Are you tired of your liquid soap products separating, thinning out, or looking unappealing on store shelves? These stability issues can damage your brand reputation and cost you customers who expect consistent quality.

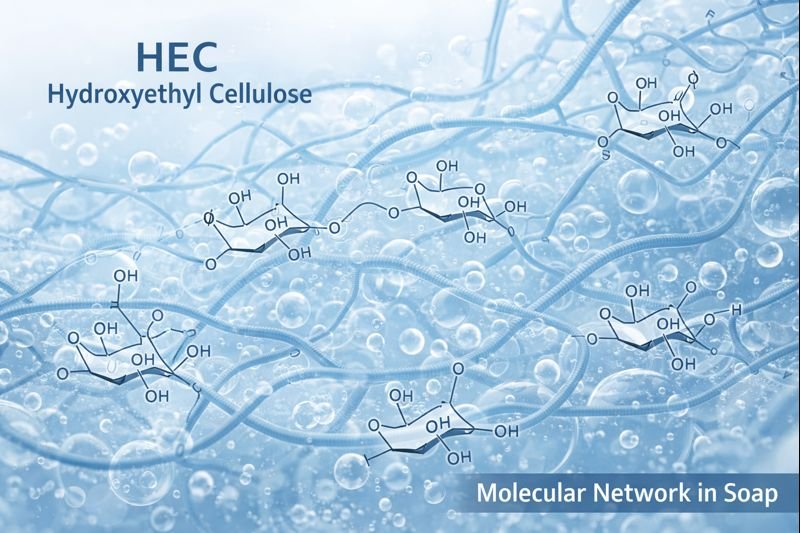

Yes, Hydroxyethyl Cellulose (HEC)1 effectively solves liquid soap stability problems2 by creating a non-ionic structural network throughout the formula. This network maintains viscosity and prevents ingredient separation even in high-alkaline environments with high electrolyte content.

I've been making liquid soaps for years, and stability has always been the biggest headache. Nothing is more frustrating than seeing a perfectly formulated batch separate or thin out after a few weeks. That's why I want to share how HEC changed our production completely.

How Does HEC Solve Stability Problems in Liquid Soap?

Have you ever seen your carefully formulated liquid soap separate into layers after just a few weeks? This happens because natural soap formulations create harsh environments that many thickeners simply can't handle.

Hydroxyethyl cellulose works as a stabilizer in liquid soaps because it's non-ionic, meaning it doesn't react with other ingredients. It creates a three-dimensional network throughout the liquid that maintains viscosity3 and physically prevents ingredients from separating, even in high pH and high salt conditions.

Think of HEC as creating an invisible fishing net throughout your liquid soap. This isn't just any ordinary thickener - it's a structural engineer for your formula. The most impressive thing about HEC is how it performs in "temperamental" systems like natural liquid soaps made through saponification (what we call "true soap").

Natural liquid soaps present unique challenges with their high alkalinity and electrolyte content. Most ordinary thickeners fail immediately in these conditions, often making separation problems worse. HEC stands apart because of its "neutral" identity as a non-ionic molecule. It doesn't participate in the chemical reactions happening in your soap. Instead, it quietly absorbs water, expands, and creates a stable structural framework.

This framework does two critical jobs: it provides the perfect viscosity and physically traps ingredients that might otherwise separate. Pearlizing agents, essential oils, moisturizers, and other additives that typically sink or float stay perfectly suspended. I've tested this with formulas that previously separated within days - with properly incorporated HEC, they remained stable for months.

What Are the Key Considerations for Using HEC in Liquid Soap?

Do you want to incorporate HEC into your formulations but aren't sure about the right techniques? Getting the best results requires understanding some important principles about how this ingredient works.

To use HEC effectively in liquid soaps, disperse it properly in cold water before adding to your formulation. The typical usage rate is 0.5-2%, depending on desired viscosity. Allow full hydration (4-24 hours) for optimal results, and adjust pH to 6-8 for maximum viscosity development.

Proper dispersion is absolutely critical when working with HEC. I've learned this the hard way after countless batches with undissolved particles floating in otherwise beautiful soap. The correct method involves creating a "vortex" in cold water - never hot water, which can cause clumping. Slowly add the HEC powder into the vortex while mixing continuously.

Temperature control matters tremendously with HEC. While it needs cold water for dispersion, its full thickening power develops best at specific temperature ranges during the hydration period. I find that allowing the solution to sit at room temperature (20-25°C) gives the most consistent results. Rushing this process almost always leads to disappointing viscosity.

The pH of your liquid soap formulation also drastically affects how HEC performs. Here's a breakdown of what I've observed across different pH ranges:

| pH Range | HEC Performance | Notes |

|---|---|---|

| 6.0-8.0 | Optimal viscosity | Perfect range for maximum thickening |

| 8.0-10.0 | Good stability but reduced viscosity | May need higher concentration |

| 10.0-12.0 | Adequate stability | Common range for natural liquid soaps |

| >12.0 | Reduced performance | May require viscosity boosters |

One often overlooked factor is the interaction between HEC and other ingredients. Salt (sodium chloride) can dramatically affect HEC's performance - sometimes improving viscosity, sometimes collapsing it completely depending on concentration. I recommend testing small batches when adjusting salt levels in formulas using HEC as the primary thickener.

Frequently Asked Questions About HEC in Liquid Soap

Are you wondering about specific technical aspects of using HEC in your liquid soap formulations? Let's address some common questions I hear from other formulators.

The most suitable HEC grades for liquid soaps are medium viscosity types (typically 30,000-40,000 mPas). HEC is compatible with most surfactants, won't affect transparency at proper usage rates, and remains stable for 18-24 months in finished products when properly preserved.

Selecting the right grade of HEC can make an enormous difference in your final product. Unlike other thickeners where one type fits most applications, HEC comes in various molecular weights that dramatically impact performance. From my experience formulating hundreds of liquid soap batches, medium viscosity grades offer the best balance of stability and ease of incorporation.

There's often confusion about whether HEC affects clarity in transparent formulations. When properly dispersed and used at recommended rates (typically 0.5-2%), HEC maintains excellent clarity in transparent soaps. I've found that problems only arise when using too much (over 2.5% in most cases) or with improper dispersion. The key is allowing full hydration before judging the final appearance.

Compatibility with different surfactant systems is another common concern. Here's what I've observed when combining HEC with various surfactant types:

| Surfactant Type | Compatibility | Notes |

|---|---|---|

| Anionic (SLS, SLES) | Excellent | No interaction issues |

| Amphoteric (Cocamidopropyl betaine) | Very good | Can enhance viscosity |

| Nonionic (Decyl glucoside) | Good | May require pH adjustment |

| Cationic | Poor | Avoid combinations |

| Natural soap (saponified oils) | Very good | Requires proper pH management |

Shelf-life questions come up frequently. In my experience, HEC-thickened liquid soaps maintain their viscosity and stability for 18-24 months when properly preserved. However, I've noticed that extreme temperature cycling during storage can sometimes reduce viscosity over time. Keeping products away from temperature extremes helps maintain the ideal structure that HEC creates.

Conclusion

Hydroxyethyl cellulose is the solution for liquid soap stability problems2, creating a non-reactive structural network that maintains viscosity and prevents separation, even in the challenging high-pH, high-electrolyte environment of natural liquid soaps.

-

Explore how HEC can revolutionize your liquid soap formulations by enhancing stability and viscosity. ↩

-

Learn about the challenges faced in liquid soap production and effective solutions to maintain quality. ↩ ↩

-

Understand the importance of viscosity in liquid soap and how to achieve optimal results. ↩