I've seen countless construction projects fail because contractors chose the wrong reinforcement method. Your concrete strength directly affects your project's lifespan and safety.

Fiber reinforced concrete1 uses tiny fibers mixed throughout, while rebar uses steel bars in a grid pattern. Both prevent cracking but work differently - fibers for small cracks, rebar for structural strength.

When I first started exporting polypropylene fiber2 to Saudi Arabia, Mark Chen asked me the same question every contractor faces: should he use fiber or rebar3? The answer changed his entire business approach.

What is Fiber Reinforced Concrete?

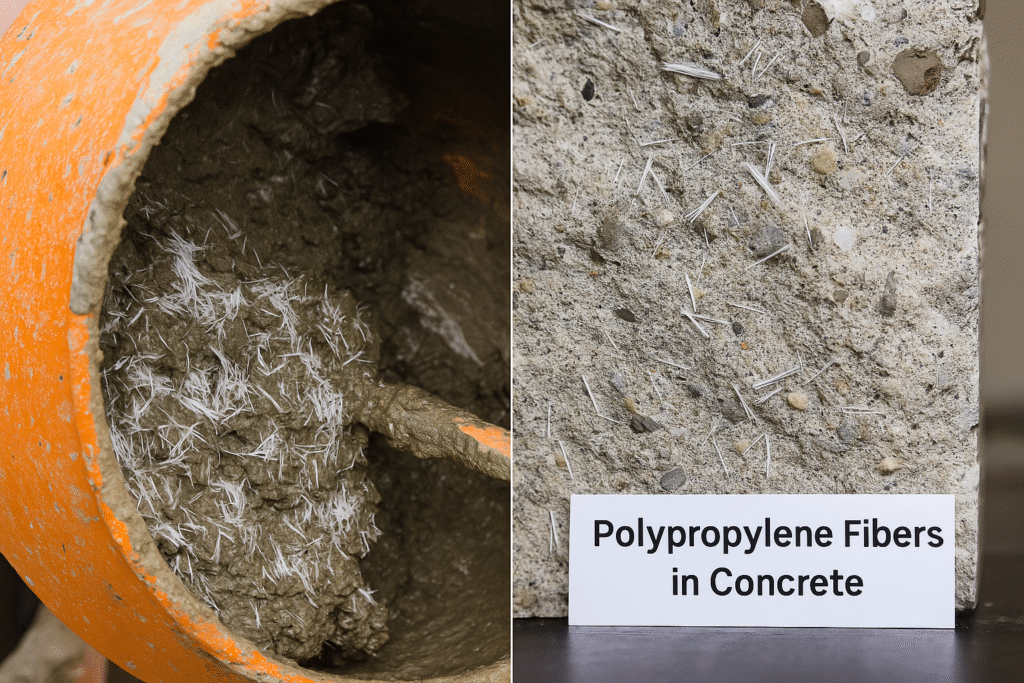

You mix tiny fibers directly into concrete to create a stronger material. This simple addition prevents those annoying surface cracks that ruin your reputation.

Fiber reinforced concrete1 contains small fibers (polypropylene, steel, or glass) distributed throughout the mix. These fibers hold the concrete together and stop micro-cracks from spreading.

I've supplied polypropylene fiber2 to paint factories for 15 years. The fibers we produce at kehao come in different lengths and thicknesses. Each type serves a specific purpose. Short fibers (6-12mm) work best for plaster and thin overlays. Longer fibers (18-54mm) suit thick slabs and industrial floors.

Fiber Types and Applications

| Fiber Type | Length | Best Use | Key Benefit |

|---|---|---|---|

| Polypropylene | 6-54mm | Slabs, overlays | Crack control |

| Steel | 25-60mm | Industrial floors | Impact resistance |

| Glass | 12-38mm | Decorative concrete | Surface finish |

The mixing process matters too. You add fibers during batching, not after. I've seen projects fail because workers dumped fibers into ready-mix trucks. The fibers clump together and create weak spots. My customers in India learned this lesson the hard way when their first batch failed quality tests.

What is Rebar Reinforced Concrete?

Steel bars create a skeleton inside your concrete structure. You place these bars in a grid pattern before pouring concrete over them.

Rebar reinforced concrete uses steel bars arranged in specific patterns to handle tension forces. The steel compensates for concrete's weakness in tension while concrete protects steel from corrosion.

I don't manufacture rebar, but I understand why contractors love it. The system has worked for over 100 years. You calculate loads, place bars accordingly, and get predictable results. My brother runs a construction company in Guangzhou. He swears by rebar for all his high-rise projects.

Rebar Specifications and Placement

| Rebar Size | Diameter | Typical Use | Spacing |

|---|---|---|---|

| #3 | 9.5mm | Light slabs | 300-450mm |

| #4 | 12.7mm | Residential | 200-300mm |

| #5 | 15.9mm | Commercial | 150-200mm |

The placement requires skilled workers. You need proper chairs, ties, and spacing. One mistake ruins the entire structure. Last year, a customer from Mexico told me about a bridge collapse. The investigation found improperly tied rebar. The bars shifted during pouring, creating a weak zone that failed under load.

Fiber Reinforced Concrete Vs Rebar: Which Performs Better?

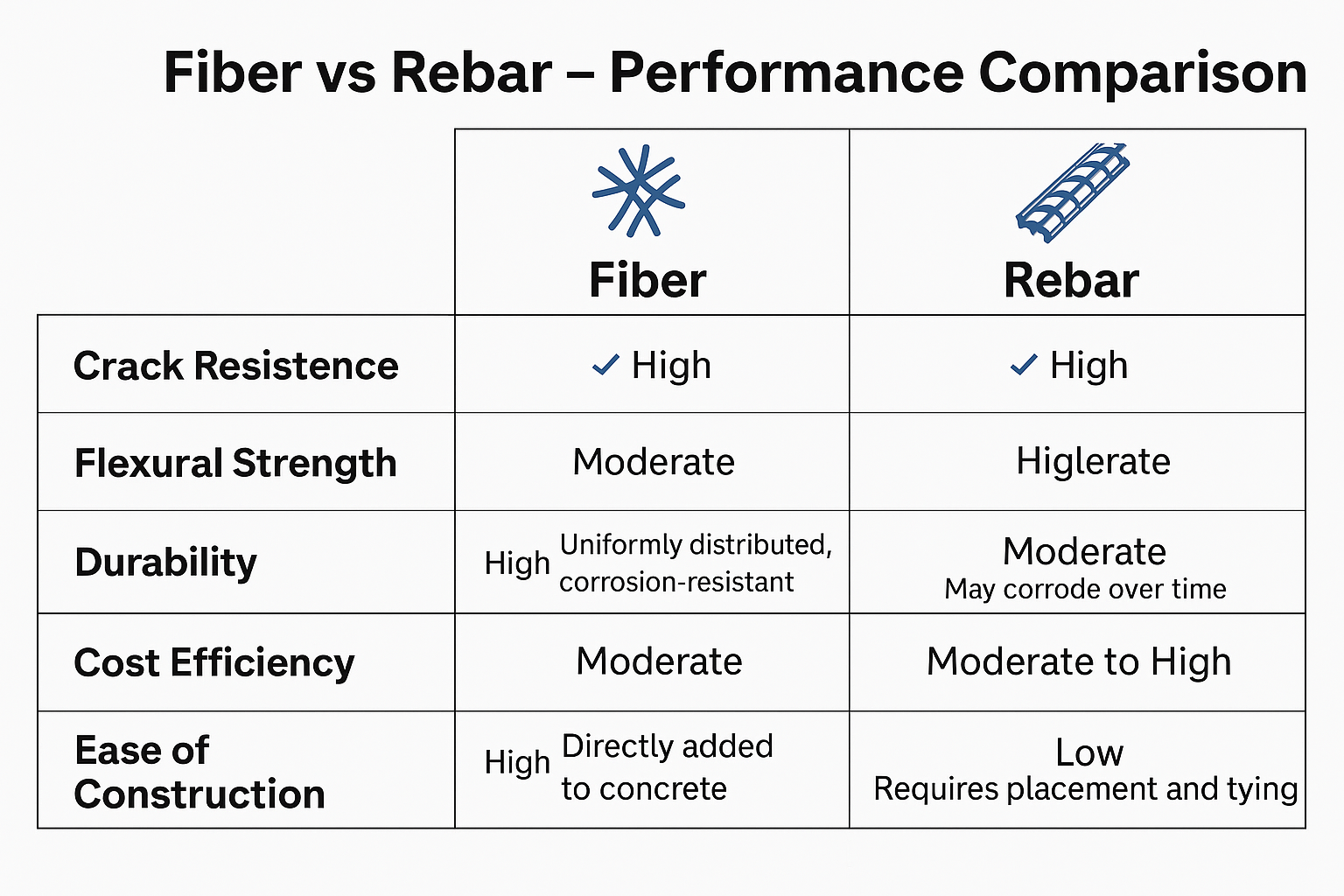

Both methods strengthen concrete, but they excel in different areas. Your project type determines the best choice.

Fiber reinforcement prevents surface cracks and improves impact resistance. Rebar provides structural strength for load-bearing elements. Many projects benefit from using both together.

I've analyzed thousands of test results from our customers. Fiber-reinforced samples show 20-40% better crack resistance in freeze-thaw cycles. But rebar samples handle 3-5 times more load before failure. The data tells a clear story: they serve different purposes.

Performance Comparison Table

| Property | Fiber Reinforced | Rebar Reinforced | Combined System |

|---|---|---|---|

| Crack Control | Excellent | Good | Excellent |

| Structural Strength | Fair | Excellent | Excellent |

| Impact Resistance | Excellent | Fair | Excellent |

| Installation Speed | Fast | Slow | Moderate |

| Cost | Low-Medium | Medium-High | High |

My Pakistani customers use fibers for warehouse floors. The heavy forklift traffic creates impact loads that crack plain concrete. Fibers distribute these stresses across the entire slab. Meanwhile, our Brazilian clients prefer rebar for their multi-story buildings. The columns and beams need tensile strength that only steel provides.

What Is the Best Reinforcement for Concrete? Rebar Or Fiber?

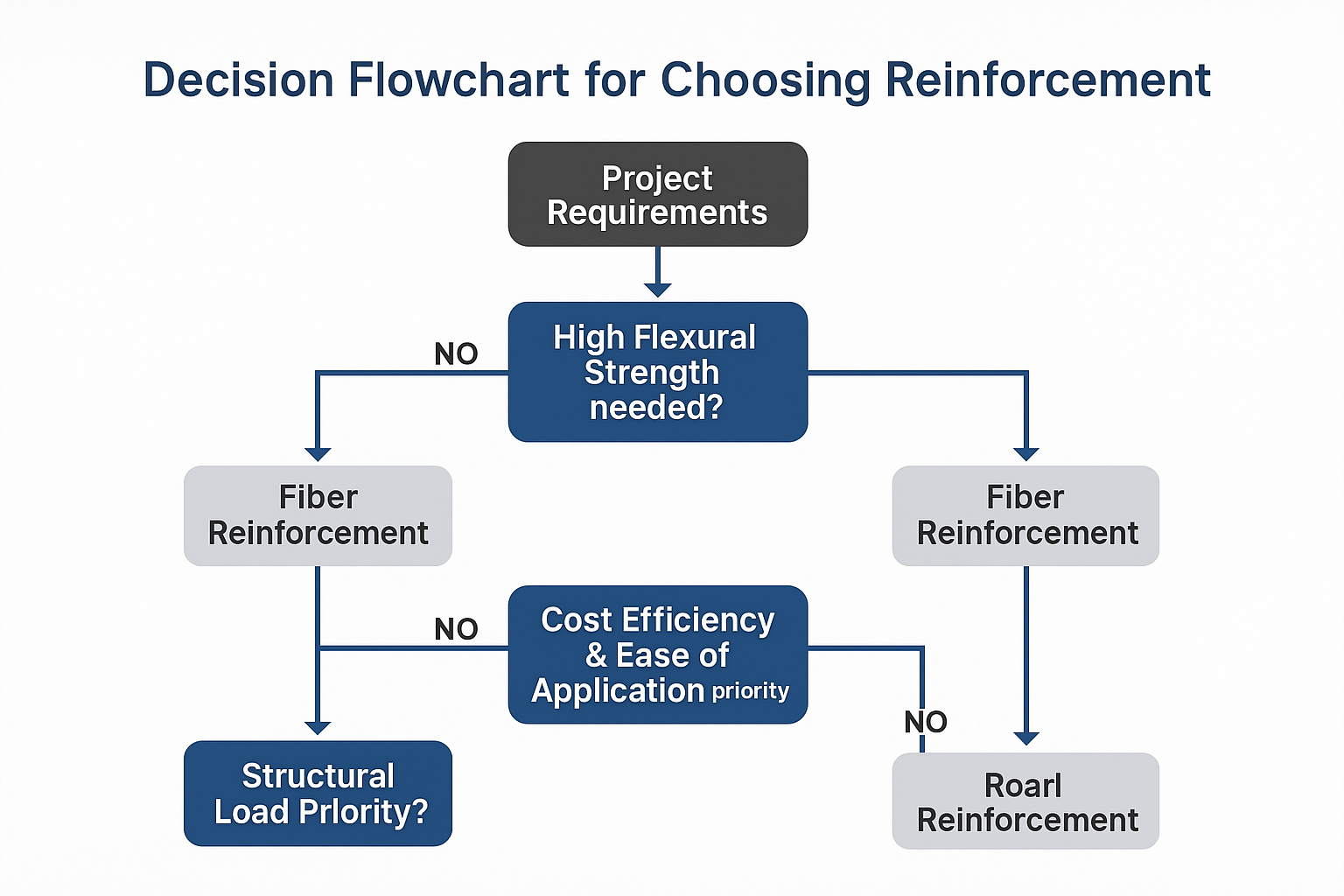

The best reinforcement depends on your specific application. I help customers choose based on their project requirements every day.

For structural elements like beams and columns, use rebar. For slabs, overlays, and crack control, choose fibers. Many modern projects combine both for optimal performance.

I created a simple decision process for my customers. First, identify if your element carries structural loads. Beams, columns, and load-bearing walls need rebar. Second, check if crack control matters more than strength. Decorative surfaces, water tanks, and pavements benefit from fibers.

Application Guidelines

| Project Type | Primary Reinforcement | Secondary Option | Key Consideration |

|---|---|---|---|

| Foundation | Rebar | Add fibers | Load bearing |

| Driveway | Fibers | Minimal rebar | Crack control |

| Water Tank | Fibers | Light rebar | Waterproofing |

| Bridge Deck | Rebar | Add fibers | Both strength and durability |

Mark Chen now uses this system in Saudi Arabia. His paint factory floors use polypropylene fiber2s exclusively. But his office building required rebar for the frame with fibers in the floor slabs. The combination saved him 15% on repairs over five years.

Does Fiber Reinforced Concrete Need Rebar?

Fiber reinforced concrete often works alone for non-structural applications4. But some situations still require rebar addition.

Non-structural elements like pavements and overlays don't need rebar when using fiber reinforcement. Structural elements always need rebar regardless of fiber content.

I supply fibers to a major airport in Vietnam. They use fiber-only concrete for their taxiways. The slabs sit on well-compacted soil and only handle compression loads. No rebar needed. But the same airport uses rebar plus fibers for their terminal building. The elevated slabs must span between columns.

When to Skip Rebar

| Application | Fiber Alone? | Reason | Typical Thickness |

|---|---|---|---|

| Sidewalks | Yes | No structural loads | 100-150mm |

| Overlays | Yes | Bonded to substrate | 25-75mm |

| Shotcrete | Yes | Compression only | 50-100mm |

| Precast Panels | Maybe | Depends on span | 50-200mm |

My customers save significant money by eliminating unnecessary rebar. A distributor in Georgia switched his warehouse floor specification from rebar to fiber-only. The labor savings alone covered the fiber cost. Plus, construction finished two weeks faster without rebar placement delays.

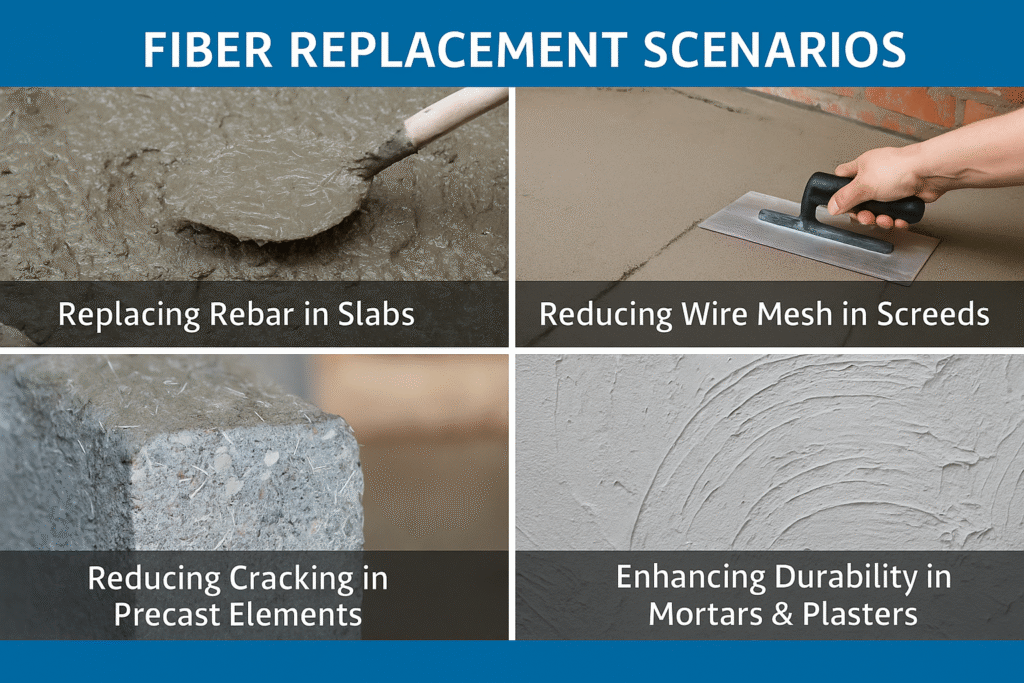

Does Fiber in Concrete Replace Rebar?

Fibers replace rebar only in specific applications. You can't swap one for the other without proper engineering analysis.

Fibers can replace light rebar mesh in slabs-on-grade and temperature steel. They cannot replace primary structural reinforcement in beams, columns, or suspended slabs.

I've seen dangerous mistakes when contractors try total replacement without understanding limits. A customer in the Philippines replaced all rebar with fibers in a parking garage. The elevated sections cracked within months. We investigated and found they used residential slab specifications for a suspended structure.

Replacement Guidelines

| Original Reinforcement | Can Replace with Fiber? | Conditions | Fiber Dosage |

|---|---|---|---|

| Wire Mesh (WWF) | Yes | Slab-on-grade only | 3-5 kg/m³ |

| Temperature Steel | Yes | Non-structural | 2-4 kg/m³ |

| #3 Rebar Grid | Sometimes | Engineer approval | 5-9 kg/m³ |

| Structural Rebar | No | Never | Not applicable |

The key is understanding force distribution. Rebar concentrates strength along bar lines. Fibers distribute strength throughout the mass. This fundamental difference means fibers excel at controlling random cracks but can't handle point loads like rebar.

Expert Guidance: Making the Right Choice

After 15 years supplying fibers globally, I've learned that success comes from matching materials to applications.

Consult structural engineers for load-bearing elements. Use manufacturer guidelines for fiber dosage. Consider combination systems for demanding applications. Never compromise safety for cost savings.

I offer free consultations to all my customers. We review their project specs, local codes, and performance requirements. Many contractors underestimate fiber dosage. They use 1-2 kg/m³ when they need 4-5 kg/m³. This mistake leads to failures that damage everyone's reputation.

kehao Fiber Recommendations

| Application | Fiber Type | Dosage | Expected Performance |

|---|---|---|---|

| Plaster/Render | PP 6-12mm | 0.9 kg/m³ | Eliminates shrinkage cracks |

| Floor Slabs | PP 18-38mm | 3-5 kg/m³ | Controls all crack types |

| Shotcrete | PP 38-54mm | 5-7 kg/m³ | Improves cohesion |

| Precast | PP 12-18mm | 2-4 kg/m³ | Reduces micro-cracks |

Contact me at ada@xhhpmc.com for specific recommendations. I maintain a database of successful projects worldwide. Your challenge probably matches something we've solved before. My team provides dosage calculations, mixing instructions, and quality control procedures.

Conclusion

Choose rebar for structural strength and fibers for crack control. Many projects benefit from using both reinforcement types together for optimal concrete performance.

-

Explore the advantages of fiber reinforced concrete for enhanced durability and crack resistance. ↩ ↩

-

Learn how polypropylene fiber improves concrete strength and prevents cracking. ↩ ↩ ↩

-

Understand the role of rebar in providing structural strength to concrete. ↩

-

Explore how fiber reinforced concrete is used in non-structural applications. ↩