Large-area flooring projects often face a frustrating problem: cracking. These unsightly fissures compromise both aesthetics and structural integrity, leaving contractors and clients equally disappointed. Is there a reliable solution?

Yes, Hydroxypropyl Methylcellulose (HPMC)1 can significantly reduce cracking in large-area flooring by controlling water retention. It works by slowing down water evaporation, giving cement enough time to develop strength before shrinkage occurs. However, it's not a complete solution on its own.

Let me share what I've learned after years of manufacturing HPMC for construction applications. When dealing with large surface areas, the biggest enemy is typically rapid water loss, which literally causes the mortar to "tear itself apart" through drying shrinkage. The larger the floor area, the more concentrated these internal pulling forces become.

How Does HPMC Prevent Floor Cracking in Construction Projects?

Contractors often face a nightmare scenario: perfectly installed flooring developing cracks within days. These defects lead to costly repairs, damaged reputation, and unhappy clients. What's the science behind stopping these cracks?

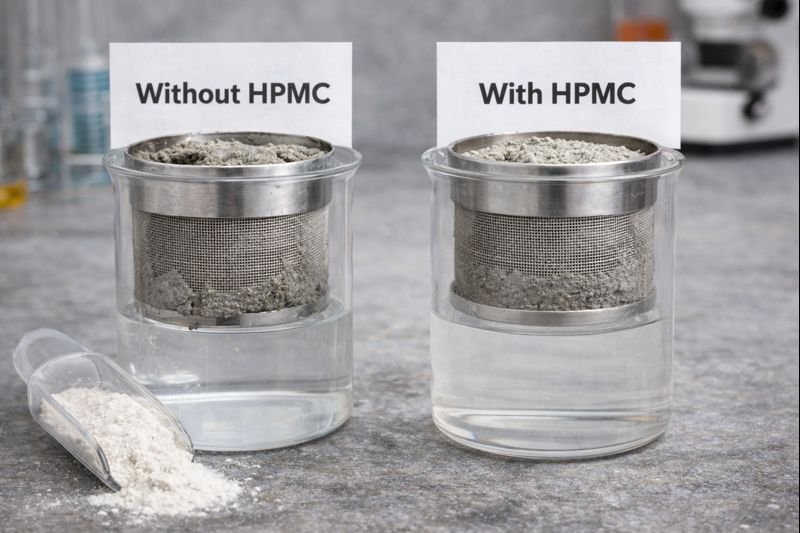

HPMC prevents floor cracking by acting as a water manager in cement-based mortars. It forms hydrogen bonds with water molecules, slowing evaporation rates by up to 70% during critical curing periods. This gives cement adequate hydration time, allowing it to develop sufficient strength to resist shrinkage forces.

HPMC plays a clever role in preventing floor cracks. Rather than acting as a "strongman" directly fighting against tearing forces, it serves as a smart "water manager." When mortar is still wet, HPMC molecules "embrace" water molecules, preventing them from evaporating too quickly in the early stages. This provides cement with sufficient time to fully hydrate and gradually gain strength.

Think of it like converting a 100m sprinter into a marathon runner - HPMC reduces the "water loss rate" of mortar. Once the internal strength of the mortar slowly builds up and becomes capable of resisting the shrinkage stress caused by later water evaporation, cracks become much less likely to form.

Types of Cracking HPMC Can Prevent

| Crack Type | How HPMC Helps | Effectiveness |

|---|---|---|

| Plastic Shrinkage Cracks | Reduces early water evaporation rate | Very High |

| Drying Shrinkage Cracks | Allows for more complete cement hydration | High |

| Thermal Contraction Cracks | Improves overall cohesion and flexibility | Moderate |

| Settlement Cracks | Limited direct impact | Low |

It's important to understand that HPMC primarily addresses cracks caused by rapid water loss, specifically "plastic shrinkage" cracks (occurring early) and "drying shrinkage" cracks (developing later). If your cracking problems stem from foundation settlement, improper mix proportions (too much water), or forgotten expansion joints, even the best quality HPMC won't be enough. It's a "key player" in crack prevention, but not a "miracle cure" for all flooring problems.

What's the Optimal HPMC Dosage for Different Flooring Applications?

DIY enthusiasts and professional contractors alike often wonder how much HPMC to add to their mixtures. Too little seems ineffective while too much wastes money and can cause other issues. What's the right balance?

The optimal HPMC dosage for flooring applications typically ranges from 0.2% to 0.5% of the total dry mix weight. Self-leveling underlayments require higher dosages (0.3-0.5%) for extended flow retention, while basic floor screeds need less (0.2-0.3%) for adequate water retention and workability.

Finding the right HPMC dosage requires understanding both the specific application requirements and environmental conditions. Based on our factory's experience supplying major flooring contractors worldwide, I've developed a practical approach to HPMC dosing that balances performance with cost-efficiency.

When working with self-leveling compounds for large areas, the higher viscosity2 of HPMC (typically 100,000-150,000 mPa·s) creates a gel-like network that significantly reduces water migration. This is crucial for maintaining uniform curing across expansive floor installations. In hot, dry climates like Saudi Arabia or UAE, where many of our customers operate, increasing the dosage by an additional 0.05-0.1% compensates for the extreme evaporation conditions.

For standard cement screeds covering large areas, a medium-viscosity HPMC (60,000-80,000 mPa·s) provides the optimal balance between water retention and cement hydration. Too high a dosage in these applications can actually be counterproductive, excessively delaying setting time and potentially causing other issues like reduced early strength development.

HPMC Dosage Guide by Application Type

| Application Type | Recommended Dosage Range | Viscosity Preference | Special Considerations |

|---|---|---|---|

| Self-Leveling Underlayment | 0.3-0.5% | High (100,000+ mPa·s) | Higher in hot/dry weather |

| Cement Floor Screed | 0.2-0.3% | Medium (60,000-80,000 mPa·s) | Balance water retention with setting time |

| Decorative Flooring | 0.25-0.4% | Medium-High | Consider workability duration needs |

| Thin-Set Tile Adhesive | 0.2-0.35% | Medium | Higher for large format tiles |

Can HPMC Work Alongside Other Additives for Better Crack Prevention?

Flooring specialists often combine multiple additives, hoping for enhanced performance. Is this synergistic approach effective or might these chemicals interfere with each other? What combinations work best?

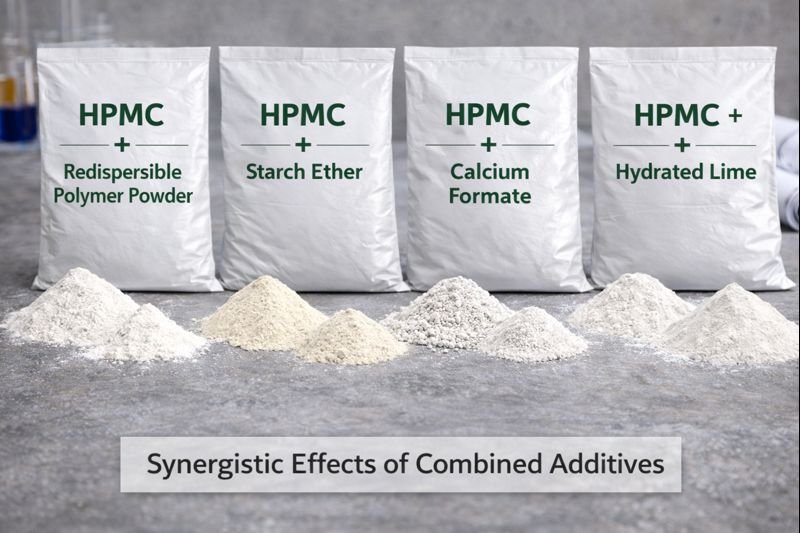

Yes, HPMC can effectively work alongside other additives to create comprehensive crack prevention systems. The most beneficial combinations include HPMC with redispersible polymer powders3 for flexibility, cellulose fibers for reinforcement, and shrinkage compensators4 like calcium oxide. These create multi-layered protection against different cracking mechanisms.

https://placehold.co/600x400 "Synergistic effects of combined additives")

https://placehold.co/600x400 "Synergistic effects of combined additives")

In my experience working with major mortar manufacturers across developing markets, the most successful crack-prevention strategies involve thoughtfully combined additive systems rather than relying solely on one component. HPMC provides excellent water retention, but when paired strategically with complementary additives, the overall performance becomes significantly more robust.

The combination of HPMC with redispersible polymer powder (RDP) creates a particularly powerful duo. While HPMC manages water retention and hydration, the polymer forms flexible bridges between cement particles, enhancing tensile strength and deformation capacity. For large area flooring in regions with substantial temperature variations (like the Middle East, where day-night temperature differences can exceed 20°C), this flexibility becomes crucial for accommodating thermal movement.

Adding polypropylene fibers5 to an HPMC-modified mix creates a three-dimensional reinforcement network that provides immediate crack resistance during the plastic phase, complementing HPMC's water retention properties. Our customers in India and Pakistan, where rapid construction schedules often don't allow for ideal curing conditions, have reported approximately 60-70% reduction in early-age cracking when using this combination approach compared to traditional mixes.

Effective Additive Combinations with HPMC

| Additive Combination | Benefit | Ideal Projects |

|---|---|---|

| HPMC + RDP | Enhanced flexibility and adhesion | Large areas with thermal movement |

| HPMC + PP Fibers | 3D reinforcement against early cracking | Fast-track projects with limited curing time |

| HPMC + Shrinkage Compensator | Active expansion to offset shrinkage | Ultra-large continuous floors |

| HPMC + Superplasticizer | Reduced water demand while maintaining workability | High-strength flooring systems |

It's important to note that while these combinations enhance performance, they must be properly balanced. For instance, certain superplasticizers can interfere with HPMC's water retention mechanism if not properly selected. This is why we often conduct compatibility testing when our customers are developing new formulations with multiple additives.

Conclusion

HPMC effectively prevents cracking in large-area flooring by controlling water evaporation rates, giving cement time to develop sufficient strength. While not a magic solution, when properly dosed and combined with complementary additives, it significantly reduces crack formation risk.

-

Explore this resource to understand how HPMC can enhance flooring projects and prevent cracking. ↩

-

Explore the significance of viscosity in HPMC and its impact on flooring performance. ↩

-

Explore the benefits of polymer powders in improving the flexibility and strength of cement. ↩

-

Find out how shrinkage compensators can help in reducing cracks in flooring systems. ↩

-

Explore the benefits of polypropylene fibers in reinforcing flooring against cracking. ↩