Are you struggling with product formulation challenges? Natural polymers1 offer sustainable solutions that synthetic alternatives can't match. Cellulose ether2 stands out among these versatile materials.

Cellulose ether2 is important because it's derived from cellulose, the most abundant natural polymer on Earth. As a modified form of cellulose, it retains biodegradability while gaining water solubility and other functional properties essential for industries ranging from construction to pharmaceuticals.

Natural polymers have gained tremendous attention in recent years. Their renewable sources and biodegradability make them ideal alternatives to petroleum-based products. Let's look deeper into why cellulose ether deserves special attention among natural polymers.

Why Are Natural Polymers Important?

Do you know what makes up most of our planet's biomass? Natural polymers form the foundation of life itself, yet many people don't understand their crucial role in both nature and industry.

Natural polymers1 are important because they're renewable, biodegradable, and often biocompatible. Unlike synthetic polymers derived from petroleum, natural polymers come from plants, animals, or microorganisms, making them environmentally sustainable and reducing our carbon footprint.

Natural polymers are everywhere around us. From the structure of plants to the proteins in our bodies, these complex molecules form the building blocks of life. The importance of natural polymers extends beyond their biological functions - they've become crucial to solving many environmental challenges.

Types of Natural Polymers

Natural polymers fall into several categories based on their sources and chemical structures:

| Type | Source | Examples | Key Applications |

|---|---|---|---|

| Polysaccharides | Plants | Cellulose, starch, pectin | Paper, textiles, food thickeners |

| Proteins | Animals | Collagen, silk, wool | Textiles, medical applications |

| Nucleic Acids | All organisms | DNA, RNA | Genetic engineering, biotechnology |

| Natural Rubber | Plants | Latex | Tires, medical gloves |

The growing demand for sustainable materials has led to increased research and development in natural polymer applications. Their biodegradability addresses waste management issues, while their renewable nature helps reduce dependence on fossil fuels. Many industries now recognize that using natural polymers isn't just environmentally responsible - it's also economically smart as regulations tighten around synthetic materials.

Is Cellulose3 a Natural Polymer?

When you look at a tree or cotton plant, have you ever wondered what gives them structure? The answer lies in a remarkable natural polymer that's literally everywhere around us.

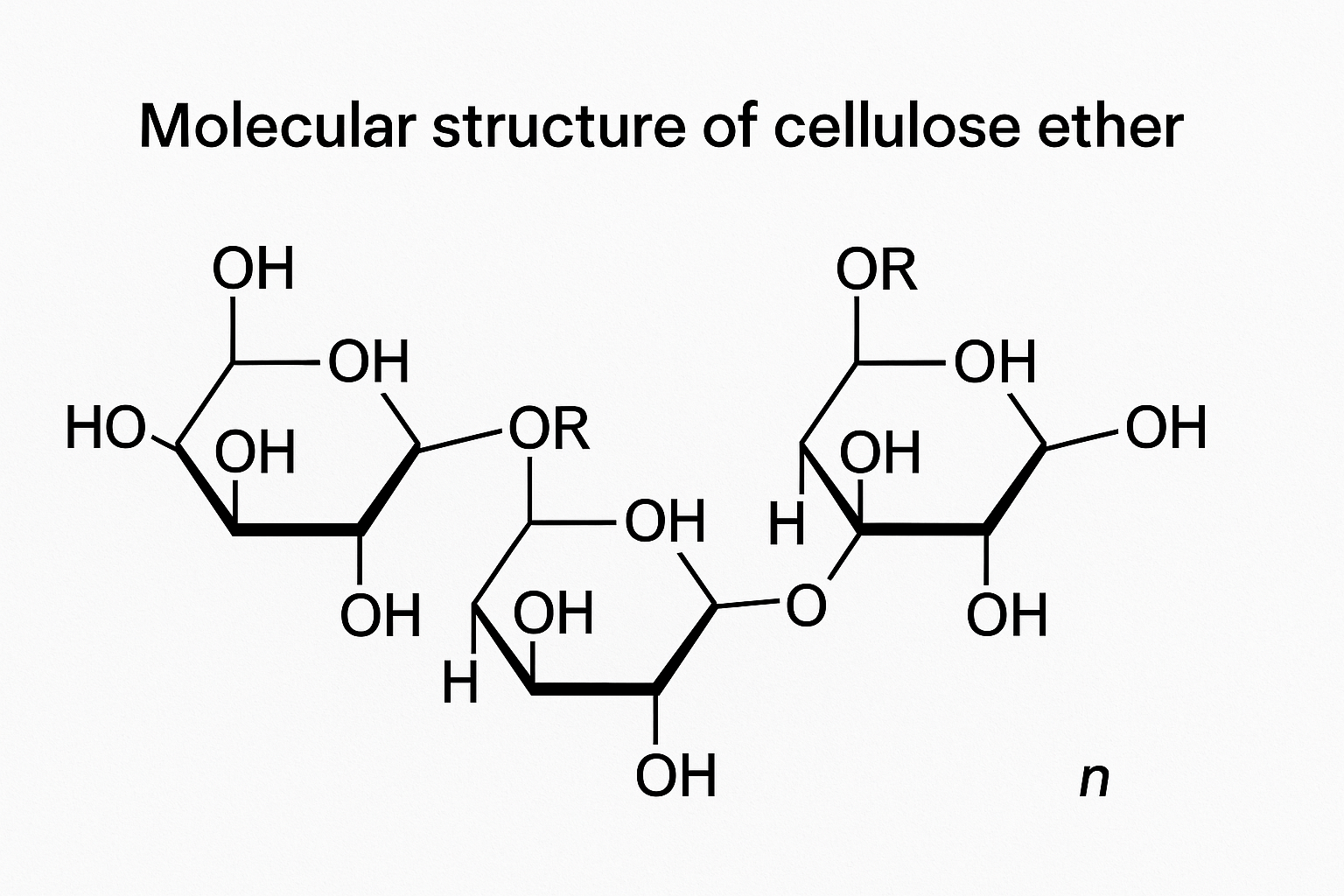

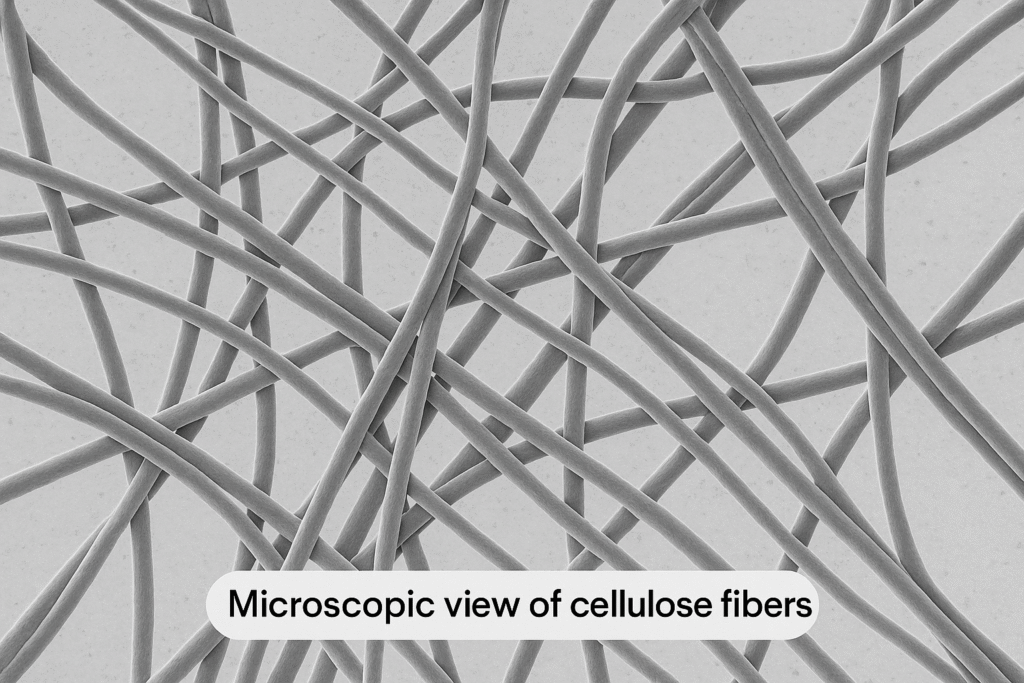

Yes, cellulose is a natural polymer found in all plants. It consists of glucose units linked in long chains, making it the most abundant organic polymer on Earth. Plants synthesize cellulose as their structural component, with wood containing about 40-50% cellulose and cotton having up to 90%.

Cellulose3's importance extends far beyond just keeping plants upright. This remarkable polymer has been integral to human civilization for thousands of years. The paper you write on, the cotton clothes you wear, and many building materials all rely on cellulose's unique properties.

Cellulose Structure and Properties

Understanding cellulose requires looking at its molecular structure:

| Property | Description | Significance |

|---|---|---|

| Chemical Composition | Linear chain of glucose units | Provides strength and stability |

| Crystallinity | Highly ordered regions mixed with amorphous zones | Affects water absorption and reactivity |

| Hydrogen Bonding | Extensive network between chains | Creates strong fibers resistant to breakdown |

| Biodegradability | Breaks down naturally in the environment | Environmentally friendly |

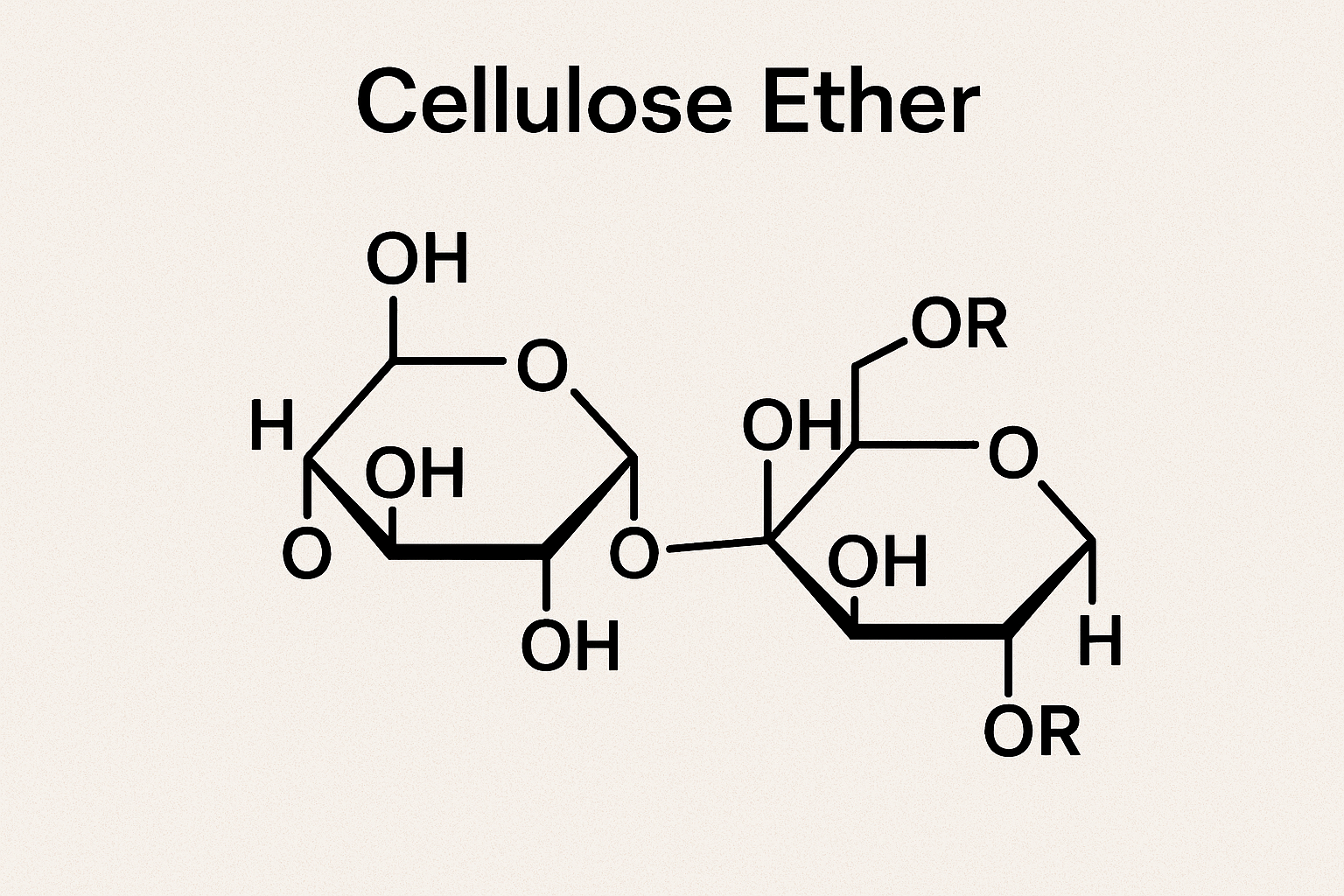

Cellulose's unique structure gives it properties that make it both valuable and challenging to work with. While its strength and abundance make it an incredible natural resource, pure cellulose isn't water-soluble and has limited reactivity. This is where chemical modification becomes important - by altering cellulose's structure slightly, we create derivatives with enhanced functionality while maintaining many of its natural benefits. The most valuable of these modifications is cellulose ether, which transforms this abundant but somewhat limited polymer into a versatile industrial ingredient.

What Are the Two Most Common Natural Polymers in the World?

Have you ever wondered what natural substances dominate our planet? From forest floors to ocean depths, two remarkable molecules form nature's most abundant building blocks.

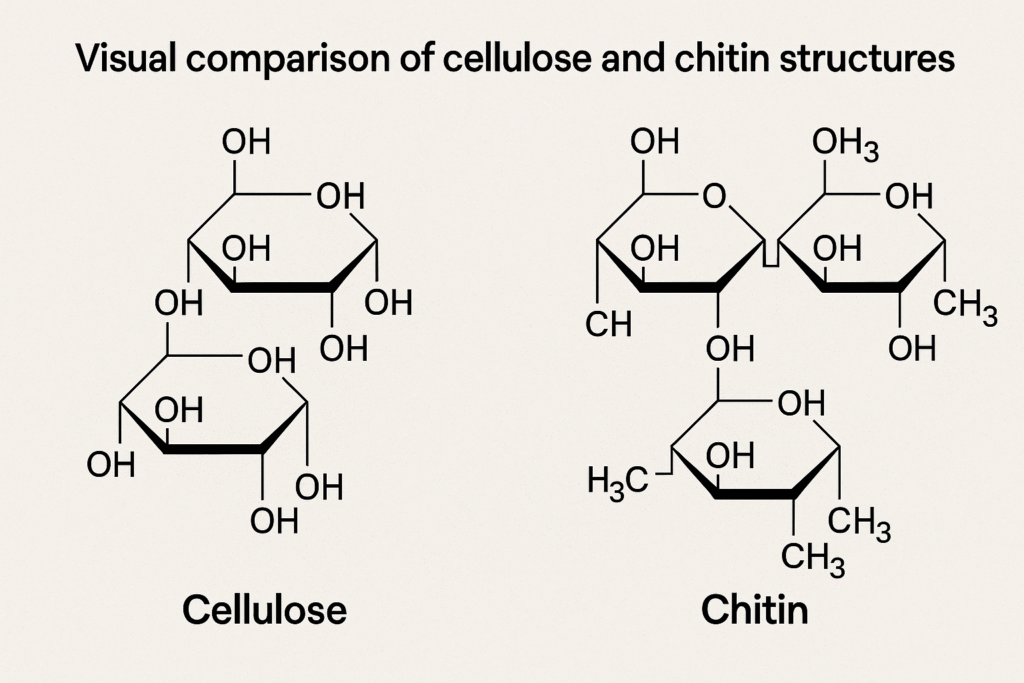

The two most common natural polymers are cellulose and chitin. Cellulose forms plant cell walls and constitutes about 33% of all plant matter worldwide. Chitin, found in fungal cell walls and arthropod exoskeletons (like insects and crustaceans), is the second most abundant, with billions of tons produced annually.

These two polymers literally shape our world. While they share similarities in structure and function, their applications and properties differ significantly. Understanding these abundant materials helps us develop better ways to use them in industrial applications.

Comparing Cellulose and Chitin

Let's examine how these two polymers stack up against each other:

| Characteristic | Cellulose | Chitin |

|---|---|---|

| Basic Unit | Glucose | N-acetylglucosamine |

| Primary Source | Plants | Arthropod exoskeletons, fungi |

| Annual Production | ~1.5 trillion tons | ~10 billion tons |

| Commercial Uses | Paper, textiles, derivatives | Food additives, medical applications |

| Water Solubility | Insoluble (unmodified) | Insoluble |

| Biodegradability | Yes | Yes |

The abundance of cellulose makes it particularly important in industrial applications. In my factory, we focus on cellulose derivatives because their versatility allows them to serve multiple industries. The modification process transforms cellulose's natural properties to create products with specific performance characteristics.

Both polymers represent immense untapped potential for sustainable development. As research continues, we're discovering new ways to utilize these abundant materials to replace synthetic polymers in everything from packaging to medical devices. The key advantage is their renewable nature - plants and arthropods continuously produce these materials, unlike petroleum-based polymers that deplete finite resources.

What Is Cellulose3 Ether Used For?

Do you ever wonder what makes your paint flow smoothly or your tile adhesive stick perfectly? Behind many everyday products lies a versatile ingredient that few people know about.

Cellulose ether is used as a thickener, binder, film former, and water retention agent across diverse industries. In construction, it improves workability of mortars and cements. In pharmaceuticals, it creates controlled-release drug formulations. Food products use it as a stabilizer, while personal care items rely on its texturizing properties.

I've seen firsthand how cellulose ethers transform ordinary products into high-performance solutions. At our factory, we produce several types of cellulose ethers, each tailored for specific applications based on their unique properties.

Major Types and Applications of Cellulose Ethers

The versatility of cellulose ethers comes from the different modification methods:

| Type | Properties | Key Applications | Benefits |

|---|---|---|---|

| Hydroxypropyl Methylcellulose (HPMC)4 | Water-soluble, thermal gelation | Construction materials, pharmaceuticals | Improved water retention, workability |

| Carboxymethyl Cellulose (CMC)5 | Highly water-soluble, ionic | Food, personal care, detergents | Stabilization, thickening, suspension |

| Hydroxyethyl Cellulose (HEC)6 | Water-soluble, non-ionic | Paints, cosmetics, drilling fluids | Consistent viscosity, compatibility |

| Methylcellulose (MC)7 | Gels when heated | Food, pharmaceuticals, construction | Thermal gelation, binding properties |

In construction applications, which represent our primary market, cellulose ethers significantly improve cement-based materials. When added to mortars and renders, HPMC increases open time, improves adhesion, and prevents water from separating too quickly. This gives workers more time to apply the product and results in stronger bonds between building materials.

Our customers in Saudi Arabia and other Middle Eastern countries particularly value the water retention properties of our HPMC products. In hot climates, preventing premature drying of mortars is crucial for proper curing and strength development. By customizing the molecular weight and substitution level, we can provide products that perform optimally in these challenging environments.

Beyond construction, pharmaceutical companies use our cellulose ethers in tablet formulations. The controlled-release properties allow medications to dissolve at specific rates in the body, improving their effectiveness and patient experience. This versatility demonstrates why cellulose ethers have become indispensable across so many industries - they offer functional benefits while maintaining the environmental advantages of their natural polymer origin.

Conclusion

Cellulose ether2 stands as a perfect example of improving upon nature's design. By modifying the world's most abundant polymer, we create versatile materials that support sustainable development across countless industries while maintaining environmental compatibility.

-

Learn about the crucial role of natural polymers in reducing environmental impact and promoting sustainability. ↩ ↩

-

Explore how cellulose ether enhances product performance and sustainability in various industries. ↩ ↩ ↩

-

Understand the significance of cellulose as a natural polymer and its applications in everyday products. ↩ ↩ ↩

-

Discover the diverse applications of HPMC in construction and pharmaceuticals. ↩

-

Find out how CMC is utilized in food and personal care products for stabilization and thickening. ↩

-

Learn about the advantages of HEC in paints, cosmetics, and drilling fluids. ↩

-

Explore the unique properties of MC and its applications in food and pharmaceuticals. ↩