Are you struggling with tile adhesives that dry too quickly or slide down walls? This problem wastes materials and time, leaving your projects incomplete and clients unhappy.

HPMC (Hydroxypropyl Methylcellulose)1 is the industry-standard solution for mortar and tile adhesives because it effectively retains water, prevents sagging, improves consistency, and enhances workability - benefits that basic cellulose cannot match.

I've tested countless additives in my years supplying construction chemicals2, and the difference between standard cellulose and HPMC in real-world applications is striking. Let me walk you through why most professionals don't even consider this a fair comparison anymore.

What is the role of HPMC in tile adhesive?

Do you know why your tile adhesive stays workable for hours instead of drying out in minutes? The secret lies in one key ingredient that transforms ordinary cement into professional-grade adhesive.

HPMC in tile adhesive functions as a water retention agent that prevents premature drying, a thickener that provides anti-sagging properties, and a workability enhancer that makes application smooth and efficient.

I've observed firsthand how HPMC transforms ordinary tile adhesive into a high-performance product. The technical magic happens at the molecular level, where HPMC forms a protective network around water molecules in the cement mixture. This network acts like a temporary reservoir, releasing water gradually to ensure complete cement hydration.

HPMC's water retention capability is measured by what we call "water retention value" - typically above 95% for quality grades. This means that when you apply adhesive to a porous surface like concrete or brick, the HPMC prevents the water from being immediately absorbed, giving you an extended working time of 20-30 minutes instead of just 5-10 minutes with regular cellulose.

Another crucial aspect is the anti-sagging property. HPMC creates a gel-like structure that holds the adhesive in place, even when supporting heavy tiles on vertical surfaces. This is measured as "slip resistance" in technical specifications. A good HPMC-enhanced tile adhesive will have slip resistance below 0.5mm, compared to 2mm+ for basic cellulose formulations.

| Property | HPMC-Enhanced Adhesive | Basic Cellulose Adhesive |

|---|---|---|

| Water Retention | >95% | 70-85% |

| Open Time | 20-30 minutes | 5-15 minutes |

| Slip Resistance | <0.5mm | >2mm |

| Workability | Smooth, buttery consistency | Stickier, more effort required |

What is the use of HPMC in cement?

Have you ever wondered why modern cement products perform so much better than their predecessors? The difference often comes down to one critical additive that transforms ordinary cement into a high-performance building material.

HPMC in cement mixtures provides extended workability time through water retention, improves adhesion to surfaces, enhances consistency for easier application, and prevents cracking by ensuring proper hydration throughout the curing process.

From my experience with large-scale construction projects across developing markets like Saudi Arabia and India, I've seen how HPMC dramatically improves cement performance in challenging conditions. The science behind this improvement involves HPMC's unique hydroxypropyl and methoxy substitution groups, which create a perfect balance of hydrophilic and hydrophobic properties3.

In hot climates where rapid water evaporation is a constant challenge, HPMC's water retention capability becomes even more critical. Without it, cement mixtures can lose up to 40% of their water content within the first 30 minutes in 35°C+ temperatures. This premature water loss leads to incomplete hydration, which significantly reduces the final strength of the cement - sometimes by up to 30-40% of the potential strength.

HPMC also contributes to improved rheology - the flow behavior of cement mixtures. This makes application smoother and reduces worker fatigue, which translates to faster project completion and better finish quality. Our customers frequently report productivity improvements of 15-20% when switching from basic formulations to HPMC-enhanced products.

The dosage rate is another important consideration. While basic cellulose typically requires dosages of 0.5-0.8% by weight of cement, HPMC can achieve superior results at just 0.2-0.5%, making it more economical despite its higher unit cost. This efficiency comes from HPMC's higher molecular weight and better substitution pattern, which maximize functional performance per gram of material.

| Benefit | How HPMC Delivers | Impact on Construction |

|---|---|---|

| Water Retention | Forms molecular network around water | Complete cement hydration, maximum strength |

| Extended Workability | Controlled water release | Longer application window, fewer batches needed |

| Improved Adhesion | Enhanced surface interaction | Better bonding to difficult substrates |

| Crack Prevention | Maintains optimal moisture level | Reduced callbacks, longer-lasting installations |

| Sag Resistance | Thixotropic behavior | Allows heavier tiles on vertical surfaces |

What is the best bonding agent for tile?

Are your tiles falling off the wall months after installation? This common problem usually traces back to choosing the wrong bonding agent for your specific project requirements.

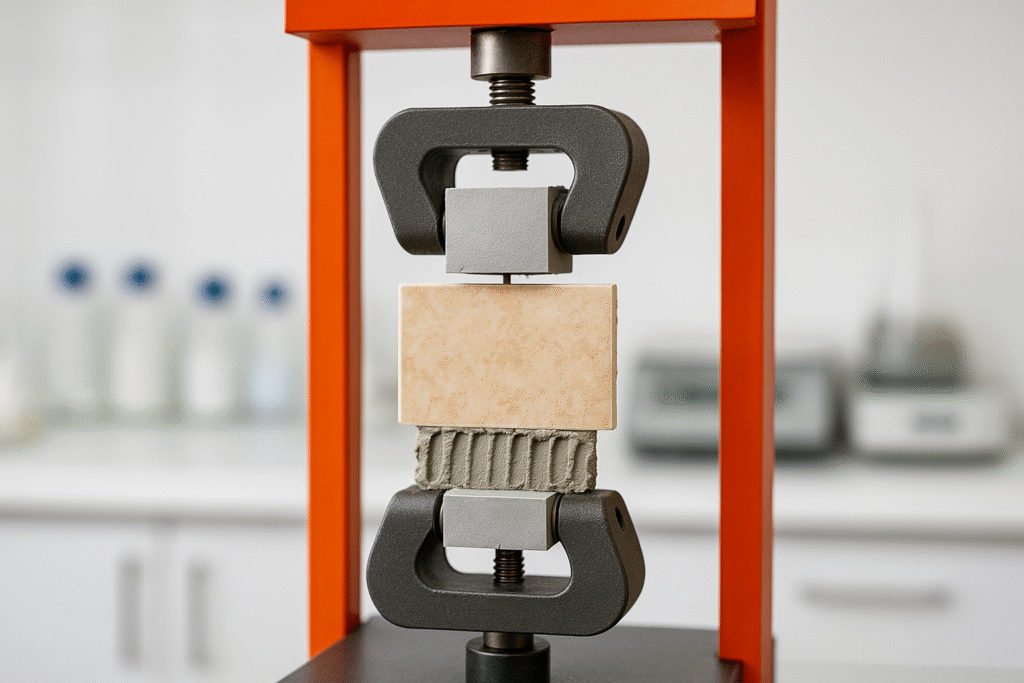

Modified thin-set mortars containing HPMC and redispersible polymer powder4 provide the best bonding for most tile installations, with bond strengths exceeding 1 N/mm², flexibility to accommodate movement, and water resistance for wet areas.

I've supplied bonding agents to major tile installation companies across Asia and the Middle East, and I've seen countless projects succeed or fail based on this critical choice. The science of tile adhesion revolves around creating both mechanical and chemical bonds between the tile and substrate.

HPMC-modified thin-set mortars5 achieve superior bonding through a combination of mechanical interlocking and polymer film formation. When redispersible polymer powder4 (RDP) is added alongside HPMC, the system creates a flexible polymer network throughout the cement matrix as it cures. This network significantly enhances adhesion while providing crucial flexibility that helps the bond withstand thermal expansion, vibration, and other stresses.

For demanding installations, the type of HPMC used matters tremendously. Higher viscosity grades (typically 100,000-150,000 mPa·s) provide better sag resistance but may reduce workability, while medium viscosity grades (40,000-60,000 mPa·s) offer an optimal balance for most applications. The methoxy/hydroxypropyl substitution ratio also affects performance - we typically recommend grades with 28-30% methoxy content and 7-12% hydroxypropyl content for tile adhesives.

In comparative testing across various substrates, HPMC-modified thin-sets consistently outperform other bonding agents:

| Bonding Agent Type | Tensile Adhesion Strength | Flexibility | Water Resistance | Cost Efficiency |

|---|---|---|---|---|

| HPMC+RDP Modified Thin-set | 1.2-2.0 N/mm² | Excellent | Excellent | Good |

| Epoxy Adhesives | 2.0-3.0 N/mm² | Poor | Excellent | Very Poor |

| Mastic Adhesives | 0.5-0.8 N/mm² | Good | Poor | Moderate |

| Unmodified Cement | 0.3-0.5 N/mm² | Very Poor | Moderate | Excellent |

For specialized applications such as exterior facades or swimming pools, the formulation can be further enhanced with higher polymer content (5-8% RDP instead of the standard 2-3%) and specialized HPMC grades6 with delayed dissolution properties to maintain workability even in challenging conditions.

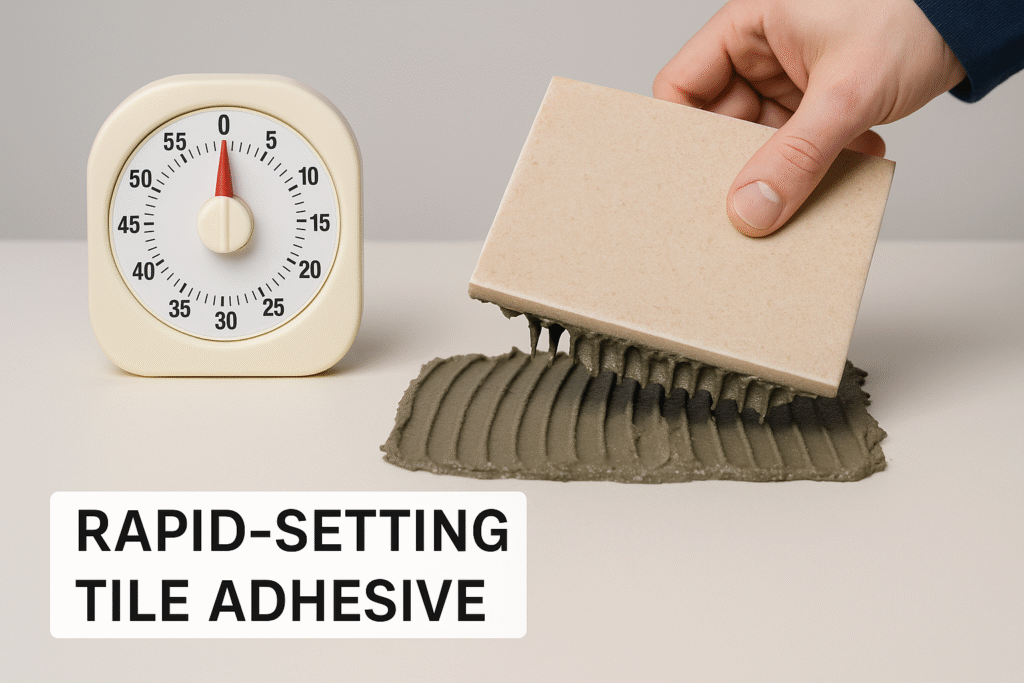

What is the fastest tile adhesive?

Are tight project deadlines forcing you to compromise on quality? Fast-setting adhesives could be the solution, but only if you understand the crucial differences between genuinely rapid-curing products and those that simply dry too quickly.

Rapid-setting tile adhesives contain special cement blends, specific HPMC grades, and accelerators that achieve walkable strength in 2-4 hours while maintaining adequate open time for proper installation, compared to 24+ hours for standard formulations.

Through my work with large construction companies facing tight deadlines, I've developed a keen understanding of fast-setting adhesive technology. The key difference between truly rapid-setting adhesives and ordinary products lies in their chemistry - specifically how they achieve rapid strength development without sacrificing workability.

Premium rapid-setting formulations use specialized HPMC grades with delayed dissolution characteristics. These grades don't immediately thicken when mixed with water, allowing proper mixing and application time. Only after application do they fully activate, rapidly building viscosity and holding tiles in place while accelerated cement hydration occurs.

The cement component also differs significantly from standard adhesives. Fast-setting formulations typically use calcium aluminate cement7 or special Portland cement blends with accelerators rather than ordinary Portland cement. These specialty cements form different crystal structures during hydration that develop strength much more rapidly.

Temperature sensitivity is another important consideration with rapid-setting adhesives. Their reaction kinetics are significantly affected by ambient conditions, with setting times potentially doubling in cold environments (below 10°C) or halving in hot conditions (above 35°C). Professional formulations include temperature-compensating components that help maintain consistent performance across varying job site conditions.

| Fast-Setting Technology | Setting Time | Strength at 3 Hours | Applications | Cost Factor |

|---|---|---|---|---|

| Standard HPMC w/ Portland | 24 hours | 0.1-0.2 N/mm² | General purpose | 1.0x |

| Specialty HPMC w/ CAC | 2-4 hours | 0.5-0.7 N/mm² | Commercial/urgent | 2.5-3x |

| Specialty HPMC w/ Accelerated Portland | 4-6 hours | 0.3-0.5 N/mm² | Residential/urgent | 1.8-2.2x |

| Two-Component Systems | 1-2 hours | 0.8-1.0 N/mm² | Industrial/critical | 3.5-4.5x |

The water-to-cement ratio becomes even more critical in rapid-setting systems. While standard adhesives can tolerate some variation in mixing water, fast-setting formulations require precise water addition - typically 22-24% by weight. Too much water dramatically weakens the final bond, while too little prevents proper hydration and workability. We often recommend mechanical mixing with controlled water dosing for consistent results.

Conclusion

HPMC is the industry-standard solution for mortar and tile adhesives, providing superior water retention, preventing sagging, and enhancing workability. This multifunctional additive delivers optimal performance that basic cellulose simply cannot match, making it the clear choice for professional construction products.

-

Explore how HPMC enhances tile adhesives, improving workability and preventing sagging, making it essential for professionals. ↩

-

Explore the role of construction chemicals in enhancing the performance of building materials. ↩

-

Understand the significance of hydrophilic and hydrophobic properties in improving material performance. ↩

-

Learn how redispersible polymer powder enhances tile adhesive performance and flexibility. ↩ ↩

-

Explore the advantages of modified thin-set mortars in tile installations for superior bonding. ↩

-

Learn about specialized HPMC grades and how they enhance performance in specific applications. ↩

-

Discover the applications and benefits of calcium aluminate cement in fast-setting tile adhesives. ↩