Construction season brings unique challenges. As temperatures fluctuate, your mortar mix behaves unpredictably. Without proper HPMC adjustments, you'll face cracked surfaces in summer and never-setting mixtures in winter.

HPMC (hydroxypropyl methylcellulose)1 performs differently in hot and cold conditions due to its temperature-sensitive properties. In hot weather, it excels at water retention to prevent premature drying, while in cold weather, its strong water-holding capacity can actually slow down cement hydration and setting time.

Understanding HPMC's temperature-dependent behavior is essential for achieving optimal results year-round. I've seen countless projects fail because contractors used the same HPMC formulation regardless of season. Let me share what I've learned after supplying HPMC to construction projects across various climate zones for over 15 years.

How Does HPMC Perform in Hot Weather Conditions?

Summer construction projects face rapid water evaporation and shortened working time. Without proper additives, your mortar will crack, lose adhesion, and develop inadequate strength, costing you thousands in repairs.

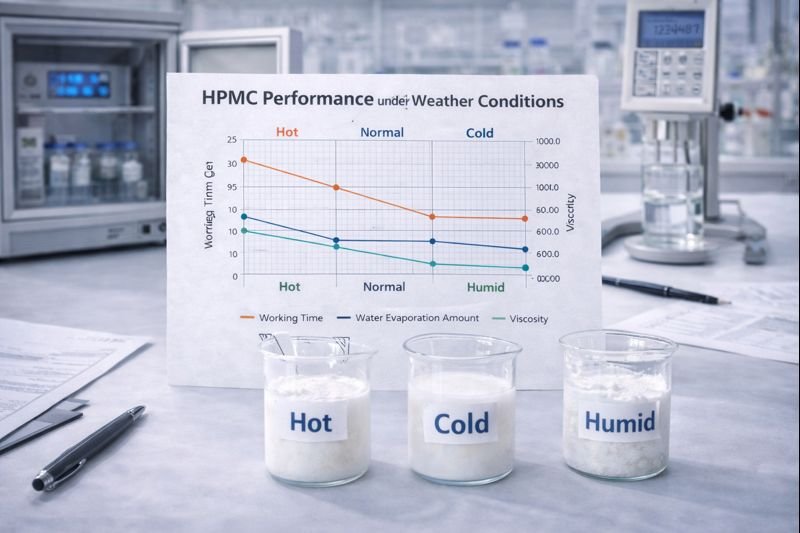

In hot weather (above 30°C/86°F), HPMC becomes the crucial "water manager" in mortar mixtures. It creates a protective colloid that significantly reduces evaporation rate, extending working time by 30-50% and allowing proper cement hydration despite high temperatures and wind exposure.

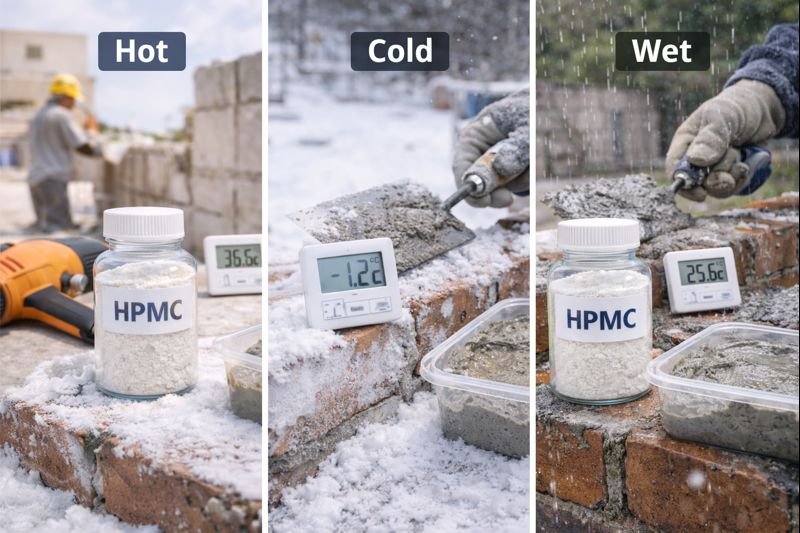

I remember visiting a large residential project in Saudi Arabia during mid-summer when temperatures reached 45°C (113°F). The contractor had been struggling with rapid surface drying that led to extensive cracking and poor adhesion. After switching to our higher-viscosity HPMC2 (100,000 mPa·s), they saw immediate improvements in workability and finish quality.

In hot conditions, HPMC's thermal gelling property actually becomes beneficial. As surface temperatures rise, HPMC forms a semi-gel layer that acts as a moisture barrier, preventing water from escaping too quickly. This is why higher viscosity grades (75,000-150,000 mPa·s) are often recommended for extreme heat conditions.

For hot weather applications, you'll also want to consider:

| HPMC Property | Hot Weather Recommendation | Benefit |

|---|---|---|

| Viscosity | Higher (75,000-150,000 mPa·s) | Enhanced water retention |

| Dosage | 0.3-0.5% by weight of dry mix | Optimal balance of workability and set time |

| Methoxyl Content | Higher (28-30%) | Better thermal stability |

| Particle Size | Finer | Faster dissolution |

Additionally, combining HPMC with a small amount of redispersible polymer powder3 (0.5-1.0%) can further improve water retention while adding flexibility to the cured mortar, reducing the risk of cracking during the initial drying phase.

How Does HPMC Behave in Cold Weather Conditions?

Winter construction brings its own set of problems. Your cement-based products already set slowly in cold temperatures. Using the wrong HPMC type can further delay strength development, leaving surfaces soft and vulnerable for days.

In cold weather (below 10°C/50°F), HPMC's strong water retention can actually hinder proper cement hydration by keeping water from reacting efficiently with cement particles. Lower viscosity grades (30,000-50,000 mPa·s) and reduced dosages are recommended to avoid excessive setting delays.

Last winter, I consulted with a major construction company in northern China that was experiencing extremely slow setting times with their exterior rendering mortar. The temperature was hovering around 5°C (41°F), and their standard HPMC formulation was keeping the mixture workable far too long – over 8 hours! By switching to a medium-viscosity HPMC (40,000 mPa·s) and reducing the dosage from 0.4% to 0.25%, we helped them achieve a more reasonable 4-hour set time.

In cold conditions, HPMC's role shifts from being the star performer to a supporting character. Its primary contributions become improving workability and sag resistance rather than water retention. The cement hydration process already naturally slows in cold temperatures, so excessive water retention from high-viscosity HPMC can be counterproductive.

For cold weather applications, consider these adjustments:

| HPMC Property | Cold Weather Recommendation | Benefit |

|---|---|---|

| Viscosity | Lower to Medium (30,000-50,000 mPa·s) | Less interference with setting |

| Dosage | 0.15-0.25% by weight of dry mix | Minimal delay in cement hydration |

| Methoxyl Content | Lower (19-24%) | Less aggressive water retention |

| Complementary Additives | Set accelerators (calcium formate, calcium chloride) | Counteract slow hydration |

It's also worth noting that HPMC dissolution can be slower in very cold water, potentially leading to lumping issues. Pre-mixing HPMC with other dry ingredients or using warm water for initial mixing can help ensure proper dispersion in cold weather applications.

What Solutions Work Best for Different Climate Challenges?

Constantly using the same HPMC formula year-round guarantees seasonal problems. Without climate-specific adjustments, you'll waste money on failed applications and damage your reputation with inconsistent results.

The key to year-round success with HPMC is adaptation. Use higher viscosity grades (75,000+ mPa·s) at 0.3-0.5% dosage for hot conditions to maximize water retention. Switch to lower viscosity types (30,000-50,000 mPa·s) at 0.15-0.25% dosage for cold conditions, possibly with set accelerators.

Our factory has developed specific formulations for various climate conditions based on extensive field testing across different regions. One approach that's proven particularly effective is to create seasonal product lines rather than trying to use one universal formula.

For transitional seasons like spring and fall when temperatures can fluctuate significantly between day and night, a medium-viscosity HPMC (50,000-75,000 mPa·s) at a moderate dosage (0.25-0.3%) often provides the best balance of properties. This allows for adequate water retention during warmer daytime temperatures while not excessively delaying set during cooler evenings.

Climate-specific HPMC solutions should consider these factors:

| Climate Condition | HPMC Recommendation | Additional Considerations |

|---|---|---|

| Hot & Dry (>35°C) | High viscosity (100,000+ mPa·s), 0.4-0.5% | Consider adding cellulose fibers4 for crack resistance |

| Hot & Humid | Medium-high viscosity (75,000-100,000 mPa·s), 0.3-0.4% | Anti-fungal additives may be necessary |

| Temperate | Medium viscosity (50,000-75,000 mPa·s), 0.25-0.3% | Most versatile option for moderate conditions |

| Cold & Dry | Low-medium viscosity (30,000-50,000 mPa·s), 0.15-0.25% | Combine with calcium formate (0.1-0.2%) |

| Cold & Humid | Low viscosity (30,000 mPa·s), 0.15-0.2% | Add both set accelerator and water repellent |

I've also found that providing technical support and application guidelines specific to seasonal conditions has dramatically improved customer satisfaction. Many contractors don't realize they should adjust their mixing processes seasonally—using colder water in summer and warmer water in winter, for example, or adjusting mixing time to account for temperature-related dissolution differences.

Conclusion

HPMC performs differently across temperature ranges, excelling at water retention in hot weather while potentially hindering setting in cold conditions. For optimal results, adjust your HPMC grade and dosage seasonally rather than using one formula year-round.

-

Explore this resource to understand HPMC's critical role in construction and how it can enhance your projects. ↩

-

Explore the advantages of higher-viscosity HPMC for improving workability and finish quality in hot conditions. ↩

-

Find out how redispersible polymer powder can improve mortar flexibility and reduce cracking. ↩

-

Find out how cellulose fibers can enhance crack resistance in construction applications. ↩