properties, which means it slows down the evaporation of water from cement or plaster mixtures. This is critical in maintaining workability and preventing the material from drying too quickly, which can lead to cracks or weakened structures.

Anti-Sagging and Improved Stability:

In vertical applications like tile adhesives or wall plasters, HPS helps materials stay in place once applied. It prevents tiles from sagging or slipping after installation, ensuring a more secure bond to the surface.

Better Adhesion:

HPS improves the adhesive properties of cement and plaster, ensuring a stronger bond between the material and the substrate (e.g., walls, tiles, bricks). This is particularly important in applications where strong adhesion is critical to prevent delamination or detachment.

Enhanced Surface Finish:

By improving the consistency of the mixture, HPS contributes to a smoother, more professional finish on walls, ceilings, and other surfaces. This is important for both aesthetic reasons and functional performance.

Reduced Cracking and Shrinkage:

HPS promotes uniform drying across the applied surface, which reduces the risk of cracks and shrinkage. Cracking can occur when certain parts of the material dry faster than others, leading to internal stress. By retaining moisture and ensuring even drying, HPS helps prevent these issues.

Cost Efficiency:Improved workability and stability mean less material is wasted during application, as there are fewer errors and defects. This results in more efficient use of resources.

Compatibility with Other Additives:HPS is compatible with a wide range of other construction additives and materials, such as cement, gypsum, and various polymers. This makes it a versatile option for enhancing different types of building materials.

Xinhong Chemical provides top-quality products, innovative solutions, and exceptional customer service. We prioritize your satisfaction and success with reliable, customizable chemical solutions.

We provide top-grade Hydroxypropyl Starch Ether for superior construction performance.

Tailored HPS formulations to suit specific construction requirements and applications.

Enjoy premium quality HPS at affordable rates, ensuring value for your investment

Professional technical assistance to optimize product use and performance.

Our HPS products are manufactured according to strict quality control procedures and meet international standards. They are compliant with ISO quality certifications and are tested for properties such as viscosity, purity, and moisture content. This ensures consistent performance and safety in various construction applications.

Yes, we offer customized HPS formulations to meet specific needs. Whether it’s adjusting viscosity levels, improving water retention, or enhancing workability, our technical team can work with you to develop a solution tailored to your application requirements.

We have rigorous quality control processes in place. Each batch of HPS is tested for key properties such as viscosity, purity, and moisture content before it leaves our facility. We use state-of-the-art technology and adhere to ISO quality standards to ensure that every product meets the highest levels of quality and consistency.

We offer comprehensive technical support to our customers. This includes product application guidance, formulation assistance, and troubleshooting. Our technical team is available to provide advice on optimizing HPS usage for specific applications and to help solve any issues that may arise.

Delivery times depend on the order size and location, but standard lead times are usually between 2 to 4 weeks. We offer global shipping and work with reliable logistics partners to ensure timely delivery. We can also arrange express shipping for urgent orders upon request.

We’re here to help!

Send us an inquiry today, and let’s start building a solution together!

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Jinzhou Industrial Park, Shijiazhuang, Hebei, China

Ada@xhhpmc.com Jay@xhhpmc.com

+86 18132059888

+86 17736071888

Mon – Fri : 9am – 6pm Sunday (Closed)

WhatsApp us

Contact us now to get free samples and various product formulations!